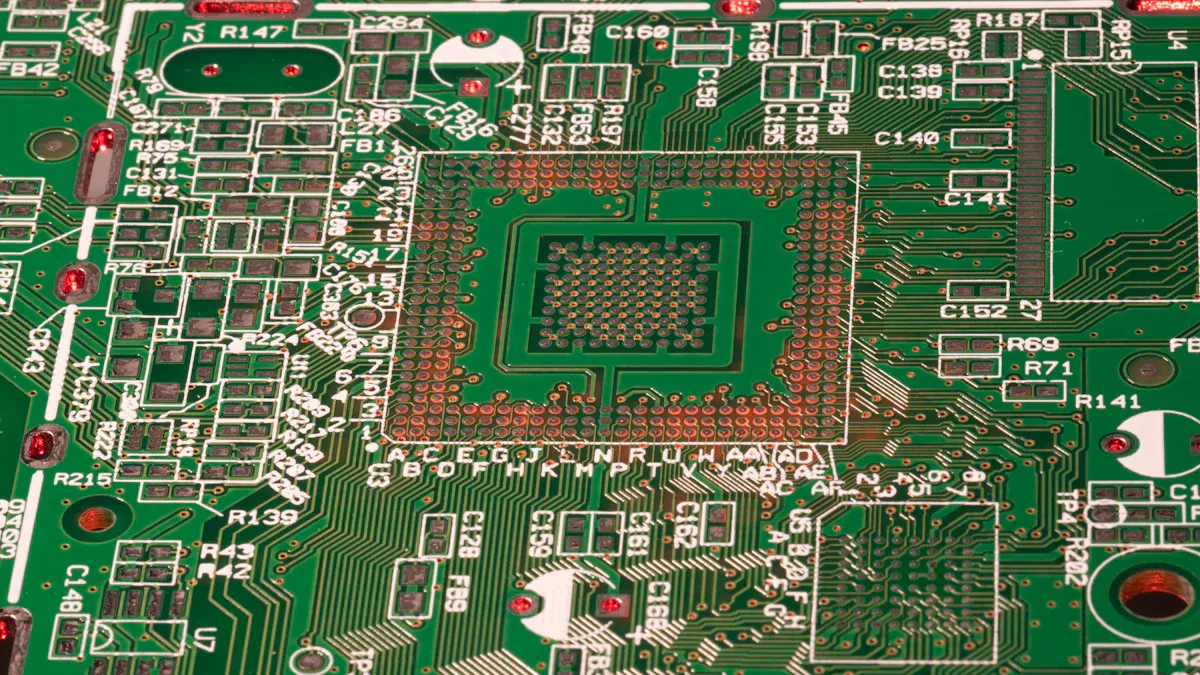

Printed circuit board assembly (PCBA) is the heart of industrial automation controller PCBAs. It helps them work smoothly and dependably. These controllers handle tough jobs in hard environments, like factory robots and process machines.

Industrial automation controller PCBAs work well in rough conditions. They are strong and keep working without problems. This makes them safe, saves money, and follows strict rules. They are very important for big tasks.

Factories use special materials and machines to make powerful industrial automation controller PCBAs. This method boosts new ideas and supports the need for small, useful designs in today’s industries.

Key Takeaways

PCBA is important for automation controllers. It helps them work well in tough places.

Smaller HDI PCBs save room and work better. They are great for modern industries.

Good signal handling in PCBs improves system teamwork. This makes responses quicker and more accurate.

Strong and heat-resistant PCBs last longer. They can handle rough conditions and keep working.

Making PCBs in eco-friendly ways helps the planet. It also meets what industries need.

Understanding Industrial Automation Controller PCBA

What is PCBA?

A printed circuit board assembly (PCBA) is the base of modern electronics. It includes a board with parts like resistors, capacitors, and microprocessors. These parts are attached to the board to make it work. PCBs are small and hold these parts together, working well even in tough places.

