Printed circuit board assembly (PCBA), or “pcba que es,” is the foundation of electronics. It enables gadgets like phones, computers, and appliances to function seamlessly. By integrating components onto a circuit board, PCBA enhances device performance and longevity.

Emerging technologies, such as compact designs and the Internet of Things (IoT), have transformed PCBA. Miniature boards now power smaller and more intelligent devices. Innovations like 5G and new materials are inspiring advancements in wearables, lighting, and beyond. PCBA is crucial in advancing consumer electronics.

Key Takeaways

PCBA is key to making electronics work. It links parts on a board, helping them run smoothly.

Good PCBA makes devices more reliable and work better. It lowers errors, speeds up production, saves money, and makes users happy.

Flexible and multi-layer PCBs are important for new gadgets. They help create small designs and cool features in phones, wearables, and home devices.

Being eco-friendly in electronics matters. PCBA cuts waste and uses less energy, helping the planet.

The need for PCBA is rising. As tech improves, more devices will need PCBA for better use and performance.

PCBA Que Es and Its Role in Consumer Electronics

What is PCBA and Why It Matters

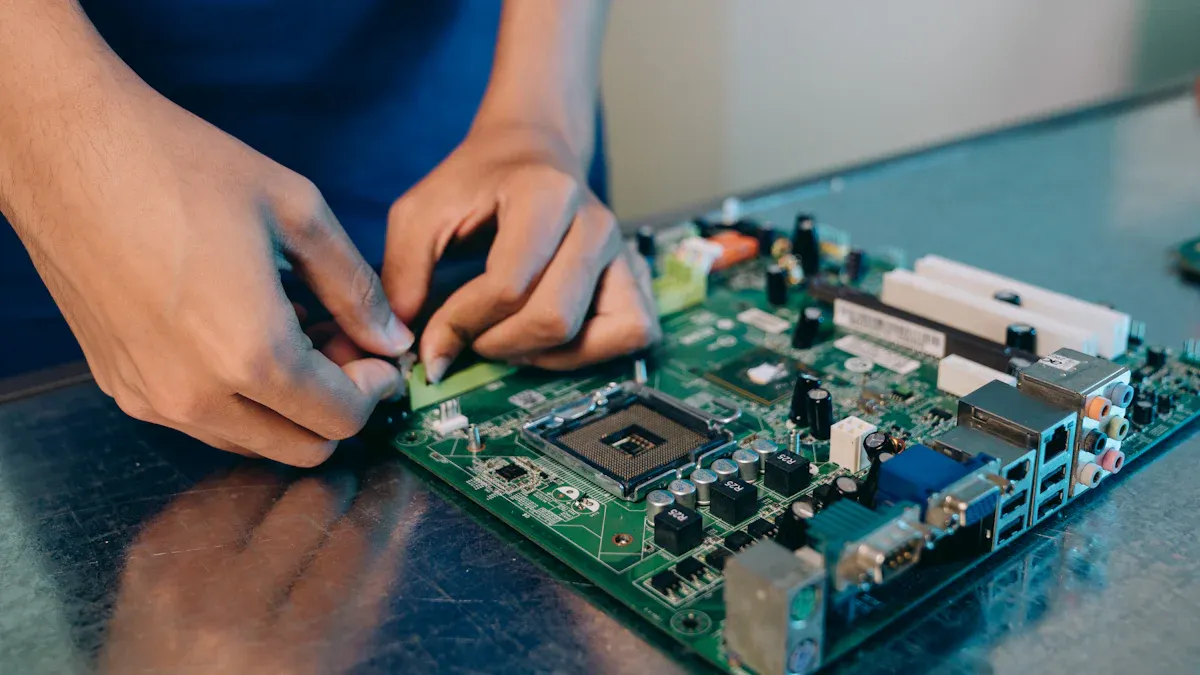

PCBA, or Printed Circuit Board Assembly, connects parts to a circuit board. This process turns an empty board into a working device. Steps include getting parts, using SMT and THT methods, soldering, and testing. Rules like IPC standards make sure every step meets high-quality levels. These rules are key to keeping electronics reliable and working well.

Why is PCBA so important? It works like the brain of your devices. Without it, things like phones, computers, and appliances wouldn’t work. PCBA helps parts talk to each other so devices run smoothly.

How PCBA Makes Devices Better

PCBA helps devices work better by finding and fixing problems. During assembly, tests check for issues and make sure parts meet design needs. These tests measure things like voltage and current to match device specs. They also mimic real-life use to see if the system works right.

