Small batch IIoT PCB assembly services focus on producing small quantities of circuit boards specifically for industrial IoT projects. These services enable you to create custom electronics without the need for large production runs. This approach allows you to test designs and enhance their functionality while ensuring compatibility with IoT systems. By utilizing small batch IIoT PCB assembly services, you can accelerate the development of new ideas, quickly produce prototypes, and adapt to changes efficiently. It also offers a cost-effective way to experiment with concepts and minimize significant risks before scaling up production.

Key Takeaways

Small batch IIoT PCB assembly makes custom circuit boards in small amounts. This is great for testing and trying out new ideas.

It lowers costs and risks, helping startups test designs without spending too much money on big production.

A big advantage is the ability to change designs easily. Quick updates can be made based on feedback or specific needs.

Faster prototyping means products can be ready for sale sooner. This helps businesses stay ahead in the fast-changing IIoT world.

Small batch assembly also helps grow production later. Once designs are ready, making more is easier.

What Are Small Batch IIoT PCB Assembly Services?

Definition and Scope of Small Batch PCB Assembly

Small batch PCB assembly means making a small number of circuit boards. These boards are designed for specific uses. Unlike making large amounts, this method focuses on being flexible and customizable. It works well for early-stage projects or unique designs. You can use small batch IIoT PCB assembly services to build prototypes, test ideas, or create special devices for smaller markets.

Here’s a comparison of small batch and mass production:

Production Type | Advantages | Limitations |

|---|---|---|

Small Batch Production | Flexible, Great for new ideas, Lower starting costs | Higher cost per unit, Slower speed, More expensive materials |

Large-scale Mass Production | Cheaper per unit, Very efficient, Stable | High initial cost, Less flexible, Needs demand prediction |

This table shows small batch production is more adaptable. This is important for making IIoT products. It helps improve designs and fix problems before making large amounts.

Role of Small Batch Assembly in IIoT Product Development

In the fast-changing IIoT world, small batch assembly is key. It helps turn ideas into real products. You can test creative designs and see how they work in real life. For example, industries like farming and mining need special IoT sensors. These sensors must fit their specific needs. Small batch IIoT PCB assembly services let you make these without spending too much money.

Small batch assembly is useful in many areas, as shown below:

Application Type | Description |

|---|---|

Environmental Sensors | Small batches are made for research, like air monitors for schools. |

Industrial IoT Devices | Custom IoT sensors are built for farming or mining needs. |

Smart Home Devices | Small batches test interest in products like smart speakers before mass production. |

Medical Monitors | Special patient devices are made in small amounts for accuracy and customization. |

This flexibility makes small batch assembly helpful for IIoT developers. It meets different market needs while keeping costs and timelines under control.

Key Components of the Process in Electronic Manufacturing Services

Small batch PCB assembly succeeds because of key factors in electronic manufacturing. These factors make the process fast, affordable, and easy to adjust:

Quick Turnaround: Small batch PCB assembly is faster, helping meet tight deadlines.

Adaptability: You can change designs even after production starts. This is great for updates or feedback.

Budget-Friendly: Making small amounts costs less upfront, which helps startups and small businesses.

By focusing on these factors, small batch IIoT PCB assembly services help bring new IIoT products to market. This reduces risks and improves efficiency.

Key Features and Benefits of Small Batch IIoT PCB Assembly Services

Cost-effectiveness for Low-Volume Production

Small batch IIoT PCB assembly services are a smart way to save money. By making fewer circuit boards, you avoid the high costs of mass production. This is great for startups and small businesses with tight budgets.

Proof of Concept Testing: Making cheap prototypes helps check designs early. This avoids expensive mistakes.

Faster Design Iterations: Quick prototypes help find and fix problems fast. This saves time and money.

Reducing Time-to-Market: Early testing ensures your product works while you keep improving it. This helps launch faster.

Lower Total Spending: Fixing issues early stops bigger costs later in production.

This method lowers risks and speeds up the process from idea to finished product.

Flexibility for Design Changes and Customization

A big advantage of small batch PCB assembly is flexibility. You can easily change designs or customize boards for specific needs. This is important for industries like medical devices and aerospace, where precision matters.

