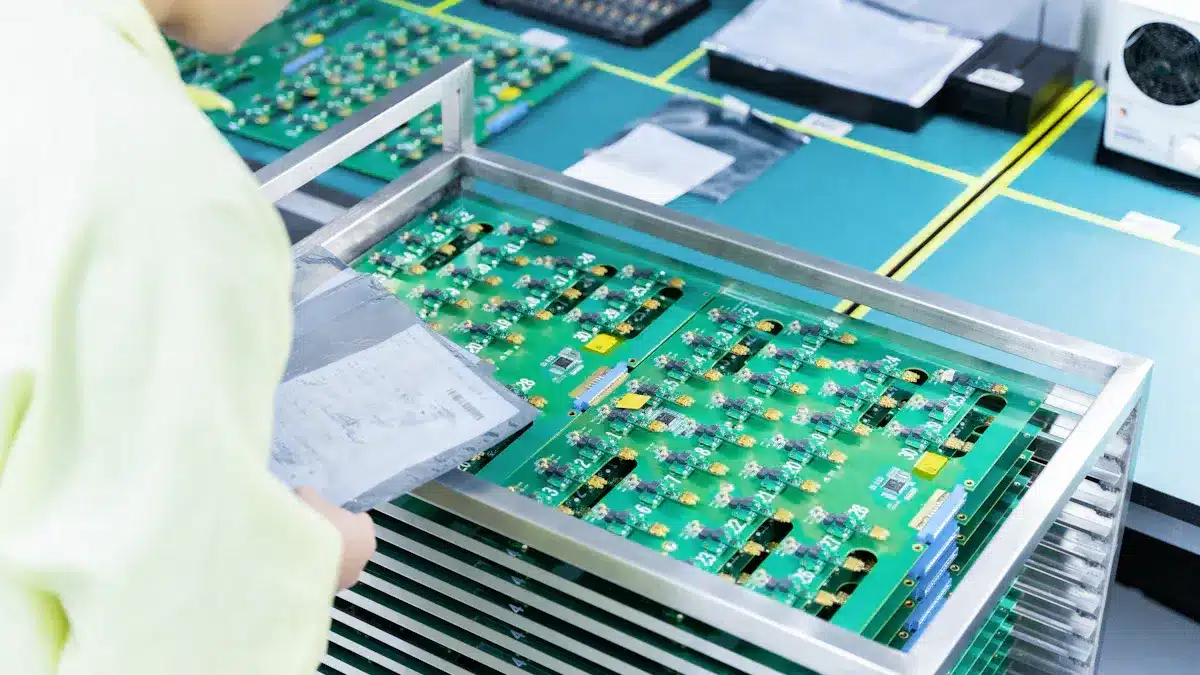

You have many options when making pcb boards. Each way has good and bad points. These affect if it works for your project. Today, pcb circuit boards are used in about 70% of electronics. The market was worth $75 billion in 2021. This shows pcb design and making are now very important. Picking a pcb production process is a big choice. Knowing about design, use, and making needs helps you avoid mistakes that cost money. The best pcb board production way helps your pcb circuit boards work well and not cost too much.

Key Takeaways

Pick the PCB production method that matches your project size, design, and budget. This helps you get the best results.

Subtractive methods are good for big orders and simple designs. They help save money and time.

Additive methods are best for quick samples and flexible designs. They also work well for small batches and make less waste.

Choose the right PCB board type for your needs. Think about strength, heat, and shape to make it work better.

Use the right surface finish to protect your board. This makes soldering easier and fits your assembly and storage needs.

PCB Board Production Methods

There are three main ways to make pcb circuit boards. Each way has its own steps and costs. Each one is best for different uses. If you know the differences, you can pick the best way for your project.

