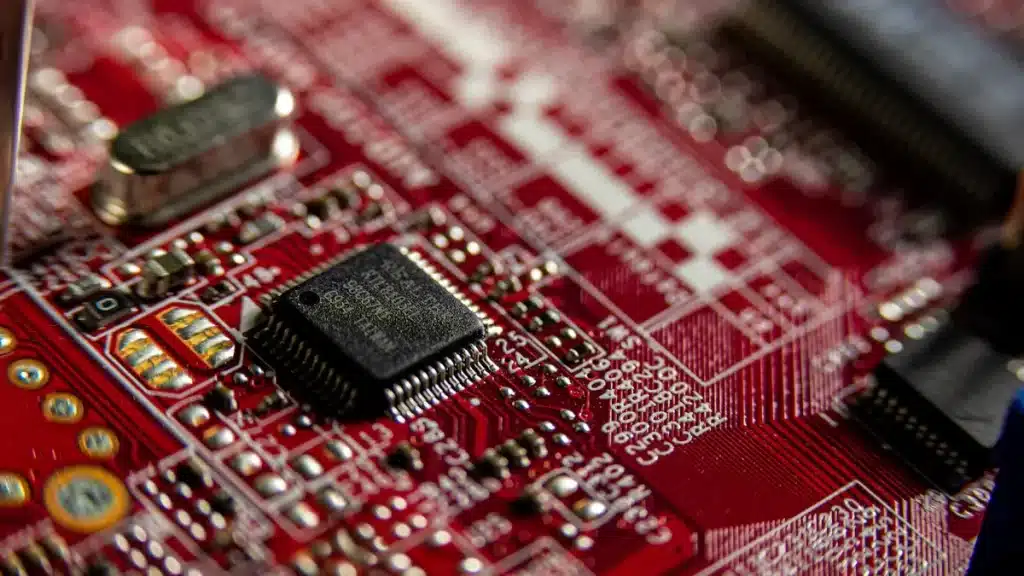

In 2025, ClearSignal Pro-X becomes the best among industrial signal conditioning boards. It works well, fits many systems, and saves money. This board is great for accurate signal tasks in tough places. Experts focused on four things: how it works, system fit, price, and lasting quality.

Key Takeaways

ClearSignal Pro-X is the best pick for 2025 because it works well and saves money.

Always look at how well it reduces noise and stays steady when choosing a signal board.

Make sure it works with your current systems to save time and avoid setup problems.

Think about future costs like fixing and upgrading to choose a board that’s worth the money.

Pick a board with features like auto-calibration and sturdy design so it lasts in hard conditions.

Evaluation Criteria for Industrial Signal Conditioning Boards

When picking signal conditioning boards, you should check key factors. These help ensure the board works well and fits your needs. The main things to consider are how it performs, if it’s compatible, and its cost.

Performance

Performance is the most important part of a signal board. A good board processes signals clearly and stays stable in tough conditions. Tools like amplifiers and ADCs help reduce noise and improve accuracy. This is very useful for systems that collect data.

Boards with filters can make performance even better. Filters block noise from different frequencies, like the common 50/60 Hz interference. Shielding and routing techniques also keep signals clean by blocking outside noise. Self-calibration features fix issues caused by heat changes, keeping the board steady over time.

Some boards use digital tools to improve signals even more. These tools, like adaptive filtering, make the board great for advanced tasks. Whether you use strain gauge boards or others, performance should always be your focus.

Compatibility

Compatibility means the board works well with your current setup. A board that connects easily saves time and effort during installation. You need to check both hardware and software compatibility.

Hardware compatibility ensures the board handles the right inputs and outputs, like voltage or current. It also needs to fit your system’s size and power limits. Software compatibility means the board follows industry rules, so it works smoothly with other devices.

Here are some common tests to check compatibility:

Test Type | What It Does |

|---|---|

Jitter Tests | Checks timing issues to keep data accurate at high speeds. |

Amplitude Tests | Makes sure voltage levels are correct for good signal flow. |

Timing Tests | Confirms signals move fast enough to stay accurate. |

Receiver Sensitivity | Tests if the receiver can handle bad conditions and still work. |

Circuit Board Tests | Looks at how wires affect signal quality, like loss or interference. |

These tests help you pick a board that fits your system and works reliably.

