In factories, ensuring that machines operate efficiently and safely is crucial. IIoT device quality assurance services play a vital role in this important task. They test and maintain industrial IoT systems to ensure they run smoothly. These systems are essential for seamless and consistent operations. By 2025, the demand for these services will become even more significant, with over 18 billion IoT devices projected to exist worldwide, valued at $714.48 billion. This substantial growth highlights the necessity for robust quality checks, as they assist in managing complex IIoT systems and the vast amounts of data they generate.

Key Takeaways

IIoT device quality checks make sure machines work well and safely. This is important for factories to run smoothly.

Predictive maintenance uses live data to find problems early. This saves time and lowers repair costs a lot.

Quality checks help follow safety rules, making workplaces safer and protecting the company’s image.

As IIoT tech improves, strong quality checks are needed to handle complex systems and stop expensive problems.

Paying attention to IIoT quality checks can boost work speed, cut downtime, and support eco-friendly practices in industries.

What Is IIoT Device Quality Assurance?

Defining IIoT and Its Role in Industry

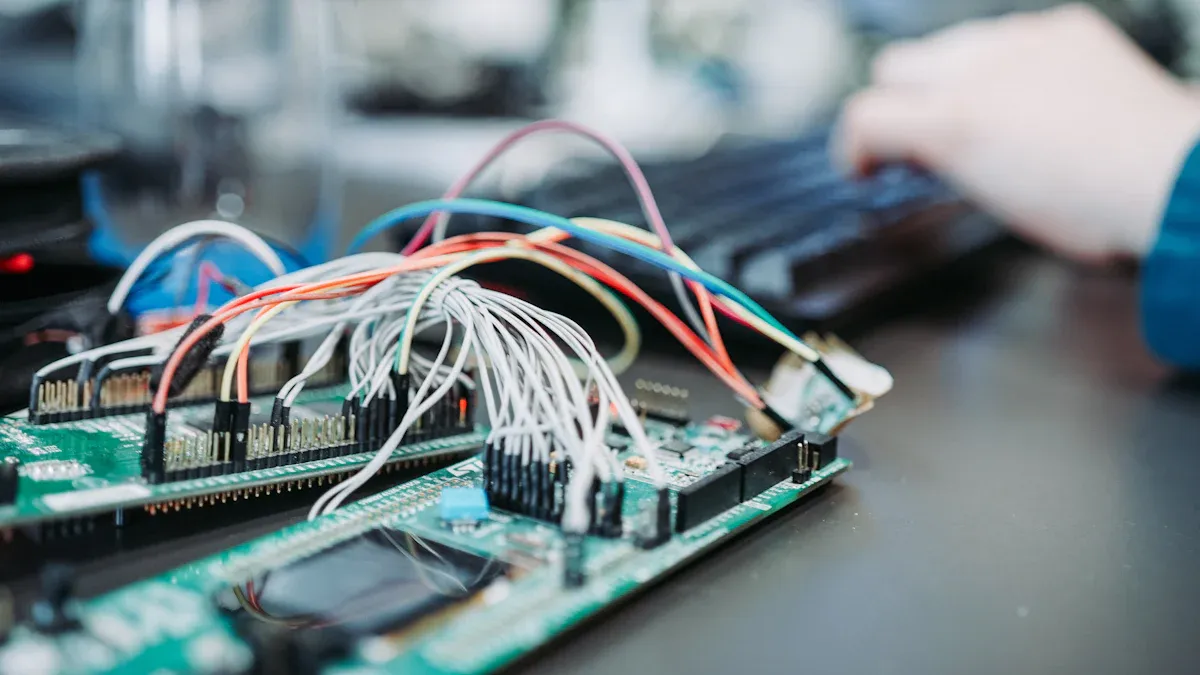

The Industrial Internet of Things (IIoT) uses connected devices in industries. These devices gather and share data to make work better. They help save money, improve efficiency, and keep things running smoothly. Unlike regular IoT, which is for everyday use, IIoT focuses on industries like factories, transport, and energy. For example, sensors in a factory can check machines in real time. This helps find problems early before they cause big issues.

The IIoT market has grown quickly over the years. In 2021, it was worth over $263 billion. By 2028, it may grow to more than $1 trillion. This shows how much industries depend on IIoT to improve. Factories and shipping companies are spending billions on these technologies. About 58% of manufacturers say IoT is key for digital change. As more industries use IIoT, making sure these systems are safe and reliable is very important.

The Concept of Quality Assurance in IIoT

Quality assurance in IIoT checks if devices and systems work well. It ensures they meet safety and performance standards. Unlike regular checks, IIoT quality assurance focuses on connected systems. It tests hardware, software, and communication to ensure everything works together.

