You might wonder, what is pcb board and why is it so important in electronics? A pcb board, or printed circuit board, serves as the main support structure for electronic components. Whether you’re using a smartphone, computer, or even a kitchen appliance, a pcb board is essential for holding and connecting all the small parts that make the device function. Over the past decade, the use of pcb boards in electronics has grown significantly due to advancements in technology and increased demand for electronic devices.

A pcb board keeps electronic components stable.

It creates pathways for signals and power.

Everyday electronics rely on pcb boards to operate effectively.

Key Takeaways

A printed circuit board (PCB) keeps electronic parts in place and connects them. This helps devices like phones and computers to work. PCBs have copper paths that move power and signals fast and clearly between parts inside devices. There are different types of PCBs, like single-sided, double-sided, multilayer, flexible, and rigid. These types fit different device needs and shapes. PCBs help make electronics smaller, stronger, and more dependable by holding parts and lowering signal issues. Careful PCB design and testing help devices last longer and work well every day.

What Is a PCB Board

Printed Circuit Board Definition

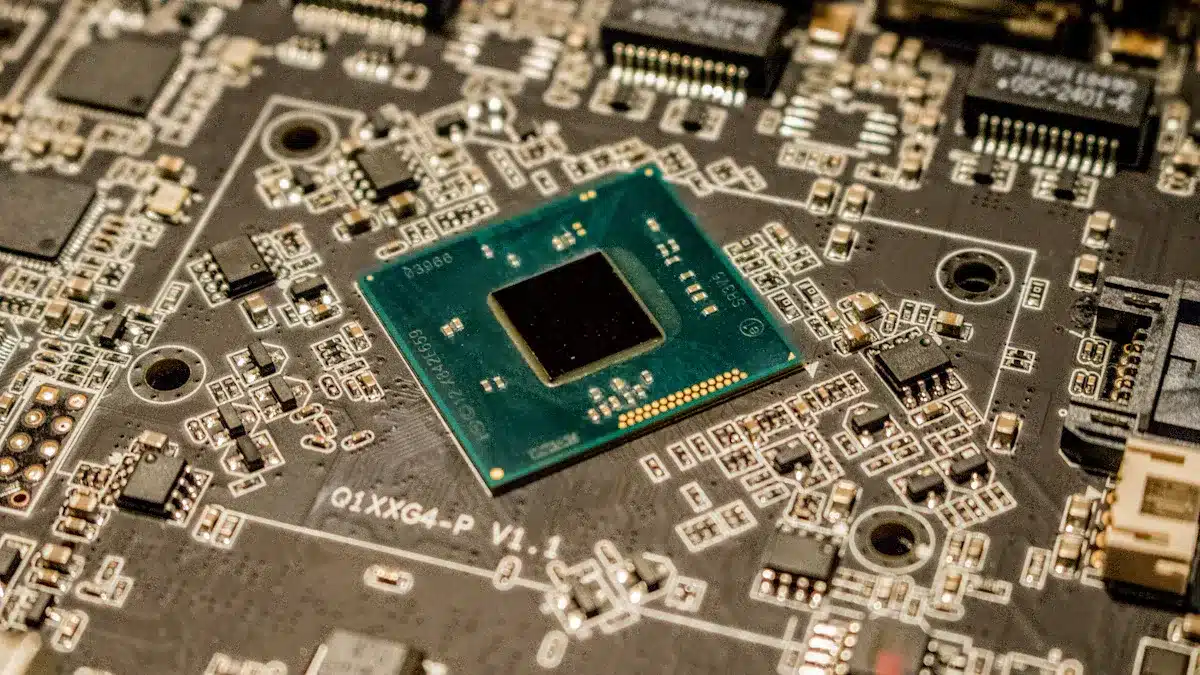

When you ask, “what is pcb board,” you are learning about the base of modern electronics. A printed circuit board connects and holds parts using copper lines. You can find these boards in almost every device you use each day. The board has layers made of copper and material that does not let electricity pass. These layers work together to make paths for signals and power.

International rules, like IPC 2221, say a printed circuit board is a platform with copper traces, pads, and planes to link parts. The board also has a solder mask and silkscreen. The solder mask covers the copper and helps with soldering. The silkscreen adds labels so you can find things easily. You see these when you look at the green board and white writing on most circuit boards.

