IIoT sensor node PCBA manufacturing plays a crucial role in modern factories, acting as the “eyes and ears” that gather vital data from machines and their surroundings. These tiny tools are essential for maintaining fast and smooth production processes. The IIoT sensor nodes check conditions instantly, enabling early problem detection and informed decision-making. Beyond mere observation, they enhance workflows by providing valuable insights into operations. In today’s fast-paced manufacturing environment, these sensors are key to achieving accuracy and consistent results.

Key Takeaways

IIoT sensor nodes work like the ‘eyes and ears’ of factories. They gather live data to improve how things are made.

These sensors check machines’ health to stop big problems early. This avoids expensive repairs and saves time.

IIoT sensors help automate tasks and make processes better. This creates smoother work and lets workers focus on harder jobs.

The data from these sensors helps factories improve constantly. It finds delays and helps use resources wisely.

Using IIoT sensor nodes cuts costs and helps make better choices. This keeps factories strong in competition.

Understanding IIoT Sensor Nodes

What Are IIoT Sensor Nodes?

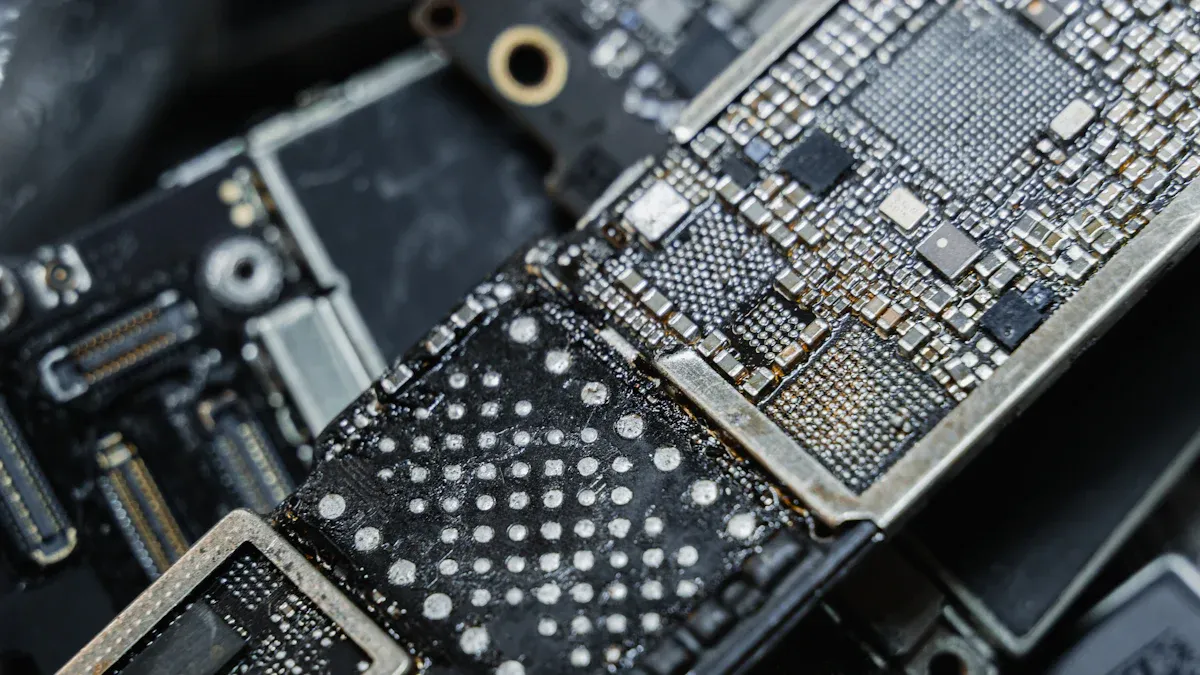

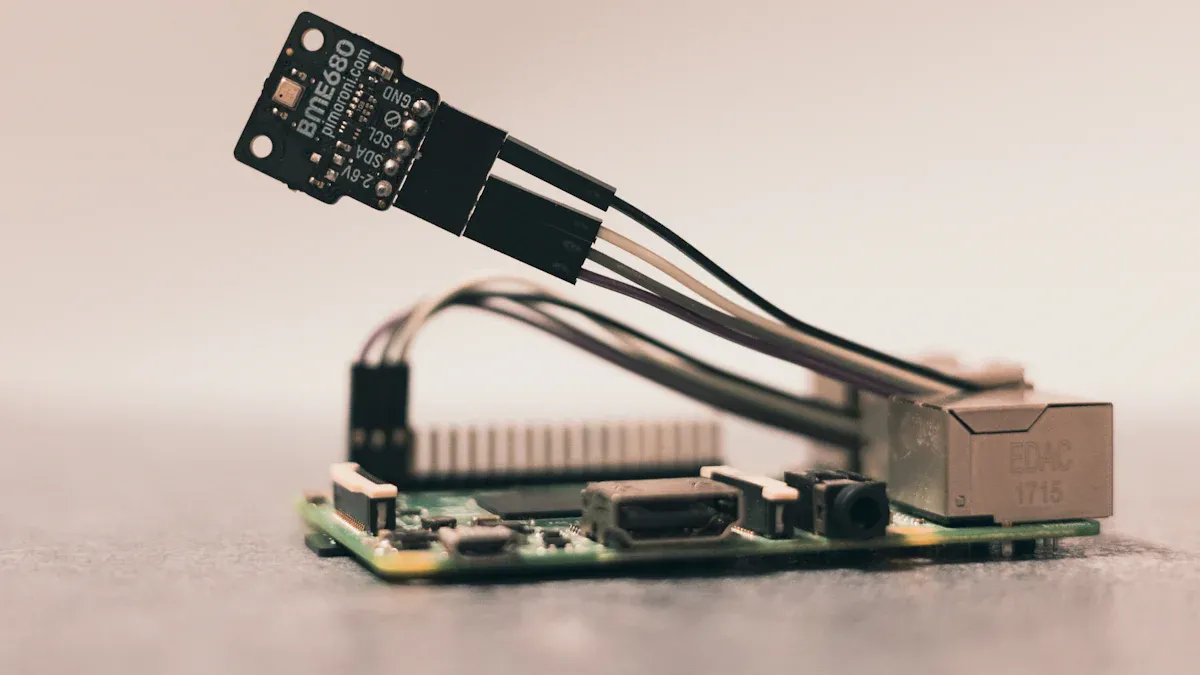

IIoT sensor nodes are small devices that collect important data. They gather information from machines, environments, or processes and send it to a central system. This system analyzes the data to help improve operations. With these sensors, you can watch processes in real time, spot problems, and make smart decisions. These nodes connect physical machines to digital systems, turning simple sensors into advanced tools for better manufacturing.

The development of IIoT sensor nodes has improved with better connectivity and data handling. Studies show more factories are using these nodes, but they also highlight the need for better planning. Picking the right sensors for your needs is very important.

Characteristics of IIoT Sensor Nodes

IIoT sensor nodes have special features that make them useful in factories. Here are some key traits:

Versatility: They work with many sensor types, like motion or pressure sensors, to track different things at once.

Connectivity: Strong communication systems ensure smooth data sharing. Tools like Qorvo’s ConcurrentConnect allow multiple IoT systems to work together.

Data Collection Methods: These sensors collect data in forms like binary or text and send it for processing.

Durability: Built tough, they handle extreme heat, cold, and vibrations.

Security: Advanced protections keep data safe from failures or outside interference.

These features make IIoT sensors essential for modern factories. Knowing their abilities helps you see how they improve production.

