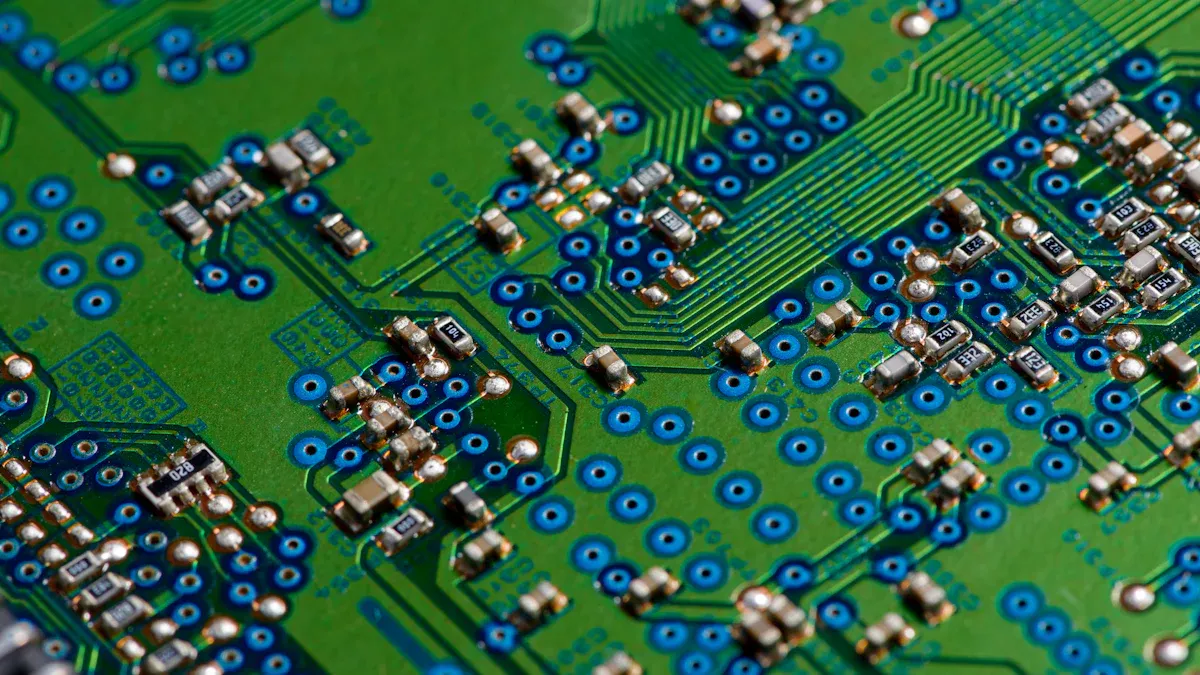

Switching to a lead-free PCBA manufacturing process in 2025 is required. Governments and industries now have stricter rules like RoHS. These rules ban dangerous materials in electronics. Lead-free materials follow the rules and are safer for people and nature. Circuit boards produced through a lead-free PCBA manufacturing process help reduce toxic waste and pollution. This change supports global efforts to protect the planet. It also matches new eco-friendly trends in manufacturing. By making this switch, you help the Earth and meet industry rules.

Key Takeaways

Changing to lead-free PCBA manufacturing follows global rules like RoHS. These rules protect people’s health and the planet.

Lead-free materials lower pollution and keep workers safer. This makes your factory better for the environment and more responsible.

Updating tools and methods for lead-free soldering improves product quality. It also saves money over time by working more efficiently.

Testing and checking are important to make sure solder joints work well. This helps customers trust your products.

Working with suppliers who follow RoHS rules makes switching easier. It also ensures you get good materials for your products.

The Importance of a Lead-Free PCBA Manufacturing Process

Environmental and Health Benefits of Lead-Free Manufacturing

Switching to lead-free PCBA helps people and the planet. Lead is harmful and can pollute soil, water, and air. Removing lead reduces pollution and keeps nature safe. Workers in factories also stay healthier. Lead exposure can cause serious health issues like brain damage.