Reliability is a big part of quality assurance. It checks if a device works well over time. For example, it measures how often a device breaks or needs fixing. Quality checks how well a device works at one moment. Together, these checks make sure IIoT systems are safe and efficient.

Key Areas of Reliability | Description |

|---|---|

Definition of Reliability | The ability to work without failure under certain conditions. |

Quality vs. Reliability | Quality is short-term performance; reliability is long-term performance. |

Includes repair time, failure rates, and replacement chances. |

How IIoT Device Quality Assurance Services Work

IIoT quality assurance involves testing and monitoring to check system performance. These services make sure devices work well, connect properly, and follow industry rules. For example, they test networks, batteries, and communication systems like MQTT and Modbus.

Description | |

|---|---|

IIoT device and hardware network and battery | Checks network and battery reliability. |

Performance and energy efficiency | Tests how well devices work and save energy. |

Device data acquisition E2E testing | Ensures smooth data collection from start to finish. |

Field level communication | Tests communication systems like NB-IoT, LTE, and 5G. |

Communication protocols and standards | Checks systems like MQTT, Modbus, and CoAP. |

These services also use advanced tools like predictive maintenance and remote monitoring. Sensors in factories track things like temperature and pressure in real time. Remote systems watch important equipment to avoid problems. Predictive maintenance uses data to find issues early. This helps fix problems before they cause downtime.

Description | |

|---|---|

Sensor Deployment | Sensors track temperature, pressure, and other changes in real time. |

Remote Monitoring | Watches important equipment to avoid problems and reduce manual checks. |

Condition Tracking | Sensors collect data for quality checks and send alerts for issues. |

Predictive Maintenance | Uses data to find and fix problems early, saving time and money. |

Facility Management | Tracks resources to keep the environment safe and fix issues fast. |

Asset Tracking and Management | Helps manage equipment better and avoid extra costs. |

By using these processes, IIoT quality assurance keeps industries running smoothly. It ensures systems meet modern demands while cutting risks and costs.

Why Does IIoT Device Quality Assurance Matter?

Ensuring Reliability and Performance

IIoT systems help keep factories running without problems. These systems need to work well all the time. Quality assurance checks make sure devices meet standards and work reliably. They test hardware, software, and communication to find issues early.

For example, sensors watch factory machines in real time. If something goes wrong, fixes can happen right away. This lowers mistakes and keeps machines working. Sensors also spot problems early to stop breakdowns. When devices work properly, factories can focus on their goals without delays.

Preventing Failures and Downtime

Breakdowns and delays waste time and money. Quality assurance helps find risks before they cause trouble. Predictive systems study data to spot wear or dangers early.

Predictive systems stopped weather damage by reducing unplanned downtime.

Queensferry Crossing repairs were planned, avoiding sudden closures.

IoT HVAC systems warned about issues, allowing quick fixes.

Defects dropped from 15% to 5%, and downtime fell from 20% to 8%. Efficiency rose from 75% to 92%.

Using quality assurance services reduces problems and improves operations. These checks keep systems working well, even in tough situations.

Enhancing Safety and Compliance

Safety and rules are very important in factories. Quality assurance helps meet safety standards and follow rules. It uses set procedures and monitoring to ensure devices are safe and legal.

Example | Challenge | Solution | Results | Key Insight |

|---|---|---|---|---|

Improving Data Accuracy | Data errors across locations | Clear rules for managing data | Better rules improved data quality | |

Faster Problem Reporting | Slow reporting of issues | New steps for faster reporting | 40% faster reporting | Clear steps improved safety |

Better Inspection Results | Different practices during checks | Standard rules for inspections | 50% fewer inspection problems | Consistent rules improved compliance |

Focusing on safety and rules protects workers and the company’s name. IIoT systems with quality checks watch for dangers and send alerts. This creates a safer workplace and ensures factories follow industry rules.

Why Is IIoT Device Quality Assurance Important in 2025?

Growing Use of IIoT Systems

More industries are using IIoT systems every year. In 2023, the U.S. industrial IoT market was worth $108.58 billion. Experts say it will grow by 18.6% each year until 2030. This shows how industries like factories and shipping depend on IIoT to work better. The need for services like setup and support is also increasing fast.

As more devices join industrial networks, quality checks are crucial. Hardware is the biggest part of the IIoT market. Reliable sensors and automation tools are very important. Without good quality checks, these systems might fail. This could cause expensive problems in factories or warehouses.

Handling Complicated Industrial Work

Factories are getting more complex. IIoT systems must manage quick communication, changes, and power use. For example, real-time communication collects data and makes decisions fast. Systems adjust to network changes with dynamic reconfiguration. Power management helps batteries last longer.