Improvement Type | What It Does |

|---|---|

Finding Problems | Tests spot PCBA issues with clear and repeatable methods. |

Checking Parameters | Tests measure things like voltage to match design needs. |

System Testing | Tests ensure the whole system works as planned in real-world-like conditions. |

By improving reliability, PCBA makes sure your devices work well and last longer.

Why PCBA is Good for Electronics

PCBA does more than just make devices work. Good assembly means better performance, which makes users happy. For example, automated processes and smart testing cut production time by 40% and keep defects under 1%. This saves money and makes products more reliable.

Good PCBA also lowers the chance of device failures. In areas like telecom, reliability is very important. A single failure can cost money or even cause safety problems. By following strict rules, PCBA keeps devices dependable.

Strong assembly also helps the supply chain. Better inventory and supplier management cut part wait times by 50%. This faster process helps companies and customers get quality products quicker.

Common Uses for PCBs in Consumer Electronics

Printed circuit boards (PCBs) power the devices you use every day. From phones to appliances, PCBs help them work well and last longer. Let’s see how PCBs are important in popular electronics.

Smartphones and Tablets

Phones and tablets depend on PCBs for their cool features. These gadgets need small, layered boards to fit their size and functions. PCBs link parts like processors, memory, and sensors so they work together.

Newer phones use flexible PCBs to make thinner, stronger designs. Foldable phones need these boards to bend and still work. PCBs also add features like wireless charging and 5G, making devices better for users.

Did you know? About 70% of all PCBs are used in electronics, computers, and telecom, showing their big role in daily life.

Laptops and Computers

Laptops and computers are another big use for PCBs. These devices need many-layered boards to handle tough tasks and run smoothly. PCBs connect key parts like the CPU, GPU, and RAM so they work together.

Smaller, faster laptops push PCB technology forward. Methods like System-in-Package (SiP) and Chip-on-Board (COB) combine parts into tiny units. This makes laptops better and smaller. In 2021, over 335 million computers were sold, proving how important PCBs are.

Evidence Type | Description |

|---|---|

Market Demand | New features and tech keep demand high. |

Production Cost | Mass production lowers costs, boosting profits. |

Complexity | Multi-layer PCBs handle advanced electronic needs. |

Home Appliances

PCBs are key in modern appliances like fridges and washers. They control things like temperature, motors, and energy use. For example, a smart fridge uses a PCB to manage cooling and connect to Wi-Fi.

Smart appliances now use advanced PCBs for new features. Robotic vacuums and smart thermostats rely on PCBs for sensors and IoT. These upgrades make appliances easier and smarter to use.

Application Area | Market Size/Usage Statistics |

|---|---|

Consumer Electronics | |

PCB Usage in Industries | 70% of global PCBs are used in electronics, computers, and telecom |

PCBs improve how appliances work and save energy too. By using power wisely, they cut electricity use, helping both you and the planet.

Wearable Technology

Wearable gadgets like smartwatches and fitness trackers use PCBs for advanced features. These devices need small and bendable PCBs to fit their lightweight designs. PCBs connect parts like sensors, processors, and batteries. This allows features like heart rate checks, step counting, and GPS tracking.

Wearables face special problems. Water and constant movement can harm PCBs. Cracks or layer damage can cause devices to stop working. For example, lab-on-a-chip (LoC) devices often have trouble with unstable readings and poor skin attachment. These issues show why strong PCB designs are needed for wearables.

Tip: Pick wearables known for lasting quality. Good PCBs keep devices working even in tough conditions.

Flexible PCBs make wearables smarter. They allow curved designs for bendable screens and skin-like sensors. As wearables improve, PCBs will help create even cooler features.

Entertainment Systems

Entertainment devices like gaming consoles and smart TVs depend on PCBs for smooth performance. Multi-layer PCBs handle tasks like fast data processing and detailed graphics. Gaming consoles use PCBs to link the CPU, GPU, and memory for better gameplay and quick loading.

Smart TVs also use advanced PCBs. These boards enable 4K video, HDR, and internet access. They connect parts that process video, manage power, and link to Wi-Fi for a better viewing experience.

Feature | How PCBs Help Entertainment Devices |

|---|---|

Fast Processing | Makes gaming and video playback smooth. |

Connectivity | Supports Wi-Fi, Bluetooth, and HDMI links. |

Power Management | Saves energy for longer device life. |

Modern systems now use IoT features, letting you control devices with apps or voice commands. PCBs make this possible by adding sensors and communication tools. This makes entertainment more fun and easy to use.

Did you know? Gaming consoles could reach $51 billion in sales by 2027, thanks to better PCBs.

PCBs improve device performance and save energy. By using power wisely, they lower electricity costs and help the environment.