Cost-Effectiveness

Cost-effectiveness means balancing price and performance. Fancy boards have extra features but may not be needed for your work. You should check if the board is worth its price.

Start by looking at the upfront cost of the board. Then think about long-term costs, like repairs, updates, or calibration. A good board keeps these costs low while working well. For example, boards with self-calibration save time and money by needing fewer adjustments.

Scalability also matters for saving money. Boards that handle more channels or future upgrades mean you won’t need new equipment later. Picking a scalable board is smart because it grows with your needs over time.

Reliability

Reliability means the board works well for a long time. It should handle tough conditions without breaking or losing accuracy. When picking a board, check how strong and dependable it is.

Key Metrics for Reliability Testing

Tests measure how often boards fail and how stable they are. Engineers use numbers to show how reliable a board is. These numbers help you see if the board lasts and works well.

Metric | What It Shows |

|---|---|

How many boards fail compared to the total tested. | |

FITS | Defects counted per billion hours of use. |

DPM | Defects counted per million boards. |

Confidence Interval | A math method to predict failure rates with limited tests. |

These tests give clear data about how often boards might fail.

Common Reliability Tests

Companies test boards to make sure they meet industry rules. These tests copy real-world conditions to find weak spots. Here are some common tests:

Operating Life: Checks how long the board works under normal use.

High Temperature Operating Life (HTOL): Tests the board at high heat for a long time.

Preconditioning (Precon): Prepares the board for harder tests by simulating real conditions.

Biased Highly Accelerated Stress Test (HAST): Tests the board in extreme heat and humidity with added electrical stress.

Temperature Humidity Bias (THB): Checks how the board handles hot and wet environments.

These tests make sure the board works well in tough situations.

Design Features That Enhance Reliability

Good boards have smart designs to avoid problems and stay steady. Look for these features when choosing a board:

Self-Calibration Circuits: Fix issues caused by heat or aging automatically.

Differential Signal Routing & Shielding: Blocks noise to keep signals clean.

Multi-Stage Filtering Design: Removes noise from signals for better clarity.

High-Precision Amplifiers & ADCs: Makes signal processing more accurate.

Boards with these features work better and last longer in hard jobs.

Long-Term Reliability Considerations

Reliability also means staying accurate and stable for years. Boards that grow with your needs often perform better over time. Features like real-time systems and smooth data flow keep them fast and efficient.

When checking reliability, think about both short-term and long-term use. Boards that pass tough tests and have smart designs will work well for important tasks.

Top Signal Conditioning Modules in 2025

Board A

Board A is very flexible and easy to use. It works with many input types, like voltage, current, or resistance. This makes it great for different data systems. Its filters remove noise, giving clear and accurate signals.

This board can grow with your needs. You can add more channels later, making it future-ready. Its small size fits well in most setups. If you need a board that adapts easily, Board A is a top choice.

