Monitoring vibration in circuit boards is essential for early problem detection. Tools such as piezoelectric sensors, MEMS accelerometers, and laser Doppler vibrometers are effective in detecting harmful vibrations. These tools ensure that vibration monitoring circuit boards remain stable and help prevent failures. For instance, piezoelectric sensors excel in high-frequency environments, while MEMS accelerometers are compact and cost-effective. Each tool caters to various requirements, including accuracy, size, or scalability. Choosing the appropriate tool for vibration monitoring circuit boards safeguards electronics and extends their lifespan.

Key Takeaways

Watching vibrations is important for circuit boards. It finds issues early and stops expensive problems.

Pick the best tool for your needs. Piezoelectric sensors are very accurate, and MEMS accelerometers are cheaper and easy to use.

Skipping vibration checks can cause big damage. Even tiny shakes can make circuit boards break fast.

Checking conditions helps circuit boards last longer. It lets you fix things before they break, avoiding surprises.

Think about price, accuracy, and where it will be used when choosing vibration tools.

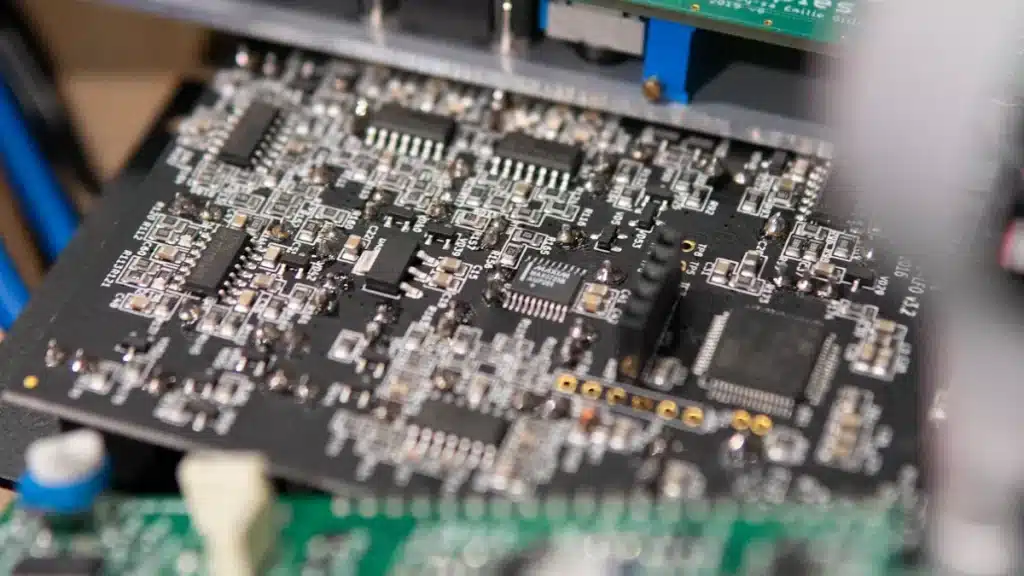

Importance of Vibration Monitoring Circuit Boards

Risks of Ignoring Vibration Monitoring

Skipping vibration monitoring can cause big problems for circuit boards. Even small vibrations can make printed circuit boards (PCBs) fail. For example, studies show that just 0.1 g²/Hz of vibration can cause a PCB to fail in only 16 hours. Over time, constant vibrations can turn small issues into permanent damage.

Dynamic forces, like those from bumpy roads, can reach 0.208 g²/Hz. These forces can bend PCBs, breaking parts and causing them to stop working. Solder joints, especially PBGA ones, are weak against constant shaking. This can lead to cracks, product failure, and expensive fixes.

Not watching for vibrations also risks sudden breakdowns. If a circuit board fails without warning, it can stop work and cost a lot to fix. Ignoring vibration monitoring puts your systems in danger and shortens their life.

Benefits of Condition Monitoring for Circuit Boards

Condition monitoring has many benefits for circuit boards. It helps find problems early so they don’t get worse. Tools like accelerometers and piezoelectric sensors can spot harmful vibrations right away. This lets you fix issues before they become costly.

Another benefit is predictive maintenance. With condition monitoring, you can tell when a part might fail and plan repairs. This prevents surprise breakdowns and keeps systems running smoothly.

