Printed Circuit Boards (PCB) and Printed Circuit Board Assemblies (PCBA) play crucial roles in electronics. When comparing pcb vs pcba, a PCB refers to the plain board made of non-conductive material with metal pathways, while a PCBA includes the PCB along with all the necessary components attached, making it functional and ready for use in a device.

Understanding the distinction between pcb vs pcba is essential. It enables you to choose the appropriate option for your project, which can ultimately save time, money, and resources, ensuring the success of your endeavor.

Key Takeaways

Know the difference: A PCB is just a board. A PCBA has all parts and works fully.

Match your needs: Use a PCB for simple tasks or tests. Pick a PCBA for harder jobs or ready-to-use items.

Spend smartly: PCBs cost less to make than PCBAs. Check your money and needs before choosing.

Test carefully: Testing is important for both PCBs and PCBAs. It ensures they work well in real life.

Plan ahead: Pick PCB or PCBA based on future goals. Think about growth and how long it will last.

Understanding PCB

What Is a PCB?

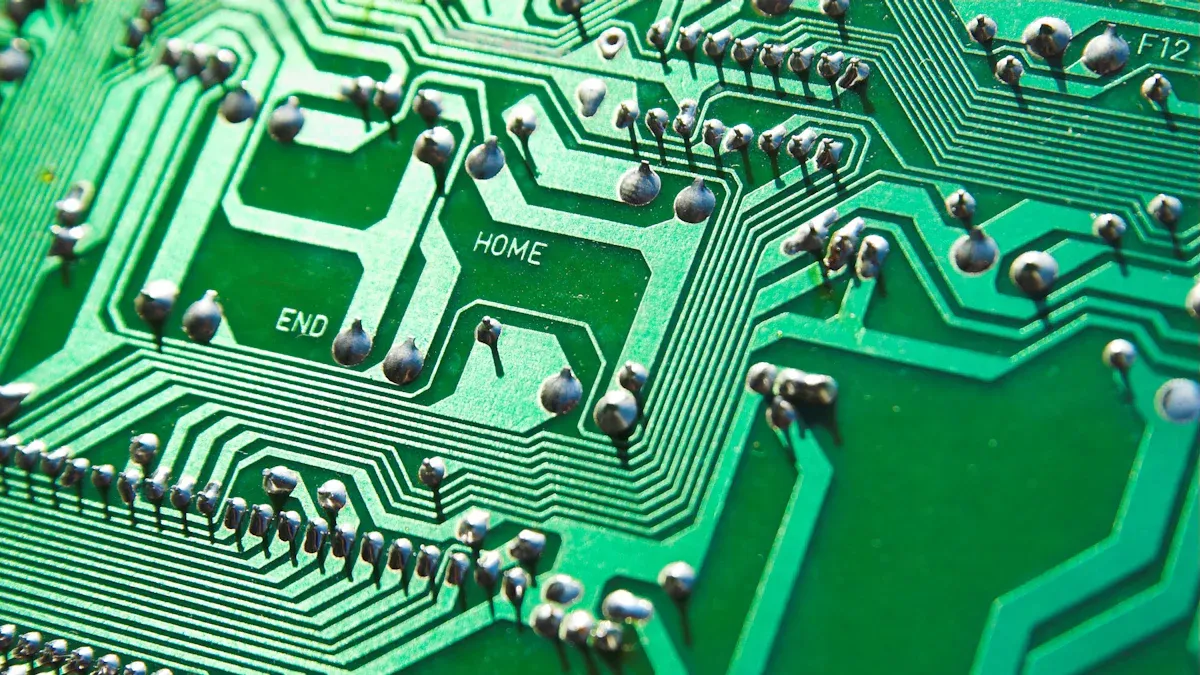

A printed circuit board is the base of most electronics. It is made of a flat material, like fiberglass, that does not conduct electricity. Thin copper lines are added to its surface to let electricity flow. These lines connect parts so the device works properly.