Studies prove RoHS rules cut harmful waste materials. For example, lead in EU waste dropped by 20% after RoHS. Cadmium and mercury levels also fell by 63% and 56%. These changes show how lead-free manufacturing helps both health and the environment.

Regulatory Compliance with RoHS and Global Standards

Following RoHS rules is key to staying competitive. RoHS ensures products meet strict global standards. This allows sales in places like the EU and California. Breaking these rules can lead to fines or losing market access.

RoHS has improved safer manufacturing worldwide. Reports show it cuts lead pollution and protects workers. Using RoHS parts also opens doors to eco-friendly buyers. It ensures safety and boosts your product’s market reach.

Benefit | Description |

|---|---|

Environmental Protection | Cuts lead pollution in soil, air, and water, helping nature and health. |

Worker Health Protection | Keeps workers safe from lead-related health problems during production and recycling. |

Market Access | RoHS compliance is needed to sell in the EU and California, growing your market. |

Industry Shifts Toward Sustainable PCB Manufacturing Processes

The industry is moving fast toward greener PCB methods. Big companies like Samsung and Apple are leading this change. By 2033, 20% of circuit boards may use eco-friendly methods. These include dry etching and low-heat soldering. They help the planet and work more efficiently.

Lead-free soldering has also improved a lot. For example, first-pass ICT yields can reach 80% to 90%. This shows lead-free methods are reliable and effective. As more companies go green, adopting these practices now keeps you ahead.

Steps to Transition to a Lead-Free PCBA Manufacturing Process

Evaluating Current PCB Manufacturing Processes

Before switching to a lead-free PCBA process, check your current setup. This helps find problems and areas to improve. For example, mixing leaded and lead-free parts can cause issues. You should see if your factory can handle two production lines. This is important for military and nonmilitary products and may affect suppliers.

Another issue is tin whiskers, which can grow unpredictably. These tiny metal strands can harm electronic parts during the change. By reviewing your process, you can fix these risks early. This makes the switch to lead-free soldering easier.

Tip: Carefully review your production steps to spot where lead-free materials might mix with leaded ones. This avoids contamination and keeps you within RoHS rules.

Selecting Lead-Free Materials and Components

Picking the right lead-free materials is key for success. Lead-free solder has been tested and works well for circuit boards. Studies show it performs as good as or better than tin/lead solder. Most problems during the switch come from how it’s made, not the solder itself.

Choose materials that follow RoHS rules and last a long time. Lead-free solder resists rust and wear, making joints stronger. Work with suppliers who focus on RoHS-compliant parts to make this step easier.

Key Tips for Choosing Materials:

Make sure they fit your current assembly process.

Test lead-free solder to check its reliability.

Pick parts that lower the chance of tin whisker growth.

Upgrading Equipment for Lead-Free Soldering

Switching to lead-free soldering means updating your tools. Lead-free solder melts at higher temperatures, so your equipment needs precise heat control. It also must stay stable under high heat.

Requirement | Description |

|---|---|

Accurate Temperature Control | Lead-free solder needs exact heat settings due to higher melting points. |

Stable Heat Levels | Tools must stay steady to handle lead-free soldering well. |

Long-lasting Tools | Lead-free solder resists rust, making joints stronger and more durable. |

Many factories have upgraded their tools for lead-free soldering. For example, a group in New England showed zero defects using the right tools. Better soldering equipment helps meet RoHS rules and improves your circuit board quality.

Note: Upgrading your tools not only supports lead-free soldering but also makes your production faster and greener.

Adjusting Reflow and Soldering Processes for Lead-Free Solder

Switching to lead-free soldering needs careful changes to your process. Lead-free solder melts at higher heat than tin-lead solder. This means circuit boards need exact heat control to avoid mistakes. Setting the right reflow profile is key for strong solder joints.

Key Process Changes:

Preheat Phase: Slowly warm the PCB to remove flux gases. This also stops sudden heat damage and gets the board ready for higher temperatures.