Printed circuit boards use different materials to do their job. The main base is usually FR-4, which is a strong fiberglass material. This gives the board strength and keeps electricity from leaking. Copper foil makes the paths for electricity. The solder mask, which is often green, covers the copper to stop rust and mistakes when soldering. The silkscreen layer puts words and symbols on the board. Some boards use other bases, like FR-2 or polyimide, for special uses.

Tip: You can find a printed circuit board in your devices by looking for a flat, green board with shiny copper lines and white letters.

Here is a simple table showing the main layers of a printed circuit board:

Layer | Purpose |

|---|---|

Substrate | Gives strength and stops electricity leaks |

Copper | Carries signals and power |

Solder Mask | Protects copper and helps with soldering |

Silkscreen | Adds labels for easy finding |

Core Function

You need the printed circuit board to make your electronics work. The main jobs of a circuit board are to hold parts and let electricity flow. The board keeps things like resistors, capacitors, and chips in place. It keeps all the parts neat and steady.

Copper traces on the board act like roads for electricity. These traces link parts so they can talk and share power. You see this when your phone lights up or your computer starts. The board’s design makes sure signals move fast and right.

The printed circuit board sends power to every part of the device.

It moves data and control signals between parts.

It holds both passive and active parts, like capacitors and transistors.

You get help from the careful way circuit boards are made. Power and ground planes inside the board give steady power. Decoupling capacitors near chips cut down noise and keep signals clear. The printed circuit board also uses special ideas to stop signal loss and problems.

Here is a quick look at the main functions of a printed circuit board:

Function Type | Description |

|---|---|

Holds and supports parts; keeps them steady and safe | |

Electrical | Links parts with copper traces; lets signals and power move |

When you use any electronic device, you count on the printed circuit board to keep it working well. Without circuit boards, making and using complex electronics would be very hard. You can see how pcb design helps your favorite gadgets work better and last longer.

