Motion control PCB assembly means adding circuit boards to systems that move machines. These boards act like the “brain” that controls how machines move. They help manage position, speed, and acceleration with great accuracy. This technology is very important in industries like making semiconductors, where precise movement is needed. For example:

Bigger wafer sizes are increasing the need for precise systems.

Factories made 8% more 300mm wafers in 2023.

78% of new machines now work with 300mm or bigger wafers.

Motion control parts make up 22-25% of costs for advanced tools.

These improvements show how motion control PCB assembly helps make things better and faster in many areas.

Key Takeaways

Motion control PCBs work like the ‘brain’ of machines. They control speed, position, and movement for accurate actions.

These PCBs are important in industries like factories, healthcare, and robots. They make work faster and more precise.

Picking the right motion control PCB means checking if it works well in hard conditions and handles quick tasks.

New ideas like using AI and eco-friendly designs are changing how motion control PCBs are made.

Motion control PCBs save money and grow with businesses, making them a smart choice.

What is Motion Control PCB Assembly?

Definition and Purpose

Motion control PCB assembly means creating and adding PCBs to systems. These systems control how machines move by managing speed and position. The PCBs work like a “control center,” sending signals and commands. This ensures machines move accurately and efficiently.

Think of these PCBs as the “brain” of motion control. They calculate distances, adjust speeds, and manage slowing down or speeding up. For example, they can store many movement instructions in their memory. This helps them handle complex tasks without using too much computer power. The result is smooth and fast machine control, even in tough situations.

One special feature is their ability to change motions super quickly. They can switch in less than a microsecond, keeping operations smooth. This is very helpful for systems that need to control multiple movements at once. From factory robots to medical tools, motion control PCB assembly is key for accuracy and dependability.

Key Features of Motion Control PCB Assembly

Motion control PCB assembly has advanced features that make it very useful. These features are important for modern motion control systems:

High-Speed Processing: These PCBs handle fast tasks without slowing the main computer. This keeps machines working well, even in tricky jobs.

Continuous Multi-Axis Control: They can smoothly control movements in different directions at once. This is needed for robots and CNC machines.

Environmental Adaptability: Special materials like ceramic or halogen-free ones make them last longer. They work well even in tough conditions.

Signal Integrity Assurance: Features like special wiring reduce signal problems. This ensures reliable communication in fast systems.

Thermal Management: Cooling designs, like copper or graphene pads, prevent overheating. This helps the PCBs last longer and work better.

Hardware-Based Switching: They can change motion frames in under a microsecond. This keeps operations running without stopping.

Compact and Scalable Design: These PCBs are small but can be expanded for more uses. They fit in many devices, from factory machines to gadgets.

Tip: When choosing a motion control PCB, check if it works well in tough environments. Also, see if it can handle fast tasks. These things affect how well your system performs.

Motion control PCB assembly combines speed, accuracy, and flexibility. Its features help machines work well, even in hard conditions. Whether building a robot or automating a factory, these PCBs are essential for reliable motion control.

How Does Motion Control PCB Assembly Work?

Components of Motion Control PCB Assembly

Motion control PCB assembly uses key parts to make machines move well. These parts work together to control how machines and systems move.

Motion control board: This is the main part that controls motion. It has microcontrollers or processors to calculate speed, position, and acceleration.

Servo motors: These motors turn electrical signals into exact movements. They are important for tasks like robotics and CNC machines that need accuracy.

Motion controller: This device acts like the “brain,” managing the board and motors. It keeps movements smooth and in sync across different directions.

Sensors: These include tools like encoders and switches that check speed and position. They help avoid mistakes and keep movements accurate.

Power supply units: These give energy to the system, keeping it stable. They make sure the system works well, even with heavy use.

Each part is important for making a motion control system work smoothly and reliably.