Data proves condition monitoring works. For example, bottom-filled solder joints last over 338,000 hours, while regular ones last only 19,500 hours. This shows how monitoring makes circuit boards last longer.

Using condition monitoring tools makes your systems more reliable and saves money on repairs. It’s a smart way to protect your equipment and keep it working well for a long time.

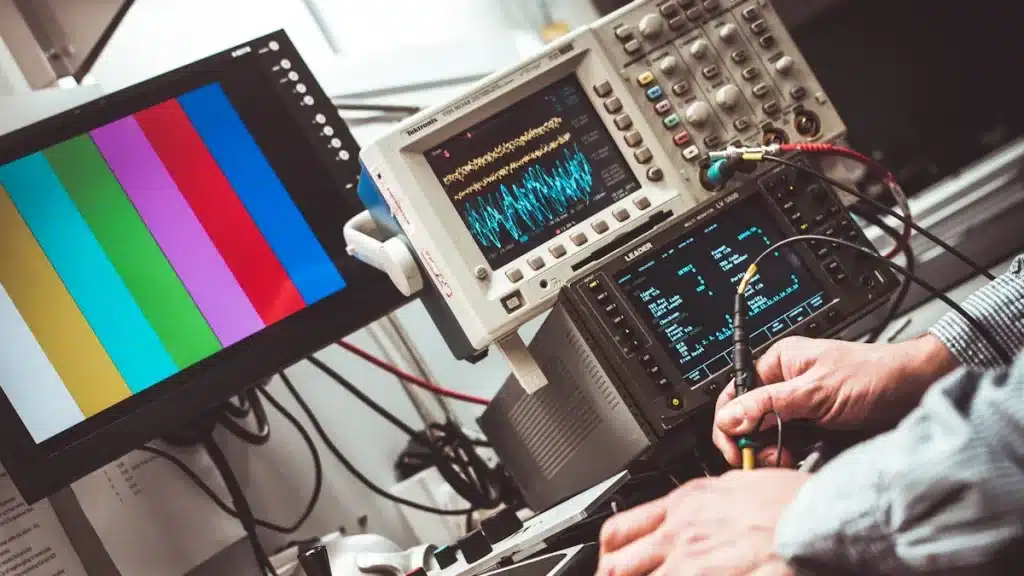

Technologies for Vibration Monitoring Circuit Boards

Piezoelectric Sensors

Piezoelectric sensors are great tools for checking vibrations in circuit boards. They turn mechanical stress into electrical signals to find tiny vibrations. These sensors can measure many frequencies, helping with accurate vibration checks.

They work well in places with high-frequency vibrations. For example, they measure vibrations from 180 to 60,000 cycles per minute. Their resolution is 0.005 inches per second, and they are very precise with only ±1% error. They also work in extreme temperatures, from -40 to 185 °F, making them useful in tough conditions.

Specification | Value |

|---|---|

0.0 to 1 in/sec pk (0.0 to 25.4 mm/s pk) | |

Output | 4-20 mA |

Frequency Range | 180 to 60000 cpm (3 to 1000 Hz) |

Broadband Resolution | 0.005 in/sec pk (0.13 mm/s pk) |

Non-Linearity | ±1 % |

Temperature Range | -40 to 185 °F (-40 to 85 °C) |

Settling Time | <15 sec |

Weight | 4.7 oz (131 gm) |

These sensors are small and fit into tight spaces on circuit boards. They are less than 0.2 mm thick and use very little power, about 10 µA. They can also stick to curved surfaces, making them flexible and easy to use.

Feature | Description |

|---|---|

Thickness | 0.2 mm or less |

Size | 2.5 × 7.0 mm |

Sensitivity | Detects displacement to the 1 µm level |

Power Consumption | Approximately 10 µA |

Flexibility | Can be attached to curved surfaces |

Using piezoelectric sensors helps you find problems early. They allow for detailed vibration checks and predictive maintenance. This reduces the chance of failures and unexpected downtime.

