Choosing the right PCB circuit board manufacturers is very important for your product’s success. Bad quality can cause big problems. Up to 20% of PCB failures happen because of manufacturing mistakes if not managed well. Picking good manufacturers improves performance and reliability. They follow strict quality rules and do careful testing. Also, trends like miniaturization and new materials affect your choices. By thinking about these things, you make sure your products meet exact needs and do well in the market.

Key Takeaways

Clearly state what your product needs. Knowing the details and how many you need helps you pick the right PCB maker.

Research manufacturers well. Look at their reputation, experience, and customer reviews to make sure they are reliable and provide good quality.

Check their quality control methods. Find manufacturers that use advanced testing to ensure their products are reliable.

Compare costs carefully. Understand how pricing works and look for hidden fees to stay on budget.

Build long-term partnerships. Good relationships with manufacturers can lead to better quality, faster service, and savings.

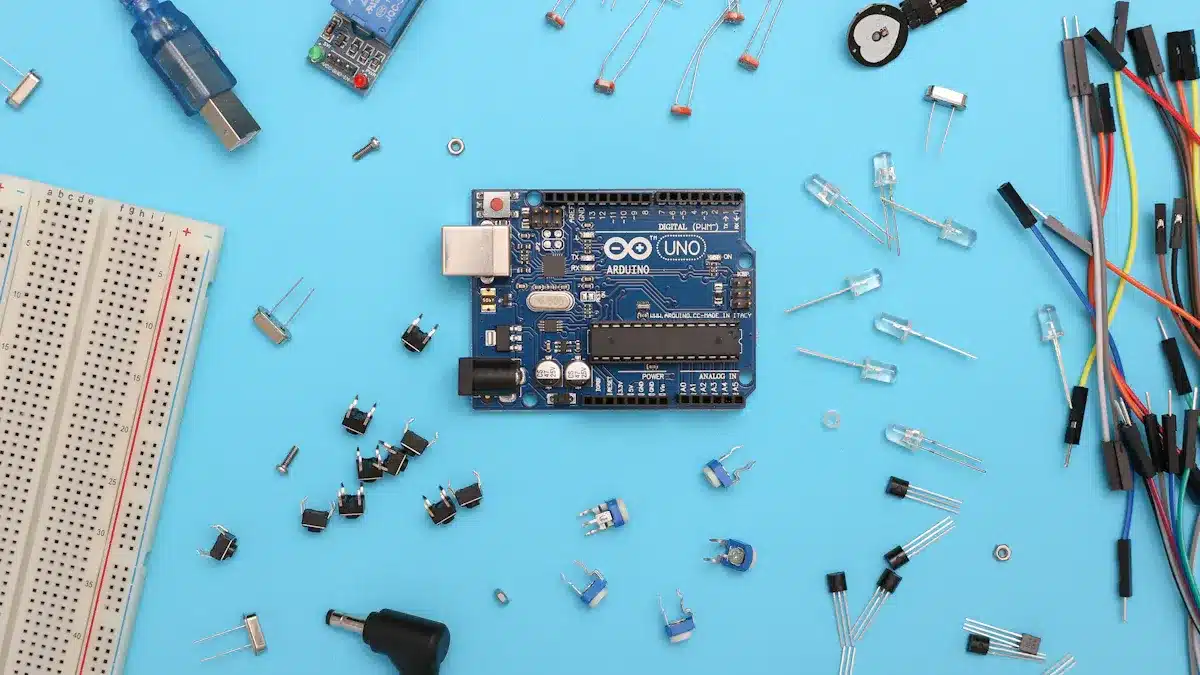

Define Product Needs

When you choose a PCB manufacturer, start by defining your product needs. Knowing your specifications and how many you need is very important. This helps make sure the manufacturer can meet your expectations.

Specifications

Specifications show the key features of your printed circuit board. These details help guide the manufacturing process. They also make sure the final product meets your performance standards. Here are some common specifications to think about:

Application Type | Consumer Electronics Specifications | Industrial Applications Specifications |

|---|---|---|

Size | Small PCBs with many connections | Thicker PCBs for strength |

Cost | Low-cost to keep the final product cheap | Higher cost because of strength needs |

Reliability | Must work well for customer satisfaction | Must handle tough conditions and rough use |

Material | Regular materials | Strong metals or heat-resistant materials |

Common Uses | Smartphones, tablets, home gadgets | Manufacturing tools, power tools, measuring tools |

Choosing the right materials is very important too. For example, FR-4 is a popular choice because it is cheap and strong. But it might not work well for fast applications. Better materials can improve performance but usually cost more. Knowing these trade-offs helps you make a better PCB design.

Volume Requirements

Volume requirements mean how many PCBs you need for production. Think about how your needs might change later. A good PCB assembly company can increase production to meet higher demands without losing quality. Here are some ways manufacturers manage volume well:

Standardizing Processes: Using standard operating procedures (SOPs) keeps things consistent during production.