Reflow Phase: Here, the solder paste melts and forms strong joints. Keep the heat rise between 1°C and 1.5°C per second. This keeps the flux working and avoids oxidation.

Cooling Phase: Cool the board slowly to stop cracks from fast cooling. Aim for a cooling rate of 1.5°C to 6°C per second to keep joints strong.

Extra Tips for Better Results:

Use smaller solder powder particles for better flux action.

Avoid slow heat rises under 1°C per second to stop oxidation.

Use a profiler to check heat and time during reflow. This tool helps you find the best settings for each board.

By adjusting these steps, you can reduce mistakes and make soldering more reliable.

Tip: Check your reflow oven often to keep heat steady. This helps make better circuit boards and lowers errors.

Testing and Validating Lead-Free PCB Assemblies

Testing is very important in lead-free PCBA production. It checks if your boards are good quality and work well. Lead-free soldering needs stricter checks, so testing is even more important.

Main Testing Methods:

Automated Optical Inspection (AOI): Use cameras and AI to find solder mistakes, misplaced parts, and surface problems. AOI gives quick feedback to fix issues early.

X-ray Inspection: Check hidden solder joints in tricky parts like BGAs. X-rays show inside problems you can’t see with your eyes.

In-Circuit Testing (ICT): Test electrical parts for short circuits, open circuits, and correct values. ICT makes sure boards work as planned.

Functional Testing: Test how the product works in real-life conditions. This includes power tests, signal checks, and firmware tests.

Quality Checks:

Use Statistical Process Control (SPC) to track production and spot problems.

Apply Six Sigma to lower mistakes and aim for less than 0.1% defects.

Do Root Cause Analysis (RCA) to fix problems and stop them from happening again.

By using smart tools and strict tests, you can make sure your lead-free boards are reliable.

Note: Testing proves your boards are high quality and builds customer trust by delivering dependable products.

Challenges and Solutions in Lead-Free Manufacturing

Managing Higher Reflow Temperatures for Lead-Free Solder

Switching to lead-free soldering means dealing with higher heat levels. Lead-free solder melts at 217°C to 230°C. This is much hotter than tin-lead solder. The extra heat can harm circuit boards and parts. Boards may bend or get damaged during production.

To fix this, adjust your reflow oven settings carefully. Make a heat plan that fits your PCB. Slowly heat the board during the preheat stage to avoid damage. Use advanced ovens with many heat zones. These ovens spread heat evenly and protect sensitive parts.

Another fix is using materials that handle high heat. Pick PCBs with strong laminates and heat-safe parts. Work with suppliers to get RoHS-compliant materials. These steps help you manage high heat challenges better.

Tip: Check your reflow oven often to keep heat steady. This stops overheating and reduces mistakes.

Ensuring the Reliability of Lead-Free Solder Joints

Lead-free solder joints can sometimes crack or break easily. This happens because lead-free solder is less flexible than tin-lead solder. Stress can make joints brittle or weak.

To make joints stronger, improve your soldering process. Use flux made for lead-free soldering. It helps solder stick better and fills gaps. Apply solder paste evenly to avoid weak spots. Try solder with silver or copper added. These metals make joints tougher and less brittle.

Testing is very important for strong solder joints. Use X-rays to find hidden problems in joints. Do heat tests to see how joints handle temperature changes. These tests show weak spots and help you fix them.

Note: Strong solder joints keep your circuit boards working well. Focus on quality checks to make better products.

Addressing Component Compatibility and Availability

Switching to lead-free PCBA can cause problems with parts. Some parts don’t work with lead-free solder. Finding RoHS-compliant parts can also be hard.

To solve this, work closely with your suppliers. Make sure all parts follow RoHS rules and work with lead-free solder. Keep a list of trusted suppliers for steady part supply. If a part is unavailable, redesign your PCB to use other parts.

Plan for possible delays in getting parts. Keep extra stock of important parts to avoid stopping production. Track your materials to use them wisely and avoid waste.

Tip: Partner with suppliers who focus on RoHS-compliant parts. This makes your switch to lead-free soldering easier.

