Circuit boards are crucial components of modern electronics. They connect various parts of devices, enabling them to function together seamlessly. The market for printed circuit boards (PCBs) is projected to experience significant growth, potentially reaching around USD 82 billion by 2024. By 2033, this figure could rise to USD 113 billion. This expansion indicates a growing demand for circuit boards. Additionally, the consumer electronics market may exceed $1 trillion by 2028. Understanding how these circuit boards operate can enhance your appreciation of their role in everyday technology.

Key Takeaways

Circuit boards link electronic parts. This helps devices work well and efficiently.

Knowing how circuit boards are built helps us see their importance in technology today.

Good power distribution is very important for circuit board performance. Reducing impedance can make them more reliable.

Active and passive parts work together on circuit boards. They help control electrical signals and energy.

Knowing about common circuit board problems, like short circuits and part failures, can help keep devices working better.

What Are Circuit Boards?

Definition and Purpose

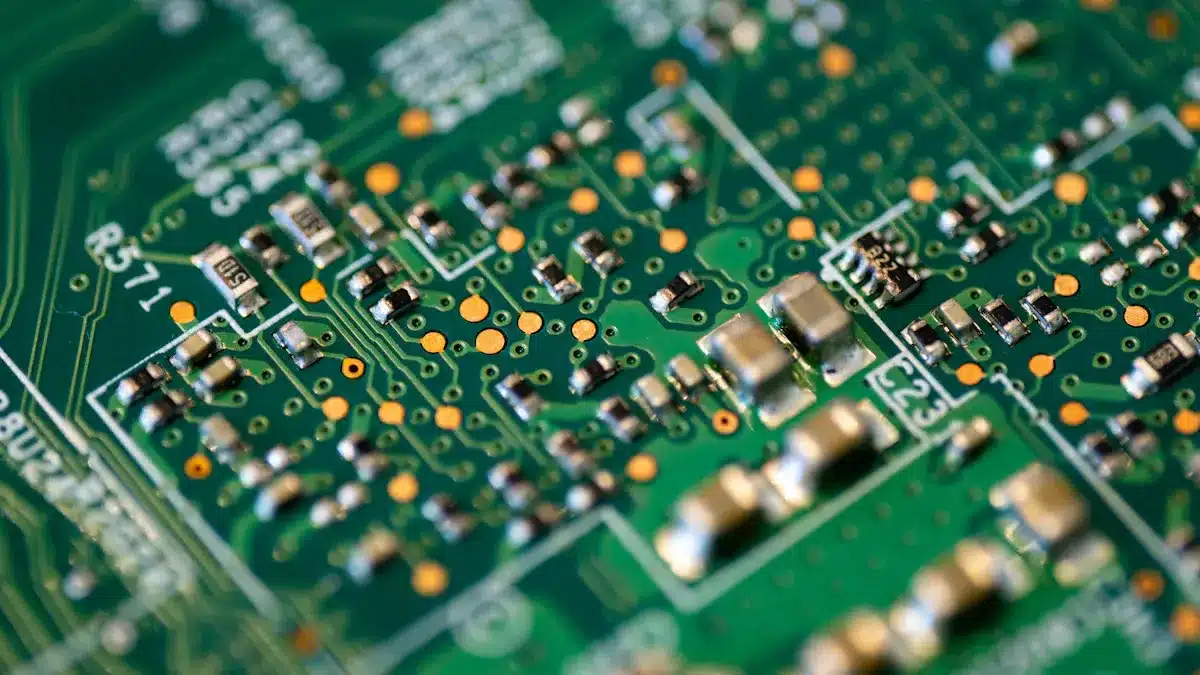

A circuit board is a flat piece that connects different electronic parts. It is the main support for most electronic devices. This helps them work correctly. The most common type of circuit board is the printed circuit board (PCB). According to electronics engineering standards, a PCB is defined as:

Term | Definition |

|---|---|

Printed Circuit Board (PCB) | A flat piece made of insulating material with a pattern of conducting material. It becomes an electrical circuit when parts are attached and soldered to it. The conducting material is usually copper, which is coated with solder or plated with tin or tin-lead alloy. The common insulating material is epoxy laminate. But there are many other materials used in special technologies. |

PCBs are very important in modern electronics. They help connect electronic parts, provide a compact design, and ensure reliable signal transmission. You can think of them as highways for electrical signals, guiding them through set paths. This guidance is key for the performance and reliability of electronic systems. As one expert said, “PCBs are the backbone to electronic devices as they aid in enabling their operation and functionality.”

