Precision Engineered, Globally Delivered

Your Global PCB Solution Partner

Engineering Excellence

Precision Engineered, Globally Delivered

Responsive Partnership

72hr Prototyping, 24/7 Support

Certified Innovation

IPC-Perfected, Innovation-Driven

Professional PCB OEM Services

From 1-piece prototyping to 100K+ mass production

One-Stop PCB Procurement

Global supply chain solutions for BOM optimization

End-to-End Manufacturing

Equipped with advanced automatic production line

Product Matrix

Full-range PCB Types with Industrial Applications

-

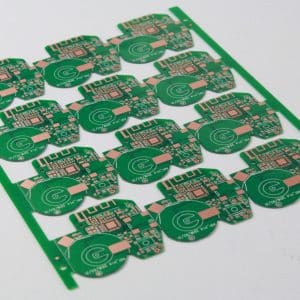

Flexible plate

Flexible plate

A Flexible PCB (FPC), also known as a Flex Circuit, is a type of printed circuit board that is designed to be bent, twisted, or folded without breaking. Unlike rigid PCBs, FPCs use flexible materials like polyimide (PI) or polyester (PET) instead of traditional FR4.

-

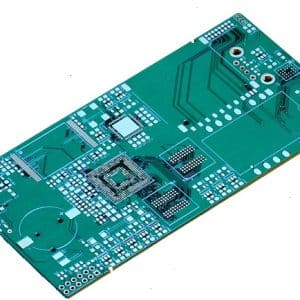

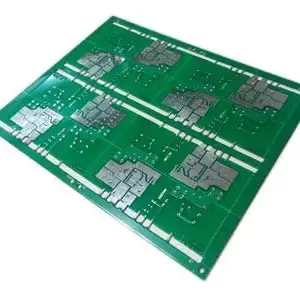

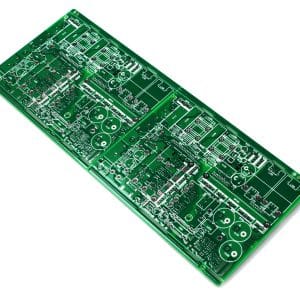

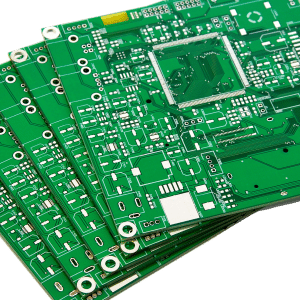

Multilayer board

Multilayer board

A Multi-Layer PCB is a printed circuit board with three or more copper layers stacked together with insulating layers in between. Unlike Single-Sided and Double-Layer PCBs, multi-layer PCBs allow for highly complex circuit designs by increasing routing space and reducing signal interference.

-

Multilayer board

Multilayer board

A Multi-Layer PCB is a printed circuit board with three or more copper layers stacked together with insulating layers in between. Unlike Single-Sided and Double-Layer PCBs, multi-layer PCBs allow for highly complex circuit designs by increasing routing space and reducing signal interference.

-

Multilayer board

Multilayer board

A Multi-Layer PCB is a printed circuit board with three or more copper layers stacked together with insulating layers in between. Unlike Single-Sided and Double-Layer PCBs, multi-layer PCBs allow for highly complex circuit designs by increasing routing space and reducing signal interference.

-

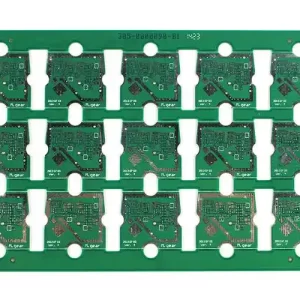

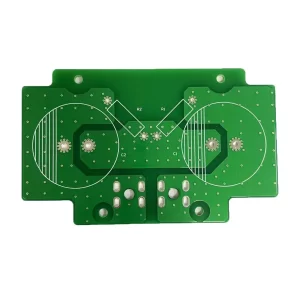

Single layer board

Single layer board

A Single Sided PCB (Printed Circuit Board) is a type of PCB that has copper traces on only one side of the board, while the other side is used for mounting electronic components. It is the simplest and most cost-effective type of PCB, making it widely used in basic electronic circuits and low-cost applications.

-

Single layer board

Single layer board

A Single Sided PCB (Printed Circuit Board) is a type of PCB that has copper traces on only one side of the board, while the other side is used for mounting electronic components. It is the simplest and most cost-effective type of PCB, making it widely used in basic electronic circuits and low-cost applications.

-

Single layer board

Single layer board

A Single Sided PCB (Printed Circuit Board) is a type of PCB that has copper traces on only one side of the board, while the other side is used for mounting electronic components. It is the simplest and most cost-effective type of PCB, making it widely used in basic electronic circuits and low-cost applications.

-

Single layer board

Single layer board

A Single Sided PCB (Printed Circuit Board) is a type of PCB that has copper traces on only one side of the board, while the other side is used for mounting electronic components. It is the simplest and most cost-effective type of PCB, making it widely used in basic electronic circuits and low-cost applications.

Built to Global Standards

Our company adheres to the business philosophy of “Quality First, Customer Above All,” continuously innovating and enhancing technical capabilities to provide world-class PCB solutions to global customers.

Whether you are looking for a reliable OEM partner, need to procure PCB-related materials, or require efficient PCB production services, KeepBooming is your ideal choice.

Explore Our Chip Solutions

20+ Years Experience” | “99.2% Yield Rate” | “24/7 Response” | “50+ Countries Served

Advanced machinery and rigorous quality systems enable rapid prototyping to mass production, supporting rigid/flexible PCBs with unmatched consistency.

Workshop Facility Image

Workshop Facility

Automated alignment and pressure control ensure bubble-free adhesion of stiffeners, critical for aerospace/automotive PCB reliability.

lawless Stiffener Bonding

Robotic micron accuracy

CNC-controlled carbide tooling achieves ±0.05mm tolerances at 800+ cycles/hour, essential for HDI board edge quality.

High-Speed Complex Profiling

Laser-calibrated punching

Interested? Shop This Plant Collection!

Neque porro quisquam est, qui dolore ipsum quia dolor sit amet, consectetur adipisci velit, sed quia non numquam eius modi tempora incidunt.