Benefit | Description |

|---|---|

Flexibility | Customize each batch for specific needs, like in medical devices. |

Risk Reduction | Small batches allow better quality checks and fewer mistakes. |

Design Changes | Small quantities make it easier to test and adjust designs. |

Prototyping | Test designs without spending too much, making changes easier. |

Making fewer boards also means more care goes into each one. This reduces errors and ensures designs are tested well before larger production.

Faster Prototyping and Testing Cycles

Speed is very important in IIoT product development. Small batch PCB assembly services are great for quick results. They make testing and improving designs much faster.

Rigid PCBs can be ready in 24 hours, while flexible ones take about a week.

Regular PCB production can take weeks, but quick turn services are much faster.

This fast process helps you improve designs quickly. It ensures your product is ready before mass production. Faster prototyping saves time and gives you an edge in the competitive IIoT market.

Reduced risks in IIoT product development

Small batch IIoT PCB assembly services help lower risks in making new products. By creating only a few circuit boards, you can test designs in real-world situations before making large amounts. This lets you find and fix problems early, saving time and money.

Here’s how small batch assembly reduces risks:

Spot Design Errors Early: Testing small batches helps catch mistakes during the design stage. Fixing these early avoids expensive problems later.

Better Quality Checks: Smaller batches allow careful inspection of each board. This ensures the final product meets high standards.

Lower Money Risk: Making fewer boards costs less if the design fails. You can improve your product without spending too much.

Tip: Use small batch assembly to get feedback from users or team members. Their ideas can help you improve your product.

This method helps you move forward with confidence while reducing uncertainties in your IIoT product development.

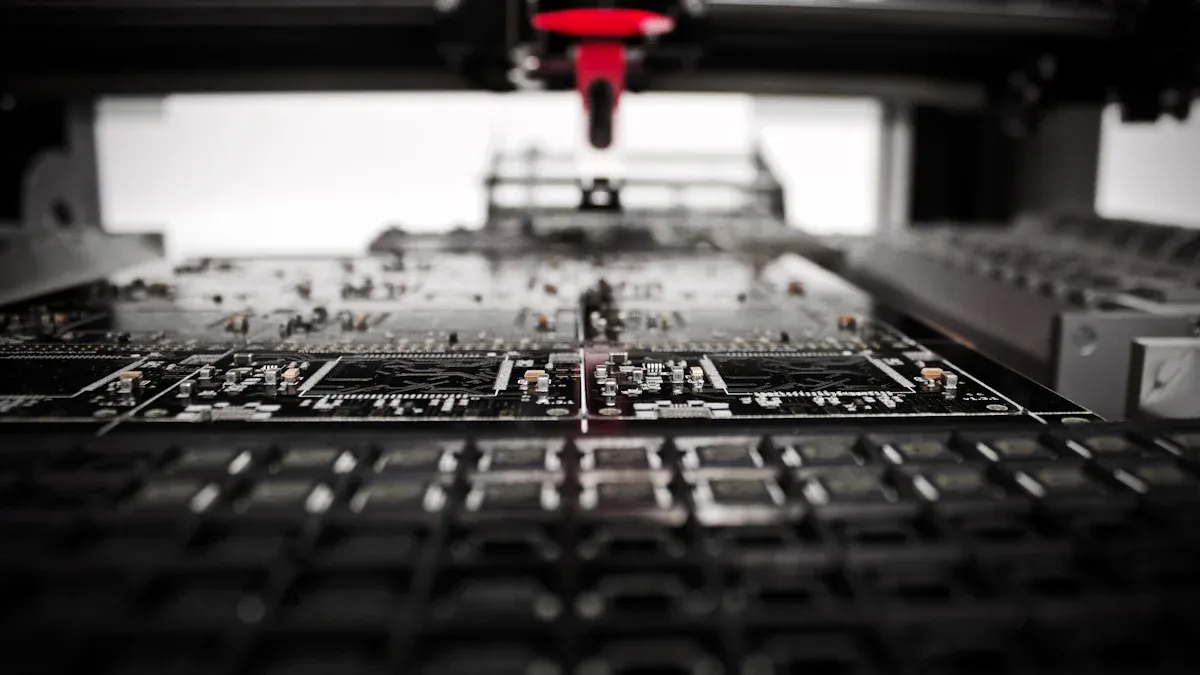

Scalability for transitioning to mass production

Small batch PCB assembly also helps you prepare for making more products later. Once your design works well, you can easily switch to larger production runs. This ensures your product is ready for market needs without delays.

