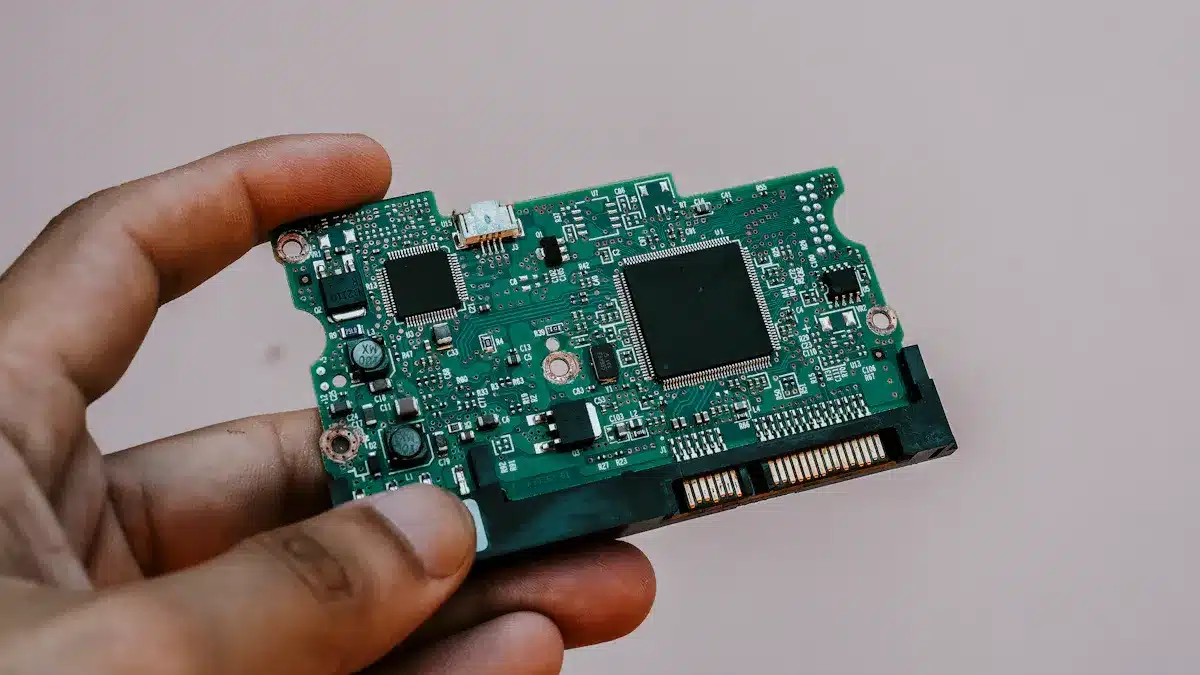

Printed circuit boards (PCBs) are very important in today’s electronics. You see them every day in things like smartphones, computers, and appliances. The worldwide PCB market is expected to hit $86.5 billion by 2029. This shows a strong growth rate. But, making PCBs can cause environmental problems. It can pollute water and soil. Knowing the different types of PCB boards helps you understand their importance and the progress in technology.

Key Takeaways

Printed circuit boards (PCBs) are very important in electronics. You can find them in devices like smartphones and computers. – Single-sided PCBs are cheap and easy to make. This makes them great for simple electronics like calculators. – Double-sided PCBs can have more complex designs. They help signals work better and fit more parts in smaller spaces. – Multilayered PCBs can hold many layers. This is important for advanced devices in telecommunications and medical tools. – Aluminum PCBs are great at managing heat. This makes them ideal for things like LED lights and power supply units.

Single-Sided PCB Boards

Features

Single-sided PCBs are the easiest type of printed circuit boards. They have one layer of conductive material, usually copper, on one side of a non-conductive base. This design makes them cheap and simple to make. Here are some important features of single-sided PCBs:

Cost-Effective: They usually cost less to produce than more complex PCB types.

Simplicity: The layout is easy, which makes the design process simpler.

Material Options: Common materials used in single-sided PCBs include:

FR4: Known for being strong and resistant to heat.

CEM-1: A low-cost option good for cheap products.

Phenolic Resin: A budget-friendly choice, often used in low-end consumer items.

