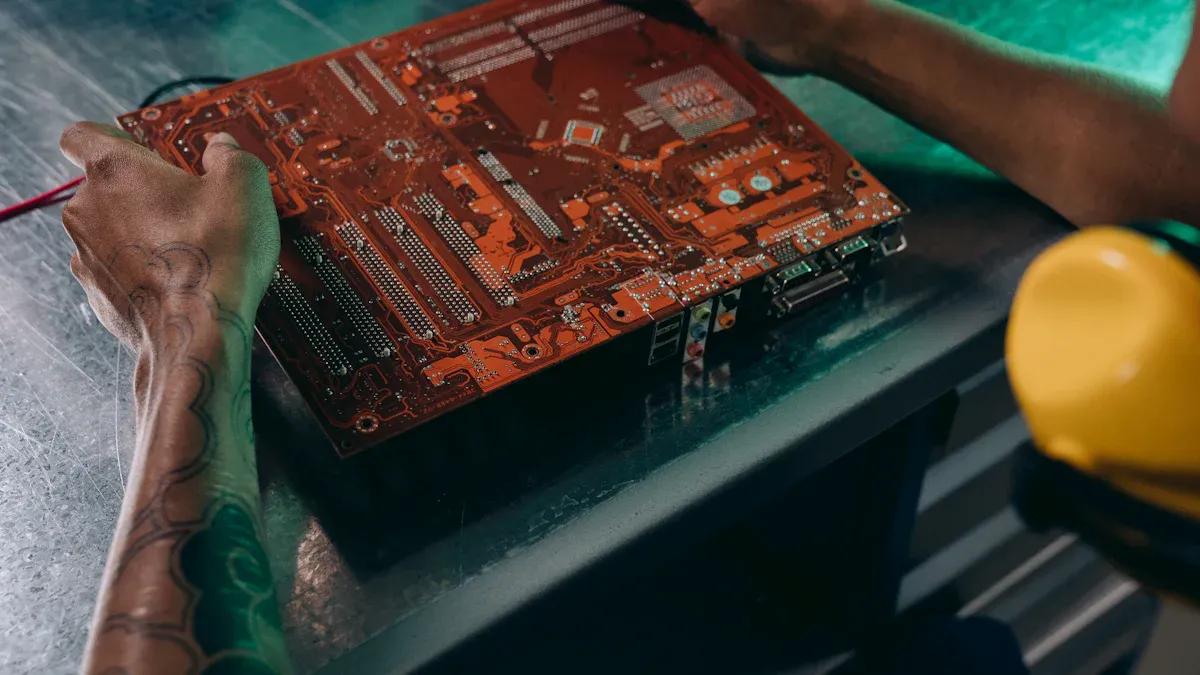

Making PCBA manufacturing crucial for building dependable electronic devices. It involves placing parts onto a printed circuit board (PCB) to ensure they function correctly. New technology has enhanced how PCBA manufacturing is conducted and verified. Machines now inspect thousands of parts in seconds, aiming for zero mistakes. Understanding this process is essential to ensure products are high-quality and operate effectively. From assembly to testing and inspection, every step in PCBA manufacturing contributes to the success of the electronics we use every day.

Key Takeaways

Knowing how PCBA is made helps build dependable electronics.

Checking quality at each step avoids errors and saves money.

Using smart tools like automated checks finds problems faster.

Picking good PCB materials makes them last longer and work better.

Testing how it works early ensures it performs well in real life.

Overview of the PCB Manufacturing Process

Making a PCB is the first step to building a working circuit board. It includes many important steps that affect how well the board works. Learning about this process shows how complex modern electronics are.

PCB Design and Layout

Designing a PCB starts with making a layout that fits the device’s needs. You need to set rules so the board can be made and assembled easily. Placing parts in groups makes wiring simpler. Putting power and ground layers in the right spots keeps the board stable. Checking signal paths ensures fast signals work without problems. A good design reduces mistakes and saves money.