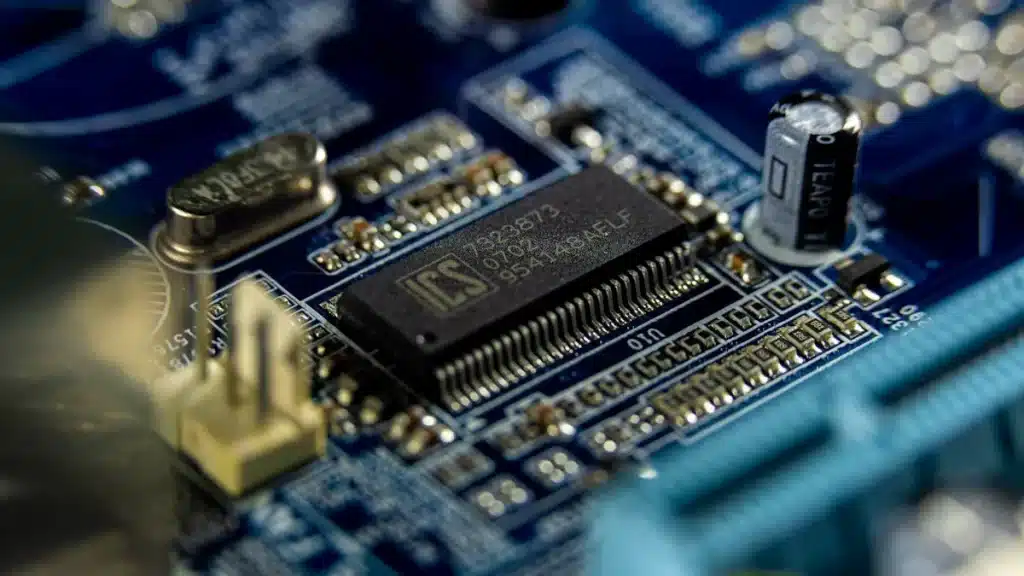

Board B

Board B is strong and handles tough environments well. It’s perfect for hard industrial jobs. Engineers tested it to meet high durability and performance standards.

Here are some test results for Board B:

Test Type | Standard | Frequency Range | Vibration Intensity | Duration |

|---|---|---|---|---|

Random Vibration (Operating) | MIL-STD 202G, Method 214A | 50-2000Hz | 7.56 Grms | 10min/axis (X, Y, Z) |

Shock (Operating) | MIL-STD-810F, Method 516.5 | N/A | 11ms | |

Swept Sine Vibration (Operating) | MIL-STD-810G, Method 514.6 | 10-2000Hz | 5Gp-p | N/A |

These tests show it works well in extreme conditions. Its shielding and signal routing reduce interference. If you work in high-stress places, Board B is a reliable pick.

Board C

Board C is a good choice if you want to save money. It works well for basic tasks like temperature or strain gauge signals. Even though it costs less, it has features like self-calibration and noise filters.

This board is great for small or medium data systems. It’s easy to set up and works with standard protocols. If you need a budget-friendly board that still performs well, Board C is a smart option.

Side-by-Side Comparison of Signal Conditioning Boards

Performance Metrics

When picking signal boards, performance is very important. Each board handles signals differently, depending on its purpose. Board A is great for precise tasks. It uses special amplifiers and ADCs to give clear, detailed readings. This makes it perfect for systems needing accurate data.

Board B is built for tough conditions. It has filters that block noise from many frequencies. These include filters that stop 50/60 Hz interference. Its design also blocks outside noise, keeping signals clean in busy setups.

Board C is cheaper but still works well for simple jobs. It has self-calibration to fix heat-related issues. This keeps it steady and reliable over time, even in basic setups.

Compatibility Features

Compatibility shows how well a board fits your system. Board A is very flexible. It works with voltage, current, and resistance inputs. Its small size makes it easy to install in most setups.

Board B is made for heavy-duty use. It meets strict industry rules and works with other devices easily. Its strong hardware handles high power, and its software supports fast data communication.

Board C has basic compatibility for simple systems. It works with common protocols and fits smaller setups. While it lacks advanced features, it’s good for easy tasks.

Cost Analysis

Cost matters when choosing signal boards. Board A balances price and features. You can add more channels later, saving money on upgrades. It’s a smart pick for long-term projects.

Board B costs more but is worth it for tough jobs. It lasts longer and needs less fixing, saving money over time. If you work in hard conditions, Board B is a solid investment.

Board C is the cheapest option. It has the basics without extra features. This makes it great for small budgets and simple tasks. Its low cost and easy upkeep make it a good choice for smaller projects.

Reliability Factors

Reliability is key for signal conditioners to work well over time. Reliable boards lower downtime, avoid expensive fixes, and keep signals accurate in tough places. To check reliability, focus on things that affect how long the board lasts and how it performs.

Environmental Durability

Signal conditioners often face harsh conditions in factories or plants. Look for boards that handle heat, humidity, and vibrations. Special coatings protect circuits from water and dust. Strong cases keep parts safe from damage. Boards tested in high heat or stress show they can survive hard environments.