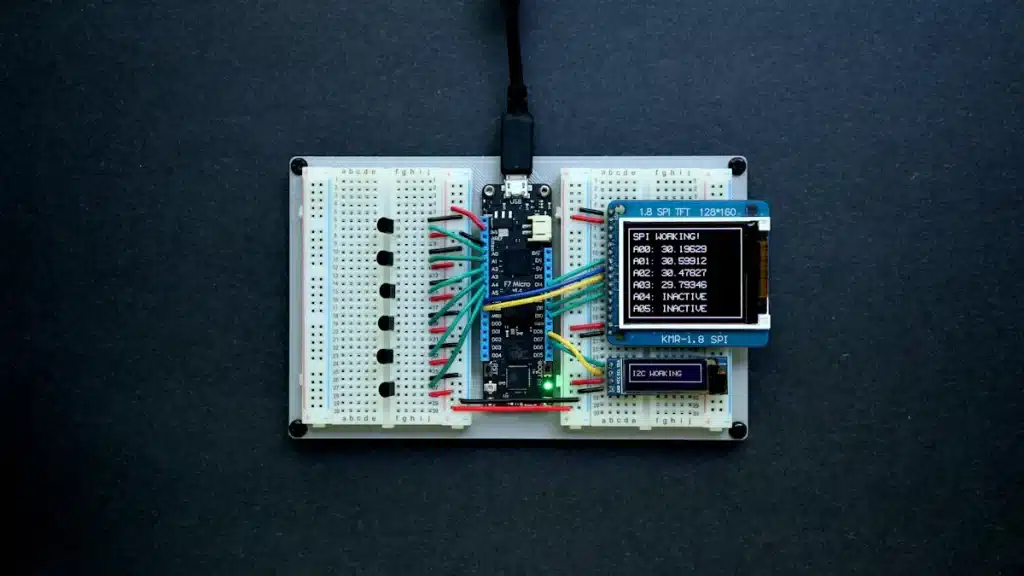

MEMS Accelerometers

MEMS accelerometers are small, light, and affordable tools for vibration monitoring. They measure vibrations by sensing changes in motion, giving accurate data. These sensors are great for places with limited space or budgets.

Tests show MEMS accelerometers work well in real-world conditions. They are accurate and reliable even when exposed to strong vibrations. This makes them a good choice for tracking vibrations in circuit boards. Their ability to mimic working conditions ensures trustworthy data for maintenance planning.

MEMS accelerometers can be scaled up easily. You can use many sensors together to monitor different parts of a circuit board. This helps you find problems early and avoid failures. MEMS accelerometers are a smart option for improving vibration monitoring systems.

Laser Doppler Vibrometers

Laser Doppler Vibrometers (LDVs) measure vibrations without touching the circuit board. They use lasers to detect motion, making them useful when contact isn’t possible. LDVs are very sensitive and can find even tiny vibration problems.

Studies show LDVs are effective for vibration checks. They use a kurtosis ratio (KR) to spot signal issues. A KR of 1 means no distortion, while values above 2 show problems. This method makes LDVs reliable for finding circuit board issues.

LDVs are helpful for quality control. They ensure circuit boards meet performance standards by spotting vibration problems. Though they cost more than other sensors, their accuracy and non-contact design make them worth it for important tasks.

Adding LDVs to your monitoring tools improves vibration checks. They help find problems early, reducing downtime and repair costs.

Comparing Vibration Monitoring Technologies

Sensitivity and Accuracy

Sensitivity and accuracy are important for checking vibrations in circuit boards. These factors show how well a system can find and measure vibrations. Piezoelectric sensors are very precise and often used as the standard for vibration tests. They work best in places needing detailed checks, like high-frequency areas.

MEMS accelerometers are accurate within ±5% and work up to 4 kHz. They are good for basic vibration checks and condition monitoring. While not as precise as piezoelectric sensors, they still give useful data for maintenance.

Sensor Type | Accuracy | Measuring Range | Frequency Range | Diagnostic Parameters |

|---|---|---|---|---|

MEMS Accelerometers | ±5% deviation | 0 to 300 rpm | Up to 4 kHz | vRMS, aRMS, aPeak, aPP |

Piezoelectric Sensors | Reference standard | N/A | N/A | N/A |

Choose sensors based on your needs. For high sensitivity, pick piezoelectric sensors. For general use, MEMS accelerometers are cheaper and still work well.