Making a PCB involves many steps. First, the layout is designed. Then, the copper lines are etched, and protective layers are added. This process makes the board strong and able to handle electricity well. A single PCB can hold many parts, showing how important it is in electronics.

Common Uses of PCB

PCBs are used in many industries and devices you see daily. Some examples are:

Consumer Electronics: Phones, TVs, and appliances need PCBs to work.

Automotive Components: Car sensors, navigation, and controls use PCBs for accuracy.

Medical Devices: Machines like CT scanners and monitors depend on PCBs.

Aerospace: Airplane communication and monitoring systems rely on PCBs.

Industrial Equipment: Factory tools and power systems use PCBs for strength.

These uses show how PCBs are helpful in many areas, from health to factories.

Benefits of Using PCB

Using a PCB in your project has many benefits, such as:

Benefit | Description |

|---|---|

Good designs improve signals, power flow, and performance. | |

Fewer Mistakes | Following rules lowers the chance of errors and fixes. |

Easier to Make | Well-planned designs are cheaper and simpler to produce. |

By focusing on design and making, your PCB can fit your project’s needs. This helps it work better and saves money and time.

Understanding PCBA

What Is a PCBA?

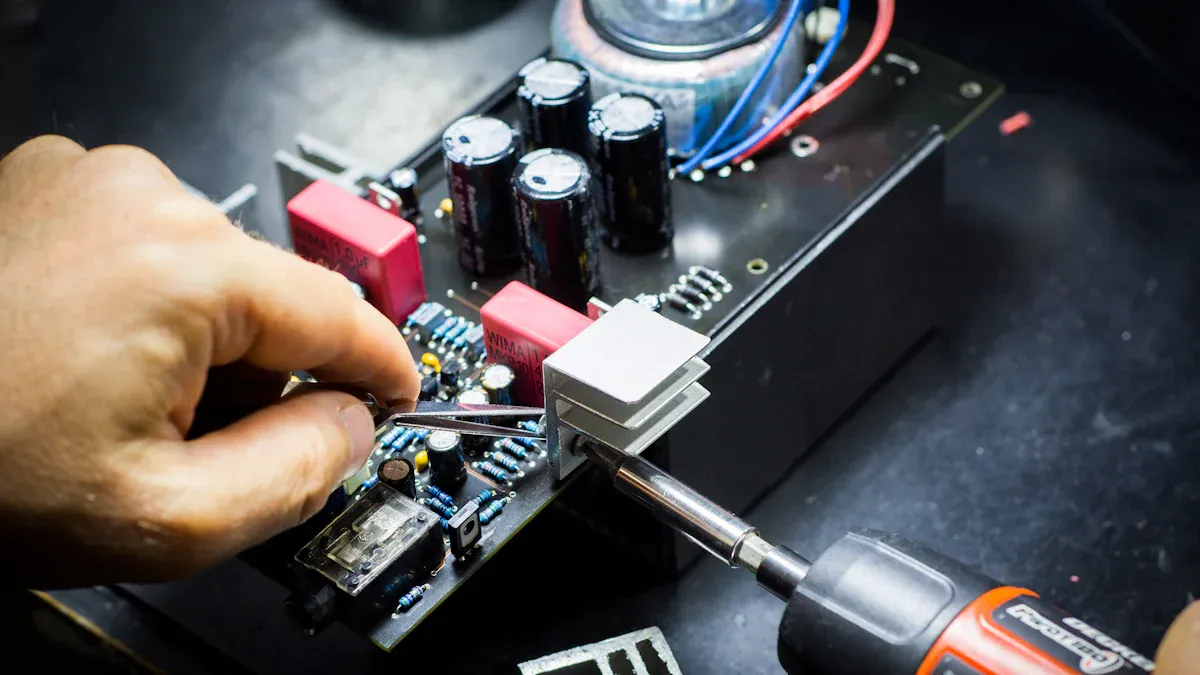

A printed circuit board assembly (PCBA) is a working electronic unit. It is made by attaching parts to a printed circuit board (PCB). The PCB is the base, while the PCBA adds life with parts like resistors and capacitors. This process uses methods like surface-mount technology (SMT) or through-hole assembly for strong connections.