In industrial automation, PCBs help run and control systems. They save space by fitting many circuits into small devices. Their design makes fixing and replacing parts easy, saving money for big industries.

Tip: Smaller designs need high-density interconnect (HDI) PCBs. These are expected to grow from $19.5 billion in 2024 to $26.6 billion by 2029.

Components of PCBA

A PCBA has many important parts, each with a job in automation controllers:

Electronic Integrated Circuits: Chips that process and store data.

Switching and Protection Devices: Boards and panels that control electricity.

Measuring Instruments: Tools to check voltage, current, and other values.

Peripheral Accessories: Extra parts that improve automation systems.

Description | |

|---|---|

8542.31.00 | Chips for processing and storing data, like microprocessors. |

8536.90.00 | Boards and panels for controlling and protecting circuits. |

9030.89.00 | Tools for checking voltage, current, and other measurements. |

8473.30.20 | Extra parts for computers and devices, used in PCBAs. |

These parts work together to keep automation controllers running smoothly.

Role of PCBA in Industrial Automation Controllers

PCBA is the main part of automation controllers. It helps with control, communication, and performance. With sensors and actuators, PCBs collect and process data fast. This helps systems react quickly to changes.

Testing makes sure every PCBA works as planned. Machines check for problems and confirm they work well. Strict quality checks make PCBs strong for tough factory conditions.

The market for industrial automation is growing fast. It may reach $246.29 billion by 2029. This growth comes from smart factories, saving energy, and using AI and IoT. PCBs are key to the future of automation.

Key Contributions of PCBs to Industrial Automation

Signal Processing and Communication

PCBs are important for handling signals in automation systems. They bring together signals from sensors, actuators, and other devices. These signals are processed by the PCB and sent to the right place.

Think of PCBs as the system’s nervous system. They send information fast and correctly. For example, if a sensor notices a temperature change, the PCB processes it. Then, it sends instructions to adjust the system. This keeps everything running smoothly without delays.

Modern PCBs use advanced communication methods like Ethernet, CAN bus, and Modbus. These methods help devices in factories talk to each other easily. Using these technologies improves how well automation systems work together.

Note: Good communication is very important for control PCBs. Without it, systems might fail or stop working.

Control Logic and System Coordination

Control logic is like the brain of automation systems. PCBs use microcontrollers and processors to run this logic. These parts follow instructions and manage system tasks.

In control PCBs, logic makes sure machines work in the right order. For example, on an assembly line, the PCB controls robotic arms and conveyor belts. This keeps everything working correctly and boosts productivity.

PCBs handle complex tasks quickly. They process lots of data and make decisions in milliseconds. This speed helps keep automation systems precise and reliable.

Tip: When making PCBs for automation, focus on improving control logic for better performance.

Integration of Sensors and Actuators

PCBs connect sensors and actuators in automation systems. Sensors collect data like temperature or motion. Actuators use this data to do things like move parts or adjust settings.

In control PCBs, sensors and actuators work together smoothly. For instance, a PCB in a robotic arm reads sensor data and controls movement. This teamwork helps machines work accurately and adapt to changes.

Using PCBs that support many sensors and actuators makes systems better. They reduce wiring problems and make upgrades easier. This saves time and money in the long run.

Callout: Connecting sensors and actuators properly is key for accurate automation in factories.

Design Considerations for Industrial Automation Controller PCBA

Durability in Harsh Industrial Environments

Factories can be tough places for PCBs. They face heat, moisture, and chemicals. Strong designs are needed to keep them working well. Engineers use special materials like high-Tg FR-4 and polyimide boards. These materials handle heat up to 160°C. For example, car engine control units work fine at 150°C while staying affordable.

Tests check how strong PCBs are. High Accelerated Temperature and Humidity Stress Testing (HAST) finds problems like cracks or rust. Temperature Cycling Testing checks how PCBs handle changes from -55°C to 125°C. Salt Spray Testing shows if they resist salty air.

