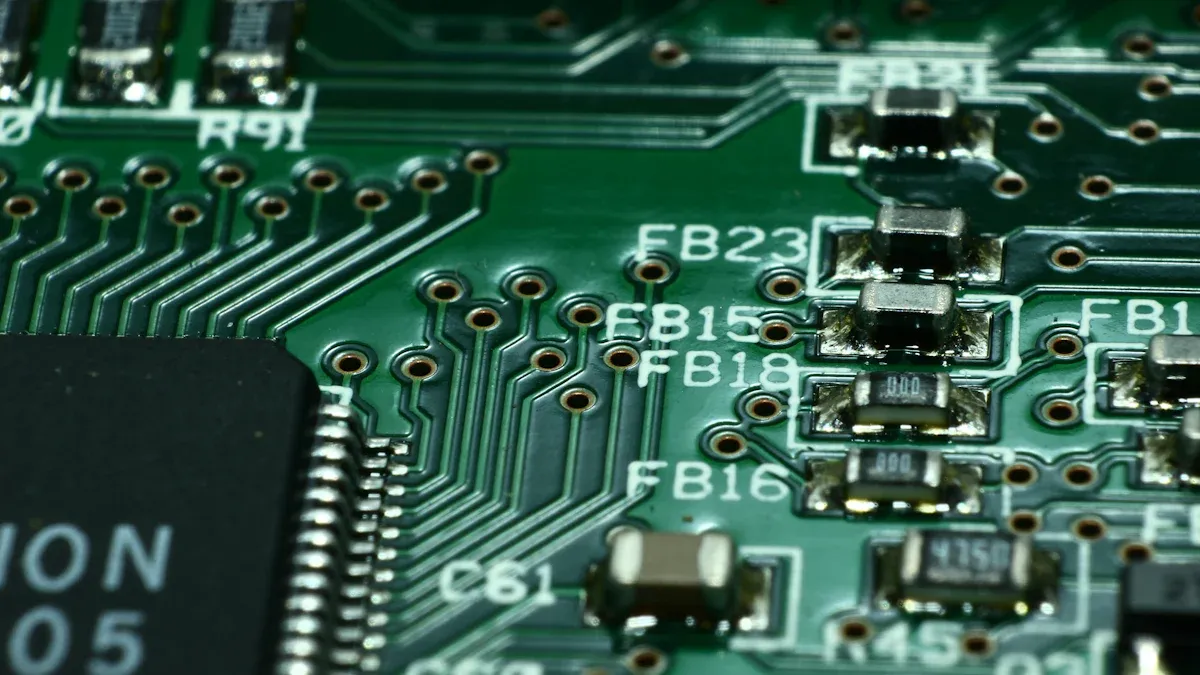

Surface Mount Technology (SMT) has revolutionized how PCBA is performed. It enables the creation of smaller, lighter, and more efficient designs. For example, products can be one-third the size and one-tenth the weight of traditional PCBA boards. This method is essential for developing compact gadgets, smart car systems, and medical devices. Automation in PCBA SMT enhances accuracy and reduces costs, making it crucial for modern manufacturing.

Key Takeaways

Surface Mount Technology (SMT) makes circuit boards smaller and lighter. This is important for modern gadgets like phones and medical tools.

Automation in SMT speeds up production and makes it more accurate. It also cuts costs by 30% to 50% compared to older ways.

SMT reduces mistakes during assembly, making products more reliable. These products work well even in tough conditions.

SMT is flexible, allowing creative designs for many industries. It is used in things like electronics and space equipment.

SMT is becoming more eco-friendly by using green materials. It also helps reduce waste during manufacturing.

Surface Mount Technology Advantages in PCBA

Enhanced Efficiency and Automation

Surface Mount Technology (SMT) makes printed circuit boards work faster. It uses machines to place and attach parts, saving time and money. Unlike older methods, SMT reduces mistakes and keeps quality steady. For example, success rates improved from 70% to 97% with automation. Machines can place about 2,340 parts per hour, sometimes reaching 2,480 parts.

Tip: Using automation in SMT improves product quality and reduces errors.

This technology also works well for high-frequency tasks by cutting down interference. Automation helps make products faster and cheaper, which is great for making many items at once.