Evidence Type | Description |

|---|---|

Real-time Communication | Collects data and makes decisions quickly. |

Dynamic Reconfiguration | Adjusts to changes in network conditions. |

Power Management | Saves energy to make devices last longer. |

Security Measures | Protects systems with passwords and encryption. |

Quality checks make sure these systems work well. They help avoid problems like slow communication or hacking. This keeps your operations running smoothly.

Rapid Changes in IIoT Technology

IIoT technology is improving very quickly. Digital tools in industries like machinery are advancing faster than others. For example, digital tools in machinery improve 39.7% faster than in medicine. These fast changes mean industries must keep up to stay competitive.

Studies show digital tools are improving in areas like healthcare, cars, and energy. These advancements make IIoT systems stronger but harder to manage. Quality checks help handle this complexity. They ensure new tools fit into your systems and keep them reliable as they change.

The Role of Predictive Maintenance in 2025

Predictive maintenance helps keep factory systems working well. It uses live data to check machines and predict problems early. Fixing issues before they grow big saves money and time. In 2025, this will be even more important as factories depend more on IIoT systems.

The advantages of predictive maintenance are huge. It can cut repair costs by 38% and lower upkeep expenses by 10-30%. Companies using smart tools have seen production improve by 10-15%. They also report a 4-5% increase in profits. These gains show how it saves money and boosts performance.

New IIoT technology makes predictive maintenance better than ever. Smart programs study sensor data to find patterns and predict failures. For example, a factory can track machines and plan repairs early. This stops breakdowns and keeps work moving smoothly.

The market for predictive maintenance is growing fast. It will rise from $5.9 billion in 2024 to $7.1 billion in 2025. That’s nearly 20% growth in one year. This shows why using predictive tools is key to staying ahead. With IIoT and predictive maintenance, factories can work better and avoid risks.

In 2025, predictive maintenance will be a must for factories. It uses IIoT, data, and AI to make systems smarter and more reliable. By focusing on this, factories can improve performance and succeed long-term.

Key Parts of IIoT Device Quality Assurance

Testing and Validation

Testing checks if IIoT devices work well in different situations. It looks at hardware, software, and communication systems to keep them reliable. Testing includes things like wireless networks, sensors, and cloud systems. For example:

Check if networks connect quickly and stay reliable.

Make sure sensors collect correct data and work properly.

Test cloud systems to handle and sync data smoothly.

Check machine learning tools for accurate predictions and decisions.

Test user interfaces and APIs to ensure they work well.

Testing also solves problems like different device types, tricky networks, and limited resources. By focusing on these, you can find weak spots, make devices easier to use, and follow rules.

Following Standards

Following industry rules is important for IIoT device quality. Standards like IEC 62443 give steps to build safe and reliable systems. For example:

Standard | What It Does |

|---|---|

IEC 62443-4-1 | Helps design secure products from the start. |

IEC 62443-3-3 | Gives tips for system backup and staying online. |

Following these rules keeps devices safe, secure, and working well. It also avoids legal trouble and builds trust with users.

Real-Time Monitoring and Fixing

Real-time monitoring helps keep IIoT systems running smoothly. Sensors collect live data to check equipment and spot problems early. For example, systems can find worn-out parts before they break. Remote tools let you watch operations from anywhere, cutting down on manual checks.

Examples include checking CO2 levels in factories or tracking pollution. These tools make work more efficient and eco-friendly. They also prevent sudden breakdowns by giving alerts and maintenance tips. A strong data system ensures your devices can handle more work while giving useful insights.

Using real-time monitoring helps reduce costs, avoid downtime, and keep factories running smoothly.

Predictive Maintenance and Analytics

Predictive maintenance uses smart tools and live data to keep machines working. Sensors gather details about how equipment is performing. This information helps spot problems early, stopping breakdowns before they happen. Fixing issues early saves money and makes machines last longer.

Data analysis is a big part of this process. Smart systems study patterns to find risks and predict repairs. For example, if a machine vibrates oddly, the system warns you to check it. This way, your equipment stays dependable and works better.

Monitoring is also very important in predictive maintenance. Sensors watch things like heat, pressure, and energy use all the time. These updates help you act fast and stop small problems from growing. For instance, tracking energy use can show waste, helping you save money and improve efficiency.

Predictive tools also boost quality checks. By studying long-term data, you can find ways to improve and lower risks. Real-time quality measures show how well your fixes are working. Adding predictive maintenance to quality checks ensures your systems stay top-notch.

Using predictive maintenance makes machines more reliable and helps you improve constantly. With sensors, monitoring, and smart tools, you can stay ahead while cutting risks and costs.

Benefits of Focusing on IIoT Device Quality Assurance

Making Operations Run Better

Focusing on IIoT quality assurance helps factories work smoothly. Sensors give live data to track production and spot problems. Fixing issues quickly keeps everything running well. For example, smart tools can find why problems happen and help reduce waste.

