Picking the right PCBA contract manufacturer is very important. They help make sure your electronics are made well and work reliably. A good manufacturing partner can stop expensive errors and create great products that people want.

The worldwide electronics manufacturing market is growing fast. It is expected to grow 58% and reach $797 billion by 2029. This shows how important it is to choose a partner who adds value to your work. A trusted manufacturer helps you grow, work better, and succeed more easily.

Key Takeaways

Pick a nearby PCBA maker for better talks, lower costs, and faster work.

Keep your ideas safe with NDAs and choose makers with good security.

Find makers skilled in DFM to make production easier and reduce mistakes.

Choose makers with ISO and IPC certificates for top quality and trust.

Check reviews and examples to see if the maker is good and experienced.

Location and Logistics

Close to Your Business

Picking a manufacturer near your business can help a lot. Studies show that being close improves how things run. It lowers costs, boosts creativity, and speeds up production. If your manufacturer is nearby, you can fix problems fast. You can visit them easily and check your product. This is very important in electronics, where delays can hurt your chances.

Why Choose Local or North American Manufacturers

Working with local or North American manufacturers has many perks. They often communicate better, leading to faster design changes and smoother production. The table below shows some key benefits:

Benefit Type | Description |

|---|---|

Better Teamwork | Quick communication for faster changes and improved designs. |

Smarter Planning | Tools to predict needs and manage logistics better. |

Full Product Management | Data insights to handle inventory and production well. |

Flexible Production | Can adjust to market changes quickly. |

Risk Prevention | Finds problems early to keep things running smoothly. |

Supply Chain Control | Manages parts delivery to avoid delays. |

These reasons make local manufacturers a smart pick for reliable and efficient PCBA production.

Easier Communication and Shipping

Having a nearby manufacturer makes talking and shipping easier. Research shows good logistics improve teamwork and production. Local partners help industries work together better. This means faster replies, quicker shipping, and better teamwork. These changes keep your supply chain strong and help you meet deadlines.

Intellectual Property Protection

Risks of IP Theft in Electronics Manufacturing

Protecting your ideas is very important in electronics manufacturing. Designs and technologies can be sensitive and valuable. If stolen, your business could face big problems. Competitors might copy your product or sell your ideas. This can hurt your reputation and lower your sales.

Pick a manufacturer who knows how to keep your ideas safe. A trustworthy partner will have rules to stop theft. This keeps your designs secure during production.

Importance of NDAs and Secure Processes

Non-Disclosure Agreements (NDAs) are important when sharing your designs. An NDA is a legal promise to keep your ideas private. Without one, your designs could be shared or stolen. Always have the manufacturer sign an NDA before sharing details.

Safe processes also help protect your ideas. Choose manufacturers with strict rules, secure systems, and encrypted data. These steps stop people from accessing your designs without permission. By using secure methods, you can share your ideas without worry.

Evaluating a Manufacturer’s IP Protection Track Record

Check the manufacturer’s history of protecting ideas before working with them. A good record shows they care about keeping designs safe. Reliable manufacturers stop problems before they happen. They also take action if someone steals ideas, proving their commitment.

See if the manufacturer has strong systems to handle risks. These tools help them protect your ideas better. By picking a manufacturer with experience, you can focus on creating new things without fear.

Expertise and Skills of the Contract Manufacturer

Why Design for Manufacturability (DFM) Matters

Design for Manufacturability (DFM) helps make PCBAs easier to build. It makes sure your product is ready for smooth production. This reduces problems during assembly and testing. By focusing on DFM early, you can:

Make manufacturing simpler.

Have fewer mistakes and better success rates.

Launch products faster with shorter wait times.

Good DFM planning avoids redesigns by fixing issues early. This improves quality and meets all requirements. Working with a PCBA manufacturer that values DFM saves time and money. It also ensures a dependable product.

Engineering and Design Skills

A manufacturer’s technical skills affect how well your project goes. Skilled manufacturers improve production and make processes smoother. Important measures of their skills include:

Measure | What It Means |

|---|---|

Shows how well production works, including first-time success. | |

First Pass Yield (FPY) | Percent of items made right the first time without fixes. |

Overall Equipment Effectiveness (OEE) | Measures productivity by checking availability, speed, and quality. |

Throughput | Number of items made in a set time. |

Picking a manufacturer with strong skills ensures high-quality products and efficient work.