Cost-Effectiveness for High-Volume Production

A big benefit of SMT is saving money, especially for large orders. Smaller parts mean more can fit on a board, using fewer materials. Automated soldering also saves money by speeding up the process. Studies show SMT can cut costs by 30% to 50% compared to older methods.

Key Benefits of SMT in Cost-Effectiveness:

Lower costs per item with bigger production runs.

Better designs save time and reduce waste.

Automation lowers labor costs and improves success rates.

Using SMT helps make affordable, reliable products, which is why industries like electronics and cars prefer it.

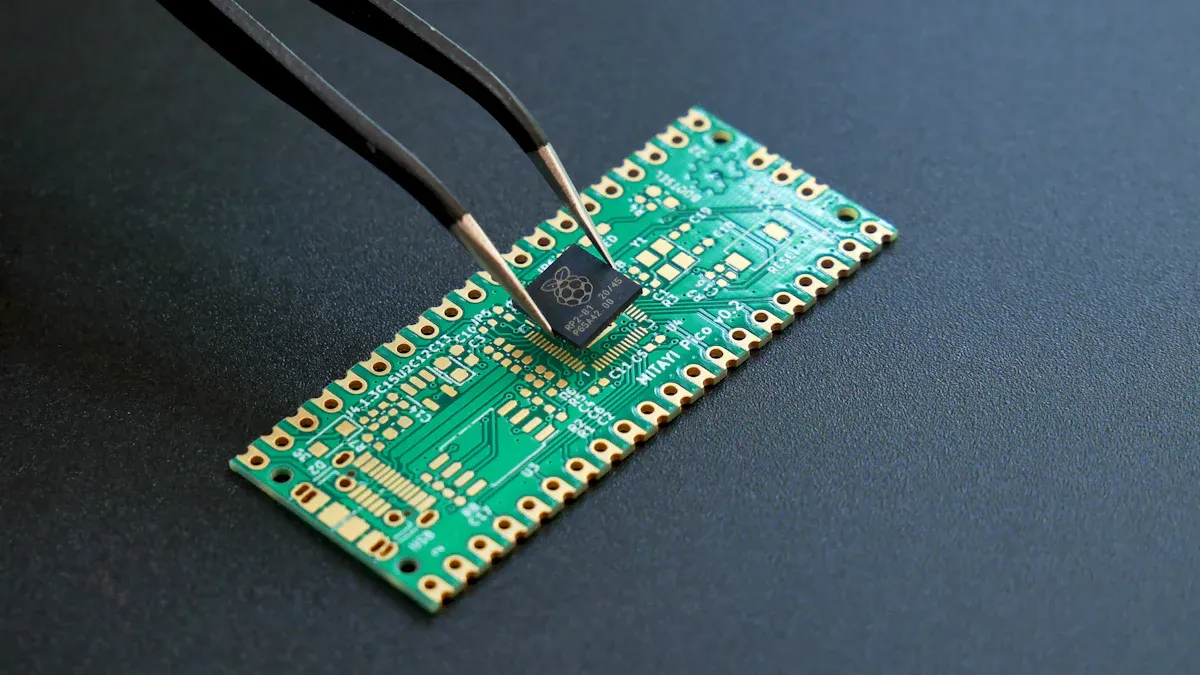

Miniaturization and Compact Designs

SMT is great for making small, modern devices. Smaller parts allow more to fit on a board, saving space. This also helps devices use less energy and stay cooler. Smaller, lighter designs mean more products can be made at once.

For example, SMT helps create portable devices like smartphones and smartwatches. These small designs still work well and last long, even in tough conditions.

Note: Making smaller devices with SMT also helps the environment by using fewer materials and less energy.

With SMT, you can create new, smaller products that people want today.

Improved Reliability and Performance

Surface Mount Technology (SMT) makes circuit boards more reliable and better performing. It improves how parts are placed and reduces mistakes. This leads to higher-quality production with fewer errors. Important measures like First Pass Yield (FPY) and Defects Per Million Opportunities (DPMO) show how well the process works.

Metric | What It Means |

|---|---|

First Pass Yield (FPY) | Shows the percentage of boards passing without needing fixes. |

Defects Per Million Opportunities (DPMO) | Counts defects per million parts, with fewer defects meaning better quality. |

Throughput | Measures how many boards are made in a certain time. |

Overall Equipment Effectiveness (OEE) | Checks performance by looking at availability, speed, and quality. |

Before mass production, parts go through tests to handle assembly stress. This helps engineers find and fix problems early. Functional testing checks if all parts are connected and meet standards. Fixing issues early stops failures and makes products more reliable.