Types of IIoT Sensor Nodes in Manufacturing

Different IIoT sensor nodes have specific jobs in manufacturing. Here’s a list of common types:

Sensor Type | Description |

|---|---|

Motion Sensors | Track how objects or people move. |

Acceleration Sensors | Measure changes in speed. |

Gyroscopic Sensors | Check how objects rotate. |

Environmental Sensors | Monitor temperature, humidity, and air pressure. |

Location Tracking Sensors | Find where equipment or items are located. |

Pressure Sensors | Measure force to ensure machines work safely. |

These sensors give a full picture of your factory. For example, motion sensors monitor assembly lines, while environmental sensors check conditions for delicate machines. Adding these nodes to your PCBA process boosts accuracy and efficiency.

Real-world examples show how IIoT sensors help factories. For instance:

Collecting real-time data on machines helps find slowdowns.

Predictive maintenance prevents problems before they happen, saving time and improving safety.

Using these sensors can upgrade your factory and keep you ahead in the competitive world of industrial IoT.

The Role of IIoT Sensor Nodes in PCBA Manufacturing

Real-Time Monitoring and Quality Control

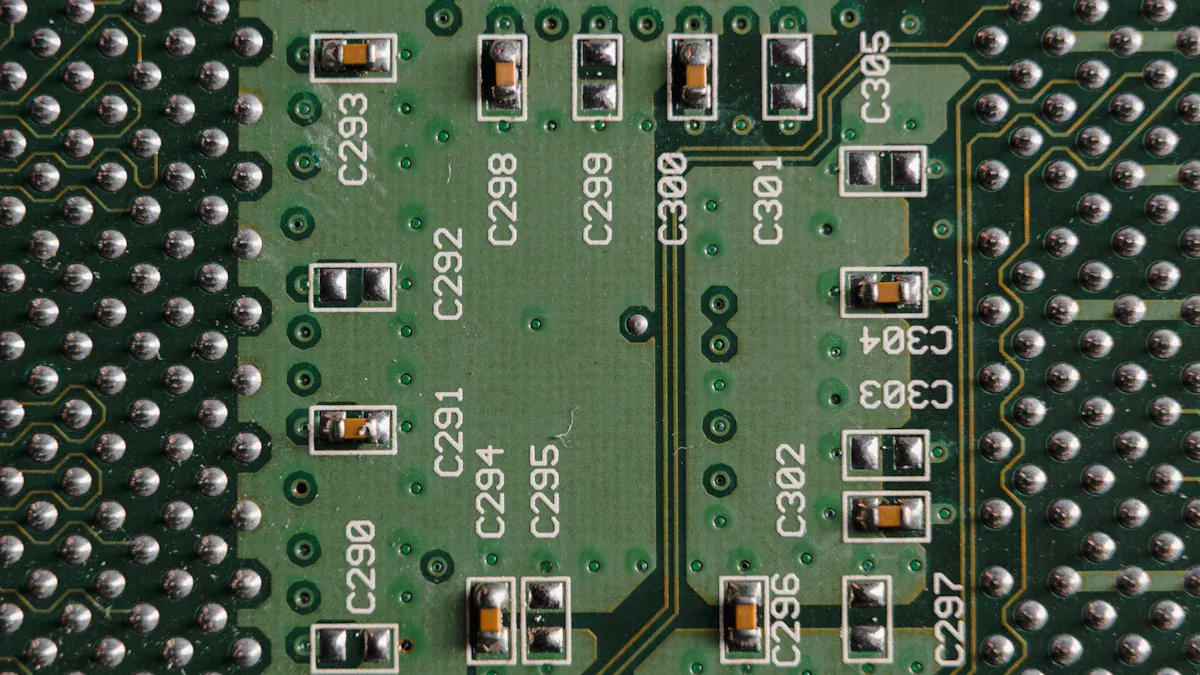

IIoT sensors are important for real-time monitoring and quality checks. These sensors watch machines and processes, collecting data all the time. They track things like temperature, pressure, and vibration to find problems fast. Quick alerts help fix issues early, keeping product quality steady.