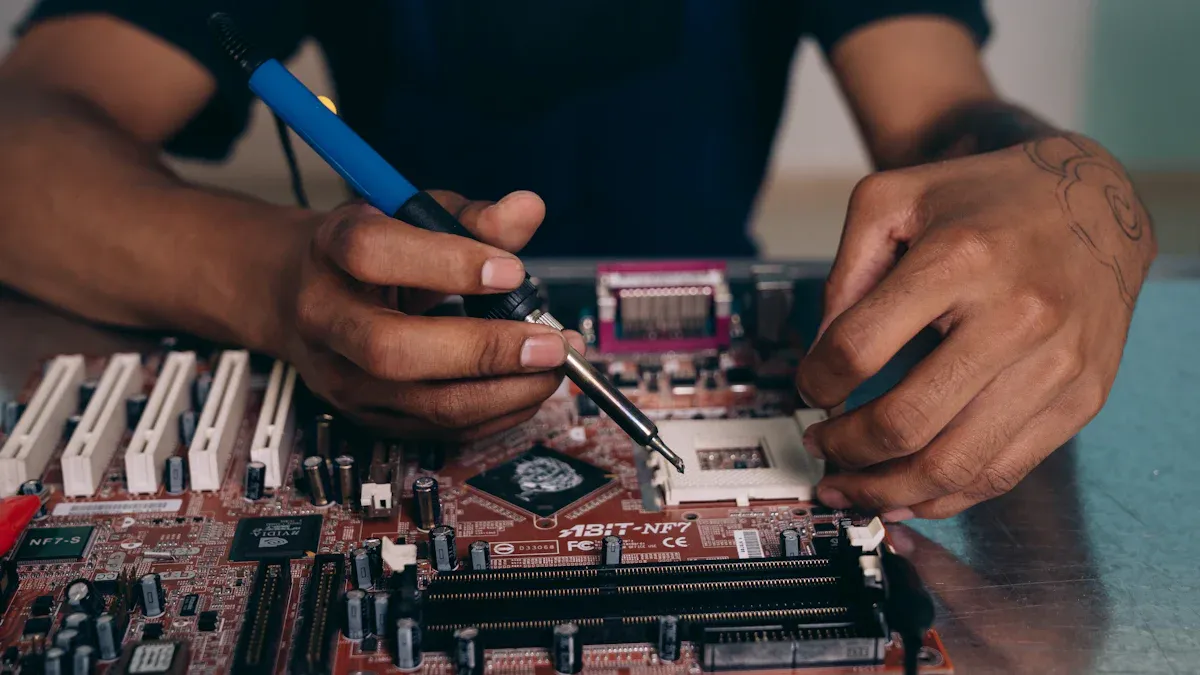

The Assembly Process

Making motion control PCBs involves steps to ensure they work well. First, engineers design the board using special software. This helps improve signal flow and cooling.

Next, machines place parts like microcontrollers and resistors onto the board. These machines work fast and accurately, saving time and reducing mistakes. Robots often help by organizing parts, making the process even quicker.

After placing the parts, the board is soldered to hold everything in place. Methods like reflow soldering create strong connections without overheating the board. Finally, the board is tested to make sure it works and lasts a long time.

Integration with Motion Control Systems

Connecting motion control PCBs to systems involves linking them to motors and sensors. The motion controller sends commands to the PCB, ensuring smooth movements.

For example, in a robotic arm, the PCB reads sensor data and tells the motors what to do. This lets the arm complete hard tasks with great accuracy. Engineers use materials like ceramic and cooling pads to make the system stronger. These materials help it work well in tough conditions.

This process makes sure all parts work together, creating a dependable motion control system.

Applications of Motion Control PCB Assembly

Motion control PCB assembly is important in many industries. It helps machines work accurately and efficiently by controlling speed, position, and acceleration. Here are some key ways it is used.

Industrial Automation

In factories, motion control PCBs help machines run smoothly. They are used in tasks like packaging, material handling, and assembly lines. These PCBs make machines repeat tasks with fewer mistakes, improving speed and quality.

Closed-loop systems are becoming popular, controlling over 65% of the market.

Electric drives, linked with IoT, hold about 25% of the market.

Material handling leads the market with a 50% share, showing its importance.

Using motion control PCBs speeds up production and improves quality. They are a must-have for modern factories.

Robotics and AI

Robots and AI depend on motion control PCBs to do hard jobs. These PCBs help robots move precisely, like assembling parts or navigating warehouses. They also allow quick adjustments for safe and smooth operations.

Dusty Robotics uses advanced drives for accurate construction bots.

Healthcare robots rely on motion control for surgeries and patient care.

Robotic grippers and wheels use PCBs for safe handling and smooth movement.

As AI improves, robots with motion control PCBs are solving more problems in different fields.

Automotive and Transportation

Motion control PCBs are changing how vehicles work. From electric cars to self-driving systems, they ensure precise and reliable control.

Example Use Case | Evidence Type |

|---|---|

Performance Data | |

Emergency stop systems improve vehicle safety. | Safety Analysis |

Driving tests check how well systems perform. | Performance Data |

SLAM and UWB tech help vehicles locate themselves accurately. | Performance Data |

Mapping systems boost accuracy and reliability. | Safety Analysis |

MQTT protocol ensures smooth system communication. | Safety Analysis |

Automated driving in factories saves time and money. | Performance Data |

These examples show how motion control PCBs are making transportation safer and more efficient.

Medical and Healthcare Devices

Motion control PCBs are very important in medical tools. They help devices move accurately, which is needed for reliable results. You can find them in machines like surgical robots, scanners, and medicine pumps. These PCBs control speed, position, and movement to ensure tasks are done precisely.