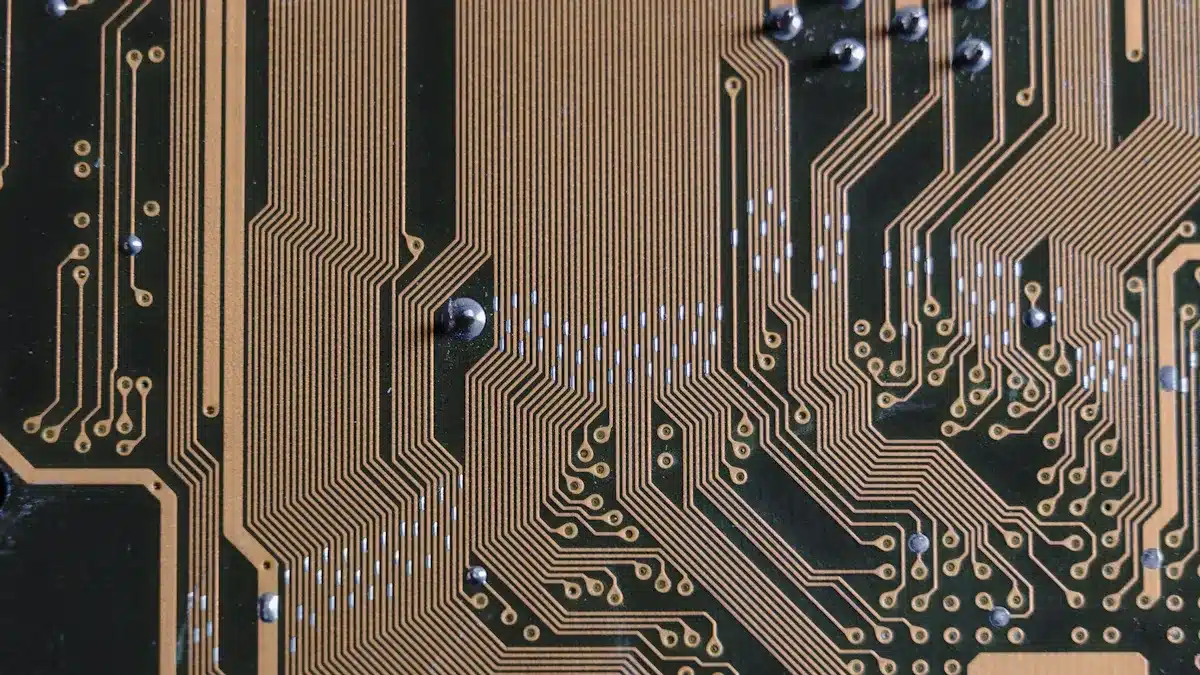

Basic Structure

The structure of a typical PCB has several layers. Each layer has a specific job, helping the circuit board work well. Here’s a breakdown of the main layers found in a PCB:

Layer Type | Description |

|---|---|

Copper Layers | Contains pads for SMD and through-hole parts, essential for electrical connections. |

Substrate Layers | Provides support and insulation, usually made of FR-4 material. |

Solder Mask Layers | Defines openings for soldering parts, ensuring copper exposure for mounting. |

Silkscreen Layers | Contains reference designators and markings for part orientation, essential for PCB layout. |

You can find single-layer PCBs, which have one copper layer, and multi-layer PCBs, which have many copper layers between insulating materials. Single-layer designs are simpler and cheaper, making them good for basic uses. In contrast, multi-layer designs allow for complex circuits and more parts.