Uses

Single-sided PCBs are used in many industries because they are simple and affordable. Here are some common uses:

Industry | Description |

|---|---|

Includes smartphones, laptops, tablets, and gaming devices. | |

Automotive | High demand, especially for electric vehicles (EVs) with advanced electronics. |

Industrial Electronics | Widely used in many industrial applications. |

You will often find single-sided PCBs in devices where space and cost matter. They work well in simple electronic devices, like calculators and basic home appliances. Their simple design helps keep signals clear, making them good for many uses.

Double-Sided PCB Boards

Features

Double-sided PCB boards have two layers of conductive material. This is usually copper on both sides of a non-conductive base. This design lets you create more complex circuits than single-sided PCBs. Here are some important features of double-sided PCBs:

Increased Density: You can fit more parts on a smaller board. This is important for today’s electronics.

Improved Signal Integrity: The two layers help keep signals clear. This reduces interference and crosstalk between parts.

Versatile Design Options: You can connect wires on both sides. This allows for more detailed designs.

The thickness and copper weight in double-sided PCB boards can change. Here’s a quick overview:

Copper Weight | Thickness (mil) | Thickness (microns) |

|---|---|---|

0.671 | 17.05 | |

1.0 oz/sq ft | 1.34 | 34.1 |

Uses

Double-sided PCBs are used in many products because they can handle complex designs at good prices. Here are some common uses:

Electronic Product Type | Examples |

|---|---|

Consumer Electronics | TV remote controls |

Automotive Systems | Air conditioning systems, ABS systems, airbags, taillights |

Power Systems | Power conversion, UPS power system |

Test Equipment | Control relays, Hard Drives |

Other Applications | Vending machines, Traffic systems, Car dashboards |

You can find double-sided PCBs in many everyday items. They are important for popular electronics like smartphones and computers. Their ability to support complex designs makes them great for car dashboards and test equipment. With double-sided PCBs, you can get high performance without using too much space or money.

Multilayered PCBs

Features

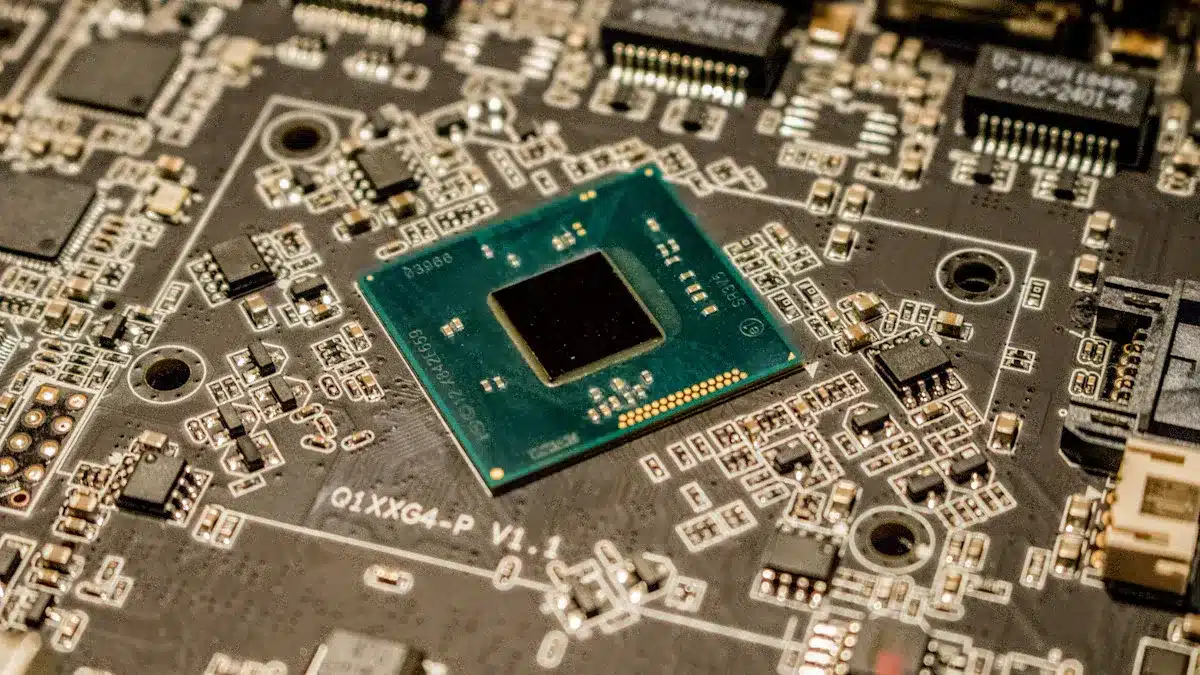

Multilayered PCBs have many layers of conductive material. This is usually copper, and they are separated by insulating layers. This design helps create high-density layouts that save space and work better. Here are some important features of multilayered PCBs:

Layer Count: Most consumer electronics use multilayer PCBs with 4 to 6 layers. Some complex devices may need up to 12 layers.

Compact Design: The extra layers let you fit more parts into a smaller space. This is important for modern devices that need to do a lot in a small area.

Enhanced Signal Integrity: More layers help improve signal quality. This cuts down on interference and makes sure everything works well.

However, making multilayered PCBs can be tricky. You might run into problems like:

Mechanical distortions, like bows and twists, that affect how flat the board is.

Thermal and electrical issues from choosing the wrong substrate material.

More chances of delamination, which makes repairs harder.

Moisture getting in, which can harm how it works.

Precise drilling needed for blind or buried vias.

Uses

Multilayered PCBs are used in many advanced electronics. Here are some common uses:

Application Area | Description |

|---|---|

Telecommunications | Used in smartphones, tablets, and networking devices. |

Medical Devices | Important for complex medical equipment like MRI machines. |

Aerospace | Essential for avionics systems and satellite technology. |

Automotive Electronics | Found in advanced driver-assistance systems (ADAS) and infotainment systems. |

Rigid PCBs

Features

Rigid PCBs are a basic type of printed circuit board. They have a solid base that gives support and stability. The most common materials for rigid PCBs are FR4 and polyimide laminates. These materials are strong and help with routing. Here are some important features of rigid PCBs:

Durability: Rigid PCBs can handle tough conditions. They do not bend or twist easily, making them great for many uses.

Thermal Stability: These boards stay strong in extreme temperatures. This is important for devices that work in hard environments.

Signal Integrity: Rigid PCBs make sure signals are clear. Their design reduces interference, which is important for high-performance electronics.

The table below shows the main materials used in rigid PCB design and how they affect durability:

Material Type | Role in PCB Design | Impact on Durability |

|---|---|---|

Polyimide Film | Base of flexible parts, giving thermal resistance and mechanical flexibility. | Great for changing environments, ensuring reliability in extreme conditions. |

FR4 and Polyimide Laminates | Main support for rigid parts, providing strength and routing help. | Keeps its shape in tough environments, stopping deformation. |

No Flow Prepregs | Joins parts without resin flowing onto flexible areas. | Important for keeping strength in rigid flex designs. |

Copper Foil | Creates electrical paths, affecting signal quality and current capacity. | Thickness and type affect performance, ensuring circuits work well without losing signals. |

Coverlay | Shields flexible parts from moisture and wear. | Key for durability in tough and high-wear environments. |

Adhesives and Stiffeners | Join layers and strengthen mechanical parts. | Polyimide adhesives resist high temperatures, while stiffeners improve mechanical strength. |

Uses

Rigid PCBs are used in many industries because they are reliable and strong. Here are some common areas that use rigid PCBs:

Aerospace: Rigid PCBs work in extreme temperatures, making them good for avionics systems. They must meet MIL-STD standards for reliability.

Automotive: These boards support important functions in cars, like engine control units and safety systems. They can handle tough conditions and temperature changes.

Medical Devices: Rigid PCBs are key in medical equipment, ensuring long-lasting reliability and performance. They often last over 20 years without failure.

Consumer Electronics: You can find rigid PCBs in everyday items like TVs and computers. They provide the needed support for complex circuits.

The table below summarizes the market value and reliability needs for rigid PCBs in different sectors:

Industry Sector | Operating Temperature | Reliability Requirement | Market Value (2025) |

|---|---|---|---|

Aerospace | -55°C to 125°C | MIL-STD compliance | $4.3 billion |

Automotive | -40°C to 125°C | 150K thermal cycles | $11.2 billion |

Medical | 0°C to 70°C | 20+ year MTBF | $8.7 billion |

Consumer | -10°C to 85°C | 10K power cycles | $23.8 billion |

Rigid PCBs are important in areas needing strength and reliability. They help ensure that electronic devices work well, even in tough situations.

