By 2025, Modbus communication PCBA products became more efficient and useful. They now allow faster data sharing and better dependability. This change improves how automation systems work. It also makes connecting Modbus communication PCBA devices simpler and reduces delays in factories.

Modbus is still popular in industrial automation because it is easy to use and flexible. By 2005, over 75% of new PLC setups used Ethernet communication. This trend grew with the rise of IoT. Modbus remains important for linking smart systems and automation tools, particularly through Modbus communication PCBA technology.

Key Takeaways

Modbus PCBA products now share data faster and work better.

Flexible boards and modular parts make connecting devices simpler.

AI tools and no-code options make setup easy for everyone.

Energy-saving designs and green materials lower costs and help the planet.

Picking products with Modbus RTU and TCP/IP works for all systems.

Key Innovations in Modbus Communication PCBA

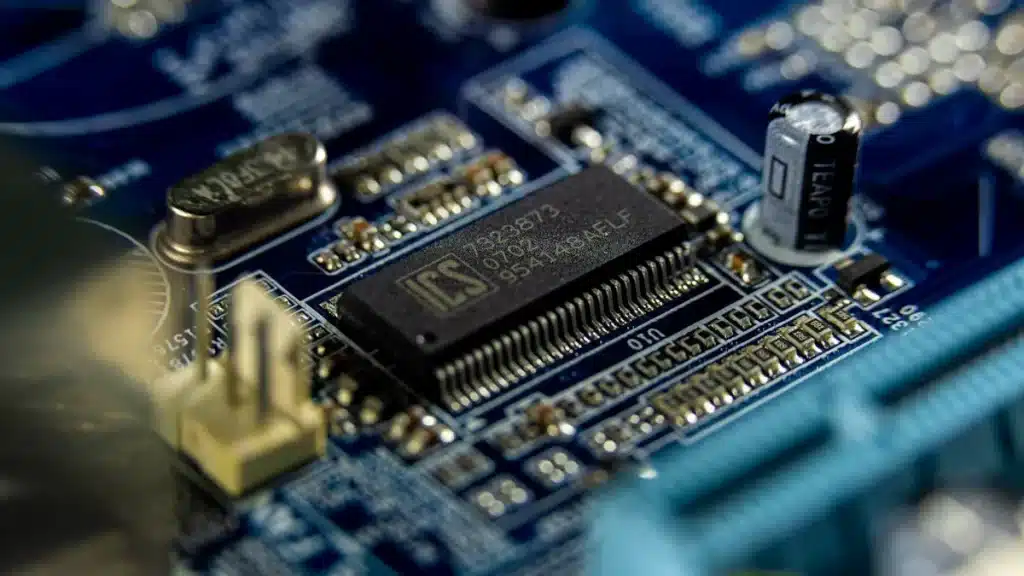

Hardware Upgrades and Flexible PCBs

Hardware changes have improved how Modbus communication PCBA works. Flexible PCBs are a big upgrade. They fit into small spaces while still working well. These PCBs are tough and handle movement or shaking better.

Manufacturers now make modular interfaces that work with CAN, Ethernet, and RS-485. This makes it easier for systems to talk to each other. Programmable controllers are also helpful. They let you update firmware to add new features, keeping devices ready for the future.

Testing ensures devices work with popular industrial tools. Protocol conversion gateways connect old systems to newer ones. These updates make Modbus communication PCBA faster and more useful for factories.

Integration of AI Tools and No-Code Solutions

AI tools make Modbus communication PCBA smarter. They check data to spot problems before they happen. This saves time and money by stopping breakdowns early. For example, AI watches machine temperature and vibration to warn about issues.

No-code tools make setup easier. You don’t need to know coding to use Modbus systems. Drag-and-drop tools help you create workflows and automate tasks quickly. This makes Modbus systems popular, even for small businesses.

AI and no-code tools also speed up decisions. They handle lots of data fast, helping factories react quickly to changes. These tools keep Modbus communication PCBA useful in modern automation.

Sustainability and Energy Efficiency Improvements

Modbus communication PCBA now focuses on saving energy. New parts use less power, cutting costs and helping the planet. Low-power processors and better circuits save energy without losing performance.

Eco-friendly PCB materials are recyclable and reduce waste. Strong connectors and durable PCBs last longer, even in tough conditions. This means fewer replacements, which helps the environment.

Energy tracking is another new feature. Modbus systems now measure energy use to find waste. Fixing these problems lowers energy use and improves system performance. These changes support global goals for greener factories.

Performance and Features of Modbus Communication PCBA

Speed and Data Transfer Enhancements

Modern Modbus PCBA products now send data much faster. Better circuits and advanced processors make this possible. Low-latency communication helps systems respond quickly, which is important for factories.

Manufacturers added modular interfaces that work with CAN, Ethernet, and RS-485. These interfaces let systems switch between protocols easily. Programmable controllers allow firmware updates to add new features. This keeps devices ready for future needs.

These upgrades make Modbus PCBA great for fast data sharing. Whether in factories or smart systems, these features ensure smooth communication.

Reliability and Error Handling Capabilities

Modbus systems are known for being reliable, and now they’re even better. New designs include tools to find and fix errors quickly. This reduces downtime and keeps systems running well.

Testing methods have improved too:

HALT testing runs for hours to find weak spots.

Big data and AI tools speed up testing and improve results.

These updates make Modbus PCBA dependable, even in tough conditions. Features like noise-blocking and opto-isolation keep communication clear in noisy places.

Compatibility with Modbus RTU and Modbus TCP Protocols

Modbus PCBA works with both Modbus RTU and Modbus TCP/IP. This means systems can connect using serial or Ethernet networks.

