Creating functional safety PCBA designs is becoming increasingly challenging due to new regulations. By 2025, we will need more straightforward methods to comply with these rules. For instance, ISO 26262 now emphasizes systems that continue to operate even in the event of a failure. This requires additional components and more intelligent designs. To assist in this effort, chip manufacturers are developing new chips that are compact yet powerful. These chips simplify the designs while ensuring adherence to the regulations. Streamlining functional safety in PCBA design not only saves time and money but also ensures compliance with the rules.

Key Takeaways

Functional safety in PCBA design makes devices safe during problems. It keeps users protected and makes devices more reliable.

Safety rules like IEC 61508 and ISO 26262 find risks early. This helps create better designs and follow important rules.

Tools like FMEA and AI make safety checks faster and easier. These tools save time and make designs more accurate.

Adding backups, like dual or triple systems, improves safety. This lets systems keep working even if one part breaks.

Clear records of designs and tests are needed for approval. Good notes build trust and make checks simpler.

Functional Safety in PCBA Design

Why functional safety matters in PCBs

Functional safety helps PCBs work safely, even in tough situations. Designing with safety in mind stops failures that could cause harm. It focuses on making systems that find and fix problems quickly, keeping devices safe.

Following rules like IEC 61508 makes PCBs more reliable for industries. Steps like design checks and outside reviews catch problems early. This lowers risks and boosts how well industries perform. Also, knowing the difference between random and planned failures helps improve designs.

Functional safety has clear benefits. Finding defects early means fixing them before products are sold. This improves quality and ensures all PCBs meet high standards. Fixing issues early also saves money and time, making production easier. Plus, meeting safety rules builds trust and avoids legal trouble.

Where functional safety is needed

Some industries must follow strict safety rules. Cars, for example, need safe PCBs to work in all conditions. Features like smart driving systems and brakes depend on safe designs.

In factories, safety keeps machines and tools working without danger. Robots and conveyor belts must be safe for workers and the environment. Following safety rules ensures these systems do their job safely.

Medical devices also need to meet safety rules. Tools like pacemakers and pumps must work perfectly to protect lives. By meeting safety levels, you can make PCBs that are safe and reliable.

Standards and Compliance Requirements

Overview of IEC 61508 and ISO 26262

Safety rules like IEC 61508 and ISO 26262 are important. They help make PCBA designs safer and more reliable. IEC 61508 is a general safety guide for many industries. It shows how to find risks and reduce them step by step. ISO 26262 focuses on car systems, solving safety problems in vehicles.

These rules make it easier to follow safety steps. For example:

Certified testing tools make checking systems faster and simpler.

Pre-approved parts lower system risks and improve reliability.

By following these rules, you can create safe PCBs that work well.

Automotive Safety Integrity Levels (ASIL) explained

ASIL levels are part of ISO 26262 and measure car system risks. They rank risks from A (low) to D (high). Higher levels need stronger safety designs to prevent problems.

ASIL-D systems, like brakes and steering, need top safety measures. These include backup systems and fault-proof designs. For example, dual-core microcontrollers are often used for ASIL-D.

Knowing ASIL helps you focus on key safety needs. By matching designs to the right ASIL level, you meet rules and improve performance.

Documentation and certification essentials

Good records are key to meeting safety rules like IEC 61508 and ISO 26262. They prove you followed safety steps and help with certifications. Keeping clear records has many benefits:

It lowers risks during safety checks.

It shows honesty and responsibility to others.

It keeps work consistent by explaining tasks clearly.

Good records also support fair business practices. Detailed files build trust and prepare you for audits. For example:

Clear records make audits faster and less stressful.

They explain who does what, improving teamwork.

They encourage safety and rule-following in your company.

To make certifications easier, set up a full safety record system. Include design plans, test results, and review notes. Using approved safety designs and parts increases your chance of success.