Supplier Connections and Part Quality

Good supplier connections help get the best parts. Manufacturers with strong supplier networks see:

30-40% faster delivery times.

Better first-pass success rates.

Clear communication with suppliers means fewer mistakes and lower repair costs. A trustworthy manufacturer will have a solid plan for getting quality parts. This builds trust and makes your product more respected in the market.

Production Flexibility and Scalability

Adjusting to Different Production Needs

Your PCBA manufacturer should handle changing production needs well. They must manage both small and large orders smoothly. To do this, they follow clear steps:

Step | What Happens |

|---|---|

1 | Plan how the process will flow |

2 | Create a Capacity Block Diagram |

3 | Build a Network for Reconstruction Activities |

4 | Define possible damage scenarios |

5 | Calculate how much capacity is lost initially |

6 | Find ways to recover capacity |

7 | Measure the economic loss |

These steps help them adjust quickly to your needs. This reduces delays and helps launch your product on time.

Growing with Your Business

A good manufacturer can grow as your business grows. They should increase production without lowering quality. Important things to check include:

Total units made over time.

How well resources are used.

The number of faulty products.

How efficiently equipment is used.

Units made per hour.

Consistent product quality.

Planning ahead and working well with suppliers is key. This ensures parts arrive on time and avoids delays.

Keeping High Quality

Quality is very important for reliable production. Choose manufacturers with certifications like ISO and IPC. These show they follow industry rules. They should also have strong systems to check and improve quality.

By picking a flexible, scalable, and quality-focused manufacturer, you prepare for success and future growth.

Product Quality and Certifications

Why ISO and IPC Certifications Matter

Certifications like ISO and IPC ensure high-quality PCBA production. They set rules manufacturers must follow for consistent results. For example:

ISO 9001 ensures products meet customer and legal requirements.

IPC-A-610 checks soldering and parts placement for good assembly.

Certified IPC trainers teach workers to follow the same standards.

Choosing a certified manufacturer gives you confidence in their quality.

Keeping Product Quality Consistent

Good quality needs strong testing and reliable systems. New manufacturers often face more quality problems. These issues improve as they gain experience and better processes.

Quality-by-Design (QbD) focuses on understanding product needs and processes. This method builds quality into every production step. Partnering with a manufacturer that values testing and documentation reduces defects and boosts reliability.

Checking the Manufacturer’s Tools and Technology

Modern tools and technology are key for smooth production and quality. Manufacturers use benchmarks to check how well their tools work. Important metrics include:

Metric | What It Means |

|---|---|

Measures how well equipment works compared to its full ability. | |

Downtime | Tracks time when machines are not working, lowering output. |

Yield | Shows the percentage of parts meeting quality standards. |

Throughput | Counts how many units are made in a set time. |

Customer Rejects | Tracks rejected products, showing where quality needs fixing. |

By reviewing these metrics, you can see if the manufacturer’s tools fit your needs. Good tools keep production smooth, avoid delays, and ensure quality.

Costing and Budget Alignment

Balancing Cost and Quality

Finding the right balance between cost and quality is key. It helps you get good value without lowering production standards. One way to do this is by grouping costs. Divide costs into groups like electrical, mechanical, and ready-made parts. This helps you see which parts cost the most. Using the Pareto principle, focus on the few parts that make up most of the cost.

Working with experts can also help improve your BOM. Experts find ways to save money while keeping quality high. Managing suppliers well ensures fair prices and good parts. Keep track of costs for materials, labor, and overhead. This helps you make smart choices and avoid wasting money.

Strategy | What It Does |

|---|---|

Grouping Costs | Sort costs into groups to find big expenses. |

Focus on Key Parts | Use the Pareto rule to check costly parts. |

Work with Experts | Experts help save money and keep quality. |

Manage Suppliers | Talk with suppliers for fair prices and good parts. |

Track Costs | Watch material, labor, and overhead costs to decide better. |

Understanding the Manufacturer’s Costing Structure

Knowing how manufacturers set their costs helps you plan better. They spend money on things like testing tools, software, and training workers. For example, testing tools cost $20,000 to $100,000. These tools check for problems and follow rules. Quality software costs $5,000 to $25,000. It tracks how well things are made. Training workers costs $3,000 to $10,000 per person. This makes workers better at their jobs.