Knowing the definition and structure of circuit boards helps you see their importance in electronics. As technology grows, the design of circuit boards keeps changing and drives new ideas in consumer electronics.

How Do Circuit Boards Work?

Knowing how circuit boards work is important for understanding electronics. The parts on a circuit board work together to let devices do different tasks. Each part has a special job, and together they form a working circuit.

Signal Flow

Electrical signals move through a circuit board using copper traces. These traces are like paths that connect different parts. Here’s how the signal flow happens:

Conductive Traces: Copper paths carry electrical signals between parts.

Components: Active and passive parts change or handle signals.

Vias: These connect traces between different layers of the PCB.

Connectors: Interfaces let signals enter or leave the PCB.

Keeping these signals strong is very important. Weak signals can create noise, which can break parts. This affects how well they work now and in the future. Weak signals can make parts use more power, causing extra heat. This heat can shorten their lifespan.

Here’s a table that shows the main parts and how they work together:

Component | Function | Interaction |

|---|---|---|

Transistors | Act as switches or amplifiers | Control current flow and boost signals, helping circuits work properly. |

Diodes | Control the direction of current flow | Let current flow one way, protecting parts and managing signals. |

Capacitors | Store and release electrical energy | Provide energy storage for handling signals and controlling power. |

Fuses | Protect circuit parts from too much current | Break the circuit when too much current flows, stopping damage to other parts. |

Potentiometers | Allow changes in resistance | Enable real-time changes of circuit settings, like volume control. |

Relays | Electrically operated switches | Control high current circuits with low-power signals, ensuring safety and isolation. |

Power Distribution

Good power distribution across a circuit board is key for its performance. You need to reduce impedance between the power source and parts to avoid voltage drops. Here are some ways to ensure good power distribution:

Minimize Impedance: This stops voltage drops that can hurt performance.

Use Wide Trace Widths: Wider traces lower resistance and improve current flow.

Incorporate Multiple Power Planes: This lowers impedance and keeps voltage steady.

Mitigate Parasitic Effects: Improve trace routing and use low-resistance materials.

Strategically Place Decoupling Capacitors: These lessen voltage ripple and noise.

Problems in power distribution can happen, especially in crowded circuit boards. Here’s a table showing common problems:

Challenge | Description |

|---|---|

Joule heating effect | Creates hot spots and raises resistance, causing voltage drops and possible part failure. |

Voltage drops | Sudden drops can lead to low voltage levels, hurting reliability and causing too much heat. |

Power supply noise | Causes voltage changes that can affect PCB design and power quality. |

Dielectric breakdown | High voltage can break insulation, leading to short circuits and overheating of traces. |

By learning how circuit boards work, you can see the detail and care needed in their design and function. This knowledge is important for anyone curious about electronics and technology.

Basic Components of a Circuit Board

Circuit boards have many parts that are important for how they work. These parts are divided into two main groups: active components and passive components. Knowing about these parts helps you understand how circuit boards function.

Active Components

Active components are key for controlling and boosting electrical signals. They need a power source to work. Here are some common active components found on circuit boards:

Transistors: They work as amplifiers or switches. They are important for both digital and analog circuits.

Diodes: They let current flow in one direction. You often see them in rectification and voltage regulation.

Integrated Circuits (ICs): These small packages have many parts inside. They improve performance and make devices smaller.

Microcontrollers: They run code and control other parts in devices, making them useful for many tasks.

Voltage Regulators: They keep voltage levels steady for sensitive parts, ensuring they work well.