Tools and Methods for Safe PCBA Design

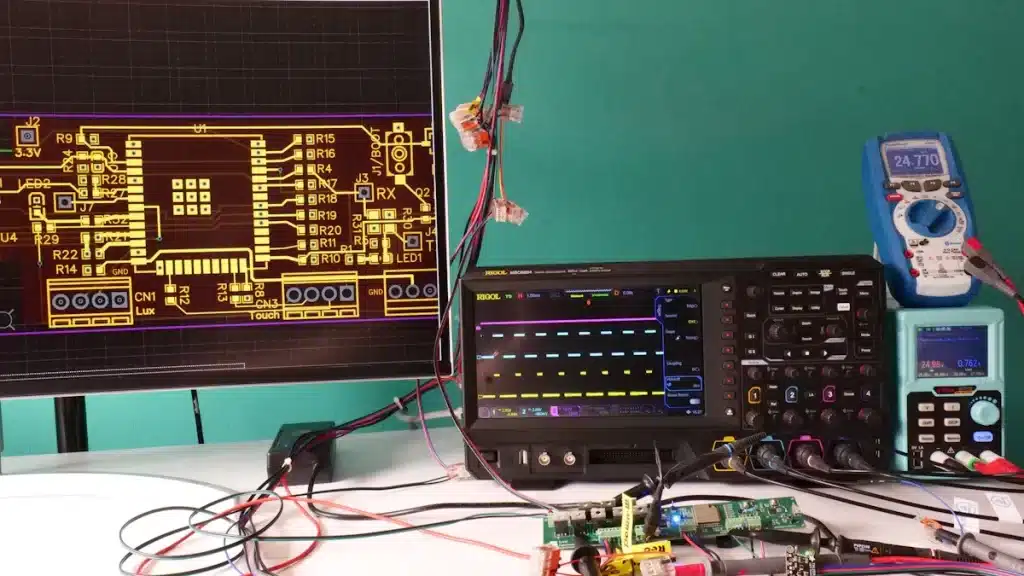

Software tools for safety checks

Modern software makes safety checks easier by spotting risks early. Tools like FMEA and STPA find problems and improve safety. A study showed using both tools together works best. Each tool finds different risks, so combining them gives better results. This shows why using many tools is important for full safety checks.

AI tools now make these tasks faster by automating boring jobs. For example, AI helps with 3D PCB designs and fixing signal issues. These tools save time and make designs more accurate. They also help meet safety rules easily.

Hardware design for handling failures

Fault tolerance keeps PCBs working even when something breaks. You can use methods like copying data, finding errors, and fixing them fast. For example:

Home computers use backups to save data.

Small businesses do regular backups to recover files.

Space systems use extra computers to stay reliable.

Separating important functions, like emergency stops, helps avoid big failures. Adding safe parts, like fused power paths, keeps systems safe without needing too many extras. These ideas follow safety rules for good designs.

Testing tools for safety rules

Testing tools check designs before making them, saving time and money. Digital twins let you test PCBs in virtual worlds. This finds mistakes and ensures safety rules are followed. AI tools make these tests smarter by predicting problems and fixing layouts.

A study found LTGM tools are best for fair testing. Real-time tools also check signals and heat levels to avoid issues. These tools make designs safer and meet strict safety rules.

Step-by-Step Design Flow for Functional Safety Compliance

Risk assessment and safety planning

Risk assessment is the first step in making safe designs. It helps find dangers and figure out how to fix them. A clear plan ensures your design meets safety levels and follows rules.

Follow these three simple stages:

Stage 1: Process Design – Use past projects to create a strong process.

Stage 2: Process Qualification – Check if the process works well every time.

Stage 3: Continued Process Verification – Watch the process during production to keep it steady.

Each stage builds on the last one for a full safety plan. For example, in Stage 1, you decide what safety features are needed. In Stage 2, you test these features to make sure they work. In Stage 3, you keep checking the system to ensure it stays reliable.

Tip: Tools like Failure Mode and Effects Analysis (FMEA) help spot problems early. This saves time and money later in the project.

