Choosing the right circuit board producer is very important for your project’s success. A good circuit board can make your product work better and last longer. For example, the kind of PCB material you pick affects how well it handles heat and stress from the environment. If you use bad materials, your board might bend or lose signals. This can hurt how your device works. So, it is important to know what you need and to check out different circuit board producers carefully to get the best results.

Key Takeaways

e ISO 90Pick a PCB maker that meets quality rules lik01 and IPC. This helps make sure they produce high-quality products.

Choose companies with a good reputation and happy customers. This can help you avoid problems later.

Check what tools and technology the makers have. This is important for your project.

Think about how fast they can work and how much it will cost. Faster services might cost more but can help with tight deadlines.

Ask for samples to check the quality. This way, you can see if the maker can meet your project needs.

Key Considerations for PCB Manufacturers

When you choose a circuit board maker, think about some key things. These can really affect how well your project does. Here are the most important things to think about:

Quality Standards

Quality is very important in making PCBs. You should find makers that follow known rules like ISO 9001 and IPC. These rules make sure the maker uses strict quality checks during production.

IPC rules help with quality checks and methods in PCB making.

They cover all steps of making PCBs, keeping product quality steady.

Following IPC rules helps teams talk better and reduces mistakes, which is key for quality.

Using these rules can save money by cutting down design mistakes and rework, helping with quality.

By checking quality standards, you can make sure the circuit board maker you pick produces high-quality work.

Experience and Reputation

The experience and reputation of a PCB maker are very important for their trustworthiness. You should choose makers with a good history in the field.

Happy customers often see the maker as reliable, high-quality, and good at service.

Customer surveys show how well a factory does in quality, communication, flexibility, and after-sales help.

Good ratings from customers show the maker is reliable and has experience.

Positive comments on after-sales help show the maker wants long-term partnerships.

Picking a trustworthy PCB maker with a strong reputation can help you avoid problems and make production easier.

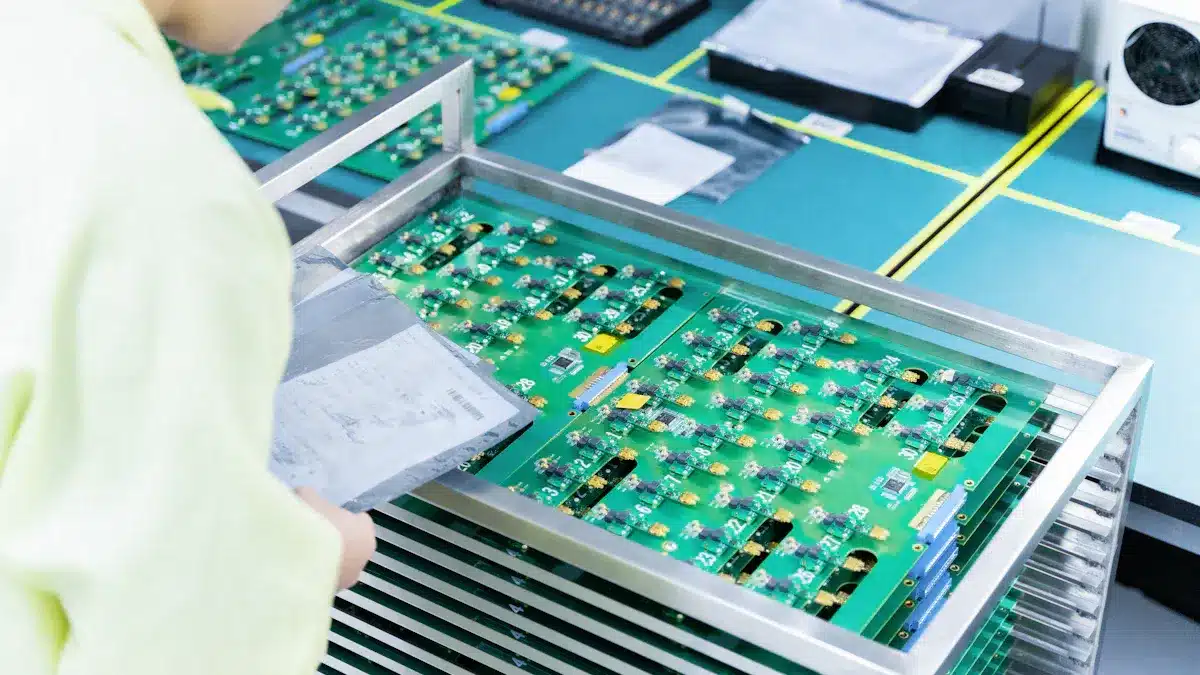

Manufacturing Capabilities

You need to check the manufacturing skills of possible PCB makers. Modern tools and technology can really change the quality and speed of production. Look for makers that use:

Computer Numerical Control (CNC) Equipment

PCB Printing and Imaging Technology

Wet Process Equipment

Multi-layer Presses

Surface Finishing Technology

Testing technologies

These skills can improve the quality of your custom PCBA and make sure the maker can meet your needs.