Integrated circuits (ICs) are very important for how a circuit board works. They do many jobs, as shown in the table below:

Functionality | Description |

|---|---|

Signal Amplification | ICs boost weak electrical signals, which is important for audio and communication systems. |

Data Processing | Microprocessors do calculations and control tasks that are essential for different systems. |

Memory Storage | Memory ICs keep data and program instructions, which help devices work. |

Logic Operations | Logic gates do binary operations, helping with decision-making and data handling. |

Signal Conversion | ADCs and DACs change signals between analog and digital, which is needed for real-world signals. |

Passive Components

Passive components do not need a power source to work. They help active components by managing electrical signals and energy. Here are some common passive components on circuit boards:

Resistors: They control electricity flow and stop parts from getting overloaded.

Capacitors: They store and release electrical energy, filter noise, and stabilize voltage.

Inductors: They store energy in a magnetic field, filter noise, and match impedance.

Transformers: They are used for circuit isolation and changing voltage levels.

Diodes: They allow current to flow in one direction, used for signal clipping and rectification.

Resistors and capacitors are very important for how electronic circuits behave on a PCB. Here’s how they affect circuit performance:

Resistors limit current and divide voltage, making sure the right levels reach different parts of a circuit.

Capacitors act as filters, smoothing out voltage changes and providing stable power.

In audio circuits, resistors control volume and signal levels, while capacitors couple signals and create audio filters.

The mix of resistors and capacitors in RC circuits forms the basis of timers and oscillators, deciding how fast they charge and discharge.

Together, resistors and capacitors form the backbone of filter circuits, allowing certain frequencies to pass while reducing others.

By learning about the basic components of a circuit board, you can see how these parts work together to make electronic devices function. Each part has a special role, helping the circuit board perform well and reliably.

Manufacturing Printed Circuit Boards

Making a circuit board has several important steps. It starts with design and prototyping, then goes to final production. Knowing these steps helps you see how complex and precise making printed circuit boards can be.

Design and Prototyping

The design and prototyping stage is very important in making PCBs. You start with an idea and follow these steps:

Conceptualization and Design: You decide what the circuit board will do and draw your ideas.

PCB Layout Design: You use software to make a detailed layout of the board. Some popular tools are:

Altium Designer: Best for complex, multi-layer boards.

Autodesk EAGLE: Good for small to medium projects.

KiCad: Great for hobbyists and professional designs.

Prototype Manufacturing: You make a prototype based on your design. This helps you test the layout and how it works.

Assembly: You put electronic parts onto the prototype board.

Testing and Debugging: You check the prototype for mistakes and fix them.

Iteration: You improve the design based on what you found during testing.

Finalizing for Production: You get the design ready for mass production, making sure everything is correct.

This process helps ensure that the final product works well and meets your needs.

Production Techniques

After finalizing the design, you move to the production techniques for making printed circuit boards. Here are some main techniques:

Mechanical Drilling: This makes holes for component leads.

Laser Drilling: It creates smaller and more precise holes, which is important for high-density boards.

Chemical Deposition of Copper: This step makes electrical connections on the board.

Outer Layer Imaging: It ensures the right pattern is put on the board.

Screen Printing: This applies solder masks and other markings.

Surface Finishing Methods: These improve the board’s durability and performance.

Making a circuit board needs careful attention to detail. Each step is important to make sure the final product is high quality and works correctly.

The materials used in making printed circuit boards also affect performance. Common materials include:

FR-4: Made from fiberglass and epoxy resin; it is strong and insulates well.

Rogers: Made of polymer and ceramic; it has high thermal stability and good electrical performance.

Metal-Core: Uses a metal base like aluminum or copper; it helps with thermal management.

Polyimide: Known for being flexible and lightweight; it resists high temperatures and chemicals.

By learning about the manufacturing process and materials, you understand how printed circuit boards are made and why they are important in modern electronics.

Common Issues with Circuit Boards

Circuit boards can have many common problems that affect how well they work. Knowing about these issues helps you fix problems and take care of your devices.

Short Circuits

A short circuit happens when electrical current takes an unwanted path. This can cause devices to fail or get damaged. Here are some main reasons for short circuits on printed circuit boards:

Dirt or contamination from poor cleaning and salt buildup.

Growth of conductive anodic filamentation (CAF) from chemical reactions.