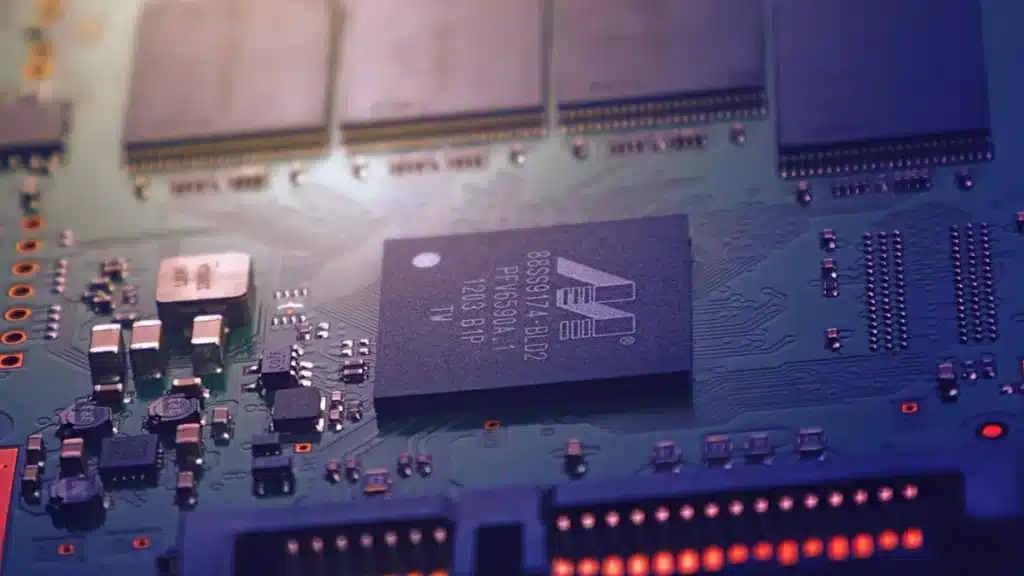

Designing for redundancy and fault tolerance

Redundancy and fault tolerance keep systems safe when parts fail. Adding these ideas to your design helps meet safety rules like IEC 61508 and ISO 26262.

Here are some common methods used in projects:

Mechanism/Strategy | Description |

|---|---|

Uses two parts to do the same job, fixing errors. | |

Triple Modular Redundancy (TMR) | Uses three parts with voting to pick the right result. |

Error Correction Codes (ECC) | Finds and fixes mistakes in stored or sent data. |

On-Demand Redundancy Grouping (ODRG) | Changes redundancy based on what the system needs. |

Triple-Core Lockstep (TCLS) | Runs three cores together, voting on outputs for accuracy. |

For example, TMR can be used in car brakes to keep them working if one part fails. ECC can protect important data in medical tools where accuracy matters most.

Note: Separating safety tasks, like emergency stops, from other functions makes systems safer.

Validation and certification process

Validation and certification prove your design meets safety rules. This step includes testing, keeping records, and audits to show your system is safe.

Focus on these key tasks to make it easier:

Testing: Use simulation tools to check designs before making them. These tools find problems early and save time.

Documentation: Keep clear records of your design and tests. Include safety plans, test results, and notes. Good records make audits simple and build trust.

Certification: Work with experts to get approval for your design. Using pre-approved safety parts, like dual-core microcontrollers, makes this step faster.

Tip: Set up a full safety record system. This helps follow rules like ISO 26262 and IEC 61508.

By following these steps, you can make safe PCBA designs that work well in real-world situations.