Focus on Supplier Quality: Good relationships with suppliers help keep materials coming and ensure quality checks.

Empower Your Workforce: Training workers on quality standards creates a sense of ownership and responsibility.

Also, manufacturers often use flexible methods to adjust to changing needs. This includes training workers in different tasks and using smart machines to handle busy times without hiring too many people.

By clearly defining your product needs, you build a strong base for working with your PCB manufacturer. This clarity helps you choose a pcb assembly partner who can give you the quality and quantity you need.

Research PCB Manufacturers

When you pick a PCB manufacturer, you need to check their reputation. A good reputation usually means they are reliable and provide quality work. You can look at different things to judge a manufacturer’s reputation:

Criteria | Description |

|---|---|

Experience | Find out how long the manufacturer has been in business. |

Technical Expertise | Check the skills and knowledge of the manufacturer in making PCBs. |

Quality Control Systems | Look at how the manufacturer manages quality and tests their products. |

Supply Chain Management | See how the manufacturer handles their supply chain to deliver on time. |

Customer Evaluations | Read what customers say about their experiences with the manufacturer. |

After-Sales Service | Think about the support the manufacturer gives after selling the PCBs. |

You should also find industry certifications that show a manufacturer’s trustworthiness. Here are some important certifications:

Certification | Description |

|---|---|

ISO 9001 | A standard for quality management that helps with other certifications. |

ISO 13485 | Focuses on medical devices and is for companies that design or make them. |

IPC | A group that sets standards and provides training for PCB design and making, with IPC-A-610 being key for soldering and assembly. |

Customer feedback is very important in your research. It shows what others think about working with the manufacturer. Here are some common points in customer feedback for top PCB makers:

Good communication with the manufacturer

Clear and open communication

Strong quality control measures

Customers often talk about balancing cost and quality. They like manufacturers who give good engineering help and keep high-quality standards, especially for tricky projects.

Also, check customer satisfaction ratings on different review sites. This can help you see how trustworthy a manufacturer is. For example:

Manufacturer | # of Reviews | Avg. Rating (out of 5) | Trustworthiness |

|---|---|---|---|

Advanced Circuits | 6 | 3.2 | No |

Sunstone Circuits | 9 | 4.2 | Yes |

Bay Area Circuits | 3 | 5 | Yes |

allpcb.com | 12 | 3.2 | Yes |

jlcpcb.com | 151 | 4.5 | Yes |

pcbgogo.com | 17 | 3.6 | Yes |

pcbway.com | 57 | 3.8 | Yes |

Camptech | 10 | 4.6 | Yes |

By carefully researching PCB manufacturers, you can make smart choices that fit your project needs. This effort will help you find a trustworthy PCB assembly partner who meets your quality and support needs.

Evaluate Quality and Support

When you choose a PCB manufacturer, you need to check their quality control and assembly skills. These things are very important for how well your printed circuit board works. A strong focus on quality means you get a product that meets your needs and works correctly.

Quality Control

Quality control is very important in making PCBs. It helps find problems early and makes sure the final product meets industry rules. Here are some common quality control methods used by top PCB makers:

Quality Control Method | Description |

|---|---|

In-Circuit Testing (ICT) | Tests circuits for performance using capacitance tests and checks for open or short circuits. |

Flying Probe Test | Finds loose connections and other problems without power using a probe aligned to a CAD grid. |

Functional Test | Makes sure the PCB works under test conditions and meets industry standards like UL and MSHA. |

Automated Optical Inspection (AOI) | Uses cameras to find missing or misplaced parts and soldering problems. |

X-Ray Inspection | Looks inside PCBs for shorts and openings that you can’t see. |

Electrical Testing | Checks output signals against performance needs while powered. |

Visual Inspection | Manual checks for physical damage like scratches and misalignment. |

Many top PCB manufacturers use quality management systems like ISO 9001 and RoHS Compliance. These certifications help keep quality consistent and ensure safety for the environment. Manufacturers with these certifications usually have up to 20% fewer defects than those without. For example, US manufacturers often keep defect rates below 0.1%, while imports can be between 2-8%.

Assembly Capabilities

The assembly skills of a PCB manufacturer can make them stand out. Advanced technology and know-how are key for handling complex electronics projects. Here are some important assembly skills to think about:

Top PCB manufacturers keep up with changes in the electronics industry.

They provide many services, like prototype development and large-scale production.

They can create multilayer and flexible PCBs, which are becoming more popular.

In-house assembly services can also change lead times and product quality. When manufacturers do assembly themselves, they often speed up lead times. This efficiency leads to happier customers, as you can expect products faster. However, outsourcing kitting and assembly can bring challenges, like needing more space and hiring extra staff.

Strong customer support is another important part of choosing a PCB assembly partner. You should look for manufacturers that offer complete support services. Here are some common customer support issues faced by PCB buyers:

The need for complete customer support services.

Importance of quick technical help and troubleshooting advice.