Subtractive Process

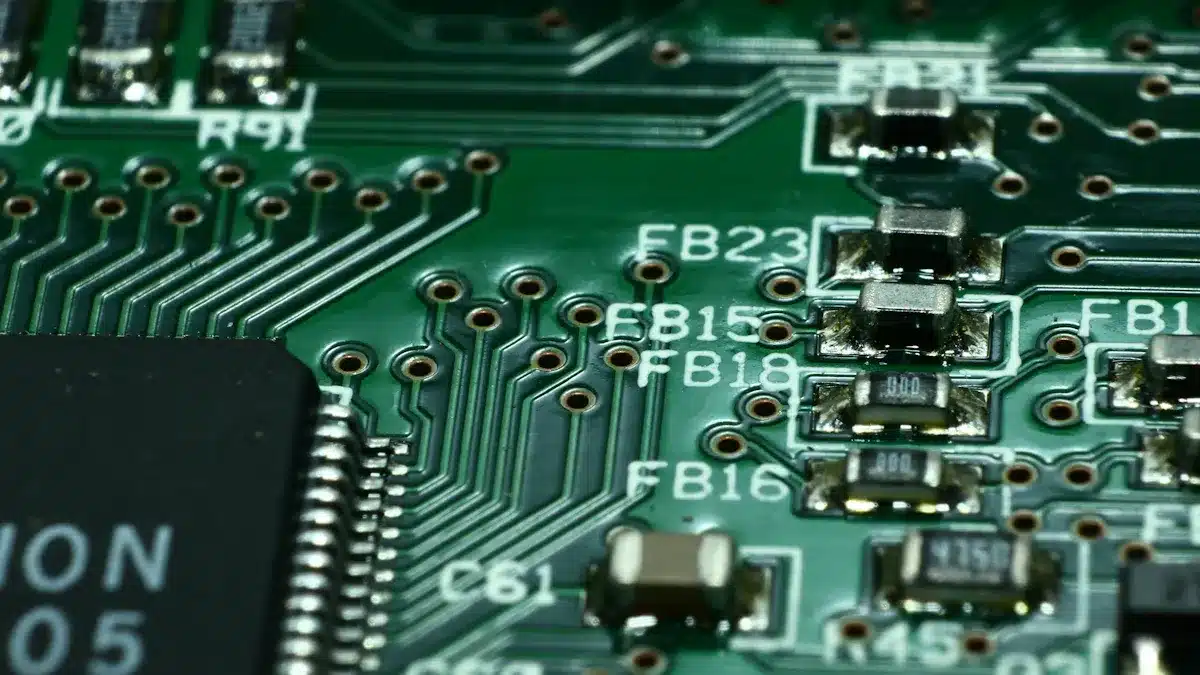

The subtractive process is used the most for pcb board production. You begin with a copper-clad board. A photoresist and UV light help mark the pattern. Next, you wash away the soft photoresist. Chemicals then remove the extra copper. Only the needed copper traces stay on the board. The main chemicals are ammoniacal etchant and cupric chloride. This way works well for regular, flexible, and high-density pcb circuit boards. Big factories use this process a lot because it is steady and saves money.

Tip: Subtractive pcb board production is good for making many boards at once. It gives you strong and steady circuits.

Additive Process

The additive process builds copper traces one layer at a time. You use metal powders, photopolymers, or special inks. This way uses less material and makes less waste. You can make very thin lines, as thin as a hair. New tools like laser direct imaging and 3D printing make this process better. Additive pcb board production is great for quick samples, flexible designs, and small batches. You can try more design ideas and use fewer chemicals, which helps the environment.

Additive Process Advances | Benefits | Uses |

|---|---|---|

Laser Direct Imaging | High precision | Advanced pcb circuit boards |

3D Printing | Fast prototyping | Flexible and custom boards |

Conductive Inks | Less waste, eco-friendly | IoT, medical devices |

Hybrid and Automated Methods

Hybrid and automated methods mix the best parts of subtractive and additive processes. You might use 3D printing to add material. CNC milling can shape the board. Some machines do both jobs at the same time. This way lets you make complex pcb circuit boards with high accuracy. Hybrid pcb board production is good for special shapes or features. Automated systems help you make more boards quickly and with fewer mistakes.

Note: Hybrid and automated manufacturing process methods give you more choices and can save time when making boards.

Types of PCB Circuit Boards

There are many kinds of pcb circuit boards in electronics today. Each kind has special features. These features change how you use them. They also help you pick the best way to make them. You need to think about your project’s size, heat, and how hard it is.

