Factories and industries need tools that handle tough conditions. Ruggedized power converter boards help systems work well in heat, cold, or dust. These boards keep working steadily and reliably, which is very important. Their tough design makes them useful for factories, transport, and energy work. Picking the right ruggedized power converter board keeps your tools strong and working, even in hard situations.

Key Takeaways

Strong power converter boards are important for tough workplaces like hot, dusty, or shaky areas.

Picking the right board, like the Grecell T-1000 for low cost or XP Power for strength, helps it work well in hard conditions.

Check for things like good cooling systems and safety labels to make sure it works well and lasts long.

Think about what you need, like how much power or space you have, before choosing a strong board.

Taking care of the board and following the maker’s rules keeps it working for a long time.

What Are Ruggedized Power Converter Boards?

Definition and Purpose

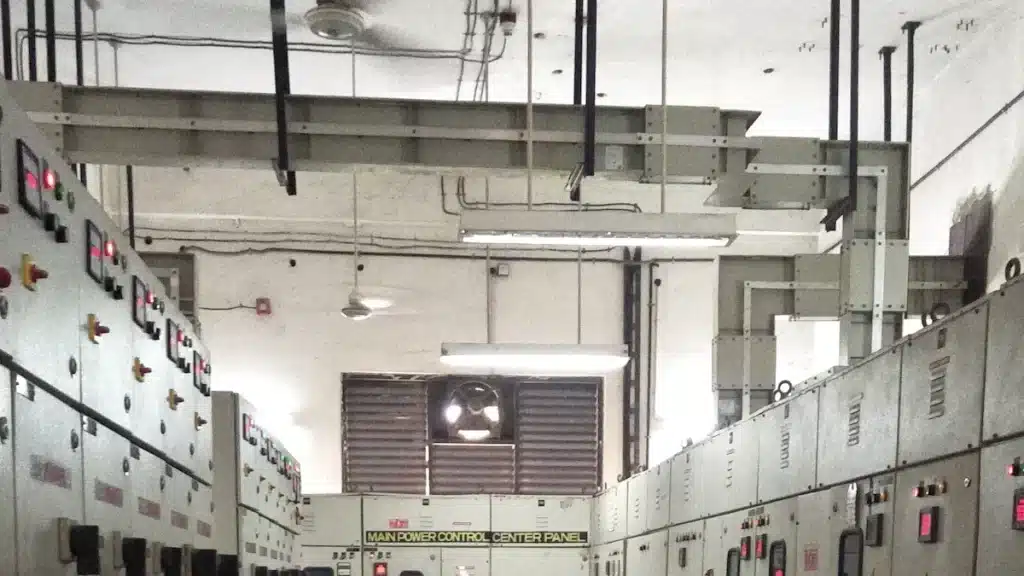

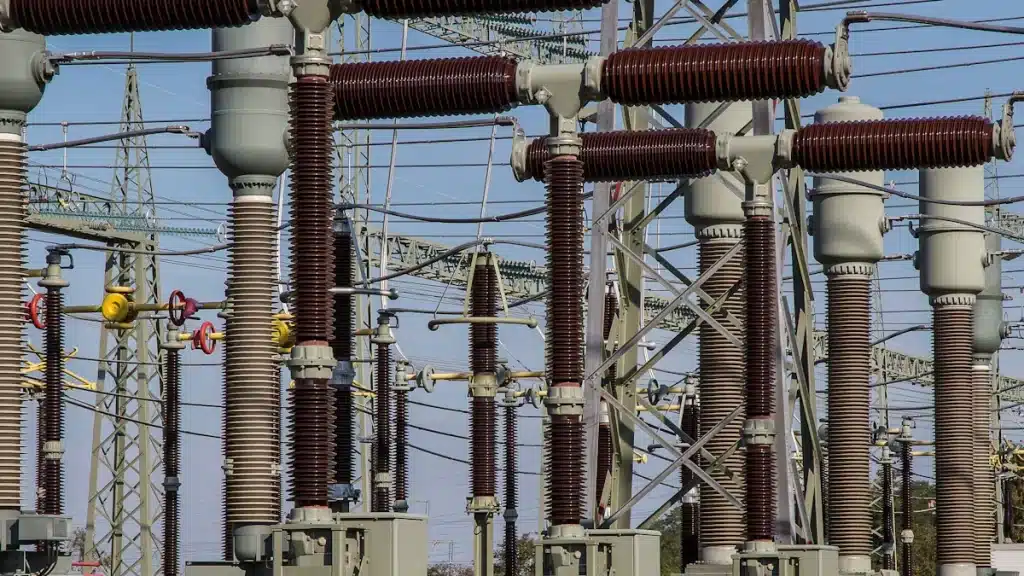

Ruggedized power converter boards are devices that change power reliably. They work well in tough places like heat, shaking, dust, or wet areas. These boards are important for industries needing steady power, like factories, transport, and defense.

They meet strict rules, such as EN 50155 for handling shocks and vibrations. They also resist water and salty air, making them great for outdoor and critical tasks. Using smart designs like two-stage power systems, they are more efficient and last longer.

Key Features of Ruggedized Boards

Ruggedized boards have special qualities that make them stand out. Here are some main features:

Durability: Handles very hot or cold temperatures, from -40 to +95°C.

Advanced Cooling: Uses cooling methods like metal cases or aluminum plates.

High Efficiency: Saves energy with digital power tools, lasting longer.

Versatility: Works in military tools, electric cars, and factory machines.

These features make ruggedized boards vital for tough power jobs.

Common Industrial Applications

Ruggedized boards are used in many industries. In defense, they provide steady power for military tools in hard conditions. Networking gear for the military also depends on these boards.

In transport, they power electric cars and trains, where strength and efficiency matter. Factory systems use them to keep working despite heat or stress. The need for military tools and power solutions shows their value in many fields.