Need for buyers to ask about response times and support staff availability.

Availability of support through different channels (phone, email, live chat).

To check and improve customer support satisfaction, manufacturers often track different metrics. Here’s a summary of some key metrics:

Metric | Description | Impact on Customer Support Satisfaction |

|---|---|---|

Customer Satisfaction Score | Measures how happy customers are with product quality and service. | Gives insights into product reliability and service speed, which is important for repeat business. |

Regular Customer Feedback Surveys | Collects ongoing customer feedback to see satisfaction levels. | Helps find strengths and areas to improve in customer interactions. |

Quality Assurance Protocols | Improves product reliability through strict quality checks. | Builds customer trust and satisfaction with product quality. |

Workflow Optimization Techniques | Makes customer service faster and more responsive. | Increases efficiency in solving customer questions and problems. |

By carefully checking quality control, assembly skills, and customer support, you can choose a PCB assembly partner that fits your project needs. This careful thought will help make sure your product succeeds in the market.

Compare Costs and Value

When you choose a PCB manufacturer, you need to compare costs and value. Knowing how pricing works helps you fit your budget with your project needs.

Pricing Structures

PCB manufacturers use different pricing models based on how many you order. Costs can change a lot based on several things. Here’s how pricing works:

Factor | Description |

|---|---|

Cost Variation | Costs change in a non-linear way with order size; doubling the amount does not double the cost. |

Fixed Costs | These include costs for making stencils, testing designs, and tooling. |

Price Reduction | The price per PCB goes down with larger orders because of shared tooling costs. |

In low-volume production, like under 100 units, costs are higher because of fixed setup fees. For example, a small PCB might cost $5 each in a batch of 50 but only $2 each in a batch of 500. This shows how economies of scale affect pricing. Also, things like PCB size, order quantity, and design complexity can change costs.

You should also think about hidden costs when looking at quotes from manufacturers. Here are some common hidden costs to watch for:

Manual Review Adjustments: Possible price changes due to flagged risks in files.

Component Substitutions: Higher costs for replacements if parts are out of stock.

Suggested Upgrades: Extra costs for improvements not included in the first quote.

Unquoted Testing Costs: Additional charges for high-reliability builds needing more testing.

Shipping Cost Variance: Increased fees for faster shipping services.

Long-term Partnerships

Building a long-term partnership with a PCB assembly company can really help your product development. Here are some benefits of keeping these relationships:

Benefit | Explanation |

|---|---|

Following strict quality standards reduces defects and boosts product performance. | |

Faster Turnaround Times | American manufacturers often work faster than overseas ones, allowing quicker project completion. |

Enhanced Collaboration | Local time zones and language compatibility make communication and teamwork easier. |

Less reliance on overseas suppliers lowers risks like tariffs and shipping delays. | |

Intellectual Property Protection | Strong IP laws in the U.S. lower the risk of intellectual property theft. |

Customized Solutions | Flexibility in manufacturing allows for tailored solutions that encourage innovation. |

Long-term partnerships can also lead to better pricing. Manufacturers might give discounts for repeat business or larger orders. This can help you save money while ensuring consistent quality in your custom PCB projects.

By carefully comparing costs and thinking about the value of long-term partnerships, you can make smart choices that improve your product’s success.

Choosing the right PCB manufacturer is very important for your project’s success. You should think about a few key things:

Match the materials and manufacturing methods to your needs.

Focus on quality control to make your product reliable.

Think about thermal stability, signal integrity, and customer support.

A careful evaluation process helps lower the chance of product failure. By spotting possible failure issues, you can manage risks better. This way, you get better reliability and happier customers.

Start today by using these tips. Your careful choice will help make your PCB projects successful! 🌟

FAQ

What should I think about when picking a PCB manufacturer?

You should think about specifications, how many you need, quality control, assembly skills, and customer support. These things help make sure the manufacturer can meet your project needs and provide reliable products.

How can I check a PCB manufacturer’s reputation?

Look at their experience in the industry, customer reviews, and certifications. Find reviews on trusted sites to see how reliable they are and the quality of their service.

What are some common quality control methods in PCB manufacturing?

Common methods include In-Circuit Testing, Automated Optical Inspection, and X-Ray Inspection. These methods help find problems and make sure the final product meets industry standards.

How do pricing structures work for PCB manufacturing?

Pricing changes based on order size, complexity, and materials. Bigger orders usually lower the cost per unit because of shared setup costs. Always look for hidden costs in quotes.

Why is customer support important in PCB manufacturing?

Good customer support makes sure you get help quickly with technical issues and project questions. Clear communication helps build a successful partnership and improves overall satisfaction.

See Also

Key Strategies for Selecting a Quality PCBA Manufacturer

Best Practices for Finding a Trustworthy PCBA Manufacturer

Important Considerations When Selecting a PCBA Contract Manufacturer

Guidelines for Choosing the Right PCB Prototype Manufacturer