Flexible PCBs

Features

Flexible PCBs are special because they can bend and fit into small spaces. This ability comes from the materials used to make them. Here are the main materials that help with this flexibility:

Material Type | Role in Flexibility |

|---|---|

Substrate | This is the flexible base; polyimide film is best because it resists heat and bends well. |

Conductive Layer | This makes electrical paths; different types of copper foil affect how much they can bend. |

Adhesives | These stick layers together; acrylic adhesives are good for flexibility. |

Coverlay | This protects circuits from harm; polyimide coverlay gives both flexibility and protection. |

Optional Layers | These can include stiffeners and EMI shielding to improve performance in tough situations. |

These materials work together to make a PCB that can bend and twist without breaking. This makes flexible PCBs great for many uses where space is tight.

Uses

Flexible PCBs are used in many modern devices, especially where small designs are needed. Here are some common uses:

Smartwatches: Combine features like heart rate tracking and Bluetooth.

Fitness Bands: Fit snugly and stay stable during exercise.

Smart Clothing: Allow for things like temperature control and activity tracking.

Medical Applications: Power wearable patches for ongoing monitoring.

Flexible PCBs help make consumer electronics smaller. They allow for designs that save space, fitting more parts into smaller devices. Their light and thin design is important for portable gadgets. Plus, flexible PCBs can bend and twist, making them dependable for devices that move a lot. They also cut down on the number of connection points, which reduces bulk and improves reliability.

Rigid-Flex PCBs

Features

Rigid-Flex PCBs mix the best parts of rigid and flexible printed circuit boards. This special design gives you strength and flexibility. Here are some important features of rigid-flex PCBs:

Structural Integrity: Rigid-flex designs stay strong in tough conditions.

Flexibility: These boards can bend and twist, which is great for small spaces.

Routing Considerations: You need to carefully route traces in flexible areas. This helps avoid strain and damage. It is important for keeping signals clear.

But, there are some technical challenges to know about. For example, the switch between rigid and flexible parts can cause impedance mismatches. This is especially true in fast applications. Good thermal management is also very important for reliable use. This helps make the components last longer.

Uses

Rigid-flex PCBs are used in many industries because they are versatile. Here are some common uses:

Medical Equipment: These boards are key in devices like MRI machines and wearable health monitors.

Automotive Systems: Rigid-flex designs help advanced driver-assistance systems and infotainment units.

Aerospace Applications: They are important in avionics systems, where reliability matters a lot.

Wearable Devices: Smartwatches and fitness trackers use rigid-flex PCBs for their small designs.

Consumer Electronics: You can find them in smartphones, laptops, and gaming devices.

The ability to mix rigid and flexible materials makes rigid-flex PCBs a popular choice in modern electronics. Their adaptability lets you create new designs that meet today’s technology needs.

High-Frequency PCBs

High-frequency PCBs are special printed circuit boards made for working at high frequencies. These PCBs usually support frequencies from hundreds of megahertz (MHz) to tens of gigahertz (GHz). Their design is important for keeping signals clear, which is necessary for good performance in fast applications.

Features

Here are some main features of high-frequency PCBs:

Material Composition: High-frequency PCBs often use materials like PTFE (Teflon) and ceramic composites. These materials help reduce signal loss and improve performance.

Impedance Control: You need to manage impedance carefully. This helps signals travel well without bouncing back.

Layer Configuration: Many high-frequency PCBs have several layers. This improves routing options and reduces interference.

The table below shows the frequency ranges that high-frequency PCB boards can support:

Frequency Range | Description |

|---|---|

Typical operating range for high-frequency PCBs | |

Up to 100GHz | Some high-frequency PCBs can work at this range |

Uses

High-frequency PCBs are used in many industries, especially where RF and microwave technologies are important. Here are some common uses:

Telecommunications: These PCBs are crucial for devices like cell phones and base stations.