Here’s how small batch assembly supports scaling up:

Better Prototypes: Small batches let you perfect your design. A tested prototype makes mass production easier.

Efficient Processes: Working with manufacturers during small batch production helps set up smooth workflows. These workflows can grow as needed.

Supplier Connections: Small batch production helps build strong supplier relationships. This ensures steady materials when scaling up.

Cost Control: Fixing problems early avoids surprise costs during large production runs.

Note: Scaling up isn’t just about making more products. It’s also about keeping quality and efficiency high as production grows.

With small batch assembly, you can scale confidently, knowing your product is tested and ready for bigger production.

Applications of Small Batch IIoT PCB Assembly Services

Industrial automation and smart manufacturing

Small batch PCB assembly is important for industrial automation. It helps make custom circuit boards for specific tasks. For example, a car-sharing startup used it to create special electronics. They needed a strong case to protect the board from heat and shaking. This method let them test and improve their design before making more.

Small batch assembly also adds features like wireless communication and sensors. These are key for smart factories that need live data. Using this method lets you adjust quickly and meet industry rules.

IoT-enabled sensors and device development

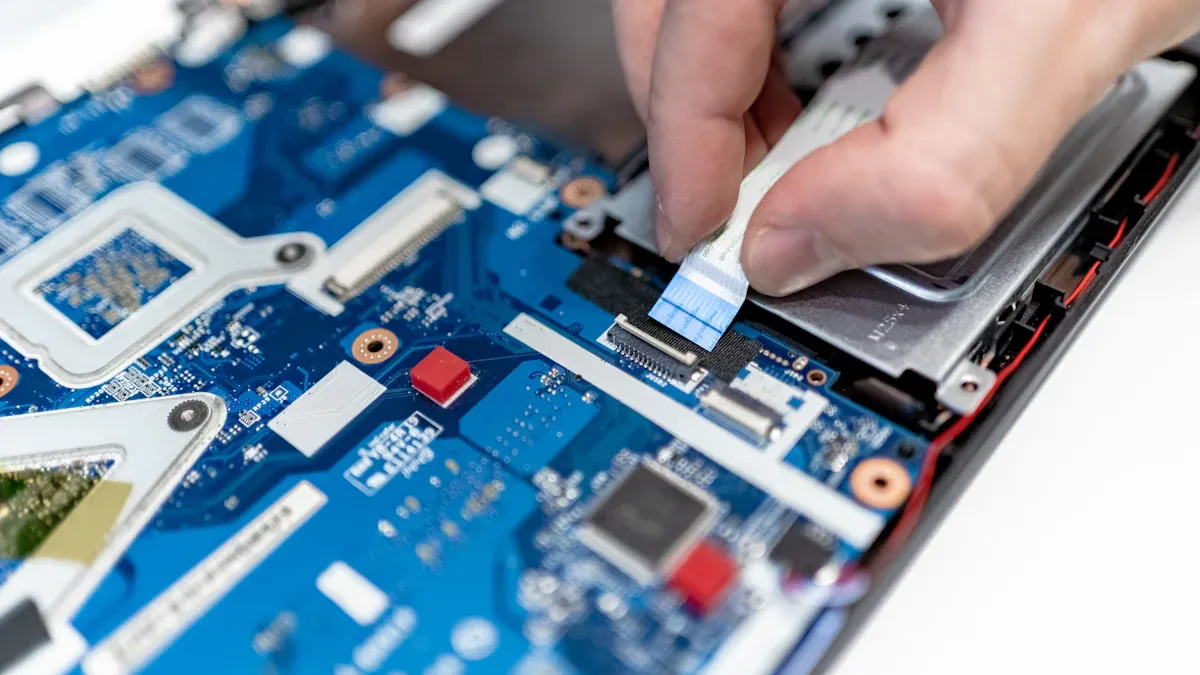

IoT devices need small, energy-saving circuit boards. Small batch PCB assembly helps make prototypes with advanced features. These include wireless connections and designs that save power. This is useful for gadgets like fitness trackers and medical tools.