Tip: Pick a ruggedized board that matches your environment for best results.

Top Picks for 2025

Best Overall: Grecell T-1000

The Grecell T-1000 is the best ruggedized power board for 2025. Its small size and strong build make it great for tough jobs. It works in many ways, offering different input and output options. It even has wireless charging, which is super handy. This board stays reliable in harsh places because of its smart cooling system.

A big plus is its low price. The Grecell T-1000 costs 40% less than similar boards. It’s affordable but still high-quality. Its large capacity handles heavy tasks like running factory machines or military tools. With its mix of strength, performance, and value, it’s a great choice for many uses.

Note: Need a board that balances cost and performance? Pick the Grecell T-1000.

Best for High Power Applications: Tripp Lite 375W Inverter

The Tripp Lite 375W Inverter is perfect for high-power needs. It handles heavy loads, making it great for industries needing steady power. Its advanced cooling keeps it stable, even in tough conditions.

This inverter uses smart heat control to stop overheating. It also has safety circuits to protect against power surges. These features make it reliable for running big machines or DC-DC converters in transport systems.

If you need strong and steady power, this inverter is a solid pick. Its tough design can handle the hard demands of industrial work.

Most Durable: XP Power DC-DC Converters

Durability matters in tough jobs, and XP Power DC-DC Converters are built for it. They survive extreme heat, shaking, and shocks. Their strong design makes them perfect for military and other hard tasks.

XP Power uses smart cooling to make them last longer. Heat-making parts are placed carefully to avoid overheating. They also test these converters in real-world conditions like shaking and heat changes.

Tip: Pick XP Power DC-DC Converters if you need something super durable.

Performance Metric | Description |

|---|---|

Keeps the board working in tough environments. | |

Real-World Testing Necessity | Proves strength with tests for heat, shaking, and shocks. |

Component Placement Strategies | Stops overheating by spreading heat evenly in the design. |

XP Power DC-DC Converters are trusted for their toughness. They work well in extreme places, making them stand out from others.