Testing Method | What It Checks |

|---|---|

HAST | Tests if PCBs survive heat and moisture. |

Temperature Cycling Testing | Finds cracks caused by big temperature changes. |

Salt Spray Testing | Checks if PCBs can handle salty environments. |

Strong PCBs last longer and cost less to fix. This makes them perfect for factory controllers.

Thermal Management and Heat Dissipation

Managing heat is very important for PCBs. Too much heat can break parts and cause failures. Engineers use buried copper layers and cooling fins to remove heat. Buried copper spreads heat evenly, making PCBs 18.5% more reliable. Cooling fins can lower heat by over 5°C when designed well.

Technique | Heat Reduction | Fin Size (mm) | Details |

|---|---|---|---|

Cooling Fins | > 5°C | 20 – 30 | Best fins are 0.5mm wide and 30mm long for low cost. |

Buried Copper | 15.3% – 18.5% | N/A | Spreads heat evenly to avoid hotspots and improve reliability. |

Thermal vias and coatings also protect PCBs in hot places. These methods help controllers work well in extreme heat, like in furnaces.

Ensuring EMC/EMI Compliance

PCBs must avoid and handle electromagnetic interference (EMI). This ensures they work without problems. Rules like IEC 61000 and EMC Directive guide testing for compliance.

Radiated Emissions Testing checks EMI sent into the air.

Conducted Emissions Testing looks at EMI through power cables.

Radiated Susceptibility Testing tests how PCBs handle outside EMI.

Electrostatic Discharge Testing ensures protection from static electricity.

AI tools help predict and fix signal issues. These steps make sure PCBs meet strict rules. This lowers the chance of failures in factories.

Advantages of PCBs in Industrial Automation Controllers

Better System Reliability

PCBs help make automation systems work reliably. They are strong and can handle tough factory conditions. Different PCB types, like rigid, flexible, and rigid-flex, have special uses for different tasks.

PCB Type | What It Does |

|---|---|

Rigid PCBs | Affordable boards with many layers for heat control. |

Flexible PCBs | Bendable boards for moving parts like actuators and controllers. |

Rigid-Flex PCBs | Mix of rigid and flexible parts for complex machine movements. |

Controlled Impedance PCBs | Keep signals fast and accurate for reliable system responses. |

EMI Hardening | Stops interference from affecting system performance. |

Verification Testing | Checks quality to ensure systems work well every time. |

Modern PCBs also track data and monitor systems in real-time. This helps find and fix problems early. Engineers design PCBs to avoid production issues, ensuring good quality. Careful testing makes PCBs dependable for automation systems.

Tip: Use controlled impedance PCBs for fast and error-free signals in systems.

Small and Efficient Designs

Smaller PCBs have changed how systems are built. They save space and make automation systems smaller and better.

Electronics today need tiny and detailed circuit designs. This has led to new ways of making PCBs. For example, high-density interconnect (HDI) PCBs fit more parts in less space. This improves how systems work without making them bigger.

Smaller PCBs also use less energy. They lower costs and are better for the environment. Many industries now focus on eco-friendly practices. Using compact PCBs helps meet these goals while keeping systems efficient.

Callout: Tiny PCBs save space and improve energy use in automation systems.

Affordable Manufacturing and Easy Maintenance

PCBs are cost-friendly to make and fix. Their simple designs make production faster and cheaper. They are also durable, so they don’t need repairs often.

Designing PCBs carefully avoids production mistakes. This saves money and ensures smooth manufacturing. Testing during production also keeps quality high, reducing waste.

For maintenance, PCBs are easy to fix. Broken parts can be replaced without stopping the whole system. This saves time and lowers repair costs, making PCBs a smart choice for factories.

Note: Modular PCBs are easy to fix, saving time and money.

Future Trends in PCBA for Industrial Automation

Miniaturization and High-Density Designs

Smaller PCBs are becoming more popular. They fit more features in tiny spaces. This is useful for industries like cars and planes, where space is tight. HDI technology helps make these designs possible. It adds more layers, letting more parts fit on one PCB.