Cost Type | Estimated Price | Why It Matters |

|---|---|---|

Testing Tools | Finds problems and follows rules. | |

$5,000 – $25,000 | Tracks how well things are made. | |

Worker Training | $3,000 – $10,000 per worker | Makes workers better at their jobs. |

Some manufacturers offer discounts for big orders or charge more for custom items. Check pricing plans often to match market changes, like rising material costs.

Avoiding Hidden Costs in Production

Hidden costs can waste money if not handled early. A clear BOM helps get quick and correct price quotes. This avoids mistakes when buying parts or assembling products. Knowing how materials, labor, and complexity affect prices helps you plan better.

Watch out for common hidden fees in PCBA pricing. Some manufacturers may add extra charges for fast shipping or extra tests. Talk with your manufacturer often to stay informed. This helps you spot hidden costs and avoid surprises. By staying alert, you can save money and keep your project on schedule.

Customer Support and Communication

Why Quick Communication Matters

Fast communication is key to working well with your PCBA manufacturer. Quick replies to your questions help avoid delays and keep things on schedule. Manufacturers who focus on fast responses often track how well they communicate.

Metric | What It Means |

|---|---|

How quickly they reply, like within 24 or 2 hours. | |

Dedicated Support | Having a specific person to talk to for help. |

Communication Technology | Using tools like EDI to handle urgent product changes fast. |

Picking a manufacturer with good communication helps solve problems quickly. This gives you better control over your project.

Checking Customer Support Services

Good customer support makes working with a PCBA manufacturer easier. It lets you focus on important tasks like designing and selling your product.

Quick support helps you focus on sales and design.

Good service reduces daily work problems.

Choose manufacturers with clear processes and strong reputations.

Look for a team that listens and acts fast. A dependable support system fixes issues quickly and avoids costly problems.

Why Transparency is Important

Being open about the manufacturing process builds trust. It also keeps you updated on your product’s progress. A clear system gives you quick updates about production and customer details. This helps you stay in control.

Traceability is also important for transparency. It lets you track where your product is, how it’s made, and its status. This openness helps find problems early and ensures everyone is accountable.

Choose manufacturers who value transparency. This creates a trustworthy and reliable partnership.

Industry Reputation and Track Record

Checking Customer Reviews and Feedback

Customer reviews help you learn about a manufacturer’s trustworthiness. Before picking a PCBA manufacturer, read online reviews to see their reputation. Reviews show what they do well and where they can improve.