Best Budget Option: LM2596 Converter Board

If you need a low-cost but reliable board, try the LM2596 Converter Board. It is known for being affordable and useful in many ways. This board gives steady voltage, making it great for small industrial tasks. Even though it’s cheap, it works well and saves energy while converting DC power.

The LM2596 is easy to use because of its simple design. You can set it up quickly without needing special skills. Its small size fits into tight spaces, perfect for projects with little room. It also has safety features like overcurrent and heat protection, which make it dependable in different conditions.

Tip: On a tight budget but need good performance? Choose the LM2596 Converter Board.

Best Compact Design: Advanced Energy Board-Mounted Converters

When space is limited, Advanced Energy Board-Mounted Converters are a great choice. These small boards are made for places where every inch counts. Even though they are tiny, they work efficiently and perform very well.

These converters use smart technology to pack a lot of power in a small size. They have systems to manage heat, keeping them cool in tight spaces. This helps them last longer and work well under tough conditions. Their strong parts handle high heat, making them good for military and harsh jobs.

They also work with a wide range of input voltages, making them flexible for different setups. Whether in a factory or outdoors, these boards adjust to your power needs. Their tough design handles shocks, vibrations, and extreme weather, making them a solid pick for rugged tasks.

Note: Need a small but powerful board? Go with Advanced Energy Board-Mounted Converters.

Buyer's Guide to Ruggedized Power Converter Boards

Factors to Consider When Choosing a Board

Picking the right ruggedized power converter board takes careful thought. First, think about where the board will be used. If it faces heat, shaking, or moisture, choose one with strong durability. Certifications like UL 1741 and ISO 9001:2015 show the board meets safety and quality rules.

Next, check how much power your tools need. Boards like the Tripp Lite 375W Inverter handle heavy tasks well. Smaller boards, such as Advanced Energy Board-Mounted Converters, fit tight spaces. If money is tight, the LM2596 Converter Board gives good performance at a low price.

Cooling systems are also important. Boards with metal cases or aluminum plates stay cool and last longer. Active power factor correction (PFC) helps reduce energy waste and keeps the board working efficiently.

Tip: Pick a board that matches your needs for the best results.

Understanding Key Specifications

Knowing the specs of ruggedized boards helps you choose wisely. Look at input voltage ranges. Boards with wide ranges, like 85–305 VAC, work in places with changing power supplies. This is helpful in areas with unstable electricity.

Efficiency matters too. Boards using SiC MOSFETs or GaN HEMTs save energy by working at over 95% efficiency. This lowers costs and reduces wasted power. Good thermal management systems keep boards cool, even in tough conditions.

Safety features are key. Multi-stage circuits protect against power problems like surges or drops. Supercapacitors store energy to keep the board running during short power outages. These features make boards reliable for important tasks.

Feature | Description |

|---|---|

Predicts market changes by region and type. | |

Cost Analysis | Studies costs and effects of trade and supply. |

Strategic Insights | Shares ideas about market shifts. |

Key Questions | Answers about market trends and top companies. |

Company Profiles | Lists big players like ABB Ltd and Advanced Energy Industries. |

Note: Choose boards with strong safety and efficiency features for long-lasting use.

Tips for Evaluating Durability and Reliability

Durability and reliability are very important for ruggedized boards. Check if the board meets industry standards. Certifications like IEEE 1547 and IEC 62109 prove the board is safe and tough.

Testing methods show how reliable a board is. For example, some experts study how heat affects parts over time. Others use tests for shaking and temperature changes to predict how boards will perform in hard conditions.

Authors | Methodology Description |

|---|---|

Studied how heat affects electrical parts over time. | |

Jiao et al. | Used tests for heat, shaking, and reliability predictions. |

Sun et al. | Combined physics and data models to check reliability. |

Martino et al. | Reviewed testing methods for power converters. |

Schuderer et al. | Shared ideas for improving dependability forecasts. |

Guan et al. | Created virtual tests for checking system reliability. |

The parts used in boards also affect durability. Boards with parts rated for high heat, like capacitors for 150°C, work well in extreme places. Smart cooling systems stop overheating and improve reliability.

