Automotive PCBA assembly services help make cars smarter and connected. Recent trends show why they are important:

Electric car sales grew to 10.5 million in 2023. This increased the need for PCBAs in key systems.

Today’s cars have up to 150 control units. This shows how complex car electronics have become.

Southeast Asia invested $2.1 billion in PCBA factories. This was due to more people using electric cars.

These changes make cars work well in tough conditions. They also support new ideas like self-driving and better safety features.

Key Takeaways

More people are buying electric cars, so better PCBA services are needed.

Smaller and tightly packed circuits add more features to cars and improve how they work.

Using AI and machines in making PCBs makes them better, cheaper, and faster to produce.

Flexible and bendable PCBs are important for new car designs. They fit tricky spaces and handle tough conditions.

Making PCBs in eco-friendly ways helps the environment by cutting pollution and waste.

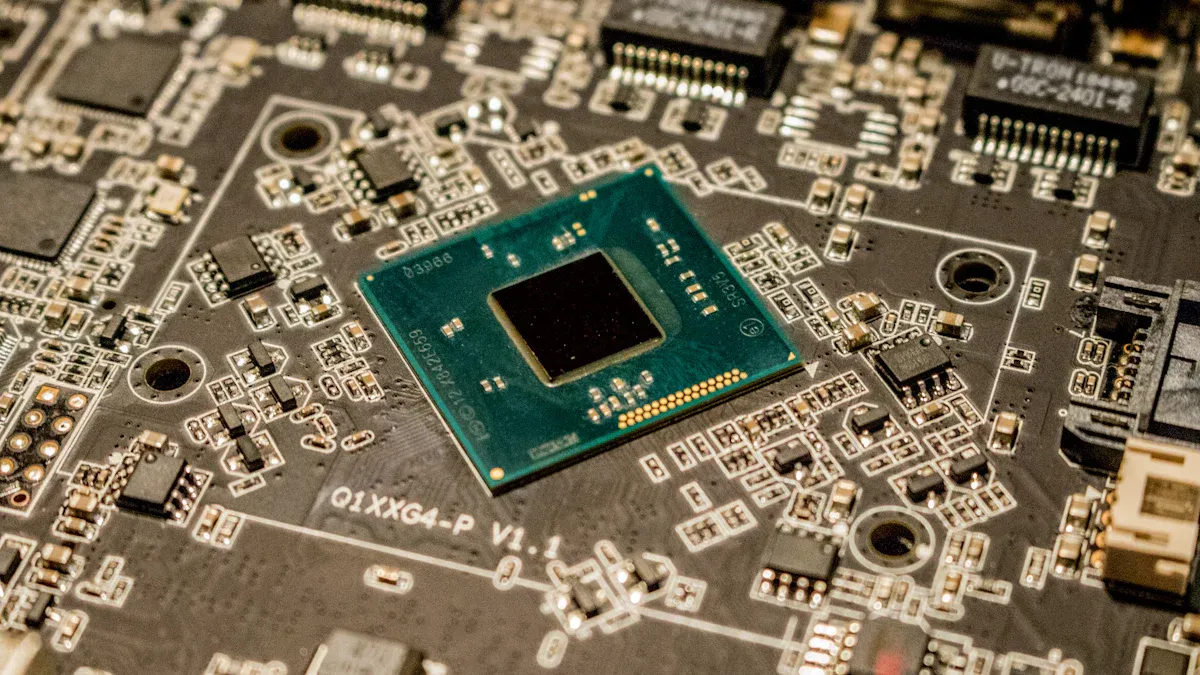

Miniaturization and High-Density Interconnects (HDI)

Small designs for today’s car systems

Modern cars need small and efficient designs for electronics. Making parts smaller helps meet this need. Smaller parts allow faster switching in DC-DC converters. This reduces the size of parts like inductors and capacitors. These parts store energy and now work at up to 1.74MHz. This saves space and keeps voltage steady during changes.

Smaller designs let cars have more features in less space.

Advanced HDI tech for better car electronics

High-density interconnects (HDI) changed how car circuit boards are made. HDI PCBs bring many benefits to car electronics.

Benefit/Feature | Description |

|---|---|

High Density and Complex Interconnections | Multi-layer HDI circuits fit more connections, great for high-tech uses. |

Enhanced Reliability | HDI PCBs work better and keep signals strong, reducing loss. |

Compactness and Functionality | They allow more connections in small spaces without growing in size. |

Critical for Advanced Applications |

These features make HDI tech vital for modern car systems. They handle complex tasks and improve reliability in key areas like safety and entertainment.

Miniaturization’s role in smart and electric cars

Making parts smaller is key for smart and electric cars. Flexible PCBs in lidar sensors improve detection in self-driving cars. Mini ECUs with flexible PCBs boost performance and fit better.

The System-on-Chip (SoC) market is growing fast, at 8.55% yearly from 2022 to 2029. SoCs process data quickly and combine sensors, which is crucial for self-driving cars. As cars get smarter, smaller parts keep systems efficient, compact, and ready for tough tasks.