How Printed Circuit Boards Work

Electrical Connections

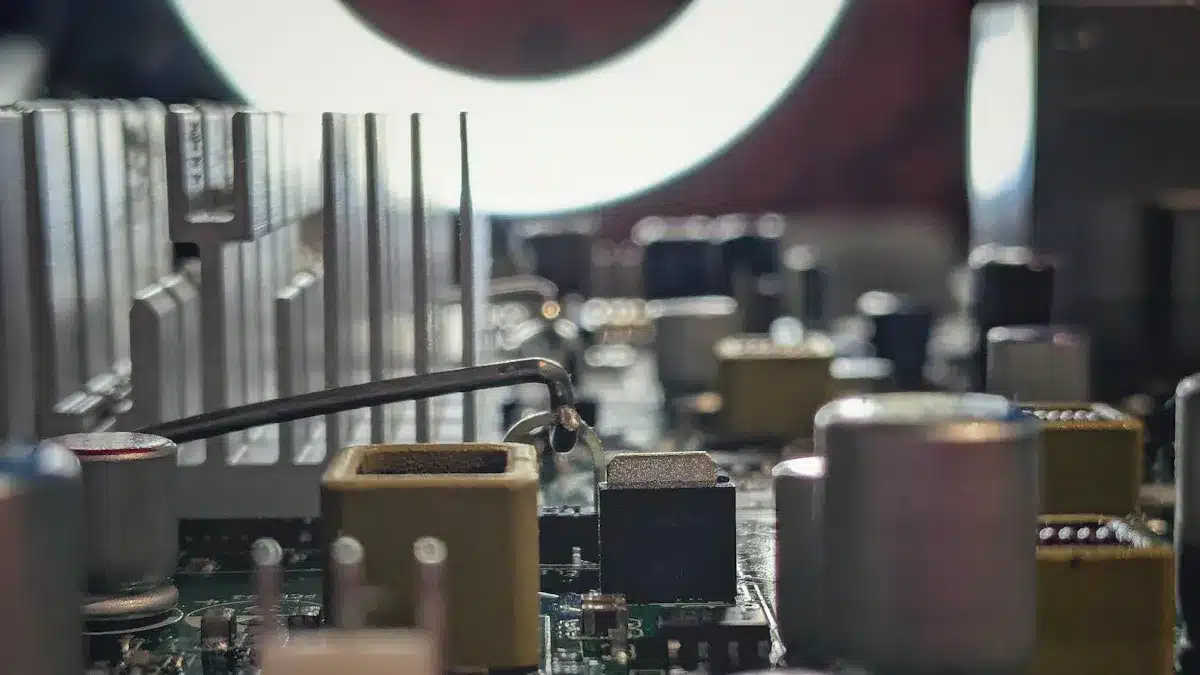

A pcb links all the parts inside your device. Copper traces on the board make paths for electricity. These traces work like tiny roads for signals and power. The board starts with copper and insulating layers. Makers press these layers together to build the base. They use light to mark the copper. Then, they remove extra copper with a special process. This leaves the needed circuit paths.

Here is a simple list showing how a pcb routes signals and power:

Press copper and insulating layers to make the base.

Remove extra copper to create the right patterns.

Drill holes for the parts to fit in.

Cover the holes with copper to link layers.

Add a solder mask and labels for safety and names.

Copper traces let signals move fast with little loss. The way the board is made is important. Short, straight traces help stop problems. Keeping parts close and traces near ground planes lowers noise. This is why your devices work well without errors.

Note: Short traces and matched pairs for fast signals keep signals clear and stop crosstalk.

Mechanical Support

A pcb does more than carry signals. It also holds all the parts in place. The board uses a hard base made from glass fibers and resin. This base keeps everything steady, even if you move the device. Some boards have metal cores, like aluminum, for more strength and to help with heat.

You can find different types of boards. Rigid boards do not bend. Flexible boards can bend without breaking. Rigid-flex boards mix both types for tricky shapes. Thick copper layers make boards stronger, especially in powerful devices.

How It Helps Stability and Organization | |

|---|---|

Rigid substrate | Keeps components steady and safe |

Flexible layers | Allow bending for special shapes |

Metal core | Adds strength and helps with heat |

Multilayer structure | Supports organized routing and extra stability |

Provide strong physical connections |

Through-hole parts go through the board for extra strength. These parts stay put during shaking or bumps. In cars or planes, you often see through-hole mounting for big or key parts. Rubber spacers and special fillings can also protect the board from shaking and stress.

The way a pcb is built helps your devices last longer and work well. Good planning supports both the electrical and physical jobs of every pcb.

Circuit Board Types

Single-Sided and Double-Sided

Not every circuit board looks the same. The single-sided pcb is the simplest kind. It has copper traces on just one side. You put parts on one side only. This makes it easy and cheap to make. Things like calculators and LED lights use single-sided boards. Basic radios also use them.

Double-sided pcb boards have copper on both sides. You can put parts on both sides. This lets you make more complex designs. Small holes called vias connect the two layers. Double-sided boards can hold more circuits. They also give better signal quality. You see these boards in computers and amplifiers. Cars use double-sided boards too.

Single-Sided PCB | Double-Sided PCB | |

|---|---|---|

Copper Layers | One side only | Both sides |

Component Mounting | One side | Both sides |

Routing Capability | Simple | Complex, higher density |

Signal Integrity | Basic | Improved with ground/power planes |

Typical Applications | Calculators, LED lights, radios | Computers, smartphones, automotive electronics |

Tip: Look for traces and solder pads on both sides to spot a double-sided board.

Multilayer Boards

If you need more power, use multilayer pcb boards. These boards stack many copper layers with insulation between. Most have 4, 6, or 8 layers. Some can have up to 100 layers for special uses. More layers mean more circuits fit in less space.

Multilayer boards help make devices smaller and lighter. They also make devices work better and last longer. You find these boards in smartphones and laptops. Medical tools and satellites use them too. Extra layers help signals move faster and clearer.

Multilayer boards work for high-speed and dense circuits.

They make devices tough and small.

Medical, car, airplane, and phone companies use multilayer boards for advanced products.