Tip: Pick boards tested in real-world conditions to ensure they can handle tough jobs.

Comparison Table of Top Ruggedized Power Converter Boards

Overview of Key Specifications

Picking the right ruggedized power converter board means knowing its specs. Each board has unique features for different industrial tasks. Below is a table comparing the main technologies used in these boards:

Parameters | Silicon (Si) | Silicon Carbide (SiC) | Gallium Nitride (GaN) |

|---|---|---|---|

Benefits | Reliable, affordable, and widely used | Handles high heat (up to 300°C) and voltage (up to 10 kV) | Fast switching, compact, and efficient |

Applications | Works in low and medium-voltage systems | Great for high-power and industrial setups | Ideal for compact and high-frequency designs |

Cost and Performance | Cheap for low-power devices | Costs more but performs better for heavy tasks | Pricey but perfect for low-loss, high-frequency uses |

Adoption Barriers | Struggles with high heat and voltage | Hard to make, higher resistance | New tech, lacks pFET, and has low hole mobility |

This table shows how materials affect cost, use, and performance. For example, silicon carbide (SiC) boards are best for heavy-duty tasks, while gallium nitride (GaN) boards work well in small, fast systems.

Tip: Choose a board material that fits your power and environment needs.

Feature Comparison Across Top Picks

The top boards for 2025 have features for different industrial uses. Here’s a simple comparison of their strengths:

Board | Durability | Efficiency | Best Use Case | Price Range |

|---|---|---|---|---|

Grecell T-1000 | Strong | 90% | General industrial tasks | Medium price ($) |

Tripp Lite 375W Inverter | Very strong | 85% | Heavy-duty power needs | High price ($$) |

XP Power DC-DC Converters | Extremely strong | 88% | Harsh environments | High price ($$) |

LM2596 Converter Board | Moderate | 80% | Small jobs on a budget | Low price ($) |

Advanced Energy Converters | Strong | 92% | Tight spaces and compact setups | Medium price ($) |

The Grecell T-1000 is a good mix of cost and performance, making it flexible. For extreme conditions, the XP Power DC-DC Converters are the toughest. If saving money matters, the LM2596 Converter Board is a reliable and cheap option.

Note: Think about your budget, power needs, and environment before choosing. This helps you find the best board for your setup.

Picking the right ruggedized power converter board helps your systems work well in tough places. Boards like the Grecell T-1000 are affordable and perform well. The XP Power DC-DC Converters are great for very harsh conditions. The demand for these boards is growing fast. Experts predict the market could hit $36.79 billion by 2032 due to new ideas and eco-friendly needs.

Tip: Check the buyer’s guide to find the best board for your needs. This ensures you choose a solution that works efficiently for your tasks.

FAQ

What makes a power converter board “ruggedized”?

Ruggedized boards are made to survive tough conditions. They handle heat, shaking, and wet areas. Strong materials and cooling systems keep them reliable. They meet strict rules like EN 50155 for safety.

Can ruggedized boards work in outdoor environments?

Yes, they can. These boards resist water, dust, and salty air. Their strong design helps them work well outside. They are great for energy systems and transport setups.

How do I choose the right board for my needs?

Think about where you’ll use the board and your power needs. Check for certifications, durability, and energy-saving features. Use the buyer’s guide to find the best match.

Are ruggedized boards expensive?

Prices depend on the board. Cheaper ones like LM2596 cost less. High-end boards like XP Power DC-DC Converters are pricier. Pick one based on your budget and tasks.

Do ruggedized boards require special maintenance?

Not really. Clean them and check for damage sometimes. Their tough design means less upkeep than regular boards.

Tip: Follow the maker’s instructions to keep your board working well.