AI and Automation in PCB Assembly

How smart factories are changing car PCB assembly

Smart factories are changing how car PCBs are made. They use machines and automation to make work faster and easier. By letting machines do repetitive tasks, mistakes are fewer, and quality stays the same. This is very helpful when making thousands of parts that must all match.

These factories also handle tricky designs well. Advanced systems can switch between PCB designs without needing people to adjust them. This saves time and money. For example, automation has cut costs and improved how well parts are made. Smart factories are now a big part of making car PCBs.

AI helps check quality for better results

AI tools make checking PCBs more accurate and reliable. They watch for size and shape problems in real-time to meet strict rules. If something is wrong, AI fixes it automatically.

AI’s success in quality checks shows in its numbers. For example:

Metric | Value |

|---|---|

Continual classification | |

Speed for 200 images | 12-14 ms |

Accuracy for 453 images | 100% accuracy |

Accuracy for 259 images | 99.62% accuracy |

Speed for object detection | 20 ms |

These numbers show how AI tools make fewer mistakes. They keep quality high and improve car PCB assembly.

Saving money and time with automation

Automation helps save both money and time in making PCBs. Companies like LACROIX Electronics use smart systems to fix problems quickly. These systems collect data from machines to stop delays and improve quality. This means less downtime and lower costs.

Automation also makes work faster and uses resources better. AI helps save materials and energy, making production cheaper and greener. With speed, accuracy, and savings, automation is now essential for car PCB assembly.

Flexible and Rigid-Flex PCBs in Automotive Applications

Useful for complex car systems

Flexible and rigid-flex PCBs are very important in cars. They mix flexible circuits with stiff parts, making them very useful. This design helps them fit into tricky layouts needed for modern car electronics.

Rigid-flex PCBs are strong and save space, great for small devices.

They can bend into 3D shapes to fit odd spaces like dashboards.

They resist vibrations, so they work well under mechanical stress.

Even though they cost more to make, their benefits are worth it. These features make them a must-have for today’s car systems.

Strong in tough conditions

Flexible and rigid-flex PCBs are tested to handle tough conditions. These tests check if they can survive stress, temperature changes, and bending.

Bend Test: Checks if they stay strong after bending many times.

Thermal Cycling Test: Makes sure they work between -40°C and +125°C.

Thermal Shock Test: Tests if they handle sudden temperature changes well.

Peel Strength Test: Measures how well copper sticks to the base material.

These tests prove that these PCBs can last in harsh car environments, staying reliable for a long time.

Used in ADAS and infotainment systems

Flexible and rigid-flex PCBs are key in driver-assistance and infotainment systems. They use flexible sensors and screens to improve safety and make driving fun.

Application Area | Description |

|---|---|

Advanced Driver-Assistance Systems | Rigid-flex PCBs help add flexible sensors for better safety features. |

In-Vehicle Infotainment Systems | Flexible screens create stylish designs and better functions for drivers. |

These uses show how flexible and rigid-flex PCBs help make cars smarter and more connected.

Sustainability in Automotive PCBA Assembly Services

Using eco-friendly materials and methods

Car makers now focus on eco-friendly ways to build PCBs. They use safer materials to protect the environment. For example, natural fibers now replace harmful materials in car interiors. This change helps reduce pollution and supports green manufacturing goals.

Eco-friendly PCB bases also make recycling easier. These materials lower risks from toxic chemicals and save resources. Reusing old parts, called remanufacturing, cuts waste and stops harmful disposal. Studies show remanufacturing can lower global warming effects by 67%. This makes it a smart choice for greener car electronics.

Saving energy with better manufacturing

Energy-saving methods are now key in making car PCBs. Machines use less energy than people, cutting power use by 40%. They also reduce wasted materials by 60%, improving efficiency.

Big companies like Apple have seen similar results. They cut energy use by 35% with automated systems. These methods save money, use less energy, and lower pollution. By using these techniques, factories can stay green and still make great products.

Following global green rules

Car PCB makers follow strict global rules to stay eco-friendly. Important standards include ISO 26262 for safety and AEC-Q100 for tough conditions. Another is IPC-A-610 Class 3, which ensures high-quality PCBs.

Standard | What It Does |

|---|---|

ISO 26262 | Keeps car electronics safe in all conditions. |

AEC-Q100 | Makes sure parts work in harsh environments. |

IPC-A-610 Class 3 | Ensures PCBs meet top quality standards. |

By following these rules, companies show they care about the planet. They also prove their products meet strict global green standards.

Advanced Materials and 3D Printing in PCB Trends

Lightweight and heat-resistant materials for automotive PCBs

New materials are improving car PCBs. Lightweight and heat-resistant materials make them stronger and last longer. For example, polyphthalamide (PPA) cuts weight by about one pound. It also resists water and glycol at 135°C for 5,000 hours. Polyphenylene sulfide (PPS) handles heat up to 392°F long-term and 500°F short-term. This makes it great for coolant system parts.