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Empty board with pathways for electricity | Board with parts that make it work |

Function | Supports and connects electronic parts | Performs tasks as an electronic circuit |

Components | None (just the board) | |

Manufacturing | Adding copper lines and protective layers | Adding and soldering parts onto the board |

Testing | Checks for proper pathways | Tests to ensure it works correctly |

Turning a PCB into a PCBA makes it ready for devices like phones, medical tools, or factory machines.

Common Uses of PCBA

PCBA is found in almost all electronics. Its wide use makes it important in many fields:

Medical Devices: PCBA helps pacemakers and scanners work accurately.

Telecommunications: Routers and modems need PCBA for fast data handling.

Industrial Automation: PCBA keeps factory machines running smoothly.

Aerospace and Defense: Critical systems depend on reliable PCBA.

IoT Devices: Smart home gadgets use PCBA for connecting and processing.

These examples show how PCBA is key to modern technology.

Benefits of Using PCBA

Using PCBA in your project has many advantages:

Advantage | Description |

|---|---|

Testing PCBA early avoids expensive mistakes later. | |

Faster Development Cycles | Quick testing helps speed up making new products. |

Improved Product Quality | Careful testing ensures the product works well. |

Simplified Complex Designs | PCBA makes fixing and improving designs easier. |

Seamless Transition to Production | Prototyping with PCBA helps prepare for smooth mass production. |

Working with a good PCBA provider ensures high-quality boards. This saves time, reduces errors, and improves your product’s quality.

PCB vs PCBA: Key Differences

Design and Assembly Complexity

When looking at PCB vs PCBA, complexity matters. A PCB is easier to design since it only needs pathways for electricity. A PCBA is harder because it includes adding parts like resistors and chips. This makes the process more detailed.

To check complexity, follow these steps:

Collect design details.

Count the PCB layers.

Check how many parts are on it.

Look at how tightly parts are placed.

Note any special features or tech used.

Give scores for each factor.

Add scores to find total complexity.

A PCB is just the base, while a PCBA makes it work. Turning a PCB into a PCBA uses advanced methods like surface-mount technology, which adds difficulty.

Cost Implications

Making a PCB costs less than making a PCBA. A PCB is just a plain board, but a PCBA includes parts and assembly. Costs depend on things like how many boards fit on a panel and how many panels are made at once. For PCBA, costs depend on the parts and assembly methods.

Tools like aPriori can help split part costs from assembly costs. This helps you find ways to save money. Knowing these details helps you plan your budget better.

Time and Resource Requirements

Making a PCB takes less time and effort than a PCBA. A PCB needs fewer steps, so it’s quicker. A PCBA takes longer because it needs parts, soldering, and testing.

Good material planning is key for PCBA. A Material Requirement Planning (MRP) system helps predict what materials are needed. This avoids delays. Checking equipment and worker use keeps things running smoothly. Working well with suppliers also helps meet deadlines.

By knowing these differences, you can manage time and resources better. This ensures your project runs smoothly.

Prototyping vs. Mass Production

When starting a project, you must pick between prototyping or mass production. Each choice has its own purpose and needs.

Prototyping is great for testing and improving designs. It lets you make changes often without spending too much. For example, you can change a PCB layout or try new parts in a PCBA. This makes prototyping perfect for early development. But, the cost per unit is higher because fewer are made.

Mass production focuses on making many items quickly and consistently. After finalizing your design, you can produce large amounts. This lowers the cost per unit due to bulk production. However, changes during mass production are costly and risky. Retooling and extra testing are needed for any adjustments.

Here’s a simple comparison of the two:

Aspect | Prototyping | Mass Production |

|---|---|---|

Design Flexibility | High; easy to make changes | Low; changes are expensive |

Quality Control | Basic checks for function | Detailed testing for reliability |

Material Choices | Simple materials like FR-4 | Stronger materials for durability |

Cost Structure | Higher cost per unit | Lower cost per unit in bulk |

Manufacturing Tools | Flexible tools for quick changes | Fixed tools for large production |

Lead Times | Shorter, faster to complete | Longer, needs setup and testing |

Prototyping allows quick design changes and testing. It uses simpler materials for speed. Mass production, however, needs better materials for strength and consistency. It also requires strict planning to avoid mistakes.