Here’s a look at trends driving this demand:

Component Type | Demand Trend |

|---|---|

Advanced Analog ICs | |

Sensors | Needed for top-performing devices |

Memory Modules | Hard to produce due to complexity |

Small batch assembly also works for niche markets like smart clothing. It lets you test new ideas without making too many products. This saves money and lowers risks.

Predictive maintenance systems

Predictive maintenance stops machines from breaking down. Small batch PCB assembly helps make boards for sensors that track heat, vibration, and speed. These sensors send data to AI tools that predict problems. This reduces downtime and keeps systems running well.

With small batch assembly, you can test these solutions in real-world settings. This ensures the boards meet strict industrial standards. You can also use feedback to make quick changes and improvements.

Smart energy management solutions

Small batch PCB assembly helps make smart energy systems. These systems need strong and efficient circuit boards to save energy. With small batch assembly, you can create PCBs for renewable energy like solar panels or wind turbines. These boards are built to last and handle heat well, working in tough conditions.

Energy systems often need to track and control energy in real time. Small batch assembly lets you add features like sensors and communication tools to your PCBs. These features help collect and study energy data, meeting industry rules. For example, smart grids use these boards to check energy flow and find problems.

Here are some benefits of small batch PCB assembly for energy systems:

Improves energy use by saving power.

Builds strong PCBs for renewable energy projects.

Adds real-time tracking with control system features.

Using small batch assembly, you can test and improve energy systems before making more. This lowers risks and ensures your products work well for modern energy needs.

Custom IIoT solutions for niche industries

Some industries need very specific IIoT solutions. Small batch PCB assembly helps make custom boards for these needs. Whether it’s farm automation or healthcare devices, small batch assembly lets you design and test creative ideas.

For example, farms may need PCBs for sensors that check soil moisture and temperature. Small batch assembly helps you quickly make and test these devices to fit the environment. In healthcare, you can create custom medical devices for accurate monitoring.

Here’s how small batch PCB assembly helps niche industries:

Allows unique designs for special needs.

Cuts costs for making fewer products.

Speeds up testing and improving designs.

By focusing on small batch production, you can solve unique problems in niche industries. This ensures your IIoT solutions are useful and affordable, keeping you ahead in the market.

Small batch IIoT PCB assembly services help improve IIoT technology. They let you create new ideas faster and lower risks. Testing and quality checks ensure products meet high standards. These services also use data to keep quality steady and find problems early. As IoT grows and customization increases, small batch assembly stays flexible. It helps meet changing needs while staying cost-effective and competitive.

📊 Key Benefits Recap:

Better accuracy and consistent batches

Faster and smoother production

FAQ

What’s the difference between small batch and mass production in PCB assembly?

Small batch makes fewer circuit boards, great for testing or special products. Mass production makes many boards for finished designs. Small batch is flexible and customizable. Mass production focuses on being fast and cheap per board.

How does small batch PCB assembly lower risks in product development?

Small batch lets you test designs in real-world situations first. Making fewer boards helps find and fix problems early. This saves money and ensures your product is ready for bigger production.

Can small batch PCB assembly handle detailed and tricky designs?

Yes, small batch PCB assembly can manage complex and advanced designs. Skilled workers and modern tools ensure high-quality results. It works well for industries like medical devices, airplanes, and IoT gadgets needing accuracy.

How does small batch PCB assembly help IIoT innovation?

Small batch PCB assembly speeds up IIoT ideas by making quick prototypes. You can test designs, get feedback, and adjust fast. This helps create useful and market-ready IIoT products.

Is small batch PCB assembly affordable for new businesses?

Yes, small batch PCB assembly is great for startups with tight budgets. It avoids big costs of mass production. You can test ideas, improve designs, and check concepts without spending too much money.

See Also

Understanding PCBA Services and Their Significance in Electronics

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

Ten Essential Tips for Cost-Effective PCBA Assembly Success