Automotive: High-frequency PCBs support advanced driver-assistance systems (ADAS) and vehicle communication systems.

Aerospace: They are important for avionics and satellite communications.

Medical Electronics: High-frequency PCBs are used in imaging systems and diagnostic equipment.

The table below shows industries that often use high-frequency PCBs:

Industry | Examples of Companies Using High-Frequency PCBs |

|---|---|

Telecommunications | Kaifa Technology, Sumitomo Electric, TTM Technologies |

Automotive | Micro Circuit Labs, Advanced Circuits |

Aerospace | TTM Technologies, Advanced Circuits |

Defense | Micro Circuit Labs, Advanced Circuits |

Medical Electronics | Unimicron Technology |

High-frequency PCBs are key for modern electronics. They help devices work well at high speeds. Their ability to keep signals clear makes them very important in today’s technology world.

Aluminum PCBs

Features

Aluminum PCBs are special because they manage heat very well. The aluminum backing helps get rid of heat effectively. Here are some important features:

High Thermal Conductivity: Aluminum can conduct heat between 200-250 W/m-K. In comparison, FR4 boards only conduct heat at 0.25-0.35 W/m-K. This means aluminum conducts heat over 50 times better than FR4. This high conductivity allows heat to escape quickly, making aluminum great for high heat applications.

Enhanced Heat Spreading: The big difference in how they handle heat makes aluminum better for jobs that need good thermal management. Aluminum PCBs can spread heat fast, stopping overheating and keeping the components safe.

Durability: Aluminum PCBs are strong and can handle tough conditions. Their solid build makes them good for many uses, including those that face vibrations or physical stress.

Uses

Aluminum PCBs are used in many industries because of their special features. Here are some common uses:

LED Lighting: One of the main uses for aluminum PCBs is in LED lighting. Their good heat dissipation helps keep LED parts working well and lasting longer.

Power Supply Units: These PCBs are often found in power supply units where managing heat is very important. They help keep the parts within safe temperature ranges.

Automotive Applications: In cars, aluminum PCBs support different electronic systems, like lights and control units. Their heat management ability is key for reliability in vehicles.

Consumer Electronics: You can also see aluminum PCBs in everyday electronics, where they help keep signals clear and stop devices like smartphones and tablets from overheating.

Aluminum PCBs are very important in today’s electronics. Their ability to handle heat well makes them essential in areas where performance and reliability matter a lot.

HDI PCBs

High-Density Interconnect (HDI) PCBs are special printed circuit boards made for small and efficient electronic devices. These boards have many components and connections packed closely together. This allows them to do more in a smaller space. You can think of HDI PCBs as the answer for today’s electronics that need both good performance and small size.

Features

HDI PCBs have many benefits that make them unique:

Small Trace Widths and Spacing: In HDI making, trace widths and spaces can be as tiny as 2 mils (0.051 mm) or even smaller. This accuracy is important for high-frequency PCBs to reduce signal loss and crosstalk.

Microvias: Using microvias in HDI helps increase density and performance. These tiny holes allow for more connections in a small area, making it easier to create complex circuits.

Improved Signal Integrity: A well-planned layer stack-up controls impedance and reduces noise and crosstalk. You can do this by carefully placing signal layers in tight designs. A solid ground plane acts as a reference for signal return paths, which helps keep signals clear in fast applications.

Uses

HDI PCBs are used in many small electronic devices. Here are some common examples:

Device Type | Description |

|---|---|

Smartphones | Small devices that need high-density packing and advanced features. |

Tablets | Portable devices that benefit from smart designs. |

Wearable Devices | Tiny devices that use HDI technology for complex layouts. |

Medical Equipment | Devices that need compact and reliable electronic parts. |

Aerospace Systems | Advanced systems that rely on small and efficient designs. |

You can find HDI PCBs in many modern devices. Their ability to support high-density layouts makes them important for smartphones, tablets, and even medical equipment. As technology keeps improving, the need for HDI PCBs will likely increase, making them a key part of the future of electronics.

Specialty PCBs

Specialty PCBs are special printed circuit boards made for specific uses. These boards often meet needs that regular PCBs cannot. They are very important in many industries, especially where conditions can be tough or where special functions are needed.

