High-temperature resistant industrial PCB manufacturing involves creating specialized boards designed to withstand extreme heat. These high-temperature PCBs perform reliably even in very hot conditions without degrading. They are crucial for industries that deal with heat-intensive tasks or operate in challenging environments. Excessive heat can damage components, reduce power efficiency, and accelerate device wear. However, these PCBs maintain their strength and functionality even under tough conditions.

The demand for high-temperature resistant industrial PCB manufacturing is rapidly increasing. For example, the market for these PCBs is projected to grow from USD 352 million in 2024 to USD 555.50 million by 2032, with an annual growth rate of 5.20%. This trend highlights their significance in sectors such as automotive, aerospace, and industrial machinery. The production of these PCBs utilizes advanced materials like ceramic and polyimide, which enhance their durability and heat resistance.

Key Takeaways

High-temperature PCBs can handle heat over 150°C. They are important for industries like cars and airplanes.

Materials like polyimide and ceramic make these PCBs stronger and better in tough conditions.

These PCBs stop devices from overheating, helping parts last longer.

They save money by needing fewer replacements and repairs in factories.

Picking the right PCB based on heat and materials is key for good performance in hard situations.

What Are High-Temperature PCBs?

Definition and Overview

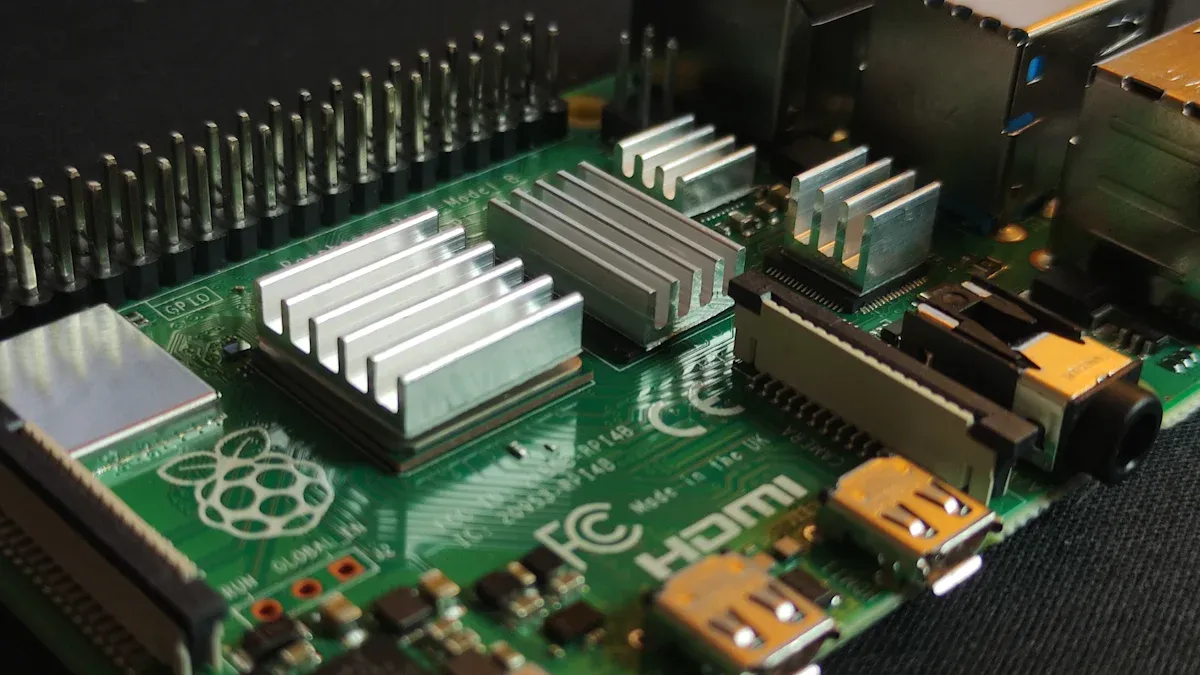

High-temperature PCBs are special circuit boards made to work in very hot places. These boards can handle heat up to 150°C or more without breaking or losing performance. They are made with strong materials like polyimide and ceramic, which help them stay stable and last longer.

