The biggest difference between pcbas and FPCAs is in how they are made and what they are made of. pcbas use hard bases like fiberglass, making them strong and affordable for devices that don’t move, such as computers. FPCAs, on the other hand, use flexible materials that you can bend or fold without breaking, which is ideal for small gadgets that move, like wearables. As demand grows for electronics in areas like IoT and cars, understanding when to use pcbas or FPCAs can make a big impact on your product’s performance and durability.

Key Takeaways

PCBAs are made with hard and strong stuff. They work best in things that do not move, like computers and routers.

FPCAs are made with bendy materials. They can fold and twist. This makes them good for small gadgets that move, like wearables and medical devices.

You should pick the right board for your device. Think about how strong, bendy, big, or cheap it needs to be.

Making flexible boards is harder and costs more money. But they save space and last longer in moving parts.

Test your designs well, especially the flexible ones. This helps make sure they work and do not break when used a lot.

PCBA vs FPCA

Definitions

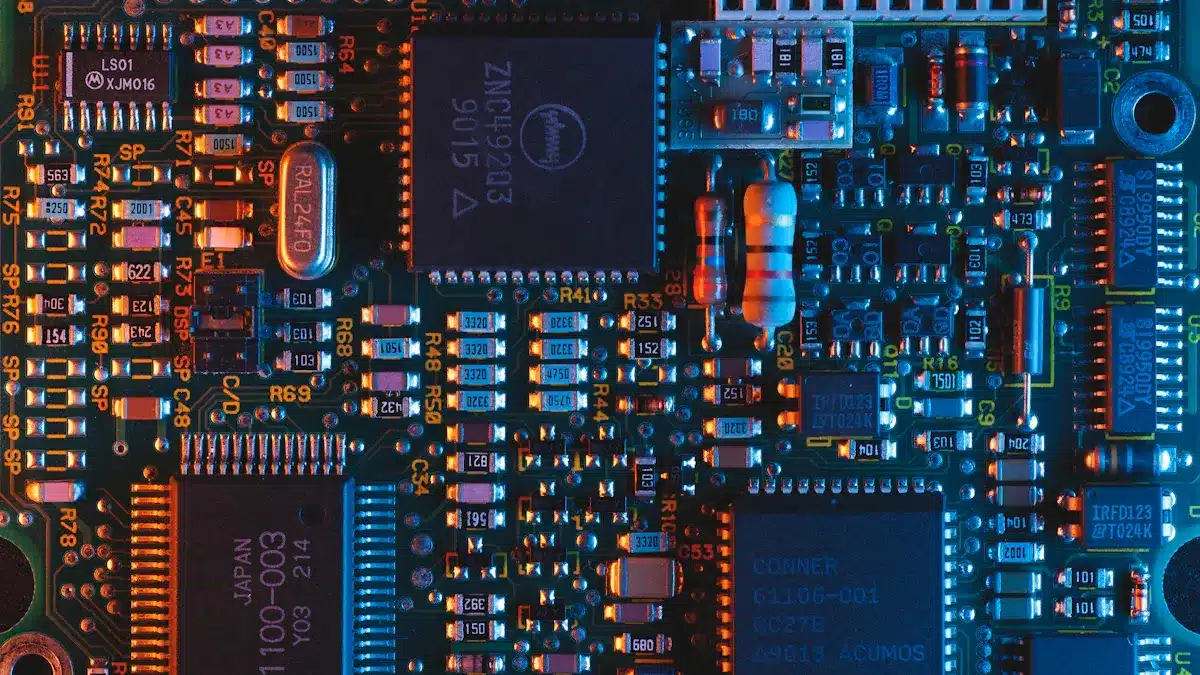

You will see the words PCBA and FPCA a lot in electronics. PCBA means Printed Circuit Board Assembly. It is a hard board made from things like fiberglass or epoxy resin. These boards are inside most computers, TVs, and routers. They keep electronic parts in place and connect them in a flat, strong way.

FPCA means Flexible Printed Circuit Assembly. This kind uses a bendable base, usually polyimide. You can fold or twist it, and it will not break. FPCAs are in things that move or need to fit in small spaces. Some examples are fitness trackers, medical sensors, and car dashboards.

Tip: If your device must bend or fit in a tight spot, use an FPCA. If you want a strong, flat board, a PCBA is a good pick.