Turnaround Time

Turnaround time is another important thing to think about. Depending on your project schedule, you might need a maker that can deliver fast. But remember, faster services usually cost more.

Fast PCB services are pricier per unit because they focus on speed.

Regular turnaround options save money, especially for larger orders.

Fast services can deliver prototypes in just 24 hours, while regular production takes 2-4 weeks.

Knowing how speed affects cost will help you decide based on your budget and timeline.

Researching Circuit Board Producers

When you begin looking for a circuit board producer, doing good research is very important. You want to find a maker that fits your needs. Here are some key steps to help you with your research.

Evaluating Feedback

Customer feedback is very important when choosing a PCB manufacturer. You should check reviews on sites like Google Reviews and industry forums. These reviews give you information about a maker’s reliability and service quality. Here are some tips for checking feedback:

Look for patterns: See if many customers mention the same strengths or weaknesses.

Talk to non-competing companies: They can share their experiences and tell you about a maker’s strengths or weaknesses.

Think about the number of reviews: More reviews can mean a more reliable view of the manufacturer.

By carefully checking feedback, you can get a better idea of which PCB makers are trustworthy and can deliver quality products.

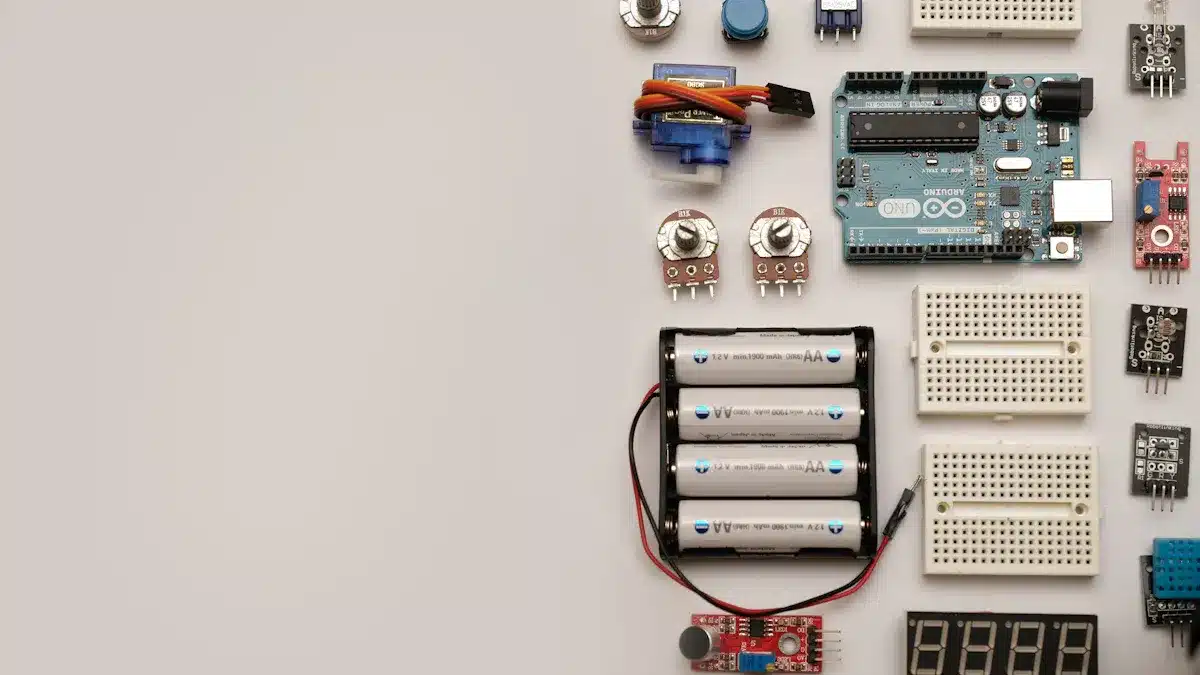

Requesting Samples

Requesting samples from possible PCB manufacturers is an important step in your selection process. Samples let you check the quality of their work yourself. When you ask for samples, think about these criteria:

Number of board layers

Size of each board

Material

Minimum hole size

Number of holes

Minimum trace width

Minimum space between traces

Outer layer copper finish

Annular ring requirements

Also, don’t forget these often missed details:

Solder mask details

Surface finish

Silkscreen

Impedance details

Stack-up details

Cut-out

By looking at these aspects, you can understand what a custom PCBA manufacturer can do and how well they can meet your project needs.