By knowing these differences, you can decide what fits your project. Use prototyping for early ideas and mass production for scaling up efficiently.

Choosing Between PCB and PCBA

Checking Project Needs

Knowing your project’s needs helps you pick between a PCB and a PCBA. Think about what your design requires and where it will be used. For example, if it faces high heat or tough conditions, you’ll need materials that can handle these challenges.

Metric | What It Means |

|---|---|

Shows how well a material works in high heat. | |

Dielectric Constant | Tells how much electrical energy a material can hold. Lower is better for fast signals. |

Loss Factor | Measures energy loss in a material. Lower means better signal flow. |

Mechanical Strength | Shows how strong a material is under stress. Important for tough environments. |

Also, think about how complex the design is. If it has many parts or tricky layouts, a PCBA might make things easier. By looking at these details, you can match your choice to your project’s needs.

Thinking About Budget and Time

Money and time are big factors in your choice. A PCB costs less because it’s just the board. A PCBA costs more since it includes parts and assembly. For tight budgets, check the cost per board, setup fees, and tools needed.

Factor | What It Means | Why It Matters |

|---|---|---|

Cost | Price per PCB, including setup and tools. | Important for saving money. |

Production Speed | How fast the factory makes and delivers your boards. | Helps meet deadlines. |

Quality Control Measures | Steps to check the product’s quality. | Ensures it works well and lasts long. |

If you’re in a hurry, pick a factory that can make PCBAs quickly. This helps you stay on schedule and finish on time.