Testing also ensures boards work well in real-life situations. This is very important for industries like cars and medical devices, where reliability matters most. With SMT, you can make boards that perform well and stay reliable under tough conditions.

Design Flexibility and Versatility

SMT allows creative designs for many uses. It works with different parts like resistors, capacitors, and chips. This makes it perfect for things like phones, smartwatches, car systems, and communication devices.

Main Benefits of SMT Design Flexibility:

Helps create small, portable devices.

Adds advanced parts for high-performance gadgets.

Fits into many industries, from electronics to space tech.

Studies show SMT improves heat control and reliability. For instance, built-in parts in SMT boards stay cooler at 34 °C, compared to 52 °C in regular boards. Silicone materials in SMT also handle heat better than epoxy ones.

With SMT, you can design new products that work well and last long. Its flexibility helps meet the needs of different industries while keeping quality high.

Applications of PCBA SMT Across Industries

Consumer Electronics and Wearable Devices

You use electronics like phones and watches every day. These gadgets use Surface Mount Technology (SMT) to stay small and efficient. SMT helps place tiny parts on boards, making devices thinner and lighter. This has boosted wearable tech, growing from 929 million to 1.1 billion worldwide between 2019 and 2022.

People want smaller gadgets with more features, so SMT is popular. Experts say consumer electronics will take up 56.78% of the SMT market. Tablets, smart home devices, and fitness trackers use SMT to fit advanced features into small spaces.

Did You Know?

Robots help make 90% of mobile phones, showing SMT’s speed in big production.

Automotive Electronics and Safety Systems

Modern cars need advanced electronics for safety and comfort. SMT helps make these systems better. It creates small, powerful parts like sensors and control units. These are key for electric cars and self-driving technology.

As cars become smarter, SMT is more important. It ensures parts meet high standards for quality and performance. For example, SMT makes compact control units that manage engines and prevent crashes.

Sector | Application Description |

|---|---|

Automotive | Electric and self-driving cars need advanced sensors and control units. SMT supports these with precise manufacturing. |

Medical Devices and Equipment

Medical tools must be small and reliable. SMT helps make these tools better. Devices like pacemakers and insulin pumps use SMT for their tiny, dependable parts.

The need for advanced medical tools makes SMT vital in healthcare. It ensures safety and high performance for life-saving devices. For example, SMT adds sensors and chips to health monitors, giving accurate real-time data.

Sector | Application Description |

|---|---|

Medical | Miniature and reliable medical devices rely on SMT for safety and performance. |

Tip: SMT’s ability to make small, reliable parts drives medical innovation.

Aerospace and Defense Applications

The aerospace and defense fields need precise and reliable systems. Surface Mount Technology (SMT) helps meet these tough demands. It builds small, lightweight electronics that handle extreme conditions. For instance, SMT makes avionics systems work well in high heat and at great heights.

In defense, SMT supports advanced tools like radars and communication devices. These tools need fast data processing and low interference. SMT places parts accurately, lowering the chance of failure during important tasks.

Tip: For aerospace and defense, focus on strong and efficient designs. SMT helps by creating durable systems with less weight.

SMT also improves unmanned aerial vehicles (UAVs) and satellites. Smaller parts mean more features can fit into tight spaces. With SMT, you can design smart solutions for the strict needs of aerospace and defense.

Industrial Automation and Robotics

Robotics and automation depend on advanced electronics. SMT is key to making small, efficient systems for these technologies. It helps create control units, sensors, and actuators that boost speed and accuracy in automated tasks.

The SMT market is growing fast because industries need smaller parts. Automated SMT machines place parts precisely, ensuring quality in large-scale production. This makes manufacturing faster and cheaper.

Metric | Impact on Industrial Equipment |

|---|---|

Miniaturization | Makes smaller, better designs for robots and machines. |

Enhanced Efficiency | Speeds up production while staying accurate. |

Cost-Effectiveness | Cuts costs with automated processes. |

Robots benefit a lot from SMT. It allows for tiny circuit boards that fit in small spaces. This helps robots do complex jobs easily. SMT also adds sensors and communication tools, which are vital for automation.