Material Selection

Picking the right materials makes the PCB strong and efficient. Materials that handle heat well keep the board cool. Strong materials help the board last longer under stress. Costs matter too, so balancing price and performance is key. Using eco-friendly materials also helps protect the environment.

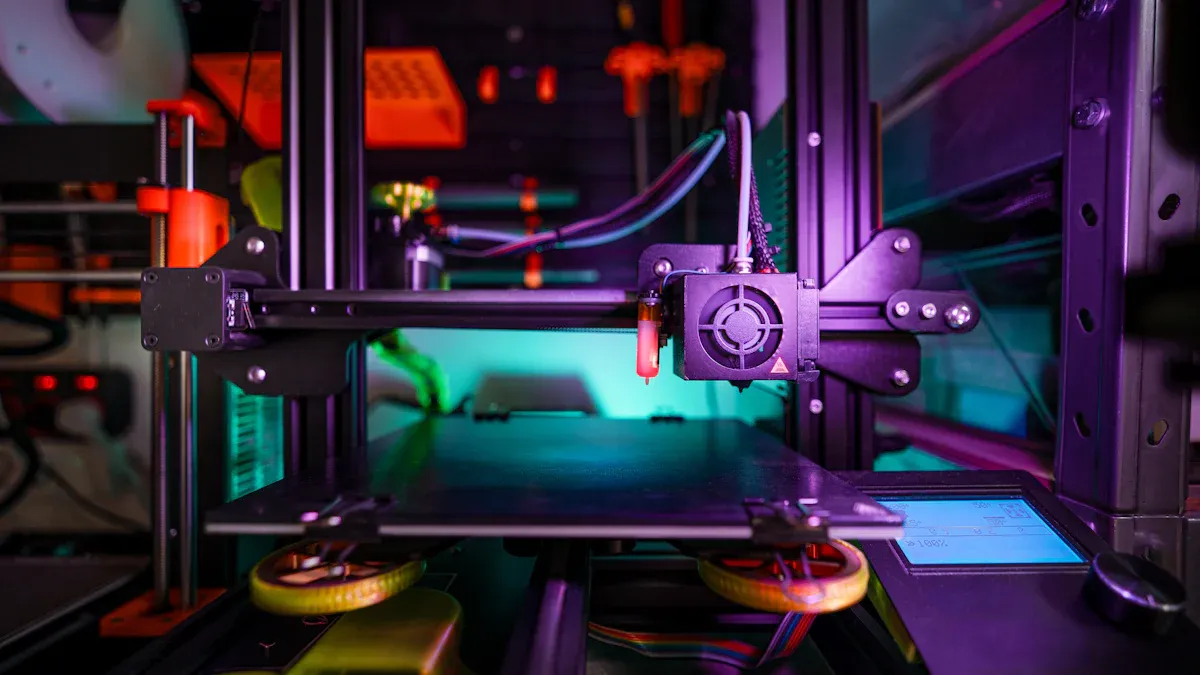

PCB Fabrication Techniques

Making a PCB means turning the design into a real board. Steps like etching, drilling, and plating create the layers and connections. Many devices use multi-layer PCBs because they save space and add features. Flexible PCBs are also popular for small or oddly shaped devices. These methods show how advanced PCB making has become.

The PCB market is growing fast. In 2023, it was worth $67.9 billion and might reach $92.4 billion by 2029. This growth shows how important PCBs are in industries like cars, healthcare, and phones. Electric cars, for example, need special PCBs for batteries and power systems. These trends show why learning about PCB making is so important.

Key Steps in the PCBA Manufacturing Process

Solder Paste Stenciling

Solder paste stenciling starts the PCBA process. A stencil spreads solder paste on the PCB. This paste helps parts stick during assembly. The stencil applies paste only where parts go. A bad stencil design can cause problems like solder bridging. This lowers the success rate of the assembly. Better stencils improve the process and profits.

Statistical process control is very important here. It reduces errors and keeps results steady. Fixing issues like uneven paste makes better circuit boards.