Skills and Knowledge Needed

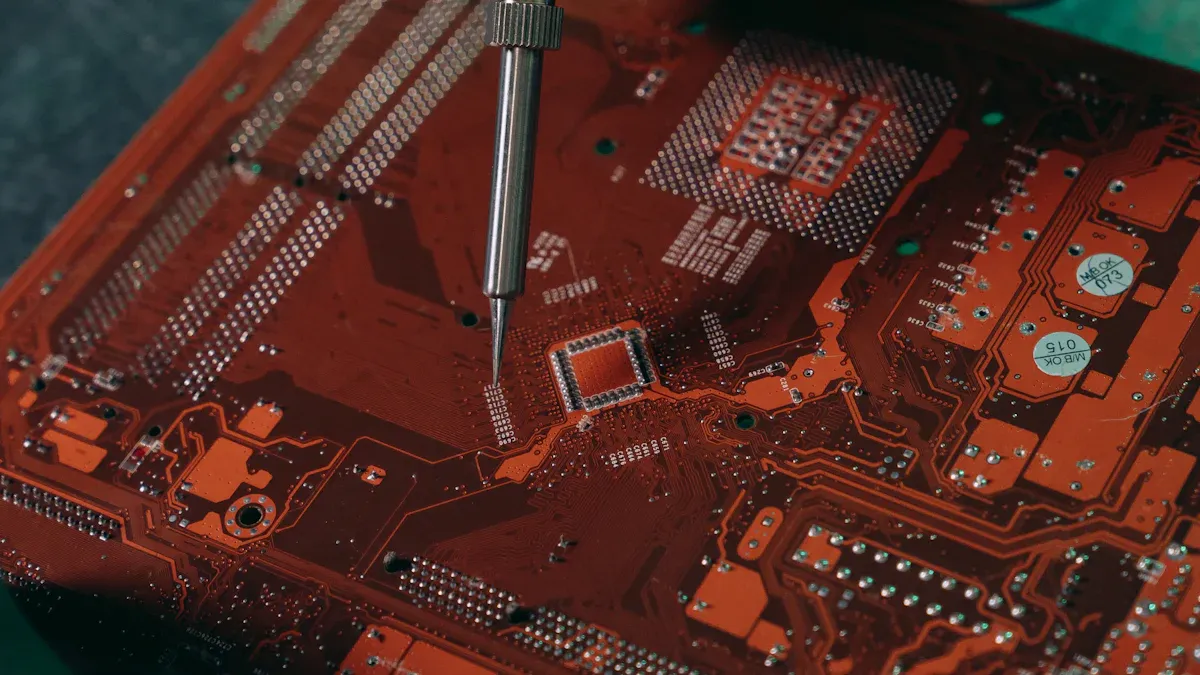

The skills you need depend on your choice. Making a PCB needs knowledge of circuits and materials. A PCBA needs extra skills like soldering and testing. New tools like Automatic Optical Inspection (AOI) and X-ray imaging are now common for checking PCBAs.

AOI is great for finding mistakes fast.

Machines now do inspections, making them quicker and more accurate.

Special skills are needed for these advanced tools.

If your team doesn’t have these skills, work with an expert manufacturer. They can help make sure your product is high quality and reliable. This reduces mistakes and improves your final result.

Long-Term Project Goals

When planning a project, think about long-term goals. Choosing between PCB and PCBA affects how strong and reliable your product will be. Focusing on these goals helps your design last and work well in real life.

Reliability is very important. A PCBA goes through many tests to check its performance over time. These tests see how it handles heat, electricity, and stress. For example, electrical tests check how it works in different situations. Thermal cycling tests make sure it survives temperature changes. These tests show how your product will perform in the future.

Testing Type | What It Checks |

|---|---|

Electrical Tests | How the PCBA works in different conditions. |

Thermal Cycling Tests | If it can handle temperature changes over time. |

Long-Term Heat Stability Tests | How stable the materials are under long heat exposure. |

Thermal Shock Tests | If it can survive sudden temperature changes. |

Life Simulation Tests | Predicts how reliable it will be over a long time. |

Scalability is another key factor. If you plan to make many products, a PCBA is easier to scale. Its pre-assembled parts save time and effort. This helps meet market needs faster.

By matching your choice to your long-term goals, you can build a product that works well and lasts. This smart planning makes sure your effort and money are worth it.

Decision-Making Checklist

Project Scope and Complexity

Knowing your project’s scope and complexity is very important. It helps you decide between PCB and PCBA. A clear scope keeps your project on track and avoids problems. Write down what the project will deliver and how to handle changes. For example, tracking changes can help you deal with surprises better.

Description | |

|---|---|

Final Deliverables | List what the project will complete. |

Change Request Criteria | Set rules for deciding if changes fit the plan. |

Out-of-Scope Process | Explain how to manage requests outside the plan. |

Decision-Making Hierarchy | Decide who approves changes to the plan. |

Change Request Tracking | Use a system to record and follow all changes. |

The type of PCB design also matters. Simple boards cost less, but complex ones cost more. Multi-layer boards are needed for advanced uses. This affects design, making, and costs.

PCB Type | Complexity | Typical Applications | |

|---|---|---|---|

Single-Layer | Lowest | $0.05 – $0.15 | Basic gadgets, simple circuits |

Double-Layer | Moderate | $0.10 – $0.30 | IoT devices, factory controls |

Multi-Layer (4-6 Layers) | High | $0.25 – $0.75 | Advanced tools, industrial machines |

Multi-Layer (8+ Layers) | Very High | $0.60 – $2.00+ | Fast computers, signal processing |

Component Sourcing and Availability

Getting parts on time is key to staying on schedule. Delays in parts can slow down your project. Track how long parts take to arrive and reorder early. Check suppliers often to ensure good quality and fast delivery.

Touchpoint | Impact | Action |

|---|---|---|

Affects project timelines | Monitor delivery times and reorder early | |

Delivery Speed | Impacts production schedules | Review supplier performance regularly |

Inventory Levels | Affects cash flow | Use systems like JIT to manage stock |

Think about the parts your project needs. Good parts make your product work better. But special parts may cost more and take longer to get. Trusted suppliers can help balance cost, quality, and timing.