Core Differences

It is important to know how pcbas and FPCAs are different before you pick one. The biggest differences are in what they are made of, how they handle stress, and where you use them.

Feature | PCBA (Rigid PCB) | FPCA (Flexible PCB) |

|---|---|---|

Substrate Material | Fiberglass, epoxy resin | Polyimide, flexible plastics |

Mechanical Properties | Hard, inflexible, strong against vibration | Bendable, can twist and fold, survives many cycles |

Electrical Properties | Good signal integrity, cost-effective | High conductivity, keeps signals clear when bent |

Typical Applications | Computers, routers, home appliances | Wearables, medical devices, automotive electronics |

Cost | Lower upfront cost, simple to make | Higher initial cost, saves money over time |

PCBA boards use solid stuff. This makes them strong and keeps parts safe from bumps or drops. They work well in things that do not move or need to last a long time. Some advanced pcbas help signals travel better at high speeds. This is good for computers and network gear.

FPCAs use bendy materials like polyimide and rolled annealed copper. You can bend these boards many times, and they will not break. FPCAs also stand up to heat, water, and chemicals. This makes them great for cars, medical tools, and things that move a lot. You can save space and weight because you do not need extra wires or connectors.

FPCAs cost more at first. But they last longer and need fewer repairs, especially in tough jobs. Rigid-flex boards mix both types. They give you the good parts of each for tricky projects.

Note: Always pick the board that fits your device’s needs. If you need both bending and strength, FPCAs or rigid-flex boards are best. For simple and strong designs, pcbas are usually enough.

Design

Rigid vs Flexible

When you make a circuit, you must pick rigid or flexible. Rigid boards, like pcbAs, have a hard base. This base keeps the board flat and steady. You can put many parts on both sides. This helps when space is tight and you need lots of connections. These boards are best for things that do not move, like desktop computers or routers.

Flexible circuits, like FPCAs, use bendy materials. You can fold or twist them to fit in small or odd shapes. This makes them great for wearables or medical sensors. They are good for anything that moves. You must plan where the board will bend. Do not put heavy parts or solder joints in these spots. If you do, the board might crack or break. Use soft curves for traces. Add stiffeners to help spots with connectors or big parts.

Tip: Always test your design in real life. Bending and flexing can cause stress. You want your circuit to last a long time.

Aspect | Flexible PCBs (FPCAs) | Rigid PCBs (PCBAs) |

|---|---|---|

Polyimide or PET film | Fiberglass or epoxy resin | |

Flexibility | Bendable, handles millions of cycles | Non-bendable, stable and flat |

Component Placement | Limited in flex zones, needs stiffeners | High-density, both sides possible |

Layout Constraints | Must plan for bends and stress | Focus on heat dissipation and cost |

Materials

The materials you pick change how your circuit works. pcbAs use hard bases like fiberglass or epoxy. These give strong support and hold copper traces in place. They are good for circuits that do not move.

FPCAs use flexible bases, like polyimide or polyester. Polyimide is special because it resists heat and insulates well. You can bend the board many times and it will not break. Good copper foil makes the board strong. It also keeps signals clear, even when the board moves.

Polyimide: Handles heat, bends well, and is strong.

Polyester: Good for simple, cheap flexible circuits.

Fiberglass/Epoxy: Used in rigid boards for support and strength.

Note: Always pick the right material for your device. Flexible materials cost more but last longer if your device moves. Rigid materials are simple and strong for things that stay still.

Manufacturing

PCBA Process

First, you design the circuit and pick the parts. Next, you check all the materials before building. This step helps stop problems later. Incoming Quality Control (IQC) checks for bad materials. Only good parts go to the next step.

Here are the main steps in making a PCBA:

Make the circuit and layout.

Buy good parts.

Build the hard board by printing, etching, and drilling.

Put and solder parts with SMT or plug-in ways.

Test the board with AOI and other checks.

Finish and pack the product.

You use tools like AOI and X-ray to find mistakes. These tools help you see missing parts or bad solder. If you find bad boards, you fix them. This keeps your work steady and safe.

Tip: Careful checks in pcbas save money and make better products.

FPCA Process

FPCA uses bendy boards. You must handle them with care because they can twist. The process starts by picking the right material. Polyimide or PET film makes the board flexible. You plan the layout so bends do not break the board.