Defining Characteristics | Typical Applications | |

|---|---|---|

Single-Sided PCBs | One copper layer; simple, low cost, easy to make; limited routing. | Calculators, radios, LED lighting |

Copper on both sides; uses vias for connections; supports more complex circuits. | Industrial controls, automotive, amplifiers | |

Made from bendable plastic; lightweight, space-saving, can twist and fold. | Wearables, aerospace, medical devices | |

Aluminum PCBs | Metal core (aluminum) for better heat dissipation; strong and durable. | LED lighting, power supplies, automotive lighting |

Thin/Custom PCBs | Ultra-thin or custom thickness; fits special shapes or needs; supports compact and lightweight designs. | Wearables, medical implants, smartphones |

Single-Sided PCBs

Single-sided pcb circuit boards are used for easy electronics. These boards have copper on one side only. They do not cost much and are simple to make. You find them in calculators and remote controls. They are also used in LED lights. If you want a basic design and low price, this type is good. The subtractive process works well for these boards because it is quick and cheap.

Double-Sided PCBs

Double-sided pcb circuit boards have copper on both sides. You can put parts and traces on both sides. This lets you make harder designs. Vias join the two layers. This helps signals move easily. These boards are used in factories, cars, and amplifiers. If you need more parts or advanced circuits, double-sided boards are better. You can use subtractive or hybrid ways to make these boards.

Tip: Double-sided pcb circuit boards save space and make electronics work better.

Flexible PCBs

Flexible pcb circuit boards use plastic that bends. You can twist or fold them to fit small spaces. These boards are thin and light. They are great for wearables and medical tools. They are also good for foldable gadgets. Flexible pcb circuit boards handle shaking and bumps well. If your design needs to move or fit odd shapes, flexible boards are smart. Additive or hybrid ways work best for these boards.

Aluminum PCBs

Aluminum pcb circuit boards have a metal core. This helps spread heat fast. You see them in LED lights and power modules. They are also used in cars. The aluminum keeps parts cool and helps them last longer. If your project makes lots of heat, aluminum pcb circuit boards help control temperature and keep things safe. You may need special subtractive or hybrid ways to make these boards.

Thin and Custom PCBs

Thin and custom pcb circuit boards let you make special shapes and sizes. Ultra-thin boards fit in small things like smartwatches and hearing aids. Custom boards can be made thicker for more power or strength. You can work with makers to get the design you want. These pcb circuit boards often use flexible stuff or special steps.

Note: The kind of pcb circuit boards you pick changes which way you should make them. Always match your board type to your project’s needs.

Advantages and Disadvantages

Subtractive Process Pros and Cons

The subtractive process is the most used way to make a pcb. You start with a copper board. You take away extra copper to make the circuit. This method has both good and bad sides.

Advantages:

You spend less money because tools and supplies cost less.

You can make lots of boards fast if you need many.

This way works well for easy designs and big orders.

You can use it for multilayer, rigid, and some flexible pcb boards.

The process uses known rules, so you get steady quality.

Disadvantages:

This way makes lots of chemical and metal waste. That hurts the environment.

You use much water and chemicals, so recycling is hard.

You cannot make very tiny lines or small details.

Etching causes most water pollution and ozone problems in pcb making.

Old boards are hard to recycle because they are tough and complex.

Note: The subtractive process is best if you want to save money and do not need tiny details or high reliability.

Advantage Aspect | Subtractive PCB Process Details |

|---|---|

Cost | Equipment costs are 40-60% lower than additive methods. Material costs stay manageable. |

Speed | Fast for simple designs. Closed-loop systems cut chemical use by 40%. |

Scalability | Works well for large-volume production. Material use is 85-95% efficient for big panels. |

Applicability | Good for multilayer, rigid, and some flexible boards. Used in consumer electronics. |

Limitations | Not for very fine features (<2 mil). Makes more waste than additive methods. |

Additive Process Pros and Cons

The additive process puts copper only where you need it. You use special inks, powders, or 3D printing. This way also has good and bad sides.

Advantages:

You can make test boards in hours, not days.

You do not need to order a lot, so you can try many ideas.

Cost and time stay about the same, even for hard designs.

You can make cool shapes, 3D circuits, and special parts.

You use only what you need, so you make less waste.

You can test and fix your design fast for better results.

Disadvantages:

This way does not work well for making many boards at once.

Some makers have trouble with the tech, so boards may not be as good.

You may not get the same quality or high reliability for big batches.

It can be hard to keep costs low for some board types.

Tip: Use the additive process for fast samples, flexible designs, or when you want to try new ideas.