Standard PCBs cannot handle extreme heat like high-temperature PCBs can. This makes high-temperature PCBs very useful for industries like cars, airplanes, and heavy machines. For example, a high Tg PCB has a glass transition temperature (Tg) over 170°C, while regular FR-4 boards have a Tg of about 135°C. The higher Tg keeps the PCB strong and working well in hot conditions.

Did You Know? High-temperature PCBs are not only heat-proof but also resist chemicals, rust, and physical damage. This makes them great for tough jobs.

How High-Temperature PCBs Differ from Standard PCBs

High-temperature PCBs are different from regular PCBs in materials, heat handling, and strength. Here’s a simple comparison:

Feature | Standard PCBs | High-Temperature PCBs |

|---|---|---|

Glass Transition Temperature (Tg) | ~135°C (FR-4) | |

Material Composition | Regular epoxy resin | Polyimide, ceramic, or high Tg FR-4 |

Thermal Stability | Works in mild heat | Handles 150°C or more |

Applications | Everyday electronics | Cars, airplanes, heavy machines |

High Tg PCBs are made to survive hot places. They use materials like ARLON 85N, ISOLA IS410, and Shengyi S1000-2, which are very strong against heat and damage. These materials also resist fire, smoke, and chemicals, making them reliable for a long time.

Importance in High-Heat Industrial Applications

In industries with lots of heat, keeping electronics working is very important. High-temperature PCBs help devices work well even in extreme heat. For example, car engine control units (ECUs) use high Tg PCBs to work at over 150°C. Oil and gas drilling tools use polyimide PCBs to handle heat above 175°C.

Managing heat is also very important. High-temperature PCBs remove heat from parts like LEDs and chips, stopping them from overheating. This helps devices work smoothly, especially in advanced tech like 3D chips, where heat is a big problem.

Pro Tip: When picking a high Tg PCB, think about the heat level, material type, and environment to get the best results.

Key Characteristics of High-Temperature Resistant Industrial PCB Manufacturing

Materials Used in High-Temperature PCBs

The materials in high-temperature PCBs are very important. These PCBs use advanced materials like polyimide, ceramic, and high-Tg FR-4. Each material has special features for different uses. For example:

Material | Features | Uses |

|---|---|---|

High-Tg variants | Tg 170–180 °C, strong against heat | Multilayer PCBs |

Polyimide | Handles high heat, Tg around 250–260 °C | Flexible and rigid PCBs |

PTFE | Low dielectric constant (~2.1–2.3), works up to ~250 °C | High-frequency and microwave uses |

Ceramic PCBs | Great heat performance, high thermal conductivity | High-power, high-heat uses |

Using these materials keeps the PCB strong and stable in tough conditions. This is why industries like aerospace and cars need them.

Tip: Pick materials based on heat levels and your project needs.

Heat Resistance and Thermal Stability

High-temperature PCBs are great at handling heat and staying stable. They work in temperatures over 150°C without breaking. Tests like MIL-STD-202G, Method 107, check if they can handle quick temperature changes. This ensures they work well even when temperatures go up and down.

Managing heat is also very important. Built-in sensors and heat calculations help spread heat evenly. This stops parts from overheating and makes them last longer. For example, steady heat control helps machines work better in high-power jobs.

Pro Tip: Good heat control makes devices last longer and saves money.

Durability in Harsh Industrial Environments

High-Tg PCBs are made to handle tough conditions. They resist stress, shaking, and chemicals. They are used in cars, airplanes, and heavy machines. For instance, car PCBs handle hot engine areas, and airplane systems face big temperature changes.

Tests like HALT and ESS check if PCBs can survive harsh conditions. These tests look at how well they resist shocks, shaking, and wetness. Standards like MIL-STD-810 prove they work in extreme places.

Choosing high-temperature PCBs ensures your devices work even in the hardest conditions.

Applications of High Tg PCBs Across Industries

High Tg PCBs are important in many industries. They handle high heat and tough conditions. Let’s see how they are used in different fields.

Automotive Electronics

High Tg PCBs are key in car electronics. They are found in engine controls, infotainment, and navigation systems. These PCBs work well even in hot engine areas. For example, an ADAS unit in cars uses high Tg PCBs. This keeps processor heat below 105°C, ensuring safety and passing tests. They are perfect for critical tasks where safety matters most.