The steps in FPCA making are like pcbas, but you must be gentle:

Get the flexible base ready.

Print and etch copper lines.

Place parts very carefully.

Solder parts without too much heat.

Check with AOI and X-ray, looking at hidden spots.

Test the board and pack it with care.

FPCA is harder to make than hard boards. It costs more and needs more steps. X-ray checks are very important for FPCAs. Many flexible boards use BGA or MEMS with hidden solder. X-ray helps you find problems you cannot see.

Step | PCBA (Rigid) | FPCA (Flexible) |

|---|---|---|

Substrate Handling | Easy, stable | Needs gentle handling |

Assembly Density | Standard | Higher, more compact |

Inspection Focus | AOI, functional tests | AOI, X-ray, functional |

Cost | Lower | Higher |

Note: You must change your tests for flexible boards. Use X-ray to check hidden spots and keep the board good.

Applications

PCBA Applications

You can find PCBAs in many things you use daily. These boards are good when you need something strong and tough. They also give steady connections. Here is a table that shows where you see PCBAs most:

Sector | Common PCBA Application Areas |

|---|---|

Consumer Electronics | Smartphones, laptops, TVs, routers |

Automotive | Entertainment and navigation systems, engine control, fuel regulators, safety sensors, autonomous driving aids |

Industrial | Manufacturing equipment, power inverters, solar power systems, pressure and temperature control devices |

PCBA boards do hard work. In cars, they must handle heat, cold, and shaking. In factories, they face dust, water, and lots of use. You can count on PCBAs to last a long time in these places. To make sure they work, you test them for heat, shaking, and bumps. This keeps your devices safe and working well.

Note: If you want a circuit that is flat and strong, pick a PCBA. These boards are great for places where you need long life and steady work.

FPCA Applications

FPCAs are best when you need circuits that bend or fit in small spaces. You see them in many new gadgets and special tools. Here are some common ways people use them:

Hearing aids and headphones

Medical wearables that check your heart or help with care

Aerospace devices that need light, bendy boards

Car dashboards and flexible screens

FPCAs help you make smaller and lighter things. You can fold them to fit inside a watch or a patch for your skin. In planes and satellites, FPCAs save weight and space, which is very important. These boards also give steady and safe connections, even when you move or bend them.

Tip: Choose FPCAs if your device needs to bend, fit in a tight spot, or stay light. They are great for wearables, medical tools, and high-tech cars or planes.

You should always pick what fits your needs. If you need something strong and long-lasting, use PCBAs. If you want something flexible and small, FPCAs are the better pick.

Cost & Performance

Cost Factors

When you start a project, you must think about cost. Flexible circuits use polyimide in most cases. Polyimide is used in about 85% of flexible boards. This material costs more than what rigid boards use. Copper thickness also changes the price. If your design is tricky, it will cost more. Special finishes like gold plating make the board even pricier. The number of boards you buy matters a lot. If you order 10,000 instead of 100, each board costs much less. Roll-to-roll manufacturing can save up to 40% on costs. But small things like stiffeners or special finishes can add extra costs you might not expect.

Here is a table that lists the main things that change the price:

Cost Driver | Description | Impact on Cost |

|---|---|---|

Material Selection | Type of substrate and copper used | High-performance = higher cost |

Production Quantity | Number of units ordered | More units = lower cost per unit |

Design Complexity | Fine features, extra layers, or special shapes | More complex = higher cost |

Surface Treatment | Finishes like HASL, ENIG, or gold plating | Advanced finishes = higher cost |

Lead Time | How fast you need the boards | Rush orders = much higher cost |

Assembly Process | Number of parts and assembly steps | More steps = higher cost |

Tip: Buy more boards at once and keep your design simple to save money.

Durability

You want your circuit to last a long time. You need to check how it handles heat, water, and stress. There are rules for safety and performance. UL 796 is for rigid boards. UL 796F is for flexible boards. These rules check if the board can resist fire. They also check the highest heat it can take. They look at how it works when wet or under stress. Flexible boards must also meet IPC 6013. This rule checks if the board is reliable in tough places. Both types can be strong, but you should pick the right one for your device.

Rigid boards are good in places that do not change much.

Flexible boards can bend and move but must pass hard tests.

Note: Always make sure your board meets the right rule for your project.