Manufacturing and Assembly Needs

Your needs depend on whether you pick PCB or PCBA. Making a PCB is simpler and cheaper. PCBA includes adding parts, which is harder and costs more.

Metric | PCBA Production Needs | |

|---|---|---|

Complexity | Simple, just making the board | Harder, includes adding parts |

Cost | Lower, fewer steps involved | Higher, includes assembly and testing |

Quality Control Measures | Basic checks for functionality | Detailed checks for soldering and parts |

Assembly Process | Only board creation | Adding and soldering components |

Focus on quality checks to get good results. For PCBs, basic tests are enough. For PCBAs, detailed checks like soldering inspections are needed. Working with a trusted manufacturer ensures good quality and stays within budget.

Testing and Quality Assurance

Testing and quality checks are important for reliable PCB and PCBA. These steps find problems early, saving time and money during production. Careful testing helps make products that work well and meet customer needs.

Key Testing Methods

Different tests are used to check PCB and PCBA quality. Each test focuses on specific features to ensure they are strong, safe, and work properly. Below is a table showing common testing methods:

Testing Method | What It Does |

|---|---|

Burn-in Test | Uses tough conditions to find weak spots and test strength. |

Circuit Function Test | Sends signals to check how parts perform and find flaws. |

Automated Optical Check (AOI) | Uses cameras to spot visual problems without touching the board. |

Visual Check | Looks for damage, bad soldering, and misplaced parts. |

Power Module Test | Checks if the power module gives correct voltage and current. |

I/O Port Test | Makes sure input/output ports connect and send signals correctly. |

Communication Port Test | Tests if parts connect and share data properly. |

HALT Test | Stresses boards quickly to find early product issues. |

HASS Test | Finds faulty PCBAs before they are shipped. |

Shock and Drop Test | Tests if the board can handle impacts and stay protected. |

These tests make sure the product works well in real-life situations.

Why Quality Checks Matter

Good quality checks offer many benefits:

Problems are found early, avoiding bad products.

Faster testing speeds up production timelines.

Fewer mistakes mean less waste and happier customers.

Safe and reliable parts prevent accidents and risks.

Focusing on quality checks makes production smoother and builds customer trust. It saves resources and ensures your product is dependable.

Deciding between PCB and PCBA means knowing their differences. A PCB is just a plain board that connects parts. A PCBA has all the parts added, so it works in devices. The table below shows how they differ:

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Completion | Plain board with no parts | Complete board with all parts attached |

Functional Status | No function; only supports and connects parts | Works as the main part of electronic devices |

Manufacturing Process | Made by designing circuits, etching, and drilling | Made by adding and soldering parts |

Application Phase | Used for planning and testing | Used in final products and large-scale production |

Choosing the right one depends on your project’s needs. Think about things like budget, testing, and goals. This helps you save money and finish your project successfully.

FAQ

1. What is the main difference between PCB and PCBA?

A PCB is just a plain board with circuits. A PCBA has all the parts attached and is ready to work in devices. The PCB is the base, while the PCBA is fully functional.

2. When should you choose a PCB over a PCBA?

Pick a PCB when you only need the board for testing or designing circuits. It’s best for early stages when parts are not finalized yet.

3. Can you reuse components from a PCBA?

Yes, parts from a PCBA can be reused if they are not damaged. Removing them needs care and special tools to avoid breaking anything.

4. How does prototyping differ for PCB and PCBA?

Prototyping with a PCB checks the circuit design. With a PCBA, you test the whole board with its parts. This helps find problems before making many units.

5. What factors affect the cost of a PCBA?

The cost of a PCBA depends on how complex it is, how many parts it has, and how it’s made. Using better materials and advanced tests can also raise the price.

Tip: Talk to your manufacturer for a detailed cost plan to manage your budget better.

See Also

Choosing Between PCB And PCBA: Make The Right Choice

Essential Advice For High-Quality Outcomes With PCBA Suppliers

Important Steps To Locate A Reliable PCBA Supplier