Modbus RTU is simple and good for low-cost setups. It’s great for basic data sharing. Modbus TCP/IP is faster and works well for IoT and smart systems.

Supporting both protocols makes Modbus PCBA future-ready. Old systems can connect with new ones without problems. This flexibility is useful for factories and other industries.

Scalability for Future Applications

Modbus communication PCBA products can grow with your needs. They are built to stay useful as technology changes. You can add them to bigger systems without replacing old parts.

A big feature is modular design. Modular interfaces let you add or remove parts easily. For example, you can switch between Modbus RTU and Modbus TCP/IP. This makes it simple to adjust to new setups or IoT systems.

Firmware updates are another benefit. Companies give updates to improve performance and add features. These updates keep devices working with new technology. Your system stays up-to-date and avoids becoming outdated.

Tip: Pick products that work with both Modbus RTU and Modbus TCP/IP. This helps connect old systems with modern networks.

Scalability also means handling more data. New Modbus PCBA products manage large data as systems grow. Better processors and circuits keep communication smooth in complex setups.

Lastly, these products support many devices at once. You can add more devices without losing performance. Whether growing a factory or building smart systems, Modbus PCBA products can scale to fit your needs.

Pricing and Value of Modbus Communication PCBA

Cost Analysis Across Leading Brands

Prices for Modbus PCBA products differ by features and brands. Top brands offer choices for various industrial needs and budgets. Modular designs and scalable features cost more but last longer. They save money by reducing the need for frequent upgrades.

Using open-source protocols like Modbus TCP/IP cuts licensing costs. This protocol allows fast and reliable data sharing in tough environments. Products with this protocol often give great value for their price, especially in factories and smart systems.

To choose wisely, compare upfront costs with long-term savings. Energy-efficient designs and strong materials may cost more at first. However, they lower running costs over time. Look for brands offering firmware updates and modular parts. These features make products last longer and adapt to new needs.

ROI and Long-Term Benefits for Industrial Automation

Buying Modbus PCBA products pays off over time. They improve automation by working well with current systems. Their support for Modbus RTU and Modbus TCP/IP ensures smooth communication. This reduces downtime and lowers maintenance costs.

Modbus TCP/IP’s open-source design saves money by removing licensing fees. Reliable data sharing and error-fixing tools keep systems running smoothly. Scalable designs also prepare for future growth, keeping your investment useful as tech changes.

Energy-saving designs help cut costs in the long run. They use less power, saving money and helping the environment. Durable materials and eco-friendly PCBs last longer, reducing replacements and waste.

To get the best ROI, pick products that match your needs. Modular designs and firmware updates help products stay flexible. Support for multiple protocols makes connecting to different systems easier. These features make Modbus PCBA a smart choice for industrial automation.

Applications of Modbus Communication PCBA

Role in Industrial Automation Systems

Modbus PCBA is important for industrial automation systems. It helps devices talk to each other easily. This ensures smooth control and monitoring. Modbus RTU is good for simple setups that cost less. Modbus TCP works faster and uses Ethernet for communication. These options make Modbus useful for many industries.

Here are some examples of its use:

A converter links old systems to modern networks.

Modbus supports IIoT by connecting devices for communication.

Modbus RTU and TCP meet needs like low-cost sharing or fast data.

These examples show how Modbus PCBA fits different industrial needs. It stays reliable and works with many systems.

Integration with IoT and Smart Infrastructure

Modbus PCBA is helpful for IoT and smart systems. It connects old setups with new technologies. Sensors, controllers, and devices can share data in one network.

The table below shows key improvements:

Feature | Details |

|---|---|

Data Sharing | |

Simulation Integration | Virtual PLC platform linked with real PLC device. |

New Communication Module | Created for easy data collection and storage. |

Reliability Testing | Checked using advanced simulators. |

These updates prove Modbus PCBA supports IoT and smart systems. It ensures clear and fast communication.

Emerging Use Cases in Energy and Manufacturing

Energy and manufacturing industries use Modbus PCBA in new ways. It handles complex tasks and large data well. It tracks energy use to find waste and save money. This helps meet eco-friendly goals.

In factories, Modbus connects machines and sensors. It allows real-time checks and predicts problems early. These features boost productivity and reduce delays.

Using Modbus PCBA improves industrial systems. It helps businesses stay competitive and efficient.

By 2025, Modbus communication PCBA products became much better. They now send data faster, use less energy, and work more reliably. These upgrades make them perfect for factories and IoT systems. They easily connect old and new devices, offering great flexibility and performance.

To pick the right product, think about what you need. Check for features like modular parts, support for Modbus RTU and TCP, and firmware updates. Reading reviews can help you compare choices. Use this information to find a product that fits your budget, works well, and stays useful for the future.

FAQ

What is Modbus communication PCBA, and why is it important?

Modbus communication PCBA is a circuit board that helps devices talk. It uses the Modbus protocol to share data between machines and sensors. This makes it very useful for running factories and smart systems smoothly.

How does Modbus communication PCBA support scalability?

Modbus communication PCBA grows with your needs. Its modular design lets you add or remove parts easily. It works with both Modbus RTU and TCP, so it fits old and new systems.

Can Modbus communication PCBA work with eplan software?

Yes, it works with eplan software. This software helps you plan and design automation systems. You can see how Modbus PCBA connects with other parts for better results.

What makes Modbus TCP different from Modbus RTU?

Modbus TCP uses Ethernet, so it’s faster and great for IoT. Modbus RTU uses serial connections, which are cheaper for simple setups. Modbus PCBA supports both for more flexibility.

How does Modbus communication PCBA improve energy efficiency?

It uses low-power processors and energy-saving circuits. It also tracks energy use to find waste. These features save power and help the environment, making it a good choice for green factories.