Tip: Always review a board’s environmental ratings before buying. Durable boards work better in unpredictable situations.

Failure Rates and Longevity

Good boards fail less and last longer. Makers share numbers like FITS (failures in time) or DPM (defects per million) to show reliability. Boards with self-fixing circuits and layered filters last longer. These features fix problems caused by aging or tough conditions.

Design Features That Enhance Reliability

Smart designs make boards more reliable. Routing signals differently reduces noise and keeps data clean. Precise amplifiers and ADCs improve signal quality. Shielding blocks interference from outside sources. These features help boards work better and last longer.

Real-World Testing

Reliable boards go through tough tests to copy real-life conditions. Vibration and shock tests check if boards can handle physical stress. Heat and humidity tests show how boards perform in extreme weather. Test results help you find boards that meet industry rules.

Long-Term Stability

Reliability also means staying steady over time. Boards with adaptive filters and real-time systems keep data flowing smoothly. Boards that grow with your system stay reliable as your needs change.

Note: Spending more on a reliable board now saves money later. It reduces repair costs and keeps your system running without problems.

By focusing on these factors, you can pick boards that work well for years. Whether you’re in a busy factory or running a small setup, reliable boards keep your system efficient and steady.

Expert Recommendations for Signal Conditioning

For High-Performance Needs

If you need precise and stable signals, pick high-performance boards. These boards keep signals clean and block interference. Look for features like isolation, low noise, and special filters.

Isolation stops ground loop problems that mess up data.

Low noise keeps signals clear and easy to read.

Anti-aliasing filters block unwanted high-frequency signals.

Features like high accuracy and protection improve performance.

For example, Dataforth’s SCM5B modules are great options. They have very low noise and ripple, keeping signals accurate. Models like SCM5B32 and SCM5B39 match original signal levels, keeping data quality high. Their six-pole filters block high-frequency noise, avoiding distortion. These features make them perfect for advanced industrial jobs.

For Budget-Conscious Buyers

If you’re on a budget, choose boards that balance cost and features. Focus on boards that do basic tasks well without extras. Self-calibration and noise filters are must-haves to save money and time.

Board C is a good example of an affordable and useful board. It works with standard systems and smaller setups. Its self-calibration feature reduces the need for manual fixes, saving effort and money. If your tasks are simple, this type of board is a smart choice.

For Long-Term Reliability

For lasting reliability, pick boards tested for tough conditions. Boards that pass durability and reliability tests work better over time.

Testing Method | Purpose |

|---|---|

Shows how tests relate to reliability and warranty costs | |

Accelerated Life Testing (ALT) | Predicts lifespan and finds weak spots in the lab |

Other tests, like vibration and static discharge tests, check if boards handle harsh environments. Features like adaptive filters and real-time systems also help boards stay reliable. These boards reduce downtime and last longer, making them worth the investment.

Tip: Spending more now on a reliable board can save repair costs later.

ClearSignal Pro-X is the best industrial signal conditioning board in 2025. It offers great performance, works with many systems, and saves money. This board is also reliable and lasts a long time. It’s perfect for jobs needing accuracy, strength, or future upgrades.

Tip: Think about what you need before choosing a board. Check your budget, system fit, and future plans. The best board will work now and grow with your needs.

FAQ

What does signal conditioning mean, and why is it needed?

Signal conditioning cleans and prepares signals for use. It removes noise, boosts weak signals, and changes them into useful forms. Without it, systems might read data wrong, causing mistakes in industrial work.

How can I pick the best signal conditioning board?

Think about what your system needs. Check if it fits, works well, and lasts long. If money is tight, choose boards with key features like self-calibration and noise removal.

Can signal conditioning boards survive tough conditions?

Yes, many boards are made for hard environments. Look for ones with strong covers, special coatings, and proof they handle heat and shaking.

Are pricey boards always the best choice?

Not always. Expensive boards may have extras you don’t need. Match the board to your job to get the right mix of cost and features.

How often should I adjust my signal conditioning board?

Boards that adjust themselves need less fixing. For others, follow the maker’s advice or check them once a year to keep them accurate.