Making high-quality and efficient PCBA production is very important. It helps companies stay competitive in the fast-moving electronics world. Manufacturers face many problems, like part shortages and supply chain issues. They also need better technology to meet higher demands. The PCB market may grow from $70 billion in 2022 to over $86 billion by 2026. This shows why using smart strategies in your PCBA production facility is so important. By improving processes and reducing mistakes, you can work faster and make dependable products. Following best practices in PCBA production helps solve problems and get steady results.

Key Takeaways

Make designs easy to build. Simple designs lower errors and speed work.

Use machines to work faster. Machines reduce mistakes and help workers do harder jobs.

Check quality often during production. Testing makes sure products are good and avoids fixing mistakes later.

Use lean methods to cut waste. Better processes save time and materials, making work faster.

Train workers often. Skilled workers learn new tools quickly and keep quality high.

Design for Manufacturability (DFM) in PCBA Production

Key principles of DFM for quality and efficiency

To make designs easier to build, keep them simple. Clear designs help with smooth assembly and testing. This lowers mistakes during early production. Important steps include:

Working with manufacturers early to spot possible problems.

Using tools like tolerance checks to review designs.

Picking common materials to save time and money.

Making prototypes to test ideas and check manufacturability.

Principle | Description |

|---|---|

PROCESS | Picking the right process keeps production affordable. |

DESIGN | Simple designs are easier to build, use, and fix. |

MATERIALS | Choosing materials early saves both time and costs. |

ENVIRONMENT | Parts should work well in their intended surroundings. |

TESTING | Products must pass industry checks at every step. |

By following these steps, you can make better and faster PCBs.

Avoiding common design pitfalls in PCBA production

Many problems come from missed design details. To avoid these:

Find weak spots in the assembly process early.

Focus on key features to ensure proper assembly.

Don’t make designs too complicated to produce.

Avoid designs that rely on tiny differences for part placement.

Designers may not know much about manufacturing, causing missed issues. Good communication between designers and manufacturers stops costly mistakes.

Working together and reviewing plans often helps meet goals. These methods improve teamwork and finish projects on time.

How DFM impacts production efficiency and quality

Designing for manufacturability makes production faster and products more reliable. It cuts down on mistakes and fixes, saving money and time. Better PCB layouts and part placements improve how circuits work. DFM also shortens production time, helping factories meet deadlines without losing quality.

By thinking about manufacturing needs during design, you can make production smoother. This method boosts efficiency and ensures high-quality products every time.

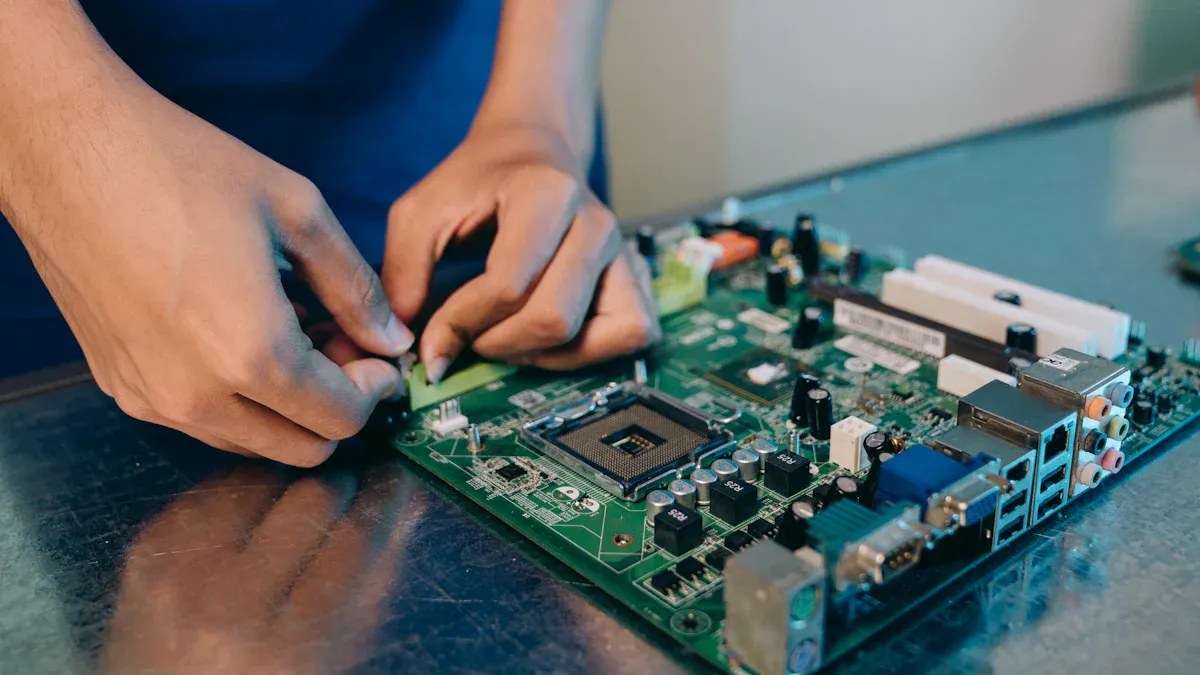

Leveraging Automation and Advanced Equipment

Benefits of automation in PCBA production

Automation helps make PCBA production faster and better. It reduces mistakes by handling repetitive tasks. This ensures consistent results every time. For example, using automation can:

Cut testing time by 30% at the end of production.