Types of PCBs Used in End User Applications

Printed circuit boards (PCBs) come in different types for various uses. Knowing these types helps you pick the right PCB for your device. This ensures it works well and lasts longer.

Single-Sided PCBs

Single-sided PCBs are the simplest kind. They have one layer of conductive material. This makes them cheap and easy to make. These PCBs are great for simple designs with parts on one side only.

You can find single-sided PCBs in many gadgets like phones, tablets, and appliances. Their basic design is perfect for devices with simple circuits. For example:

Wearables use them because they are light and small.

The growing tech market increases the need for these PCBs.

Tip: For low-cost and simple designs, single-sided PCBs are a smart pick.

Double-Sided PCBs

Double-sided PCBs are more advanced. They have conductive material on both sides. This allows parts to be placed on both sides, making the circuit more complex and efficient. These PCBs are used in devices needing advanced features.

Double-sided PCBs have several benefits:

More Connections: They support more parts, improving device functions.

Smaller Size: Using both sides saves space for compact designs.

Better Performance: They allow flexible designs for complex circuits.

But they also have downsides. They cost more and need special manufacturing. The table below compares double-sided PCBs with other types:

PCB Type | Advantages | Disadvantages |

|---|---|---|

Double-Sided | – More Connections: Adds complexity and power. | – Higher Cost: Expensive to produce. |

– Compact Design: Saves space. | – Harder to Make: Needs advanced techniques. | |

– Flexible Design: Handles complex circuits. | – Planning Needed: Avoids performance issues. | |

Single-Sided | – Low Cost: Cheapest to make. | – Limited Use: Simple circuits only. |

– Easy to Produce: Simple process. | – Larger Size: Needs more space for parts. | |

– Basic Design: Good for simple needs. | – Less Flexible: Not for advanced devices. |

Double-sided PCBs are a good choice when you need both cost and performance balance.

Multi-Layer PCBs

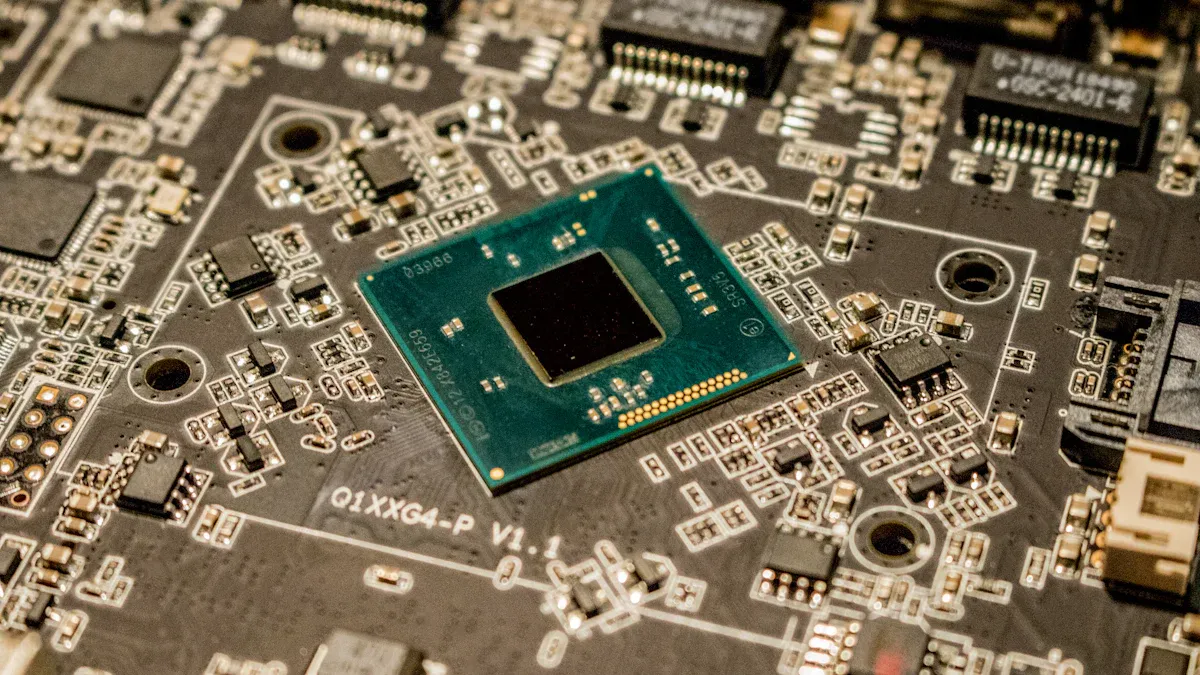

Multi-layer PCBs are the most advanced type. They have many layers of conductive material separated by insulation. This design supports high-density circuits, perfect for powerful devices.