Space Efficiency

If you want your device to be small or light, flexible circuits help a lot. These boards are thin and light. You can fit them in tight or odd spaces. You can bend, twist, or fold them to match your needs. Flexible boards also need fewer connectors. This saves even more space. Surface mount technology lets you put parts right on the flexible base. This helps you make smaller gadgets.

Bend and fold to fit tight spots

Fewer connectors needed

More freedom for creative layouts

Callout: Flexible circuits help you build devices that are smaller, lighter, and more advanced.

Choosing the Right Option

Decision Criteria

Before you pick a circuit type, think about what your project needs. Ask yourself some simple questions. Does your device need to bend or fit in a small space? Will it face lots of movement, heat, or water? Is saving money most important, or do you want it to last a long time? How many will you make? Is it just a few or a lot? Will you change the design often, or keep it the same?

If you pick a rigid or flexible circuit, it changes how your product works over time. Here is a table to help you compare both types:

Factor | Rigid Circuits (Panel Arrays) | Flexible Circuits (Singulated on Carriers) |

|---|---|---|

Material Handling | Easy to hold, does not bend much | Needs gentle touch, can get damaged |

Alignment & Registration | Very exact, easy to control | Harder to line up, needs extra help |

Production Volume | Good for making lots at once | Best for small groups or special jobs |

Component Density | Can fit many parts close together | Needs care when parts are close |

Production Versatility | Not easy to change, best for simple designs | Easy to change, good for new ideas |

Cost Considerations | Can waste more material | Can save material by checking each one |

Tip: Pick the type that matches your product’s shape, how it will be used, and how many you need. This helps you avoid problems later.

Pros & Cons

You should look at the good and bad sides of each type. Here is a quick list to help you decide:

Advantages of Rigid Circuits:

Easy to build and fix

Used in many products

Costs less to make

Well-known ways to put together

Advantages of Flexible Circuits:

Can bend and twist to fit small places

Good for tight designs with many parts

Light and small

Stands up to heat, chemicals, and fire

Works well in things that move or you wear

Lets you control things like capacitance and impedance

Disadvantages of Flexible Circuits:

Harder to make and put together

Costs more, especially at first

Hard to fix because of extra layers

Size can be limited when making them

Can break if not handled gently

Note: If you want something simple and cheap for a steady device, rigid circuits are a good choice. If you need something that bends, is light, or has a special shape, flexible circuits are better.

Picking the right circuit assembly helps your project work better. It also makes it last longer. You must choose the type that fits your needs. Think about how strong or bendy you want it. Also, think about cost and space. Look at the table below for a quick guide:

Assembly Type | Rigidity & Flexibility | Cost & Complexity | Typical Uses |

|---|---|---|---|

Rigid PCB | Strong, no bending | Lower, simple | Computers, machines |

Flexible PCB | Bends, folds easily | Higher, complex | Wearables, sensors |

Rigid-Flex PCB | Highest, hardest | Aerospace, medical |

Try not to make these mistakes:

Bending flexible boards too much.

Picking materials that do not fit your needs.

Using connectors that are not good.

Forgetting about fast signals.

Not protecting from heat or water.

Not planning for testing.

Tip: If you are not sure, ask an expert for help. This can save you money and help your project work its best.

FAQ

What is the main difference between a PCBA and an FPCA?

You will see that PCBAs use hard boards. FPCAs use flexible boards. PCBAs work best in devices that stay still. FPCAs fit in gadgets that bend or move.

Can you use both rigid and flexible circuits in one device?

You can use rigid-flex circuits. These mix hard and bendy parts. You get strength and flexibility in one board. Many medical and aerospace devices use this type.

Are flexible circuits more expensive than rigid ones?

You will pay more for flexible circuits. The materials and process cost more. You save space and weight, but the price goes up at first.

How do you test flexible circuits for quality?

You use AOI and X-ray tools. These help you find hidden problems. You must check bends and solder spots. Careful testing keeps your device safe.

Which type should you choose for wearable devices?

You should pick FPCAs for wearables. These boards bend and fit in small spaces. They last longer when you move or twist them.

See Also

Comparing Structural And Functional Traits Of PCB And PCBA

Understanding FCT In PCBA And Its Importance Explained

Benefits And Challenges Of Flex PCBA In Electronics Today