In-circuit testing plays a crucial role in ensuring that components and circuits on a printed circuit board assembly (PCBA) function correctly. This process verifies that every part operates as intended, which is essential for producing reliable and high-quality electronics. Using a PCBA in circuit tester, manufacturers can detect issues such as poor soldering or defective components at an early stage.

This approach significantly reduces manufacturing errors. For instance:

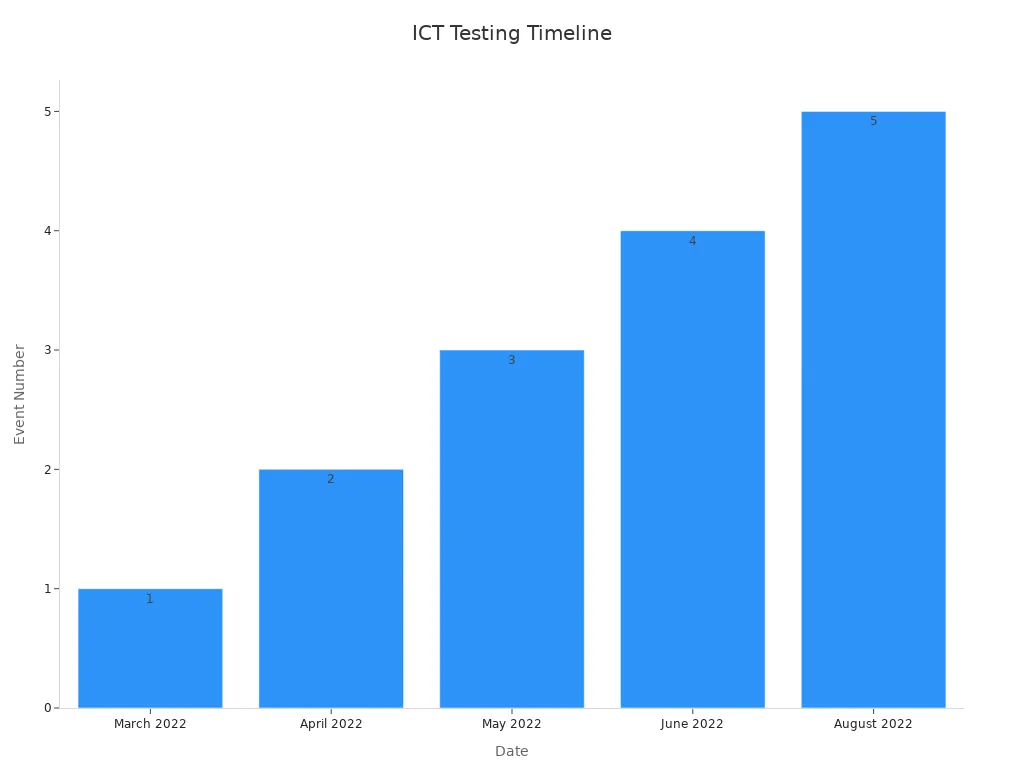

Automotive systems experienced a 20% reduction in manual testing and a 10% increase in production speed.

A car parts manufacturer accelerated testing processes by six times.

A major electronics company improved efficiency by four times and achieved substantial cost savings.

By emphasizing functional components early on, a PCBA in circuit tester ensures consistent results and helps prevent costly errors down the line.

Key Takeaways

In-circuit testing (ICT) checks each part on a circuit board to make sure it works right, stopping costly mistakes.

Using a circuit board tester makes production faster and cuts down on manual checks, improving efficiency a lot.

Finding problems early with ICT saves money by reducing waste and avoiding costly product recalls.

Spending on in-circuit testing makes products more reliable and helps customers trust the brand, making it important for quality control.

New technology like automation and AI is making in-circuit testing quicker and more precise, keeping up with modern electronics.

What is In-Circuit Testing?

Definition and Purpose

In-circuit testing (ICT) checks if parts on a printed circuit board assembly (PCBA) work properly. It makes sure every piece is in the right spot and functions well. Special tools, called a pcba in circuit tester, send signals to parts and check their responses. Unlike tests that check the whole circuit, ICT focuses on each part separately.

Aspect | Details |

|---|---|

Definition | ICT is a type of PCB test that checks many points at once. |

Purpose | To confirm each electronic part on the PCB works correctly. |

Advantages | Quicker testing and easier problem detection than other methods. |

Disadvantages | Costs more and needs complex tools and software. |

ICT helps find problems like broken connections, bad soldering, or short circuits. Fixing these early saves money and keeps products reliable.

Key Components of a PCBA In Circuit Tester

A pcba in circuit tester has important parts that work together:

Test probes: These touch the PCB to check electrical signals.