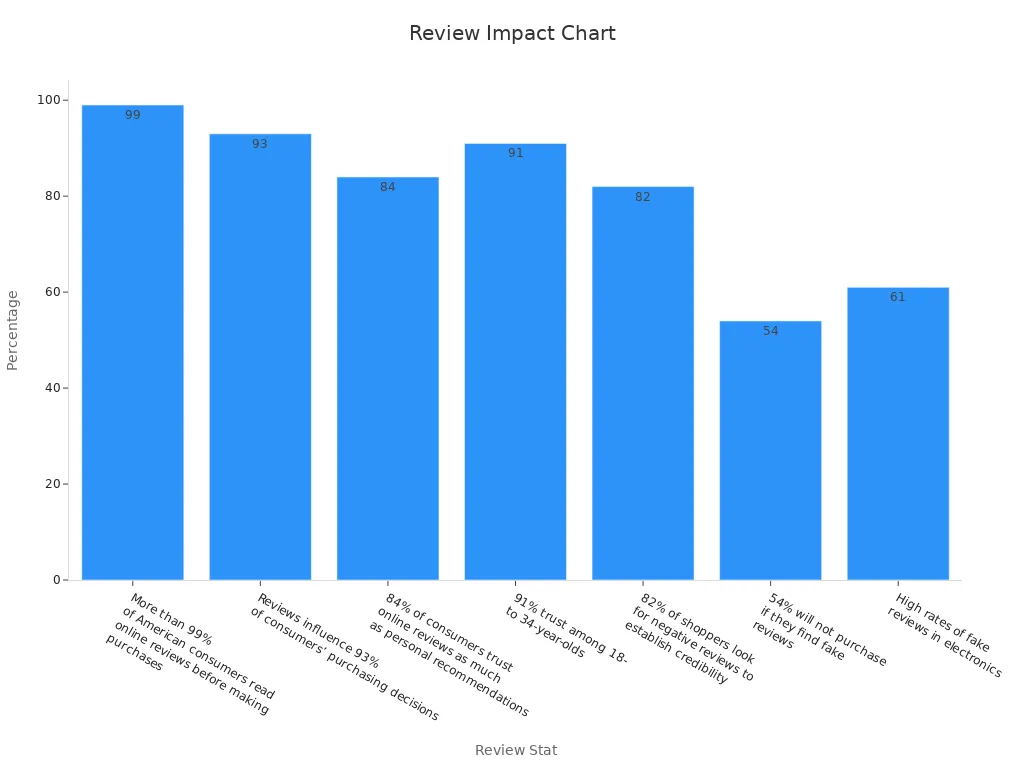

Studies say 99% of Americans read reviews before buying. About 93% say reviews affect their choices. Younger people, aged 18 to 34, trust reviews even more, with 91% relying on them. Also, 82% of shoppers read bad reviews to check honesty.

Statistic | Percentage |

|---|---|

People reading reviews before buying | 99% |

Reviews affecting decisions | 93% |

Trust in reviews by 18- to 34-year-olds | 91% |

Shoppers checking bad reviews | 82% |

Avoiding fake-reviewed products | 54% |

Look for patterns in reviews instead of single opinions. This helps you spot common feedback about quality, communication, and delivery.

Reviewing Case Studies and Success Stories

Case studies show how manufacturers solve problems and succeed. They prove the manufacturer can handle tough projects and meet goals. For example, AccuSpec Electronics worked with Athena SWC to improve sales. In three months, they got RFQs worth over $5 million. This helped them focus on deals and work better.

These examples show why choosing a proven manufacturer matters. Case studies help you see if they can meet your needs and deliver results.

Checking the Manufacturer’s Industry Experience

Experience in your industry is key to project success. Skilled manufacturers know your industry’s challenges and rules. They can solve problems and offer smart solutions. For example, a manufacturer with consumer electronics experience knows how to find good parts and meet deadlines.

Ask about similar projects they’ve done before. Pick manufacturers who have worked in your field. Their knowledge ensures smoother work and better outcomes.

Picking the best PCBA contract manufacturer means checking key factors. These include location, protecting ideas, skills, flexibility, quality, costs, support, and reputation. Each part is important for a strong partnership. For example, good design skills improve quality. A nearby location cuts shipping time and costs. A trustworthy partner handles problems well and keeps your ideas safe.

To get the most value, focus on working smarter. Watch for mistakes and match production to your goals. Research carefully to find a manufacturer that fits your needs. Contact trusted manufacturers for quotes and reviews. Start building a great partnership today!

FAQ

What matters most when picking a PCBA manufacturer?

Their experience in your industry is the key factor. A skilled manufacturer makes better products, works faster, and avoids mistakes. Check their certifications, past projects, and customer feedback to ensure they can meet your needs.

How do I keep my ideas safe?

Always sign an NDA before sharing your designs. Pick manufacturers with strong security systems and a good history of protecting ideas. Ask about their data safety tools and how they control access.

Why are ISO and IPC certifications needed?

These certifications show the manufacturer follows strict quality rules. ISO checks customer and legal needs, while IPC ensures good assembly work. Certified manufacturers lower risks and make reliable products.

How can I check a manufacturer’s communication skills?

See how fast they reply and if they have support teams. Ask about tools like EDI for quick updates on urgent changes. Good manufacturers share updates often and keep you informed during production.

What should I know about a manufacturer’s scalability?

Ask if they can handle both small and big orders. Check if they keep quality high as they grow. Review their plans for managing resources and scaling production to match your business growth.

See Also

Essential Aspects To Evaluate When Selecting A Custom PCBA Maker

Tips For Choosing The Ideal PCBA Manufacturer For Your Business

Important Factors To Keep In Mind When Selecting PCB Or PCBA

Strategies To Find The Perfect PCBA Manufacturer For Success

Locating The Most Suitable PCBA Manufacturer For Your Requirements