Flexible and Rigid Boards

Some circuit boards bend, but others stay stiff. Flexible pcb boards use special stuff that lets them twist and fold. These boards fit into tiny spaces and odd shapes. You see flexible boards in phones and watches. Hearing aids and satellites use them too. They are light and handle shaking well.

Rigid pcb boards use strong materials like fiberglass. These boards give support for heavy or fast parts. You find rigid boards in desktop computers and TVs. Home appliances use them too.

Some devices use rigid-flex pcb boards. These mix both types for strength and bending. Rigid-flex boards work in tricky devices that need both support and flexibility.

PCB Type | Performance Highlights | Typical Uses |

|---|---|---|

Rigid | Strong, stable, supports heavy components | Computers, TVs, appliances |

Flexible | Bends, fits tight spaces, absorbs vibration | Wearables, medical, aerospace |

Rigid-Flex | Combines strength and flexibility | Smartphones, cameras, military |

Note: Flexible boards help you make smaller, lighter, and stronger electronics.

Applications and Importance

Everyday Electronics

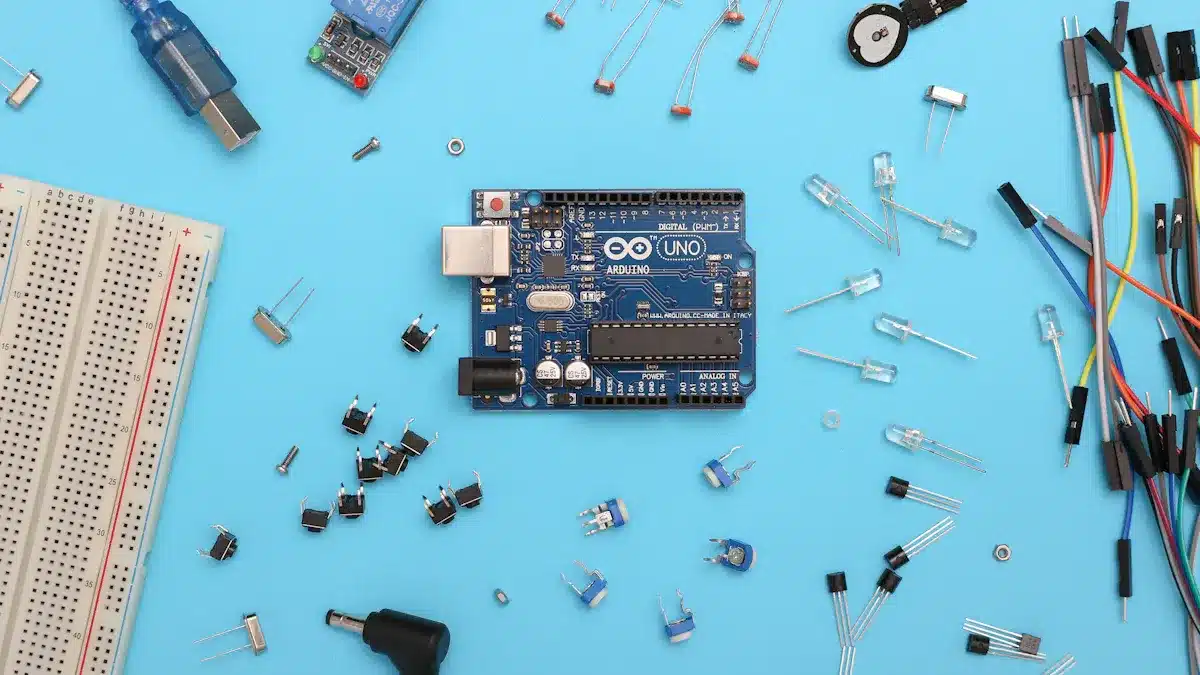

You use devices with a pcb every day. You might not notice them. The pcb is a key part inside many electronics. It connects and holds all the small parts together. These boards are in your smartphone and computer. You can also find them in your kitchen blender. Pcbs help your devices work well and stay reliable.

Here is a table showing where pcb boards are found:

Category | Examples |

|---|---|

Consumer Electronics | Smartphones, tablets, computers, digital cameras, microphones |

Home Appliances | Coffee makers, refrigerators, alarm clocks |

Security Systems | Electronic door locks, security cameras, smoke detectors |

Automotive | GPS systems, dashboard displays, engine control units |

LED Lighting | Home lighting, car headlights, computer screens |

You can see pcb boards in gaming consoles and TVs. Stereo systems also use these boards. Pcbs make sure signals and power reach every part.