Aerospace and Defense Systems

Aerospace and defense need strong and reliable electronics. High Tg PCBs provide great heat resistance and strength. They are used in airplane systems, radar, and military devices. Aluminum PCBs lower heat in these systems, improving performance. These PCBs are vital for tasks where failure is not allowed.

Consumer Electronics and Appliances

High Tg PCBs are also used in gadgets like phones, tablets, and laptops. These devices need to work well under heat. The demand for high-temperature PCBs is growing fast. This is because more advanced electronics are being made for homes. High Tg PCBs help gadgets and appliances work smoothly, even when they get hot.

Note: Green energy is inspiring new uses for high Tg PCBs in eco-friendly tech.

Industrial Equipment and Robotics

High-temperature PCBs are important for industrial machines and robots. These systems often face heat, shaking, and stress while working. Reliable parts are needed to keep them running smoothly, and high-temperature PCBs do just that.

Machines like CNC tools, power systems, and robotic arms create a lot of heat. High-temperature PCBs handle this heat without losing their performance. For example, in robots, these PCBs manage heat from motors and sensors. This helps robots move accurately and work without problems. Their dependability keeps production steady and avoids expensive delays.

Another big benefit is their toughness. High-temperature PCBs resist damage from tough conditions. They can handle chemicals, dust, and moisture, making them great for factories. Using these PCBs helps machines last longer and lowers repair costs.

Tip: Choose PCBs based on the heat levels and environment for best results.

Oil and Gas Exploration

The oil and gas field needs electronics that survive extreme heat and pressure. High-temperature PCBs are key for tools used in drilling and exploration. These PCBs ensure equipment works well in very harsh places.

In downhole tools, high-temperature PCBs work at up to 215°C. These tools check reservoir conditions and give data for better drilling. For instance, well-logging tools use PCBs that work at 200°C. This ensures accurate data even in high heat and pressure.

Reservoir monitoring systems also use high-temperature PCBs. These systems use advanced tech to work at 240°C nonstop. This helps track small changes in reservoirs and extends their life.

Here’s how high-temperature PCBs help in oil and gas:

Application | Temperature Capability | Purpose |

|---|---|---|

Downhole Monitoring | 240°C | Tracks small reservoir changes |

Well Logging | 200°C | Works reliably under high pressure |

Downhole Tools | 215°C | Provides steady power for subsystems |

Reservoir Monitoring | 240°C | Runs continuously with advanced technology |

The industry is also improving recovery with better high-temperature electronics. Future tools may use materials like silicon carbide or diamond for more heat resistance.

Did You Know? High-temperature PCBs boost safety in oil and gas by lowering equipment failure risks.

Benefits of High-Temperature PCBs in Industrial Applications

Better Performance in Tough Conditions

High-temperature PCBs work well where regular boards fail. They quickly remove heat, keeping parts cool and working. For example, in cars, these PCBs help engine control units (ECUs) and advanced driver-assistance systems (ADAS) stay steady. This is important for safety and smooth operation in hot areas.

In airplanes, these PCBs are very important. They handle the heat and pressure at high altitudes, keeping avionics running without problems. Renewable energy systems, like solar inverters and wind converters, also use these PCBs. They manage heat well, helping these systems work steadily even when temperatures change.

Tip: Use materials like polyimide or ceramic to improve heat resistance and strength.

Higher Reliability and Safety

High Tg PCBs do more than resist heat. They make devices safer and more reliable in many industries. For instance, in electric cars, these PCBs stop batteries from overheating, making them last longer. In military tools, their heat resistance is vital for important missions.

Here’s how industries benefit from these PCBs:

Industry | Application | Benefit |

|---|---|---|

Automotive | Engine Control Units (ECUs) | Keeps working in changing temperatures. |

Automotive | Advanced Driver-Assistance Systems (ADAS) | Stays reliable in hot conditions. |

Automotive | Electric Vehicle Battery Systems | Prevents overheating and lasts longer. |

Aerospace | Avionics | Works well in extreme heat and pressure. |

Aerospace | Military Equipment | Needed for critical, high-heat tasks. |

Renewable Energy | Solar Inverters | Manages heat for steady performance. |

Renewable Energy | Wind Converters | Stays efficient under constant high power. |

These features show why high-temperature PCBs are key for safety and reliability today.