Real-World Examples of Functional Safety PCBA Design

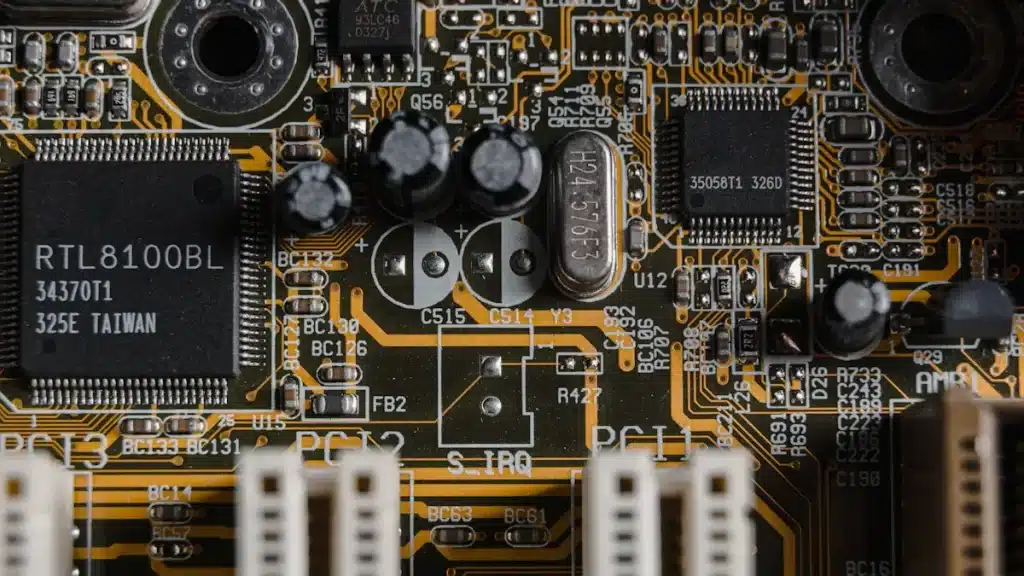

Automotive PCB design case study

Cars need reliable systems for safety features like brakes. A good example is using backup systems in modern cars. These backups ensure the system works even if one part fails. For instance, dual-core microcontrollers are used in brakes to meet strict ASIL rules.

Testing is very important in this process. Tests mimic tough conditions like heat, shocks, and vibrations. This ensures the circuit boards work well in real life. Smart diagnostic tools also find and fix problems quickly. These steps make cars safer and build trust in their technology.

Metric | Description |

|---|---|

Redundant Systems | Backup pathways keep systems working even if one fails. |

Fault Detection and Correction | Tools find and fix problems fast to keep cars running. |

Rigorous Testing Protocols | Tests check boards under heat, shocks, and vibrations. |

Industrial safety system design insights

Factories need safe systems to protect workers and equipment. The SEIPS model shows how people and their surroundings affect safety. It focuses on five parts: people, tasks, tools, environment, and company rules. These parts help make safer designs.

Important safety steps include:

Setting clear safety goals

Managing risks carefully

Checking safety often

Teaching safety to workers

For example, robots in factories use emergency stops and backup designs. These features stop harm if something breaks. Following these ideas makes boards safer and boosts factory work.

Role of emerging technologies in compliance

New technology is changing how safety is handled. Standards like ISO 26262 and ISO/SAE 21434 guide safety in electronics. They focus on managing risks and testing designs. This ensures new systems meet safety needs.

ASIL levels help by ranking risks and setting safety rules. As cars use more software, testing becomes even more important. Tools like AI make testing faster and better at finding problems. This helps meet safety rules easily.

Using these tools, you can design boards that follow rules and improve technology.

Making functional safety PCBA design easier helps meet safety rules. Using the right steps and tools lowers risks and saves time. It also makes systems more reliable and better for real use. Functional safety is not only about following rules. It’s about creating trusted and dependable products. Begin using these ideas now to stay ready for 2025.

FAQ

What is functional safety in PCBA design?

Functional safety means your PCB works safely even with problems. It finds and fixes risks to stop harm. This makes designs safe and follows rules like IEC 61508 and ISO 26262.

Why do you need redundancy in functional safety designs?

Redundancy adds backups to keep systems working if parts fail. Methods like Dual Modular Redundancy (DMR) or Triple Modular Redundancy (TMR) make systems safer and meet safety rules.

How can software tools help with functional safety compliance?

Software tools like FMEA and STPA find risks early in designs. AI tools save time by automating tasks and improving accuracy. These tools help follow rules like ISO 26262 easily.

What industries benefit most from functional safety PCBs?

Industries like cars, medicine, and factories need safe PCBs. These designs protect systems like brakes, pacemakers, and factory robots.

How do you prepare for certification audits?

Keep clear records of designs, tests, and checks. Use approved parts and simulation tools to meet rules. Good records make audits faster and build trust with reviewers.