Tip: When you use your coffee maker or play games, remember a pcb is inside making it work.

Reliability and Miniaturization

A pcb does more than connect parts. It helps electronics last longer and work better. Makers use special ways to make sure each pcb is high quality. They test for heat, moisture, and shaking. This keeps your devices safe and working well.

Miniaturization helps you because pcb boards let devices get smaller and lighter. Engineers use smart designs and tiny parts to fit more features in less space. Flexible pcb boards can bend and twist. This helps them fit in wearables and foldable gadgets. Surface mount technology and microvias let designers add more circuits to one board. This makes your electronics small and strong.

Custom pcb layouts keep devices neat and small.

Surface mount parts and microvias add more parts.

Careful testing makes sure each pcb can handle tough use.

Pcbs help make modern electronics small and reliable. You get smarter and better devices because of these new pcb uses.

PCB Manufacturing Basics

Design and Fabrication

Every pcb starts with a careful design. People use special software to make the layout. Some popular programs are Altium Designer, OrCAD, Autodesk EAGLE, and KiCad EDA. These tools help you draw circuits and check for mistakes. They also help you get files ready for making the board. You can see 3D views and check signals in these programs. They have big libraries of parts to use.

Making a pcb follows clear steps. Here is a simple list to show how it works:

Get your pcb design files ready. Export Gerber files, drill files, and a Bill of Materials.

Check your pcb design for mistakes and see if it is easy to make.

Print photo films for each pcb layer to line them up.

Put on photoresist and use UV light to mark copper paths.

Remove extra copper, leaving only the needed traces.

Press layers together for multilayer boards.

Drill holes for connections and cover them with copper.

Add a solder mask and silkscreen for protection and labels.

Finish the surface and test the bare pcb.

Place and solder parts onto the pcb.

Test the finished pcb before using it.

Tip: A good pcb design helps you avoid mistakes and makes building the board easier.

Quality and Testing

You want every pcb to work well and last a long time. Quality control starts with the pcb design. You check files for mistakes and make sure the layout follows rules. During production, you watch each step to catch problems early.

Makers use many tests to check each pcb. Here are some common ways:

Automated Optical Inspection uses cameras to find missing parts or bad solder joints.

X-ray Inspection looks inside the pcb to find hidden problems.

In-Circuit Testing checks each circuit and part to see if it works right.

Functional Testing turns on the pcb to see if it works as planned.

Flying Probe Testing uses moving probes to test connections without special tools.

Environmental Stress Testing puts the pcb under heat, cold, or shaking to check strength.

You also see final checks and paperwork to track results. Certifications like ISO 9001 and IPC-A-600 show that a pcb meets industry rules.

Note: Careful testing and strong pcb design give you electronics that work well and last longer.

You use PCBs when you use your phone or computer. These boards hold and link every part inside. They help make electronics smaller and faster. They also make devices work better and last longer.

New gadgets like foldable phones use high-density and flexible boards.

Smart materials and new ways to build boards help devices work well and protect nature.

When you use your favorite device, think about the PCB inside. It helps your device work and pushes technology ahead.

FAQ

What does PCB stand for?

PCB stands for Printed Circuit Board. You see these boards in almost every electronic device. They connect and support all the small parts that make your device work.

Why do electronics need PCBs?

You need PCBs to keep electronic parts organized and connected. PCBs help signals and power move between parts. They also make devices smaller and more reliable.

Can you repair a damaged PCB?

You can fix some simple problems, like broken traces or loose parts. For big damage, you may need special tools or a new board. Always check for safety before trying repairs.

Are all PCBs green?

Most PCBs look green because of the solder mask. You can find boards in other colors, like blue, red, or black. The color does not change how the board works.

See Also

Comparing Structural And Functional Aspects Of PCBA Versus PCB

How PCBA Is Utilized In Modern Consumer Electronics

Understanding PCB Busbars And Their Importance In Electronics