Fixture: This holds the PCB steady so probes can align correctly.

Measurement system: It reads signals from probes to find problems.

Software interface: The software runs the test and shows the results.

These parts combine to give accurate and dependable testing. Testing each part separately makes this tool very useful in PCBA production.

Importance in PCBA Manufacturing

In-circuit testing is key to keeping PCBA quality high. It checks how well each part works and finds problems before final assembly. This lowers the chance of product failures and makes devices more reliable.

ICT is better than other methods because it finds more faults and is more precise. It ensures circuits work well, making it a must for quality checks. Using a pcba in circuit tester boosts production speed and helps deliver trustworthy products to customers.

How In-Circuit Testing Works

Overview of the Process

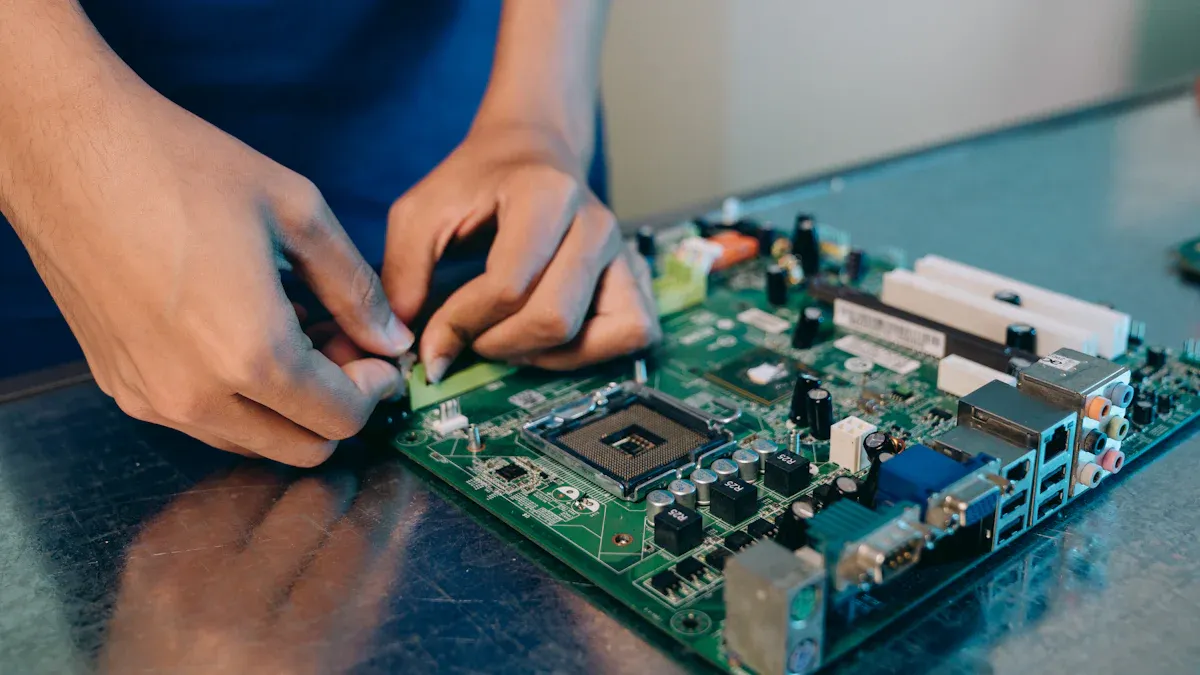

In-circuit testing checks each part of a circuit board. It works like a step-by-step check to ensure all parts function properly. First, the circuit board is placed in a special holder. This holder keeps the board steady and lines it up with test probes. The probes send signals to different spots on the board.

The tester reads how each part reacts to the signals. If a part doesn’t react correctly, it is marked as faulty. This method finds many problems and catches them early. By fixing issues early, in-circuit testing ensures only working boards continue in production.

Equipment and Setup

Specific tools are needed for in-circuit testing. The main tools include:

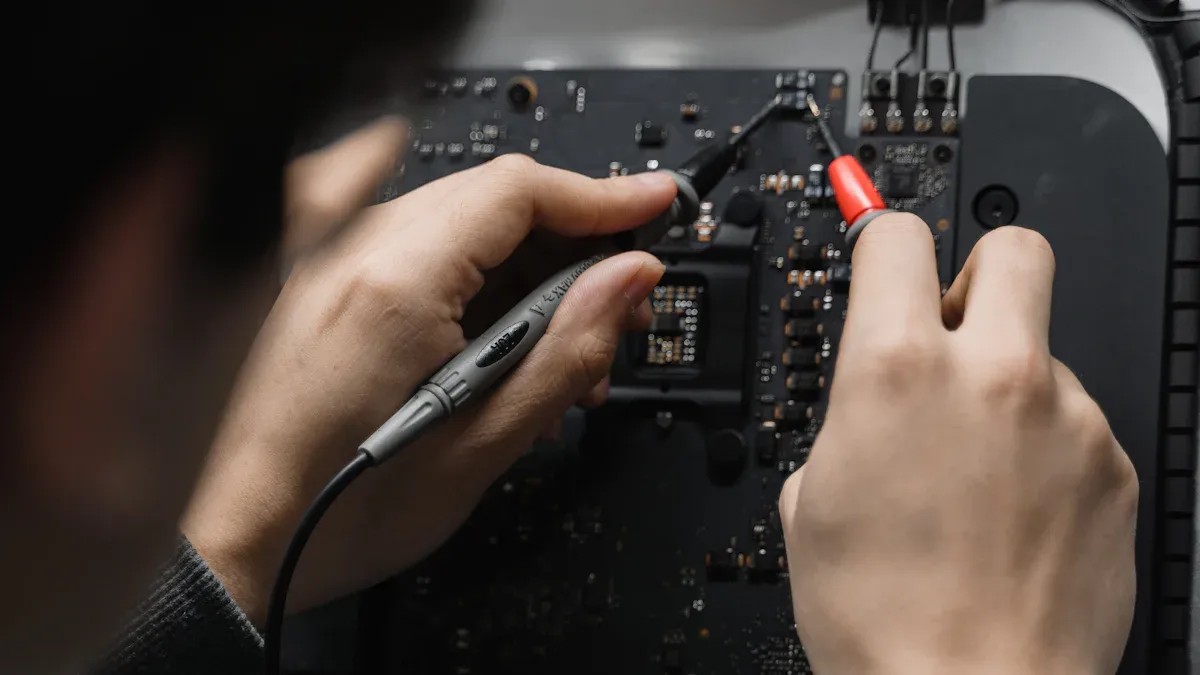

Test probes: These touch the board and send signals to its parts.

Fixture: This holds the board steady and aligns the probes.

Measurement system: It collects data from the probes and finds problems.

Software: The software runs tests and shows the results.

Setting up the tools needs careful work. The probes must match the test points on the board. The measurement system also needs to be set up correctly for accurate results.

Types of Tests Performed

In-circuit testing does different checks to find problems. These include:

Resistance tests: Check if parts have the right resistance.

Capacitance tests: Ensure capacitors store charge properly.

Continuity tests: Find broken connections or open circuits.

Short circuit tests: Spot unwanted connections between parts.

Each test looks at a specific part of the board. Together, they make sure the board is fully tested. This process ensures all parts meet quality standards before moving forward.

Advantages of In-Circuit Testing

Fault Detection and Troubleshooting

In-circuit testing is great at finding problems in circuit boards. It checks each part one by one to spot issues. Problems like broken wires or bad parts are easy to find. For example, if a resistor doesn’t work right, the test shows it. Fixing these problems early saves time and money later.

This detailed fault-finding is a big benefit of in-circuit testing. It makes sure no bad parts are missed, keeping your product reliable.

Cost-Effectiveness

Setting up in-circuit testing can cost a lot at first. But it saves money over time by catching problems early. This stops bad products from being made and reduces waste. Fixing fewer mistakes also means lower costs for repairs or recalls.

In-circuit testing also speeds up production. Machines can test many parts at once, saving time. Faster testing helps make more products quickly, improving efficiency.

Quality Assurance and Reliability

In-circuit testing helps ensure high-quality products. It checks that every part works before the product is sold. This testing makes devices more reliable and trustworthy.

Using in-circuit testing shows you care about quality. Customers trust products that are tested well, which builds your reputation.

Tip: Adding in-circuit testing to your process improves quality and customer trust.

Disadvantages of In-Circuit Testing

High Initial Costs

Setting up in-circuit testing costs a lot at first. The tools, software, and fixtures needed are expensive. For small productions, the cost per item is higher. This happens because fewer products share the setup costs. In bigger productions, costs drop due to making more items.

Cost Factors | Small-Scale Production | Large-Scale Production |

|---|---|---|

Initial Setup Costs | Lower per unit | |

Operational Costs | High per unit | Lower per unit |

Economies of Scale | Limited | Significant |

Maintenance & Calibration | High relative cost | Lower relative cost |

Rework & Scrap Rates | Potentially higher | Reduced due to better detection |

Even though the starting costs are high, the benefits like finding faults early and less rework often make it worth it.