Speed up delivery times for finished products.

Lower costs by reducing errors during assembly.

Automation also lets workers focus on harder tasks. This boosts creativity and makes the team more productive. It improves assembly methods, helping meet deadlines without losing quality.

Advanced equipment for improving production efficiency

Using modern machines can greatly improve how fast and well things are made. New tools make work smoother, reduce delays, and increase output. The table below shows how certain machines help PCBA production:

Equipment Type | How It Helps |

|---|---|

SMT pick and place machine | Speeds up production and places parts accurately, avoiding mistakes. |

Automatic wave soldering machine | Makes soldering better and faster with smart temperature control and checks. |

Intelligent Inspection Equipment | Finds problems quickly, cutting down on rework and improving efficiency. |

Automated production line layout | Needs less manual work, keeping production steady and efficient. |

Flexible line configuration | Adjusts to different needs, making the process more efficient. |

Adding these machines to your factory can help you produce more while keeping quality high.

Evaluating ROI for automation investments

Before buying automation tools, check if they are worth the cost. This helps you see the long-term benefits. Think about these key points:

ROI Factor | Why It Matters |

|---|---|

Improved Quality Control | Automation keeps products consistent, reducing waste and meeting standards. |

Enhanced Customer Satisfaction | Faster production means on-time deliveries, making customers happy and loyal. |

Reduction in Lead Times | Automated systems cut delays, helping factories respond to changes quickly. |

By studying these factors, you can choose the best automation tools for your goals. Automation not only makes production better but also helps you stay ahead in the market.

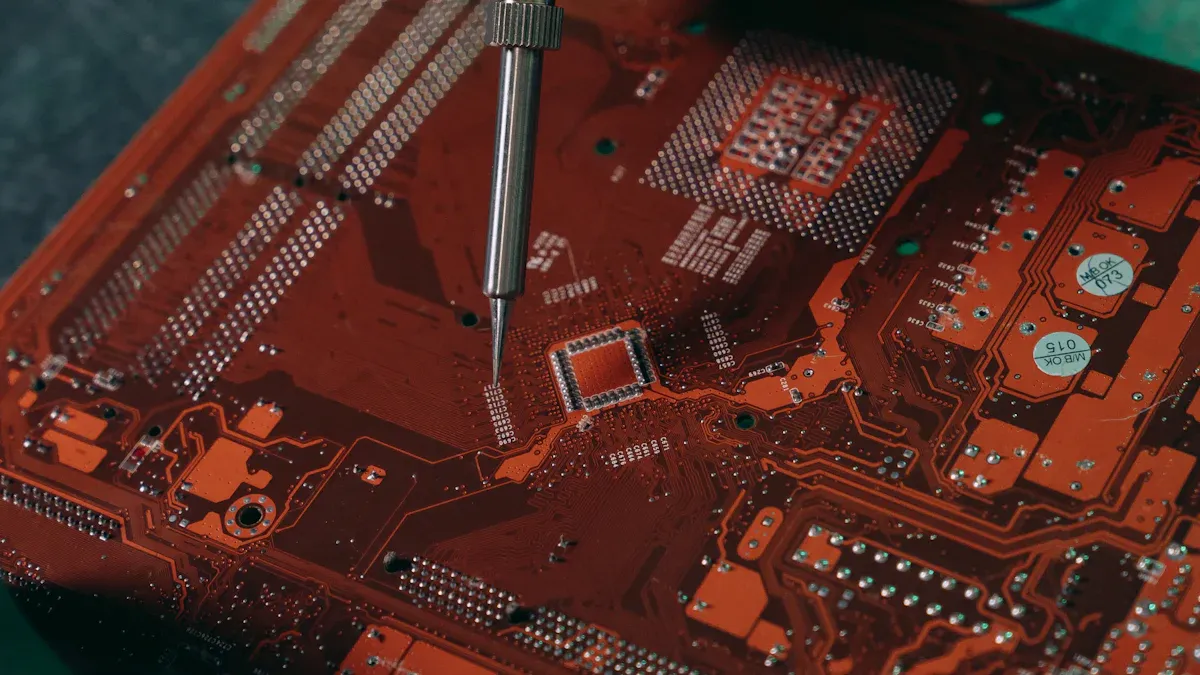

Ensuring Quality with Strong Testing and Monitoring

Important quality checks in PCBA production

To keep PCBA quality steady, use strong quality checks. These checks find problems early, saving money and making products more reliable. Use top-quality materials that meet industry rules. Accurate assembly is key, and machines help ensure precision. Careful testing, like automated optical inspection, spots physical flaws fast. Following rules like IPC-A-610 ensures electronic parts meet standards.