Hybrid/Automated Pros and Cons

Hybrid and automated ways mix people and machines. You might use robots, AI, or special tools to help. These ways have their own good and bad sides.

Advantages:

Machines make boards faster and cut down on mistakes.

Machines check boards better than people, so quality is higher.

Automated systems can make more boards at once, good for big orders.

Hybrid assembly lets you use different parts and soldering for better results.

You can pick which steps to automate to balance cost, quality, and flexibility.

Disadvantages:

Buying and setting up machines costs a lot at first.

You need time to set up and program machines for each new design.

Fixing and caring for machines adds to your costs.

Automated systems use more power and need regular care.

For small jobs or test boards, the high setup cost may not be worth it.

Aspect | Details |

|---|---|

Initial Investment | Entry-level machines start at $10,000; advanced systems can cost over $100,000. |

Setup Time | Programming and calibrating can take hours. |

Maintenance | Annual maintenance for mid-range machines is $1,000 to $3,000, plus power costs. |

Operational Costs | Includes electricity, maintenance, and replacement parts. |

Suitability | Best for high-volume production; less cost-effective for small batches. |

Note: Hybrid and automated ways help you get high quality and speed, but you need to plan for the extra cost and setup time.

Board Type Pros and Cons

Different pcb board types have their own good and bad sides. Your choice changes cost, strength, how well it works, and the effect on the environment.

Single-Sided PCBs

Advantages: Simple, cheap, and easy to make. Good for basic electronics.

Disadvantages: Not much room for parts. Not for hard or high reliability needs.

Double-Sided PCBs

Advantages: More space for parts and lines. Better for hard circuits.

Disadvantages: Costs more and needs more steps to make. Soldering both sides is harder.

Flexible PCBs

Advantages: Bendable, light, and fit in small spaces. Good for wearables and medical tools.

Disadvantages: Materials cost more. Soldering is harder. Not as strong as rigid boards.

Aluminum PCBs

Advantages: Great at spreading heat. Strong and tough. Good for power and LED products.

Disadvantages: Costs more. Needs special steps for solder and assembly.

Thin and Custom PCBs

Advantages: Fit special shapes and tight spaces. Good for custom projects.

Disadvantages: Can break easily. May need special soldering and care.

Tip: Rigid-flex boards are very reliable and save space, but they cost more and need careful design.

PCB materials matter too. FR4 is cheap and easy to get but does not handle heat or high frequencies well. PTFE costs more but works better for fast or high-frequency circuits. All pcb boards use copper, solder, and other stuff that can hurt the environment if not handled right. Many boards have lead, flame retardants, and other chemicals. These can pollute water and soil if you do not recycle them the right way.

Note: Always pick your board type based on your project’s needs for cost, strength, and high reliability. Think about how your choices affect the environment, especially when you use solder and other chemicals in assembly.

PCB Surface Finishes

Common Finishes

When you make a PCB, you must keep copper safe from air and water. A pcb surface finish covers the copper and helps you solder parts. There are many types of surface finishes. Each type is best for certain jobs.

Here is a table with the most common pcb surface finish choices and where you use them:

Surface Finish | Characteristics | Typical Applications |

|---|---|---|

Hot Air Solder Level (HAL) | 60/40 tin-lead; cheap; strong; bumpy surface; not great for SMD. | Through-hole technology; general use; low-cost projects. |

Lead-Free HAL | Like HAL but no lead; tough; good soldering; works at higher heat. | General use; RoHS safe; not best for tiny boards. |

Immersion Silver (IS) | Flat surface; conducts well; not costly; can tarnish; not very tough. | SMD assembly; eco-friendly choice. |

Immersion Tin (Sn) | Flat, shiny surface; can grow tin whiskers; rusts easier. | SMD assembly; press-fit pins; cheap but does not last long. |

ENIG (Electroless Nickel Immersion Gold) | Nickel and gold layers; lasts long; solders well; costs more and is harder to do. | Fine-pitch parts; high-reliability; many reflows; tough places. |

You can also use Organic Solderability Preservative (OSP). OSP is a water-based layer. It protects copper and is good for the environment.

Pros and Cons

Each pcb surface finish has good and bad sides. You should think about price, how easy it is to solder, and how long it lasts.