These PCBs are ideal for small spaces but need high performance. For example:

They are used in phones, laptops, and gaming consoles for tough tasks.

Their strong build makes them last in harsh conditions.

Multi-layer PCBs have key advantages:

Strong Signals: They prevent signal loss for reliable performance.

Efficient Design: They improve trace routing for better results.

High Reliability: They pass strict tests to meet industry standards.

The table below shows why multi-layer PCBs are great for electronics:

Evidence Type | Description |

|---|---|

Strong Signals | Keeps signals clear in high-frequency designs. |

Efficient Design | Improves routing for better performance. |

Testing Procedures | Includes tough tests to find and fix issues. |

Meets strict rules for industries like aerospace. |

If your device needs to be small but powerful, multi-layer PCBs are the best choice. They handle complex circuits and are vital for modern gadgets.

Flexible PCBs

Flexible PCBs are changing how modern electronics are made. These boards use bendable materials, so they can twist and fold without breaking. This makes them perfect for small devices or gadgets that move a lot.

You can find flexible PCBs in wearables, medical tools, and foldable phones. They fit into unique shapes, helping create cool designs. For example, a fitness tracker uses a flexible PCB to wrap around your wrist. It stays connected and collects accurate data, even during tough workouts.

Here’s why flexible PCBs are special:

Benefit | Explanation |

|---|---|

Flexible PCBs match body curves, keeping connections stable for accurate data. | |

Saves Space | They bend and fold, making devices smaller and more efficient. |

Tough in Hard Conditions | Built to handle movement and weather changes, they last longer without breaking. |

Easy to Carry | Lightweight design makes devices portable and easy to use. |

Reliable Performance | They spread out stress evenly, resisting heat and moisture for smooth operation. |

Supports Many Features | Multi-layer designs allow more parts in small spaces, adding more functions. |

Tip: Want durable and portable gadgets? Look for ones with flexible PCBs. They’re made to last in tough situations.

Flexible PCBs also help the environment. Their light design uses fewer materials, and their durability reduces waste. As technology improves, flexible PCBs will keep making devices smarter and better.

Rigid-Flex PCBs

Rigid-flex PCBs combine the strength of rigid boards with the flexibility of bendable ones. These boards have stiff parts linked by flexible layers, making them great for devices needing both stability and flexibility.

You’ll see rigid-flex PCBs in phones, laptops, and medical tools. For example, a phone might use one to connect its camera to the main board. This saves space and keeps the device working well, even in tight designs.

Here’s how rigid-flex PCBs are used in different fields:

Sector | Application Areas | Key Drivers |

|---|---|---|

Phones, tablets, laptops, wearables | Need for small, multi-use devices, space-saving, and high reliability | |

Automotive | Control systems, infotainment, driver assistance | Growth of electric cars, need for strong PCBs in tough conditions |

Aerospace & Defense | Navigation, communication, drones | High reliability, precision, and new defense technologies |

Medical Devices | Diagnostic tools, monitors, implants | Focus on compact, flexible, and reliable healthcare devices |

Rigid-flex PCBs have many benefits. They don’t need extra connectors, which makes assembly easier and more reliable. Their small size saves space, perfect for tiny gadgets. Plus, they handle tough conditions like heat and vibrations, ensuring they last a long time.

Did you know? Rigid-flex PCBs are vital in aerospace, where accuracy and reliability are critical.

As people want smaller, stronger devices, rigid-flex PCBs will become even more important. They help designers create advanced gadgets, leading to the next wave of amazing electronics.

Emerging Applications and Trends in Consumer Electronics

Miniaturization for Compact Devices

Making devices smaller has changed consumer electronics. Now, gadgets are tiny but powerful. This is seen in phones, wearables, and medical tools. Small designs need advanced PCBs to fit tight spaces and still work well. For example, the uHVA high voltage amplifiers, launched in 2023, show how small electronics can still be strong. These amplifiers are used in areas like threat detection and mass spectrometry.

Smaller devices are also boosting market growth. In 2023, the mini electronics market was worth $42.75 billion. It is growing at 10.5% yearly and may reach $66.57 billion by 2028. This shows how shrinking devices are changing designs and what people expect.

Year | Market Size (in billion USD) | CAGR (%) |

|---|---|---|

2023 | 42.75 | 10.5 |

2024 | 47.25 | 10.5 |

2028 | 66.57 | 9.0 |

Integration with IoT and Smart Devices

PCBs and IoT make smart devices better. They help connect smart homes, wearables, and industrial tools. For example, PCBs in smart locks and thermostats let you control them with apps. Fitness trackers use small, bendable PCBs to stay light and give accurate data.