Cutting Costs When Switching to Lead-Free Processes

Switching to lead-free soldering might seem costly at first. But with smart planning, you can save money and manage costs well.

Look at Long-Term Savings

Switching to lead-free soldering needs new tools and materials. These upfront costs can save money later. Lead-free solder lasts longer and needs less fixing. It also follows rules like RoHS, so you avoid fines and sales bans.

A study shows U.S. electronics companies risk losing $240 billion in three years if they delay. Acting now avoids losses and helps your business grow globally.

Tip: Think about the long-term gains of lead-free soldering. Following global rules can open new markets for your products.

Improve Production Steps

Making your production process better can cut waste and costs. For example, fine-tuning reflow settings for lead-free solder saves energy and improves results. Using modern ovens with exact heat control lowers mistakes and fixes.

You can also use lean manufacturing to spot wasteful steps. By cutting extra steps and improving workflows, you save time and money.

Work with Suppliers

Team up with suppliers who focus on RoHS-compliant materials. They can offer bulk discounts on lead-free parts, saving you money. Building good supplier relationships ensures you get quality parts on time. This avoids delays in production.

Note: Choose suppliers who focus on lead-free materials. This makes switching easier and cheaper.

Train Your Team

Teaching your workers about lead-free soldering prevents errors. Lead-free soldering needs careful handling because it melts at higher heat. Training helps your team learn these details, improving quality and cutting waste.

You can hold workshops or bring in experts for hands-on lessons. Skilled workers make fewer mistakes, saving money over time.

Learn from Others

Small businesses are leading the way in using lead-free methods. They show that affordable solutions are possible. By studying their methods, you can find ways to save money. Industry reports and case studies can teach you how to improve lead-free soldering.

Tip: Keep up with industry trends to find smart ways to save money during the switch.

Best Practices for Effective Implementation of Lead-Free Processes

Training Staff on Lead-Free PCBA Manufacturing Processes

Your team is key to lead-free soldering success. Training helps them learn the special needs of lead-free methods, like higher melting points and exact heat control. Start with workshops to teach handling lead-free solder and setting reflow profiles. Hands-on practice helps workers get used to new tools and skills.

Let your team practice soldering on circuit boards. This builds their confidence and lowers mistakes during production. You can also bring in experts to share tips and best practices. A trained team reduces waste, improves quality, and meets RoHS rules.

Tip: Make simple guides and charts for your team. These can be quick reminders during work.

Collaborating with RoHS-Compliant Suppliers

Working with trusted suppliers makes switching to lead-free soldering easier. Suppliers who focus on RoHS-compliant parts give you high-quality materials that follow the rules. Building good relationships with these suppliers ensures you always have the parts you need, avoiding delays.

Here are some examples:

Case Study | Description |

|---|---|

ESCATEC | Solved problems meeting RoHS and other rules. |

Dedicated Computing | Used a green platform to improve compliance. |

IMI plc | Teamed up with Assent to meet customer ESG needs. |

These stories show how teamwork helps meet compliance and eco-friendly goals.

Note: Check your suppliers often to make sure they stay RoHS-compliant and keep quality high.

Implementing Robust Quality Assurance Measures

Quality checks are very important for good PCB assembly. Use smart testing tools to find and fix problems early. Automated Optical Inspection (AOI) spots solder mistakes and misplaced parts. X-ray inspection finds hidden issues in tricky parts like BGAs.

In-Circuit Testing (ICT) checks if parts work properly, while functional testing ensures products perform well in real-life situations. Combine these with Statistical Process Control (SPC) to track trends and cut down on errors.

Using Six Sigma methods helps you aim for fewer than 0.1% defects. Root Cause Analysis (RCA) fixes repeating problems and keeps improving your process. These steps make your lead-free PCBs more reliable and build trust with customers.

Tip: Use live data tracking to quickly spot and fix issues. This boosts efficiency and saves time.