Comparing Options

After you gather feedback and samples, you need to compare your options. This step helps you find the best fit for your needs. Think about these factors when comparing different circuit board producers:

Size capabilities: Find out the biggest dimensions a vendor can handle during making.

Material choices: Check if larger raw material sheets are available.

Complexity of designs: See how the number of layers and complex designs affect production quality.

Production volume: Understand how larger boards change costs and production processes.

Lead times: Check how shipping and packaging limits affect delivery times.

Quality assurance measures: Make sure the manufacturer has strong quality assurance processes.

By comparing these factors, you can make a smart choice about which PCB manufacturer fits best with your project goals.

Making the Final Decision with a PCB Assembly Company

Pricing and Cost

When you pick a PCB assembly company, knowing about pricing and costs is very important. Many things affect these costs, like materials and how complex the design is. Here are some key points to think about:

Fixed and Variable Costs: PCB making has both fixed and variable costs. Fixed costs include making stencils and testing designs. Variable costs change based on how many units you order.

Bulk Order Discounts: The price for each PCB goes down with larger orders because of shared tooling costs. For example, low-volume orders may cost more because of setup fees. On the other hand, mass production can give you the lowest price per unit.

Order Volume | Cost Per Unit Reduction |

|---|---|

Low-volume orders | Higher due to setup fees |

Medium Volume (50-100 pcs) | |

Mass Production (1000+ pcs) | Lowest price per unit |

Knowing these details helps you plan your budget for printed circuit board assembly.

Contract Terms

Looking over contract terms is very important when working with a PCB assembly company. Key terms to check include:

Key Term | Description |

|---|---|

Scope of Work | Lists services like PCB assembly, sourcing parts, and testing. |

Product Specifications | Contains technical details like Gerber files, tolerances, and assembly drawings. |

Quality and Inspection Standards | Shows quality goals and testing methods. |

Pricing and Payment Terms | Explains pricing structure, payment schedules, and cost changes. |

Lead Times and Delivery Schedule | Describes usual lead times, shipping details, and penalties for late delivery. |

Intellectual Property Protection | Protects unique designs and requires confidentiality. |

Change Management (ECOs) | Explains how to submit and approve design changes. |

Warranty and Liability | Covers warranty periods and limits for defects. |

Dispute Resolution | States governing law and ways to solve conflicts. |

Termination Conditions | Lists conditions for ending the contract and what happens after. |

These terms help protect your interests and ensure clear communication during the project.

Establishing Long-term Partnerships

Creating long-term partnerships with a PCB assembly company has many benefits. Here are some advantages:

Benefit | Description |

|---|---|

Commitment to Quality Standards | Following strict quality standards ensures high quality and reliability, reducing defects and improving product performance. |

Faster Turnaround and Shorter Lead Times | American manufacturers provide big advantages in turnaround times, helping businesses finish projects faster and meet tight deadlines. |

Enhanced Collaboration and Communication | Being local helps with better teamwork, allowing for quick problem-solving and real-time feedback. |

Environmental Benefits and Cost Savings | Local manufacturing cuts down transportation distances, lowering carbon emissions and supporting eco-friendly practices, which can lead to better pricing. |

Supporting Local Economies and Workforce Development | Partnerships create jobs and boost investment in the community, helping economic growth. |

Building a long-term relationship with a circuit board producer can improve supply chain stability and encourage innovation, which is good for your projects.

Choosing the right circuit board maker is very important for your project’s success. Pay attention to these key points:

Quality Standards: Make sure the maker follows industry rules.

Experience and Reputation: Pick producers with a good history.

Manufacturing Capabilities: Check their tools and technology.

Service: Look at delivery times and customer help.

Don’t make common mistakes, like ignoring design quality. By following these steps, you can make smart choices. Act now to find a circuit board maker that fits your needs and boosts your project’s success.

FAQ

What should I think about when picking a PCB maker?

You should think about quality standards, experience, manufacturing skills, turnaround time, and pricing. Each of these affects how well your project does.

How can I check a PCB maker’s quality?

Look for certifications like ISO 9001 and IPC standards. Check customer reviews and ask for samples to see their quality yourself.

Why is it important to ask for samples?

Asking for samples lets you check the maker’s work quality. It helps you see what they can do and makes sure they fit your project needs.

How do I compare different PCB makers?

Compare makers based on size capabilities, material options, design complexity, production volume, lead times, and quality checks. This helps you make a smart choice.

Why should I build a long-term partnership with a PCB maker?

A long-term partnership can improve teamwork, boost quality, and lower costs. It also encourages new ideas and stability in your supply chain, which helps your projects.

See Also

Tips for Choosing the Right PCB Prototype Manufacturer

Finding the Ideal PCBA Manufacturer for Your Business

Selecting the Perfect PCB Fabrication Manufacturer for You