Microvias make these designs even better. They improve how circuits are connected and save space. Microvias also keep signals clear for fast data transfer. Now, HDI technology costs less, so it’s used in medical devices and other areas.

Innovation Trend | What It Does |

|---|---|

Advanced HDI Technology | Adds more layers to fit more parts on small PCBs. |

Microvia Integration | Makes connections better and saves space on PCBs. |

Improved Signal Integrity | Keeps signals clear for fast and reliable data transfer. |

Application Expansion | Lower costs make HDI useful for cars, planes, and medical tools. |

These updates help make smaller PCBs that work better and faster.

AI and Machine Learning Integration

AI and ML are changing how PCBs are made. AI speeds up inspection, cutting time from hours to minutes. ML makes inspections more accurate, finding hard-to-spot problems. These systems learn from data, so they don’t need constant reprogramming.

AI places parts faster, needing fewer manual changes.

Neural networks study old designs to group parts better.

Predictive tools check designs early to stop mistakes.

Improvement Area | Old Way | AI/ML Way |

|---|---|---|

Inspection Time | Took hours or days | Takes 5 to 10 minutes |

Inspection Accuracy | Limited to basic checks | Finds tricky defects |

Adaptability | Needed extra programming | Learns from new data |

Defect Detection | Done by hand | Learns to spot problems |

Data Use | Needed lots of real-world data | Creates fake data for testing |

Using AI improves how parts are placed and systems are built, making automation faster and smarter.

Green and Sustainable Manufacturing Practices

Making PCBs eco-friendly is now a big focus. Factories use lead-free solder and recyclable materials to cut waste. Energy-saving methods also lower pollution.

Future PCBs will be greener without losing quality. Smaller designs, like HDI, use fewer materials. Better microcontrollers also save energy, helping meet global green goals.

Tip: Picking eco-friendly PCBs helps the planet and supports modern business trends.

PCBA is the key part of automation controllers. It helps them work well, stay reliable, and be efficient. PCBs handle signals, control systems, and connect parts. These jobs are important for modern factories.

What PCBs Do | |

|---|---|

Programmable Logic Controllers (PLCs) | Run complex tasks in factories, like managing machines. |

Industrial Robots | Control movements for jobs like welding and building things. |

Automated Guided Vehicles (AGVs) | Help vehicles move, avoid obstacles, and do tasks. |

Machine Vision Systems | Check product quality and recognize objects on assembly lines. |

Smart Sensors | Track equipment health and factory conditions using IoT. |

PCBA will keep improving automation in the future.

AI will make systems faster and more accurate.

Predictive tools will find problems early to avoid delays.

AI will help factories make perfect products without defects.

Custom designs will let factories build products for special needs.

PCBA is vital for smarter and greener automation systems in the future.

FAQ

What does a PCB controller do in automation?

A PCB controller runs automation systems. It handles signals, organizes tasks, and helps sensors and actuators work together. This keeps systems running smoothly and reliably.

How do PCB assembly methods make controllers better?

PCB assembly methods make controllers stronger and more accurate. They attach parts securely and improve signal flow. This helps controllers handle tough jobs in factories.

Why is signal processing needed in PCB controllers?

Signal processing helps controllers understand data from sensors and actuators. It ensures quick reactions to changes, keeping systems efficient and error-free.

How do PCB controllers survive tough factory conditions?

PCB controllers are made with strong materials and smart designs. They resist heat, moisture, and chemicals. Tests like temperature cycling and salt spray check their strength for harsh environments.

Why are PCB controllers a good value for factories?

PCB controllers are cheap to make and easy to fix. Their modular design allows fast repairs without stopping work. They are reliable, cutting downtime and saving money over time.

See Also

PCBA’s Role In Elevating Today’s Electronic Innovations

Exploring The Uses And Advantages Of PCBA Today

Why PCBA Manufacturing Skills Are Crucial For Electronics