Problems with applying solder paste that create solder bridges.

Too many components close together causing spacing problems.

You might also see design problems, manufacturing mistakes, and environmental issues that cause short circuits. For example, not having enough space between traces and a bad layout can lead to trouble. To stop short circuits, think about these steps:

Description | |

|---|---|

Isolation Techniques | Use slots or trenches on the PCB to keep high-voltage and low-voltage traces apart. |

Design Rule Checking (DRC) | Use DRC software to make sure design rules are followed, preventing spacing and clearance problems. |

AOI-Automated Optical Inspection | Use AOI systems to find soldering mistakes that could cause short circuits. |

Controllable Current Limiting | Add resistors in series with important traces to limit current flow and protect parts. |

Thermal Overload Protection | Put in thermal protection devices to disconnect the circuit if it gets too hot. |

Component Failure

Component failure is another common problem with circuit boards. Many things can cause this issue, such as:

Poorly designed PCBs that can overheat and lose power.

Low-quality components that show defects and connection problems.

Environmental factors like dust, temperature changes, and moisture that can harm PCBs.

Old components that cause power issues and eventually fail.

You might see specific types of component failures, like opens, too much solder, cold joints, and solder bridges. To find these problems, you can use several methods:

Description | |

|---|---|

Visual Inspection | Finds clear problems like burn marks, bulging parts, and bad connections. |

Testing with Multimeters | Checks individual components to see if they work within expected values. |

Comparing with Functional Boards | Looks at a broken board next to a working one to spot differences in parts and behavior. |

By knowing about these common issues with circuit boards, you can take steps to troubleshoot and maintain your electronic devices better.

In summary, circuit boards are very important in today’s electronics. They support and connect different parts, making sure devices work well. Here are some main points about their importance:

Key Takeaways | Description |

|---|---|

Circuit boards give support and connect different electronic parts, which is key for how devices work. | |

Signal Transmission | They send signals and share power among electronic parts, helping devices run correctly. |

Variety of Types | There are many types of circuit boards for different uses, from simple gadgets to complex medical and aerospace tools. |

Importance in Industries | The use of circuit boards in consumer electronics and many industries shows how crucial they are in modern technology. |

Looking ahead, circuit board technology will keep changing. You can expect:

Miniaturization and High-Density Interconnects (HDI): This trend lets devices do more in smaller sizes, which is important for wearables and IoT uses.

Flexible and Stretchable PCBs: These allow for creative designs in wearables and medical sensors, fitting different shapes.

Advanced Materials for High-Frequency Applications: Needed for 5G and car technologies, requiring special materials for better performance.

As technology grows, circuit boards will be even more important in our daily lives. Knowing how they work and their parts will help you see the new ideas shaping the future of electronics.

FAQ

What is the anatomy of a circuit board?

The anatomy of a circuit board has layers like copper, substrate, solder mask, and silkscreen. Each layer has a special job. They work together to make sure electronic devices function well and are reliable.

What are the types of printed circuit boards?

You can find different types of printed circuit boards. These include single-sided, double-sided, and multi-layer boards. Each type is used for different tasks based on how complex they are and how much space they need.

How does the role of copper in PCB design affect performance?

Copper is very important in PCB design. It makes conductive traces that connect parts. This allows signals and power to flow easily. The right thickness of copper helps ensure good performance and reliability.

What are common assembly techniques for circuit boards?

Common assembly techniques are surface mount technology (SMT) and through-hole technology. These methods attach components to the circuit board. They make sure connections are correct and the board works well.

Why is testing and quality assurance important in circuit board manufacturing?

Testing and quality assurance are important. They make sure circuit boards work correctly and meet standards. This process finds problems early, which helps lower the chance of failure in electronic devices.

See Also

Essential PCBA Components And Their Important Functions

Understanding The Functionality Of PCBA Motherboards And Its Importance

Defining PCBA And Its Significant Uses In Electronics

Examining The Key Differences Between PCBA And PCB Structures