Did You Know?

The SMT market is expected to grow 5.8% yearly from 2023 to 2030, reaching USD 5,271.9 million. This shows the rising need for small parts in industrial machines.

With SMT, you can build smart systems for automation and robotics. Its accuracy and speed make it perfect for today’s industrial needs.

Future Potential of Surface Mount Technology

Advancements in SMT Equipment and Processes

The future of SMT looks bright with new tools and methods. Modern machines now use smart features like AI, machine vision, and data tools. These upgrades make production faster and more accurate. For example, AI systems can spot mistakes instantly, cutting errors and waste. This accuracy is vital for industries like electronics and car-making, which need high-quality products.

The demand for SMT tools is growing quickly. Experts predict a yearly growth rate of 5.67% from 2025 to 2030. This rise shows the need for smaller and better devices in areas like telecom and electric cars. With advanced tools, manufacturers can make products faster and improve quality.

Integration with IoT and Smart Manufacturing

SMT is changing with the Internet of Things (IoT) in smart factories. IoT-powered systems help predict problems and monitor machines remotely. This can lower unexpected downtime by 22%. For instance, Henkel’s Loctite brand improved machine use by 30% with IoT tools. These changes boost efficiency and give helpful data for better production.

IoT also helps make smarter gadgets. Combining SMT with IoT creates electronics that are flexible and responsive. This is especially useful for robots and automated machines, where precision matters most.

Sustainability and Eco-Friendly Innovations

Making SMT greener is now a big focus. Scientists are testing eco-friendly materials to lower the impact of electronics on the planet. One study showed a PCB made of 70% green materials, including 28% wood. This proves biodegradable boards can work well.

Sustainable PCBs also focus on recycling and using better materials. Stretchable electronics offer a greener option than stiff designs. These ideas help the planet and meet customer demand for eco-friendly products. By using these methods, manufacturers can protect the environment while keeping quality high.

PCBA SMT brings many benefits to modern manufacturing. Its automated systems make work faster, cheaper, and more creative. For instance, pick-and-place machines speed up production and save materials. The table below shows how SMT improves efficiency, saves money, and offers flexibility:

Benefit | Description |

|---|---|

Cost-Effectiveness | Automated SMT processes lower costs by reducing manual labor. |

Efficiency | Machines work quickly, boosting production speed and output. |

Lower Material Costs | Smaller parts cost less, cutting down material expenses. |

Design Versatility | SMT supports creative PCB designs for different uses. |

Rapid Prototyping | Faster prototyping helps launch products sooner. |

Adaptability | Design changes are easy and quick to make. |

Unlike older through-hole methods, SMT uses smaller parts and automated assembly. It also fits more components on a PCB. These features make it vital for industries like electronics, cars, and healthcare.

Tip: Use PCBA SMT to build fast, affordable, and flexible products for today’s needs.

FAQ

What is PCBA SMT, and why is it important?

PCBA SMT means making circuit boards with Surface Mount Technology. It helps create small, efficient, and reliable electronics. This method is key for industries like electronics, cars, and healthcare. It’s fast and saves money, making it very useful.

How does SMT differ from through-hole technology?

SMT puts parts on the board’s surface. Through-hole puts parts in drilled holes. SMT is faster, smaller, and works better. Through-hole is stronger for tough conditions but slower and less efficient.

Can SMT handle high-volume production?

Yes, SMT is great for making many products quickly. Machines can place thousands of parts every hour. This lowers labor costs and mistakes. It’s perfect for industries like electronics and car-making.

Is SMT suitable for small devices like wearables?

Yes! SMT is made for tiny designs. It fits more parts into small spaces. This makes it ideal for smartwatches and fitness trackers. These gadgets need light and compact designs, which SMT provides.

How does SMT contribute to sustainability?

SMT uses less material and energy, cutting down waste. New ideas like recyclable boards make it eco-friendly. Using SMT helps create green products that are still high quality.

Tip: Pick SMT for smart, planet-friendly manufacturing. 🌱

See Also

Exploring The Role Of PCBA In Today’s Electronics

The Unmatched Impact Of PCBA On Modern Electronics

Understanding PCBA Services And Their Importance In Manufacturing