For instance, companies like Sanmina Corp. use smart systems to improve work. Adjusting solder paste amounts during PCB assembly reduces mistakes. With IIoT sensors, you can control production details for better results. This turns your factory into a smart one, where every step is efficient.

Real-time monitoring also makes operations clearer. You can see where delays or problems happen. This helps you make better choices, improving both speed and quality.

Predictive Maintenance and Equipment Health

IIoT sensors also help with predictive maintenance. They check machine health by watching vibration, temperature, and usage. By studying this data, you can predict breakdowns and plan repairs early. This reduces downtime and keeps machines running longer.

In manufacturing, predictive maintenance cuts repair times by over 20%. It also prevents costly failures. For example, tracking vibrations can show problems before they stop production. Fixing these early keeps your factory running smoothly.

This method also improves maintenance schedules. Instead of fixed times, you service machines when needed. This saves time and resources. Adding IIoT sensors makes maintenance smarter and equipment more reliable.

Automation and Process Optimization

IIoT sensors are key for automation and improving processes. They let machines share information, making tasks flow smoothly. This allows repetitive jobs to be automated, freeing workers for harder tasks.

Research shows IoT sensors improve control and decision-making. For example, studying sensor data finds patterns and improves workflows. This boosts quality and speeds up production. Robots with IIoT sensors also handle tough jobs and work with people.

Real-time monitoring reduces surprise equipment failures. You can adjust processes quickly to avoid delays. This flexibility helps you stay ahead in fast-moving industries.

Using IIoT sensors turns your factory into a smart one. Automation and data insights make operations smoother and more reliable.

Data Collection and Analysis for Continuous Improvement

Collecting and studying data is key to better PCBA manufacturing. IIoT sensor nodes gather important details from machines and production lines. This helps find patterns, fix problems, and improve how things work.

These sensors collect data nonstop from different factory areas. They track things like temperature, pressure, and machine performance. Looking at this data shows hidden issues and areas to improve. For instance, if a machine runs slower than it should, the data will show this. You can then fix it to make it work better.

Tip: Check your data often to spot problems early and keep things running smoothly.

Here’s how data collection and analysis help improve processes:

Finding Delays: Sensor data shows where production slows down. Fixing these delays speeds up work.

Using Resources Better: Data helps you use materials and workers more wisely.

Keeping Quality Steady: Insights let you adjust settings to ensure good product quality.

Measuring Changes: Past data helps you see if changes are working over time.

Modern tools make it easy to handle lots of data. These tools create charts and graphs to explain complex details simply. With this knowledge, you can make changes that boost productivity and product quality.

Improving processes means being flexible and making updates. IIoT sensor nodes give you the data and tools to do this. Using data-driven methods keeps you ahead in the fast-moving PCBA manufacturing world.

Benefits of IIoT Sensor Nodes in PCBA Manufacturing

Improving Efficiency and Reducing Downtime

IIoT sensors help factories work faster and avoid delays. These sensors watch machines and processes in real time. They find slow spots and help improve workflows. For example, wireless sensors remove the need for extra workers. This makes factories more flexible and productive. Sensors also give accurate data and help prevent problems early.

Studies show how IIoT sensors improve efficiency. GE Aviation cut inspection times by half, changing how they maintain equipment. Caterpillar reduced unexpected machine stops by 20% using remote checks. These examples show how sensors save time and money while improving factory work.

Key Factors | Description |

|---|---|

Wireless Connectivity | Wireless sensors make factories more flexible and productive. |

Sensing Technology | Accurate data and early fixes improve safety and reliability. |

Industry 4.0 | Smart sensors automate tasks and find errors quickly, saving time. |

Improving Product Quality and Consistency

IIoT sensors help keep product quality steady. They check things like temperature and pressure during production. If something goes wrong, sensors alert you to fix it fast. This keeps products the same and avoids mistakes.

Research shows sensors are great for quality control. They provide safe and accurate data, building trust in products. Privacy features also improve performance. Energy-saving designs make sensors work better. With these tools, you can make high-quality products and gain customer trust.