For example, in surgeries, robotic arms use these PCBs to move exactly as needed. This reduces mistakes and helps patients recover better. In MRI and CT scanners, PCBs help place parts correctly. This gives clear pictures for doctors to use.

Medicine pumps also use these PCBs to control how medicine flows. This makes sure patients get the right amount at the right time. Wearable devices like insulin pumps and heart monitors also rely on these PCBs. They keep these devices working smoothly and for a long time.

These PCBs can handle tough conditions, like sterile or high-pressure areas. Their small size lets them fit into tiny devices without losing any features. This makes them a key part of today’s healthcare technology.

Consumer Electronics and Smart Devices

Motion control PCBs are behind many cool features in gadgets. They are used in things like phones, smartwatches, and home devices. These PCBs make sure movements are smooth and devices work well.

As smart gadgets grow, smaller and better PCBs are needed. Companies now use flexible and advanced designs instead of old rigid ones. This helps make smaller devices with more features.

For example, your smartwatch tracks steps or your phone camera stays steady. These features work because of motion control PCBs. They read sensor data and adjust parts like motors quickly. This keeps everything running smoothly.

Motion control PCBs also connect with IoT devices, like smart homes or health trackers. They ensure strong connections and fast data processing. New manufacturing methods, like automation, make these PCBs better and easier to customize. This helps create special PCBs for things like 5G phones or electric cars.

PCB designs are changing to fit modern gadgets.

Smart devices need smaller, high-performing PCBs.

IoT gadgets depend on PCBs for strong connections.

Research is helping create better PCBs for the future.

These changes show how motion control PCBs improve everyday devices. From making phones better to powering IoT gadgets, they are shaping the future of technology.

Benefits of Motion Control PCB Assembly

Precision and Accuracy in Motion Control

Motion control PCBs help machines move with great precision. They control speed, position, and acceleration accurately. This is very important for robots and medical tools. Closed-loop systems check sensor feedback and fix errors instantly. This makes tasks like robotic surgery or chip-making very reliable.

These PCBs also manage movements across multiple axes at the same time. For example, CNC machines use them to make smooth and perfect cuts. Advanced signal technologies keep communication steady during fast operations. This ensures machines work well, even on hard jobs.

Enhanced Efficiency and Performance

Motion control PCBs make systems work faster and better. Closed-loop systems save energy by adjusting motor speeds as needed. This lowers energy waste and helps parts last longer. Cooling designs stop overheating, keeping machines running at their best.

Machines respond quicker because of hardware-based switching. Commands are processed in microseconds, keeping operations smooth. This is useful for industries like cars and robots, where speed matters. Better efficiency and performance mean more work gets done in less time.

Cost-Effectiveness and Scalability

Motion control PCBs save money, especially in large-scale production. Making many units lowers costs while keeping quality high. Automation reduces the need for workers, cutting labor costs. This makes the technology affordable and easy to scale.

Evidence Type | Description |

|---|---|

Cost Efficiency | Producing many units lowers the cost per item. |

Long-term Savings | Savings grow over time, improving return on investment. |

Reduced Labor Costs | Automation replaces manual work, saving money on labor. |

Economies of Scale | Fixed costs spread across more units, lowering average costs. |

These PCBs can be adjusted for small gadgets or big machines. Their flexible design lets you expand without spending too much. This makes them a smart choice for growing businesses.

Versatility Across Applications

Motion control PCB assembly works in many industries. It is one of the most flexible technologies today. It handles different tasks, making it useful for manufacturing, healthcare, transportation, and energy systems.

These PCBs are made to fit the needs of each industry. For example, in car factories, they help robotic arms move accurately. In aerospace, they control parts like helicopter doors, working well in tough conditions. Medical devices also use motion control PCBs to manage pumps and testing tools.

Here’s how motion control PCB assembly is used in different industries:

Application | Industry | Description |

|---|---|---|

GST-40 Tandem | Automotive | Guides robotic arms for precise movements |

GS-8 to GS-70 | Aerospace | Controls helicopter doors under extreme conditions |

GZ-15 to GZ-40 | Medical | Manages pumps and testing systems |

HB-12 to HB-70 | Transportation | Operates container flaps smoothly |

PLM | Energy | Reduces vibrations in audio systems |

SCS33 to SCS64 | Manufacturing | Stops linear modules during emergencies |

Tip: Choose motion control PCBs that match your industry’s needs for better results.

These PCBs work in both big industrial machines and small gadgets. Whether you’re building a robotic arm or a medical pump, they offer the accuracy and dependability you need. Their ability to handle different conditions makes them valuable in many fields.

Emerging Trends in Motion Control PCB Assembly

Smaller and Smarter Designs

Devices are getting smaller and more efficient. This has led to the creation of tiny motion control PCBs. Engineers now make boards with more parts packed into less space. New technologies, like second-generation HDI PCBs, made this possible in the early 2000s. By 2017, pattern plating improved how circuits are made, making them stronger and more reliable. Today, optical interconnections aim to replace copper wires. This change makes PCBs even smaller and faster.