Systems like MES (Manufacturing Execution Systems) are also helpful. They follow production steps and check important measures like OEE (Overall Equipment Effectiveness). Using IIoT tools makes work faster, meets quality rules, and improves results.

Some key benefits are:

Watching production in real time to fix problems fast.

Finding mistakes early to avoid bigger issues.

Using smart tools to solve problems and improve processes.

Cutting Downtime and Saving Money

Quality checks for IIoT devices lower downtime and repair costs. Predictive maintenance uses live data to find problems before they get worse. This stops sudden breakdowns and helps machines last longer.

Here’s how quality assurance helps:

Metric | Improvement Percentage |

|---|---|

Less Machine Downtime | |

Fewer Unexpected Failures (first year) | 45% |

Lower Maintenance Costs | 25-30% |

Fewer Breakdowns | 70-75% |

Reduced Downtime Costs | 35-45% |

Higher Production Levels | 20-25% |

Better Productivity | 25% |

Using IIoT tools for maintenance saves money and keeps work moving without delays.

Making Workplaces Safer

Good quality checks make factories safer and more reliable. Collecting data about accidents helps find risks and stop them. Watching trends over time shows where improvements are needed. This creates a safer place to work.

Smart decisions based on data improve safety. Reporting systems let workers share problems, helping find patterns and fix them. Root Cause Analysis (RCA) finds why accidents happen and prevents them in the future.

Steps to improve safety include:

Collecting data about accidents to find risks.

Using risk indicators to predict problems.

Watching trends to fix repeated issues.

By focusing on safety, you protect workers and build trust in your factory.

Supporting Sustainable Practices

Caring for the environment is now a global focus. Using IIoT device quality assurance helps industries lower their environmental impact. It also supports eco-friendly actions. Improved IIoT systems let industries track and use resources wisely. This leads to smarter and greener ways of working.

In the U.S., industries create about 7.6 billion tons of waste yearly. Greenhouse gas emissions from energy and factories have grown by 6.2% as the economy improves. These facts show the need for better solutions. IIoT helps solve these problems. For example, automated tools save energy by cutting waste. Smart sensors help manage trash by spotting recyclable items.

Evidence | Description |

|---|---|

94% of decision-makers | Believe IIoT boosts sustainability efforts. |

72% of companies | Plan to spend more on IIoT for its eco benefits. |

IIoT systems also track harmful gas emissions accurately. This helps meet environmental rules and cut pollution. Sensors give live data to check energy use and find waste. Fixing these issues saves money and lowers your carbon footprint.

Here’s how IIoT helps the environment:

Emissions Reduction: Track and reduce harmful gases.

Energy Conservation: Stop wasting resources with smart systems.

Waste Management: Use sensors to improve recycling.

By using IIoT device quality assurance, you help create a cleaner world. These systems make work more efficient and protect the planet for the future.

IIoT quality assurance helps factories stay reliable and work better. It checks systems to keep them running smoothly and safely. By 2025, as industries use smarter IIoT tools, quality checks will be even more important. For instance, IIoT sensors collect data to improve factory tasks. Edge computing processes this data faster for quicker decisions.

Key Area | How It Helps Factories |

|---|---|

Improving Factory Tasks | Sensors gather data to predict problems and avoid delays. |

Overseeing Remote Work | Monitoring systems check quality at different factories, making supply chains better. |

New Technology | Edge computing speeds up data use, helping factories work faster and smarter. |

Focusing on quality assurance keeps you ahead, reduces risks, and strengthens your business. The success of IIoT depends on keeping high standards.

FAQ

What is the difference between IIoT and IoT?

IIoT is for industries like factories and energy systems. IoT connects everyday items like smartwatches and home devices. IIoT focuses on safety, reliability, and efficiency for big operations.

How does predictive maintenance save money?

Predictive maintenance finds problems early using live data. Fixing small issues stops bigger repairs and downtime. This saves money and makes machines last longer.

Why is real-time monitoring important for IIoT systems?

Real-time monitoring checks equipment instantly to find problems fast. It prevents breakdowns and improves how things work. Sensors give live updates, cutting the need for manual checks.

What standards should IIoT devices follow?

IIoT devices must follow rules like IEC 62443. These rules ensure systems are safe, reliable, and well-designed. Following them avoids legal trouble and builds user trust.

How can IIoT support sustainability?

IIoT tracks energy use and reduces waste. Smart tools improve recycling and lower pollution. Using IIoT helps industries meet eco-friendly goals.

See Also

Ensuring Quality And Reliability Through PCBA Functional Testing

The Importance Of Dell Inc’s PCBA Testing In Today’s Market

Improving Quality Control Measures Within The PCBA Process

The Significance Of PCBA Cleanliness For Reliable Performance