Pick and Place Assembly

Pick and place assembly adds parts to the PCB. Machines pick parts from trays or reels. They place them on the solder paste with great accuracy. About 96% of placements are within ±20 µm. This ensures parts fit perfectly, lowering mistakes.

Modern machines learn and improve placement over time. This technology makes the process faster and more reliable. It is a key part of PCBA manufacturing.

Reflow Soldering

Reflow soldering secures parts to the PCB. The board goes through a reflow oven. Heat melts the solder paste, making strong bonds. A Ramp-Soak-Spike (RSS) profile is often used. RSS heats the board slowly, then melts the solder at a peak temperature. This reduces problems like solder bridging.

Custom heat profiles improve solder joint quality. Optimizing this step increases success rates and makes boards more reliable.

Through-Hole Component Insertion

Through-hole component insertion is an important part of PCBA. It means putting parts with leads into drilled holes on the PCB. The leads are soldered to pads on the other side. This makes a strong and lasting connection.

This method has many benefits. Parts in holes stay firmly in place. This makes them good for tough conditions or physical stress. They also handle high power and heat well. That’s why they are used in power supplies and industrial machines. Fixing or assembling these parts by hand is easier since they are easy to reach.

But, there are some downsides too. This process is slower than surface-mount technology. It needs careful drilling and often manual work. Automation is harder, which raises costs. Bigger holes take up space, so fewer parts fit on the PCB.

Here’s a simple table showing the pros and cons of through-hole insertion:

Advantages | Challenges |

|---|---|

Strong and secure connections | Fewer parts can fit on the PCB |

Works well in tough conditions | Slower to assemble |

Easy to fix and assemble by hand | Harder to automate |

Handles high power and heat | Costs more to produce |

Good at managing heat | Big holes limit design options |

Even with these issues, through-hole insertion is still very useful. It’s great for products that need to work in harsh conditions. Knowing this process helps you pick the best way to build your PCB.

Inspection and Quality Control in PCBA Manufacturing

Inspection and quality checks are crucial for reliable PCBA production. Finding problems early avoids expensive mistakes and ensures the PCB works well. Let’s look at the main methods used.

Visual Inspection

Visual inspection is the first step to check quality. It means looking at the PCB by hand to spot problems like misplaced parts, solder bridges, or missing pieces. This method is easy and cheap, so it’s often used for small projects.

But visual checks have limits. People can miss mistakes, especially on complex boards with many layers. For large-scale production, this method alone may not be enough. Using it with machines gives better results.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) uses cameras to check PCBs fast and accurately. These systems find issues like misplaced parts, wrong polarity, or bad soldering. AOI works quickly, checking thousands of parts every minute. It gives instant feedback, helping fix problems right away and improving quality.

AOI systems are very precise. For example, they can spot tiny placement errors. Here’s a quick look at what AOI can do:

Metric | Description |

|---|---|

Positional accuracy | Finds small placement errors that could cause problems. |

Adding AOI to your process makes it faster and ensures high-quality PCBs.

X-Ray Inspection

X-ray inspection looks inside the PCB to check hidden parts. It shows solder joints and layers that can’t be seen otherwise. This method doesn’t damage the PCB and takes clear pictures. It’s great for finding problems like cold joints or voids, especially in multi-layer boards.

X-ray inspection has many benefits, like spotting problems early and being cost-effective. Here’s a summary of its advantages:

Benefit | Description |

|---|---|

Non-destructive testing | Keeps the PCB safe during checks. |

High-resolution imaging | Shows clear details of inside parts. |

Early defect detection | Finds issues early, saving money. |

Thorough inspection | Checks hidden solder joints for strong connections. |

Using X-ray inspection helps ensure your PCBA meets top standards, especially for advanced electronics.

Functional Testing

Functional testing is important to check if a PCBA works well. It tests if the PCB does its job in fake working conditions. Finding problems early saves money and ensures the product is good.

Special machines test the PCBA during different steps of making it. These tests include turning it on, checking signals, and testing in heat or moisture. Turning it on checks if it powers up right. Signal tests make sure electrical signals work properly. Heat and moisture tests see how it works in tough conditions. Each test helps check if the PCB works as it should.