Benchmark | Description |

|---|---|

Component Quality | Use parts that meet rules for good performance and reliability. |

Manufacturing Processes | Make sure every step is precise with the help of machines. |

Use tests to find flaws and check if products meet rules. | |

Quality Control Measures | Set up systems to keep quality steady through checks and reviews. |

Follow rules like IPC-A-610 to ensure parts are acceptable and high-quality. | |

Proper Handling and Storage | Keep parts safe from damage during storage and handling. |

Collaboration and Communication | Work with others to meet goals and improve the process. |

By following these steps, you can make reliable products and work efficiently.

Ways to test for flaws and ensure quality

Testing is very important for keeping quality high. Automated optical inspection (AOI) finds visible flaws like bad soldering. Automated X-ray inspection (AXI) finds hidden problems inside parts. Functional testing checks if all parts work in real-life conditions. Environmental tests check if PCBAs can handle heat, cold, or shaking.

Testing Method | Advantages | Disadvantages |

|---|---|---|

Visual Inspection | Easy and non-damaging | May miss some issues, needs extra tools sometimes |

Functional Testing | Checks if everything works, ensures reliability | Takes time, needs special tools |

X-Ray Inspection | Finds hidden flaws quickly | Costs a lot, slower for large batches |

Using different tests together ensures only good boards are sent out. This builds trust in your brand.

Real-time monitoring to keep quality high

Watching production in real-time helps keep quality high. It shows repeated problems so you can fix them fast. For example, checking soldering temperatures ensures good soldering and fewer mistakes. One factory changed solder paste thickness after monitoring and cut defects by 20%.

Tip: Use live data to improve your process and save resources. This helps keep quality steady and reduces waste.

Real-time monitoring helps you make great PCBAs and keep customers happy.

Optimizing PCBA Production with Lean Manufacturing

Principles of lean manufacturing for efficiency

Lean manufacturing aims to cut waste and improve processes. In PCBA production, it ensures every step adds value. Use value stream mapping to find and fix inefficiencies. The 5S method—Sort, Set in Order, Shine, Standardize, and Sustain—keeps workspaces neat and reduces mistakes. Kaizen events encourage small, ongoing improvements to boost efficiency over time.

By following these ideas, you can lower costs and make reliable PCBAs. Standardizing tasks makes work smoother and reduces errors. This leads to better results for both factories and customers.

Reducing waste and improving production flow

Cutting waste is key in lean manufacturing. Waste in PCBA production includes extra materials, unneeded steps, or wasted energy. Improve steps and use low-temperature methods to reduce waste. Automated systems can lower energy use by 40% and material waste by 60%.

Using recyclable or biodegradable materials also helps cut waste and protect the environment. Real-time monitoring finds problems quickly and improves workflow. Fixing issues fast ensures smoother assembly and better efficiency.

Tip: Save resources and improve performance by reducing waste at every step.

Collaborating with suppliers for cost efficiency

Good supplier relationships help save money in PCBA production. Working with suppliers lets you plan inventory better and avoid shortages. This keeps production on schedule.

Suppliers can also provide quality parts at good prices. Talking openly helps find ways to save, like buying in bulk or using cheaper materials. Strong partnerships reduce waste and improve production efficiency overall.

Industry 4.0 Technologies for Smarter PCBA Production

Role of IoT and data analytics in PCBA production

Industry 4.0 tools like IoT and data analytics are changing PCBA production. IoT devices help track machines and progress in real time. This helps find problems early and keeps things running smoothly. For example, AI-powered robots improve accuracy during assembly and quality checks. These robots catch mistakes that people might miss, especially in repetitive tasks.

Data analytics is key to making production better. By studying big data, you can predict problems with high accuracy, precision, and recall—94%, 99%, and 89%, respectively. This helps fix issues early, like adjusting temperatures to avoid defects. Using AI with human skills speeds up work and ensures top-quality results every time.

Tip: Use IoT and data analytics to watch your production live. This improves reliability and cuts down on waste.

Benefits of smart factories for quality and efficiency

Smart factories use advanced tech to boost quality and efficiency in PCBA production. Automation and machine learning predict problems and improve assembly steps. This reduces delays and keeps the workflow smooth. IoT sensors monitor production in real time, showing areas that need improvement.