One example is Exelonix, which worked with TE to improve fleet tracking devices. They fixed weak signals and battery problems by improving antenna placement. This shows how PCBs are key for IoT, making devices work better.

Application Type | Description |

|---|---|

Smart Home Systems | PCBs connect devices like smart locks and thermostats. |

Industrial Internet of Things | Flexible PCBs help in tough industrial settings. |

Wearable Technology | Small PCBs power fitness trackers and smartwatches. |

Biomedical Devices | Stretchable PCBs allow lightweight health monitoring. |

Use of Advanced Materials for Durability

New materials make PCBs stronger and better. Phones and laptops need PCBs that handle heat, moisture, and heavy use. Materials like flexible substrates and high-frequency laminates improve cooling and signal quality. These are perfect for modern gadgets.

Flexible PCBs and hybrid materials also allow cool designs like foldable devices. Polyimide, a common material, is strong and flexible. These advances meet the demand for better electronics, especially wearables and tablets.

Evidence Description | Key Benefits |

|---|---|

Advanced materials like high-frequency laminates and flexible substrates are being incorporated into PCBs. | Improve strength, cooling, and signal quality. |

These materials are essential for applications in automotive electronics, aerospace, and 5G telecommunications. | Boost performance in many industries. |

Tip: Choose gadgets with advanced PCBs. They last longer and work better, even in tough conditions.

Role of PCBA in Sustainable Electronics

Sustainability is now a big focus in electronics. You might ask how PCBA helps with this. Printed Circuit Board Assembly (PCBA) reduces waste and saves resources during device production and use.

PCBA helps make energy-saving products. Using better materials and smart designs, it cuts energy use in devices like medical tools and industrial machines. For example, new PCBA designs lower heat loss, making devices more energy-efficient. This saves money on electricity and lowers the environmental impact of electronics.

PCBA also helps save water. The electronics industry uses over 500 billion liters of water each year. But new PCBA methods aim to use less water. From 2025 to 2035, water use in the industry is expected to grow slower, at just 8% per year, thanks to these improvements.

Reliable PCBA makes devices last longer. This means fewer replacements are needed, which reduces waste. This is especially important for medical tools and industrial machines, where durability matters most. By making devices last longer, PCBA helps cut electronic waste and save resources.

The table below shows key sustainability facts about the electronics industry:

Metric | Value/Trend |

|---|---|

Energy usage growth rate | 12% from 2025-2035 |

Water usage growth rate | 8% from 2025-2035 |

Annual water usage | Over 500 billion liters |

PCBs made in APAC region | 90% |

PCBA is not just about making devices work. It also helps build a greener future by saving energy, conserving water, and improving device reliability.

PCBA is the heart of today’s electronics, helping devices work accurately. It is used in phones, computers, appliances, and more.

The global PCB market may grow past $95 billion by 2030. This growth is due to the rising need for advanced electronics.

By 2025, over 6.5 billion people will own smartphones. This increases the demand for PCBs that save energy.

IoT expansion pushes makers to design smarter connected devices.

As tech improves, PCBA will keep making devices smarter and more efficient for daily life.

FAQ

1. What is the difference between PCB and PCBA?

A PCB is just a plain circuit board. It has no parts on it. A PCBA is a complete board with all parts attached. It is ready to work in a device.

2. Why are flexible PCBs important in modern electronics?

Flexible PCBs let devices have cool shapes and small sizes. They can bend and twist without breaking. This makes them great for wearables, foldable phones, and medical tools. They are also strong and work well in tough conditions.

3. How does PCBA improve device reliability?

PCBA makes sure parts are firmly attached and tested. This lowers the chance of problems and helps devices last longer. Good assembly also reduces mistakes, so your gadgets work as they should.

4. Can PCBs be recycled?

Yes, PCBs can be recycled. Special methods recover useful materials like copper and gold. Recycling helps cut down on electronic waste. Always throw away old electronics properly to protect the planet.

5. What industries benefit most from PCBA?

PCBA is used in many fields like electronics, cars, space, and healthcare. It powers things like phones, vehicles, satellites, and medical machines. Its wide use makes it very important in today’s technology.

Tip: Buy gadgets from trusted brands. Good PCBA means better quality and longer-lasting devices.

See Also

Exploring PCBA Uses and Advantages in Today’s Electronics

Defining PCBA and Its Importance in Electronic Systems

Grasping PCBA Concepts and Their Essential Uses in Electronics