Here’s a simple table of common functional tests:

Test Method | Purpose |

|---|---|

Functional Testing | Checks if it works in fake working conditions. |

Power-on Testing | Makes sure it powers up correctly. |

Signal Testing | Ensures signals are strong and correct. |

Environmental Testing | Tests it in heat and moisture. |

Functional testing is key to making sure the PCBA works well. It helps find big problems before shipping the product. But it doesn’t give details to improve the process, which can make it harder to use. Even so, it’s very useful for catching issues early.

Adding functional testing to your process helps make reliable PCBs. This step ensures your products work well, even in tough situations.

Final Assembly and Shipment in PCBA Manufacturing

Component Integration

The last assembly step starts with adding components. Here, the PCBA is joined with parts like cases, connectors, or cooling systems. This makes a complete product that works well together. Careful handling is needed to avoid breaking the PCB or other parts.

Quality checks are very important in this step. Before production, tests check the design and materials. During assembly, tools like AOI and inline tests find problems early. Functional tests make sure the PCBA works properly. After production, X-ray checks confirm hidden solder joints are strong. Feedback from these checks helps improve the process.

Quality Check Step | What It Does |

|---|---|

Pre-Production Testing | Checks design and materials before making many products. |

In-Process Inspection | Uses AOI and inline tests to find mistakes during assembly. |

Functional Testing | Tests the PCBA’s electrical work with special machines. |

Post-Production Analysis | Uses X-rays and other tools to check hidden solder joints. |

Feedback and Improvement | Uses test results to make the process better. |

Packaging and Labeling

After assembly, packaging and labeling are done. Packaging keeps the PCB safe during shipping. Anti-static bags stop static electricity from damaging parts. Labels help identify and track the product. This step keeps things organized and follows rules.

Shipment and Delivery

The last step is shipping the finished product. Good delivery systems ensure products arrive safely and on time. Tracking delivery times shows where improvements are needed. Checking suppliers often ensures they meet quality and service standards. Managing supplier inventory helps keep parts available.

Delivery time tracking shows how well suppliers perform.

Regular checks ensure suppliers meet quality and service needs.

Watching delivery data finds problems in the supply chain.

By focusing on these steps, you can make sure your PCBA process creates reliable products and delivers them efficiently.

The PCBA process has many steps, from PCB design to shipping. Each step is important for making a reliable product. Quality checks are done at every stage. Tools like automated inspection and testing find problems early. This saves time and improves the process.

Good PCBA manufacturing helps electronics work better. Using strong materials and smart methods makes devices last longer. Fewer mistakes mean happier customers. Quality control ensures PCBs meet top standards. This helps modern electronics succeed.

FAQ

1. What is the difference between PCB and PCBA?

A PCB is just the empty circuit board. A PCBA has all the parts attached to the PCB. The PCBA is ready to be tested and used in devices.

2. Why is quality control important in PCBA manufacturing?

Quality control makes sure the PCBA works well. It finds problems early, saving time and money. Good checks also make products better and customers happier. Without it, broken products could cause big issues.

3. Can you automate the entire PCBA manufacturing process?

Yes, many steps like applying solder paste and placing parts use machines. But some steps, like adding through-hole parts, might need people. This depends on the PCB’s design and how complex it is.

4. How do you choose materials for a PCB?

Pick materials that handle heat, last long, and fit your budget. For high-tech devices, use materials that can take high heat and stress. If you care about the planet, eco-friendly choices are available too.

5. What industries rely on PCBA manufacturing?

PCBA manufacturing helps industries like cars, healthcare, and phones. For example, electric cars use PCBAs for batteries, and medical tools need them for accuracy and safety.

See Also

Essential Strategies for Obtaining Superior Results from PCBA Makers

Enhancing Productivity in the PCBA Manufacturing Process

Crucial Actions to Locate a Reliable PCBA Vendor

Investigating PCBA Testing Methods for Modern Electronics Production

Determining the Ideal PCBA Producer for Your Business Growth