Hot Air Solder Level (HAL) is strong and cheap. It works well for through-hole parts. The surface is bumpy, so it is not good for small SMD parts.

Lead-Free HAL is like HAL but safer for nature. It handles heat and makes strong solder joints. It is not great for very small boards.

Immersion Silver is flat and easy to solder. It protects well and is good for SMD parts. It can tarnish if stored too long or in wet places.

Immersion Tin is shiny and flat. It is easy to solder but can grow tin whiskers. It does not last as long as other finishes.

ENIG gives a smooth, gold surface. It is great for fine-pitch parts and strong boards. It costs more and takes longer to put on.

Tip: The right pcb surface finish helps you get strong solder joints and keeps your board working longer. Always match the finish to your assembly process and storage needs.

You should also think about how the finish handles heat, water, and chemicals. Some finishes, like ENIG, fight rust and last longer. Others, like OSP, cost less but do not last as long. The finish you pick changes how your board works and how easy it is to build.

Choosing the Right PCB Production Method

Project Requirements

You must pick a pcb production method that fits your project. First, check if your design is simple or complex. Simple boards with few parts can use basic methods. If your board has many layers or odd shapes, you need advanced ways. Think about how fast you need your boards. 3D printing gives you quick samples. Subtractive manufacturing takes longer but is better for big orders.

Check if your project needs to be very reliable. Medical and car projects need high-quality materials and strict checks. Make sure your manufacturer can do pcb assembly and prototyping. Good support and clear talk help you avoid mistakes when you put parts on and solder.

Tip: Always ask if the manufacturer has the right certificates and experience. This helps you get the quality and reliability you need.

Cost and Volume

Cost and how many boards you need are important. If you need lots of boards, subtractive methods save money and time. These ways use less material for each board and are good for big batches. If you only need a few boards or want to test a new idea, additive methods like 3D printing cost less. Hybrid methods are good if you want special features and want to save money.

Best For | Cost Efficiency | Typical Use Cases | |

|---|---|---|---|

Subtractive | High-volume orders | High | Finished products, mass pcb |

Additive | Small batches | Good for low volume | Prototyping, custom designs |

Hybrid | Special projects | Balanced | Complex shapes, repairs |

Always balance cost, quality, and speed. Check setup costs, what materials you use, and how fast you need boards. This helps you not pay extra for things you do not need.

Environmental Factors

Rules about the environment are getting stricter every year. Many places want lead-free solder and safe chemicals in pcb making. You must pick materials and finishes that meet rules like RoHS and REACH. Some finishes, like OSP, use fewer bad chemicals and less energy. Others, like ENIG, last longer but use more harmful stuff.

You can help the earth by picking recyclable materials and eco-friendly solder. Find manufacturers with green certificates. They often recycle copper and use less energy. These steps make less waste and help you follow the law.

Note: Picking the right pcb production method means thinking about design, cost, how many boards you need, and the environment. This helps you get strong, safe, and reliable boards for your project.

You have many choices when making PCB boards. Each way and board type has good and bad sides. To pick the best one, you should do a few things. First, know what your project needs and how much you can spend. Next, use design software and online tools to check materials and make your layout better. Work with makers who follow IPC rules and do strong tests like X-ray, in-circuit, and automated checks. Ask for clear prices and look for quality certificates. If you balance your goals and costs, you can make boards that work well for your project. Planning ahead helps you do well at every step of making PCB boards.

FAQ

What is the best PCB production method for beginners?

You should start with the subtractive process. This method uses simple tools and costs less. You can make basic boards for school projects or small electronics. Many online guides and kits use this method.

How do you choose the right PCB material?

You need to match the material to your project. FR4 works for most uses. PTFE suits high-speed circuits. Aluminum helps with heat. Always check your design needs before you pick.

Can you recycle old PCB boards?

You can recycle some PCB boards. Many companies remove copper and other metals. You should not throw boards in the trash. Recycling helps protect the environment.

Why do PCB boards need a surface finish?

A surface finish protects copper from air and water. It also helps you solder parts to the board. Some finishes last longer or work better for small parts.

Tip: Pick a finish that matches your assembly process and storage needs.

See Also

Emerging Innovations Shaping PCB And PCBA Design

A Deep Dive Into PCBA Assembly And Manufacturing

Best Practices For Maximizing PCBA Quality And Efficiency