Year | New Technology | How It Helps |

|---|---|---|

Early 2000s | Second-generation HDI PCBs | Smaller parts and more compact designs |

2017 | Pattern plating | Better strength and reliability |

Now | Optical interconnections | Faster and smaller PCBs |

Smaller PCBs help make tiny devices that still work well. This is very useful for robots and gadgets where space is tight but performance matters.

AI and IoT in Motion Control

AI and IoT are changing how motion control works. AI helps find problems early and improves quality checks. IoT connects machines in smart factories, letting them talk to each other. This allows quick fixes and better automation. These tools are key for Industry 4.0, where smart factories are the future.

The motion control market may grow from $16.2 billion in 2023 to $26.45 billion by 2032.

Energy-saving designs and better manufacturing are speeding up this growth.

Robots and CNC machines use these tools to work more accurately and avoid mistakes.

Better Ways to Make PCBs

New methods are making PCB production faster and more precise. Robots and machines now handle most of the work, cutting costs and reducing errors. Advanced soldering keeps parts connected securely. AI chips inside PCBs improve how signals move and make boards smaller.

Faster production means less waiting time.

AI helps spot problems early, improving quality.

Built-in components make signals stronger and reduce issues.

These improvements make it easier to create powerful systems for today’s needs. With smarter designs and quicker production, motion control PCBs are ready for the future.

Focus on Sustainability and Green Energy Solutions

Motion control PCB assembly is changing to support eco-friendly goals. As industries go green, this technology helps reduce harm to the planet while staying effective.

Eco-Friendly Materials

Manufacturers now use safer materials for the environment. For instance, halogen-free laminates and biodegradable bases replace older ones. These choices cut down toxic waste and make recycling simpler.

Tip: Pick PCBs with certifications like RoHS to ensure they meet green standards.

Energy-Efficient Designs

New motion control PCBs are built to save energy. Engineers create circuits that use less power, cutting electricity costs and pollution. Features like low-power chips and better cooling systems help machines run efficiently.

Renewable Energy Integration

Motion control PCBs now work in renewable energy setups. They are used in wind turbines, solar trackers, and hydro plants. These PCBs control moving parts precisely, boosting energy production.

Renewable Energy Application | How Motion Control PCBs Help |

|---|---|

Solar Panels | Tilt panels for more sunlight |

Wind Turbines | Adjust blades for better energy capture |

Hydroelectric Systems | Control water flow for steady power |

Waste Reduction in Manufacturing

Making PCBs is now less wasteful. Automated systems cut material waste, and advanced soldering uses fewer chemicals. Recycling old PCBs also keeps waste out of landfills.

By using these green methods, motion control PCB assembly supports a cleaner world. You can help by choosing products that focus on saving energy and protecting the environment.

Motion control PCB assembly is important for making systems work accurately. It helps industries like factories, healthcare, and robotics do hard tasks well. These systems are used in many areas, from factory machines to medical tools. This shows how useful and dependable they are.

The motion control market might grow from USD 16.7 billion in 2024 to USD 25.3 billion by 2033. This growth is because of better automation and robotics.

New ideas in entertainment, factory systems, and robotics could make the market reach USD 17.59 billion by 2025, with a CAGR of 5.4%.

New trends, like using AI and eco-friendly designs, will change motion control PCB assembly. Using these new ideas can help you succeed in industries that need accuracy and speed.

FAQ

What is the main purpose of motion control PCB assembly?

Motion control PCB assembly helps machines move with precision. It controls speed, position, and acceleration. This ensures smooth operations for robots, medical tools, and factory systems.

How do motion control PCBs improve efficiency?

These PCBs process instructions fast and adjust motor speeds. This saves energy and improves performance. Cooling features stop overheating, keeping machines running smoothly.

Can motion control PCBs handle tough environments?

Yes, they can. Engineers use strong materials like ceramic and halogen-free laminates. These materials help PCBs work well in extreme, sterile, or high-pressure conditions.

What industries benefit most from motion control PCBs?

Industries like manufacturing, healthcare, robotics, and transportation use motion control PCBs. They improve accuracy, efficiency, and dependability in tasks like factory work and medical surgeries.

Are motion control PCBs eco-friendly?

Manufacturers now use safer materials and energy-saving designs. These PCBs also support renewable energy systems like solar panels and wind turbines, helping sustainability efforts.

Tip: Choose RoHS-certified PCBs to ensure they meet green standards.

See Also

Exploring The Essential Steps In PCBA Assembly Process

Unraveling The SMT Process In PCBA Assembly Production

A Comprehensive Overview Of PCBA Manufacturing Techniques