Cost and Scalability

Cost and scalability are key when picking vibration tools. MEMS accelerometers are cheap and small, making them great for large projects. Their size lets you use many sensors on one board without spending too much.

Piezoelectric sensors cost more but are very accurate. They are best for jobs needing high precision. However, their price can make them hard to use in big projects with tight budgets.

Laser Doppler Vibrometers (LDVs) are the most expensive option. They don’t touch the board and are very sensitive, making them good for special tasks. But their high cost makes them less practical for wide use. If you need many sensors and want to save money, MEMS accelerometers are the best choice.

Application Suitability

Each vibration tool works best for certain jobs. Piezoelectric sensors are great for high-frequency places like factories or airplanes. They handle extreme temperatures and tiny movements, making them perfect for precise work.

MEMS accelerometers are ideal for small and budget-friendly projects. Their size and low cost make them good for gadgets and cars. They also help find problems early in maintenance setups.

LDVs are best for testing and research. They measure vibrations without touching the board, which is helpful in labs.

Pick a tool based on your needs. For high-frequency tasks, use piezoelectric sensors. For affordable and scalable options, go with MEMS accelerometers. For special jobs, LDVs are the most accurate choice.

Choosing the Right Vibration Monitoring Technology

Factors to Think About

Picking the best vibration monitoring tool for circuit boards takes thought. Each type has its own strengths, so knowing them helps you decide.

Precision and Data Quality

Getting clear data is key for good monitoring. Piezoelectric sensors are great for detailed vibration checks. They work well when you need very accurate data. MEMS accelerometers are cheaper and good enough for simpler tasks.Cost and Scalability

Money matters when choosing tools. MEMS sensors are low-cost and easy to use in large numbers. You can place many on a circuit board without spending too much. This makes them perfect for big projects.Real-Time Monitoring and Analysis

Tools like Python or MATLAB help you see data right away. Real-time checks are important for fixing problems early. This stops small issues from becoming big failures.Application Environment

Where you use the tool also matters. Piezoelectric sensors handle high-frequency and hot or cold places well. Laser Doppler vibrometers are better for jobs where touching the board isn’t possible, like in labs.Performance Metrics

Look at things like how often data is sampled and how it’s collected. For example, a sampling rate of 8.123 Hz works well with sensors for accurate data. Skipping bad samples makes your analysis more reliable.

Feature | What It Does |

|---|---|

Helps collect very accurate data for better monitoring. | |

Affordable MEMS Sensors | Offers good performance at a lower price than piezoelectric sensors. |

Real-Time Data Tools | Lets you quickly check and analyze vibration problems. |

By thinking about these points, you can pick the right tool. This ensures your circuit boards stay safe and reduces unexpected breakdowns.

Watching for vibrations is key to keeping circuit boards safe and lasting longer. Different tools, like piezoelectric sensors, MEMS accelerometers, and laser Doppler vibrometers, have their own benefits. Piezoelectric sensors are very precise. MEMS accelerometers are cheap and can be used in many places. LDVs are great for accurate checks without touching the board.

Tip: Think about what you need most, like cost, accuracy, or where you'll use it. Try out different tools or ask an expert for advice. Picking the right tool stops expensive problems and keeps your systems working well.

FAQ

What is the best vibration monitoring tool for beginners?

MEMS accelerometers are perfect for beginners. They are cheap, simple to use, and give accurate data for basic checks. Their small size makes them great for learning and testing on circuit boards.

Can vibration monitoring extend the life of circuit boards?

Yes, it can. Finding harmful vibrations early stops damage to parts and solder joints. This helps reduce wear, making circuit boards last longer and work better.

How do I choose the right vibration monitoring technology?

Think about what you need. For very accurate checks, pick piezoelectric sensors. If you want something affordable, MEMS accelerometers are a good choice. Use laser Doppler vibrometers for jobs where touching the board isn’t possible. Match the tool to your task.

Are vibration monitoring tools hard to install?

No, they’re easy to set up. Tools like MEMS accelerometers and piezoelectric sensors are small and simple to attach. Some even have sticky backs or mounts, making installation quick and hassle-free.

Do vibration monitoring tools require regular maintenance?

Not much. Just check the sensors for dust or damage and keep them calibrated. Follow the maker’s instructions to ensure they work well for a long time.