Smart factories also make processes consistent, leading to better product quality. Automated systems cut material waste and make machines work better. This lowers costs and shortens delivery times. Connected systems also give real-time updates to supply chain partners, helping with planning and faster deliveries.

Performance Metric | Description |

|---|---|

Increased Efficiency | Automation makes assembly lines more flexible and productive. |

Reduced Manufacturing Costs | Real-time data helps save materials and use machines better. |

Improved Lead Time | Fixing delays quickly allows faster responses to changes. |

Standardized Process Quality | Every step is consistent, ensuring repeatable product quality. |

Overcoming challenges in adopting Industry 4.0 technologies

Using Industry 4.0 tech in PCBA production has some challenges. Updating old machines can be hard, but plug-and-produce systems make it easier. These systems let you add new tech without replacing everything.

Another issue is supply chain visibility. Better communication with vendors makes operations smoother. Predictive maintenance also helps reduce human errors in SMT processes. It prevents breakdowns, cutting downtime and improving efficiency.

Challenge | Solution |

|---|---|

Human error in surface mount technology (SMT) processes | Use predictive maintenance to stop problems before they happen. |

Need for supply chain visibility | Improve communication with vendors for smoother operations. |

Difficulties in retrofitting older equipment | Use plug-and-produce systems to easily add new technology. |

By solving these problems, you can fully use Industry 4.0 tech. This creates smarter and more efficient production systems.

Continuous Training and Equipment Maintenance

Why training workers boosts production efficiency

Training workers is key to keeping PCBA production efficient. Workers who know the latest methods do their jobs better. New hires learn faster with clear training programs. Workshops and classes help workers stay updated on new tech. Teaching workers multiple skills lets them switch roles easily. This reduces delays during assembly and keeps things running smoothly.

Training Method | Benefit |

|---|---|

Builds skills in new tools and better work methods. | |

Employee Engagement | Involves workers in solving problems for better results. |

Good training helps your team work smarter and make production more reliable.

Tips for keeping equipment in top shape

Taking care of machines prevents sudden breakdowns and keeps them working well. Regular checks and fixes make machines last longer and work better. For example, checking SMT machines often avoids costly delays. Fixing problems early also keeps production steady and product quality high.

Benefit | Description |

|---|---|

Regular care makes machines more dependable and reduces downtime. | |

Enhanced Productivity and Efficiency | Well-maintained machines work better, boosting speed and output. |

Cost Savings | Early fixes cost less than emergency repairs, saving money. |

Quality Assurance | Reliable machines ensure products meet quality standards. |

These steps save money and keep production running smoothly.

Encouraging constant improvement in PCBA production

Encouraging constant improvement helps PCBA production get better over time. Asking workers for ideas through events or suggestion boxes improves workflows. Lean manufacturing helps find and remove waste, making processes better.

Using digital tools stores knowledge in one place, so everyone can access it. This helps teams work together and follow the same methods. For instance, sharing tips on soldering can make work consistent across teams.

Supporting constant improvement makes workers feel valued and motivated. This not only improves production but also builds a strong and creative team.

Improving PCBA production needs smart plans for quality and speed. Strong quality checks help make products reliable every time. Using Industry 4.0 tools adds automation and makes work smoother. Training workers often helps them learn new tools and keep high standards. For instance, Crown Audio improved quality and got a 171% ROI in seven months. By following these steps, you can make dependable PCBAs, cut waste, and stay ahead in the market.

FAQ

What is the key step in PCBA production?

Making designs easy to build is very important. It helps the assembly process go smoothly, lowers mistakes, and saves time. Working with manufacturers early and keeping designs simple avoids big problems and makes great PCBAs.

How does automation help in PCBA production?

Automation makes repetitive tasks faster and more accurate. It reduces human mistakes and keeps results consistent. This lets workers focus on harder tasks while keeping production fast and high-quality.

Why is live monitoring important in PCBA production?

Live monitoring finds and fixes problems right away. It keeps quality steady, cuts waste, and improves how work flows. For example, checking soldering heat can stop defects and keep standards high.

How does lean manufacturing improve PCBA production?

Lean manufacturing cuts waste and makes work smoother. It ensures every step is useful, saves money, and boosts efficiency. Methods like value stream mapping and 5S keep the assembly process organized.

Why is worker training important in PCBA production?

Training teaches workers how to use new tools and methods. It improves speed, lowers mistakes, and keeps quality steady. A skilled team handles challenges well and keeps production running smoothly.

See Also

Enhancing Workflow Productivity in PCBA Production Processes

Ten Proven Strategies for Cost-Effective PCBA Assembly

Streamlining PCBA Testing Through Automation for Precision

Investigating PCBA Testing Methods for Superior Electronics Production

Choosing the Ideal PCBA Manufacturer for Your Business Requirements