Quality Feature | Description |

|---|---|

Trust | |

Privacy | Protects data while keeping performance strong. |

Energy Efficiency | Saves energy while keeping sensors effective. |

Saving Money with Predictive Maintenance

IIoT sensors help save money by predicting problems early. They collect data to spot issues before machines break. This lets you fix things on time and avoid costly repairs.

Reports show how predictive maintenance saves money. McKinsey says sensors can cut costs by 15-20% in one year. IBM found a 25-30% drop in ownership costs due to fewer failures. A North American company saved over $24 million yearly by improving operations. These numbers show how sensors make maintenance cheaper and smarter.

Source | Cost Savings Percentage | Notes |

|---|---|---|

McKinsey & Company (2022) | 15-20% | Savings in the first year of using sensors. |

IBM Institute for Business Value (2023) | 25-30% | Lower costs due to fewer machine failures. |

North American Utility | 15-25% | Saved over $24 million yearly with better systems. |

Enabling Better Decision-Making with Data Insights

IIoT sensor nodes collect lots of data to improve decisions. These sensors gather information from machines, processes, and environments all the time. Studying this data gives useful ideas to solve problems and find opportunities.

A big benefit of IIoT data is helping with predictive maintenance. Watching equipment health in real time shows possible issues early. You can fix machines before they break, avoiding delays. This keeps operations smooth and makes machines last longer.

IIoT data also helps improve plans by showing trends and patterns. For example:

Study supply chain data to manage inventory better.

Use sensor data to improve how products are designed.

React to market changes faster with smart, data-based decisions.

Tip: Use tools to turn data into charts or graphs. These make hard-to-read details simple and clear.

Sensors also boost efficiency by showing slow spots in production lines. Fixing these areas improves workflows and saves time. This helps use materials, workers, and time wisely.

Adding IIoT data to your decisions gives you an advantage. It helps you work faster, save money, and meet market needs. Using these insights makes your factory smarter and more flexible.

IIoT sensor nodes are key to modern PCBA manufacturing. They link machines with digital systems for real-time tracking. These sensors help predict problems and improve processes. They boost efficiency, make products better, and cut costs. Using their data insights helps you make smarter choices and stay competitive.

Tip: Using IIoT technologies keeps your factory flexible and ready for the future. Add these sensors now to improve operations and succeed long-term.

FAQ

What are the main benefits of using IIoT sensor nodes in PCBA manufacturing?

IIoT sensor nodes make factories faster and more reliable. They help monitor machines, predict problems, and improve decisions. These sensors save time, cut costs, and keep production steady.

How do IIoT sensor nodes support predictive maintenance?

IIoT sensors check machines by watching vibration, heat, and use. They find problems early so repairs happen before breakdowns. This keeps machines running longer and reduces downtime.

Tip: Check sensor data often to get the most from predictive maintenance.

Are IIoT sensor nodes difficult to integrate into existing systems?

No, most IIoT sensors are simple to add to systems. They use wireless connections and common protocols to work smoothly. Ask your equipment provider for help with setup if needed.

Can IIoT sensors help reduce manufacturing costs?

Yes, IIoT sensors lower costs by stopping unexpected failures. They also use resources better and automate simple tasks. Predictive maintenance alone can save up to 20% on repairs. Real-time data helps you make smarter choices, saving even more.

What types of data do IIoT sensor nodes collect?

IIoT sensors gather data like temperature, pressure, and motion. This helps track machines, environments, and production lines. Studying this data shows problems and ways to improve.

Note: Pick sensors that match the data your factory needs.

See Also

Understanding PCBA and Its Significance in Electronics

Exploring PCBA Services and Their Importance in Manufacturing

Significance of PCBA Manufacturing Skills in Electronics Design

Key Stages Involved in the PCBA Manufacturing Process

The Role of PCBA Numbers in Enhancing Manufacturing Efficiency