Saves Money and Lasts Longer

Using high-temperature PCBs saves money over time. They are strong and don’t need to be replaced often. For example, hard gold PCBs resist rust and damage, lasting longer. This makes them a smart choice for industries needing reliable parts.

Here’s how they save costs:

Benefit | Description |

|---|---|

Hard gold PCBs don’t rust, so they last longer. | |

High Reliability | They work well for a long time, reducing failures. |

Durability | Gold plating makes them strong and reduces replacements. |

Better Signal Performance | Signals stay clear, improving how devices work. |

Longer Lifespan | They last longer than regular PCBs. |

Cost-Effectiveness | Fewer repairs and replacements save money. |

Choosing high-temperature PCBs improves system reliability and lowers costs. They are a smart pick for any industry needing durable and efficient solutions.

Used in Many Industries

High-temperature PCBs are useful in many different industries. They work well in hot and tough conditions, making them reliable for various uses.

Industries That Use High-Temperature PCBs

Healthcare and Medical Devices

Medical tools like MRI machines and surgical devices use high-temperature PCBs. These tools get hot when working. High-Tg PCBs keep them steady, ensuring accurate results and patient safety.Telecommunications

High-temperature PCBs are in devices like 5G systems and satellites. These devices run all the time and get very hot. High-Tg PCBs help them stay cool and work without stopping.Renewable Energy Systems

Solar panels and wind turbines need high-temperature PCBs. These PCBs handle heat from power-making processes. They help these systems last longer and work better.Industrial Automation

Factories use high-temperature PCBs in robots and sensors. These PCBs resist heat, shaking, and chemicals, keeping machines running smoothly.

Tip: Pick high-temperature PCBs that match your industry’s needs for the best results.

Why Being Useful Everywhere Matters

High-temperature PCBs can be used in many technologies. Whether in healthcare, energy, or factories, they provide strength and reliability. Their wide use makes them important for progress in many fields.

High-temperature PCBs are important for today’s industries. They use strong materials like polyimide to handle heat up to 260°C. Regular boards can’t work in such hot conditions. Special features like thermal vias and copper coins help remove heat. These PCBs are used in cars, airplanes, and power systems. They make devices work better, last longer, and allow flexible designs. As technology advances, the demand for tough, heat-resistant PCBs keeps increasing quickly.

FAQ

What makes high Tg PCBs different from standard PCBs?

High Tg PCBs can handle heat above 170°C. Standard PCBs work only up to 135°C. High Tg PCBs use strong materials like polyimide or ceramic. These materials make them tough in hot conditions. They are perfect for industries like cars and airplanes.

Tip: Use high Tg PCBs for hot and demanding environments.

How do high-temperature PCBs make devices more reliable?

High-temperature PCBs stop parts from overheating by spreading heat well. This lowers the chance of parts breaking and keeps devices working. They also resist damage from stress, chemicals, and rust. This helps devices last longer and work better in tough places.

Can high-temperature PCBs be used in everyday electronics?

Yes, they are used in laptops, phones, and home gadgets. These PCBs help devices work well even when they get hot. Their strength also supports advanced features in modern electronics.

What materials are used in high-temperature PCBs?

High-temperature PCBs use materials like polyimide, ceramic, and high-Tg FR-4. These materials are great at handling heat and staying strong. For example, polyimide can take heat up to 260°C. This makes it good for tough jobs.

Why are high-temperature PCBs useful in factory machines?

Machines and robots make a lot of heat while working. High-temperature PCBs handle this heat, keeping machines running smoothly. They also resist shaking, chemicals, and water. This makes them dependable in factories.

Did You Know? High-temperature PCBs help factories save money by reducing repairs.

See Also

Exploring The Role Of PCBA In Today’s Electronics

PCBA’s Impact On Advancing Today’s Electronic Innovations

Understanding The Pros And Cons Of Flex PCBA

Unveiling The Advantages Of PCBA Surface Mount Technology

Essential Strategies For Overcoming PCBA Manufacturing Hurdles