Maintenance and Calibration

Keeping in-circuit testing tools working adds extra costs. Regular calibration is needed for accurate results. This requires skilled workers and special tools. For small productions, these costs can feel very high. Skipping maintenance can lead to wrong test results and bad product quality.

It’s smart to keep records of maintenance costs. This helps plan budgets and avoid surprises. While maintenance is necessary, it is one of the downsides of in-circuit testing.

Limitations in Testing Complex Designs

Testing crowded circuit boards is hard for in-circuit testing. It’s tough to reach all test points on these boards. Designers must plan carefully to make testing easier. Some parts are also delicate and can get damaged during testing if not handled well.

Challenge | Description |

|---|---|

Testing crowded boards is hard because reaching all test points is tricky, needing careful design planning. | |

Component Sensitivity | Some parts are delicate and can get damaged during testing. Training workers and using adjustable tools can help prevent this. |

Functional Failure Detection | In-circuit testing might miss some problems that only show up under certain conditions. Combining it with other tests like Functional Testing can help find these issues. |

In-circuit testing also misses some problems that happen only in specific situations. Using it with other tests, like functional testing, can solve this. Even with these limits, in-circuit testing is still very useful for checking PCBA quality.

Advancements in In-Circuit Testing Technology

Automation and Robotics

Automation and robots have made in-circuit testing quicker and better. Machines now handle tasks like placing probes and running tests. This reduces mistakes and improves accuracy. For example, Bosch Automotive Group uses automatic testers to speed up production.

Robots are also helpful for testing crowded circuit boards. They use sensors to reach tight spaces and test thoroughly. These tools make it easier to check complex designs without losing precision.

Software Innovations

New software has greatly improved in-circuit testing. Programs now use AI and machine learning to predict problems before they happen. This saves time and lowers costs by fixing issues early.

Cloud-based tools are another big improvement. They let you analyze data and work together from anywhere. For instance, Digitaltest’s FlashRunner 2.0 made testing complex boards easier, showing how software helps simplify testing.

Innovation Type | How It Helps Testing |

|---|---|

Automation | Speeds up testing and ensures thorough checks. |

AI Integration | Finds problems early, saving time and money. |

IoT Requirements | Adds new tests for connected devices to ensure safety and compatibility. |

Cloud Computing | Allows remote monitoring and faster product development. |

5G Technology | Tests for high-speed data and low-latency performance. |

Integration with Industry 4.0

Industry 4.0 has added smart tools to in-circuit testing. IoT devices collect data from many testing stations at once. This helps make better decisions and fix problems faster.

AI and machine learning improve testing by finding more defects and making processes smoother. For example, SPEA S.p.A. and JTAG Technologies worked together to improve fault detection using boundary scans.

These updates make in-circuit testing faster, smarter, and more reliable. They help meet the needs of today’s electronics industry.

In-circuit testing is vital for making quality PCBAs. It checks each part to ensure it works properly. Problems like short circuits or wrong parts are found early. Fixing these issues early saves money and improves production. This method also makes products last longer and work better.

In-circuit testing is growing in the global PCBA Test Service Market. It plays a big role in checking electrical performance and reliability. As the market focuses on quality, using in-circuit testing helps meet these needs.

Note: Adding in-circuit testing ensures reliable, high-quality, and cost-saving PCBAs. It also keeps you ahead in the changing electronics industry.

FAQ

What is the main purpose of in-circuit testing?

In-circuit testing checks if every part on a PCBA works well. It finds problems like bad parts, poor soldering, or short circuits early. This helps make products more reliable and reduces mistakes during production.

Can in-circuit testing handle all types of PCB designs?

In-circuit testing works better for simpler boards. Testing crowded or very complex boards can be harder. Other methods, like functional testing, may be needed for tricky designs.

How does in-circuit testing save costs?

It spots problems early, stopping bad products from being made. This lowers waste, fixes fewer mistakes, and avoids recalls. Over time, the money saved is more than the setup costs, especially for big productions.

Is in-circuit testing suitable for small-scale production?

In-circuit testing costs a lot for small productions. But it ensures good quality, which can be worth it for important or expensive products.

What advancements have improved in-circuit testing?

Automation, AI, and cloud tools make testing faster and better. Robots test complex boards, and AI finds problems early. These updates fit with Industry 4.0, making testing more precise and efficient.

Tip: Use in-circuit testing with other methods to check complex boards better.

See Also

Innovative PCBA Testing Methods for Modern Electronics Production

Understanding PCBA Services and Their Significance in Electronics

Significance of PCBA Test Jigs in Today’s Electronics Manufacturing