Optimizing Inventory Management for Lead-Free Materials

Managing inventory well is very important for lead-free PCBA. You need a system to keep enough RoHS-compliant materials without wasting money. Good inventory management stops delays and helps follow RoHS rules.

Use Vendor Managed Inventory (VMI)

Vendor Managed Inventory (VMI) lets suppliers handle stock levels. Suppliers track inventory and predict what you’ll need. This prevents running out of parts or having too many. Suppliers use real-time data to refill materials, keeping your stock balanced.

Tip: Work with suppliers who focus on RoHS-compliant parts. They make inventory easier and ensure high-quality materials.

Analyze Inventory Data

Watching inventory data helps you make smart choices. Use software to check supplier performance, spending, and stock levels. Stick to trusted suppliers to save money and avoid problems. Don’t buy from random vendors, as it can lead to higher costs and rule-breaking.

Statistic | Description |

|---|---|

Total number of vendors | Count of all suppliers you work with. |

Number of vendors per product group | List of suppliers based on product types. |

Dollars spent per vendor | Amount spent with each supplier. |

Dollars spent per product group | Money spent on different product categories. |

Dollars spent with preferred vendor | Spending focused on trusted suppliers. |

Maverick purchases | Buying outside of approved supplier agreements. |

OEM purchases | Items bought directly from Original Equipment Manufacturers. |

Price variances between OEM and MRO | Cost differences between OEM and Maintenance, Repair, and Operations items. |

Price variances through a preferred vendor | Price comparison between trusted suppliers and others. |

Price variance between preferred and non-preferred vendors | Cost differences between trusted and random suppliers. |

Plan for Demand Fluctuations

Lead-free materials can face supply chain issues. Predict demand carefully to avoid running out. Use past data and market trends to plan ahead. Keep extra stock of key parts to avoid stopping production.

Note: Check your inventory plan often to adjust for supplier changes or market shifts.

By managing inventory better, you make switching to lead-free easier. You save money, work faster, and meet global rules.

Switching to lead-free PCBA manufacturing helps your business and the planet. Lead-free soldering makes products more reliable and safer for health. It also lowers harm to nature. Tin-silver-copper alloys create strong solder joints but cost more due to silver. Tin-zinc-bismuth alloys are cheaper and still work well.

Eco-friendly laws are growing, making RoHS rules important for global success. In Japan, companies use lead-free soldering to attract buyers. This shows how green manufacturing can boost sales. Using lead-free methods keeps you competitive and supports a cleaner future.

Tip: Begin by working with RoHS-compliant suppliers and managing lead-free materials better. These steps make switching easier and save money.

FAQ

1. Why is lead-free soldering important for PCBA manufacturing?

Lead-free soldering helps the planet and keeps people safe. It follows rules like RoHS, making products meet world standards. Switching to lead-free methods prepares your business for the future and supports eco-friendly trends.

2. What are the main challenges of switching to lead-free soldering?

Lead-free solder melts at higher heat and can crack easily. Some parts may not work well with lead-free solder. Fix these issues by upgrading tools, using strong materials, and testing carefully. Working with RoHS-compliant suppliers makes the change easier.

3. How do I ensure the reliability of lead-free solder joints?

Improve your process for better results. Use special flux for lead-free solder and spread solder paste evenly. Check solder joints with X-rays and heat tests to find weak spots. Good quality checks make solder joints strong and dependable.

4. Can lead-free soldering increase production costs?

At first, yes. Buying new tools and lead-free materials costs more. But over time, you save money by fixing fewer mistakes and following rules. Better inventory planning and smarter production steps also lower costs.

5. How can I train my team for lead-free PCBA manufacturing?

Teach your team with hands-on lessons and practice sessions. Show them how to handle lead-free solder and set heat levels correctly. Use charts and guides to help them remember key steps. A trained team makes fewer mistakes and works faster.

Tip: Train a small group first, then teach the rest of the team for a smoother switch.

See Also

Best Practices for Achieving Quality and Efficiency in PCBA

Emerging Trends in PCB and PCBA Design and Manufacturing

An In-Depth Overview of PCBA Manufacturing Procedures