Material Type | Weight Savings | Heat Resistance | Uses |

|---|---|---|---|

Polyphthalamide (PPA) | Saves ~1 lb | Resists water and glycol at 135°C | Drivetrain and underhood parts |

Polyamide 66 (PA66) | N/A | N/A | Electrical systems and electronics |

Polyphenylene sulfide (PPS) | N/A | 392°F long-term, 500°F short-term | Coolant system electronics |

These materials help car PCBs work well, even in hot conditions.

3D printing for fast prototypes and production

3D printing has changed how PCBs are made. It helps create designs quickly and cheaply. Engineers can test and improve PCBs without waiting for old methods. This saves time and speeds up new ideas.

With 3D printing, custom parts can be made for specific car needs. This is useful for advanced driver-assistance systems (ADAS) and electric cars. 3D printing makes detailed designs with accuracy, making it a key tool for modern PCB production.

New ideas for cheaper manufacturing

New methods in PCB making lower costs but keep quality high. These include picking the right parts, designing for easy assembly, and buying in bulk.

Strategy | What It Does |

|---|---|

Component Selection | Using cheaper parts and standard ones saves money. |

Better designs cut assembly time and waste, making work faster. | |

Strategic Sourcing | Buying in bulk and working with suppliers lowers costs. |

For example:

A small company saved 30% by using better parts and designs.

A big factory cut costs by 15% with bulk buying and smarter designs.

A research group saved 20% by using advanced methods while keeping quality.

These ideas help make car PCBs affordable and ready for the future.

IoT and AI Integration in Smart PCBs

Smarter car systems with IoT and AI

IoT and AI have changed how cars work today. These technologies help car systems connect and share information easily. Multi-layer PCBs are important for advanced systems like ADAS and battery management. The need for these PCBs is growing with more electric and self-driving cars.

Modern cars use sensors and AI to handle lots of data. For example, AI processes 2-3 terabytes of data weekly from sensors like LiDAR. This data helps cars detect people and navigate better in real-time. IoT and AI make sure smart PCBs work well, even in tough car environments.

The car PCB market is growing at 5.8% yearly because of flexible PCBs made for AI-based systems.

Fast data processing for better cars

Fast data processing is key for smarter cars. Advanced PCBs quickly analyze data from many sources for fast actions. For example, Tesla Model 3 uses special PCBs for better cooling and reliability. Waymo’s self-driving cars focus on strong EMI/EMC control to keep data safe.

Example | What It Does |

|---|---|

Tesla Model 3 | Better cooling and reliability improve car performance. |

Waymo’s Self-Driving Cars | Strong EMI/EMC control keeps data safe and accurate. |

NVIDIA DRIVE AGX Platform | Combines GPUs with smart cooling and power-saving designs. |

These examples show how advanced PCBs help cars process data fast, making them safer and smarter.

V2X tech and its role in car electronics

V2X (Vehicle-to-Everything) tech lets cars talk to roads, other cars, and people. This improves safety and traffic flow. AI makes V2X better by predicting crashes and fixing traffic problems. For example, AI can change traffic lights or reroute cars to avoid jams.

V2X and AI together make smarter choices and safer roads using predictions.

Adding V2X tech to smart PCBs makes connected cars better. It helps create safer and more efficient transportation systems.

The car industry is changing fast with new PCBA trends. Smaller parts, AI, and eco-friendly methods are improving cars. AI tools are growing quickly and making cars safer and smarter. Experts say AI in cars will grow 27.23% yearly. By 2025, it could be worth USD 7.84 billion. These changes help save fuel and protect drivers. Using new ideas helps car makers stay ahead in this fast-moving market.

FAQ

What does PCBA do in today’s cars?

PCBA (Printed Circuit Board Assembly) is key for car electronics. It links and powers parts like sensors and processors. This helps cars have features like self-driving, entertainment, and safety systems.

How does making parts smaller help car electronics?

Smaller parts fit more into tight spaces in cars. This makes them lighter and more efficient, which is great for electric cars. Tiny designs also make systems faster and work better together.

Why is being eco-friendly important in PCBA making?

Eco-friendly methods cut pollution by using safer materials and less energy. They follow global green rules and reduce waste. This makes making car electronics cheaper and better for the planet.

How does AI make PCB assembly better?

AI finds problems in PCBs quickly and accurately. It checks for mistakes automatically, so fewer errors happen. AI also speeds up work and saves resources while keeping quality high.

Why are flexible PCBs useful in cars?

Flexible PCBs bend to fit tricky spaces in cars. They handle vibrations and tough conditions, so they last longer. These PCBs are perfect for safety systems and entertainment, making cars smarter and stronger.

See Also

Emerging Innovations in PCB and PCBA Design Processes

The Role of PCBA in Advancing Today’s Electronics Industry

Significance of PCBA Production Skills in Electronics Development

Benefits and Obstacles of Flex PCBA in Today’s Electronics

Comprehending EMS and PCBA Solutions for Contemporary Electronics