Features

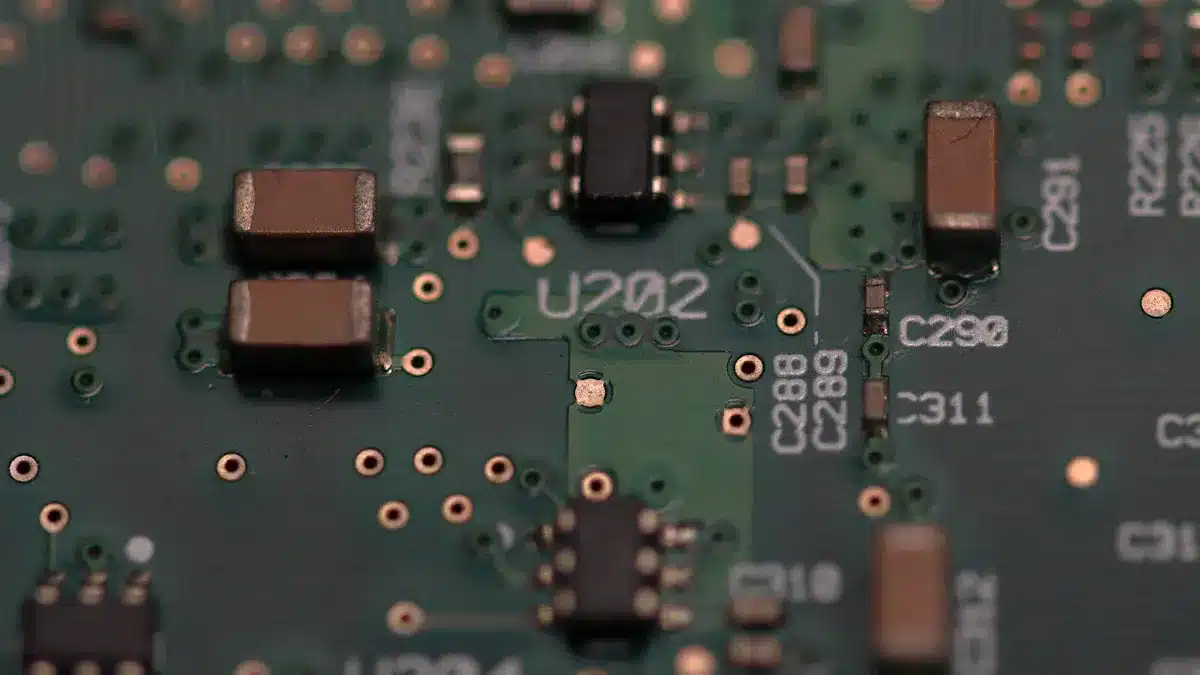

Specialty PCBs have several unique features that make them different from regular types. Here are some key traits:

Durability: Many specialty PCBs can handle rough environments. For example, metal-clad PCBs use an aluminum base to help get rid of heat. This is important for things like LED light panels.

Thermal Management: Ceramic PCBs are made from materials that conduct heat well. They help control heat effectively and often have coatings that improve their heat management.

Signal Integrity: Specialty PCBs keep signals clear, which is very important for uses that need precise performance.

Uses

You can find specialty PCBs in many specific markets. Here are some common uses:

Aerospace: These PCBs can handle temperature changes, vibrations, and radiation. They are important for systems like inertial measurement units (IMUs) used in navigation.

Healthcare: In medical devices, being durable and following strict rules is very important. Specialty PCBs ensure reliable performance in critical uses.

Automotive: These boards can deal with different temperatures and vibrations, making them good for advanced driver-assistance systems.

Vintage Equipment: Specialty PCBs are key for fixing vintage audio equipment and older military devices. They help keep old systems working and make replacement boards that are no longer available from original makers.

Low volume PCB assembly is very important for these specific markets. It allows for making specialized PCBs that meet unique technical needs. This way, you can keep and fix older systems effectively.

In conclusion, knowing the different types of PCB boards is important for anyone working with electronics. Each type has its own job, from single-sided boards for simple gadgets to complex multilayered designs for advanced uses. As technology changes, you will notice big trends that will shape the future of printed circuit boards. The growth of the Internet of Things (IoT) increases the need for smaller and better designs. The advanced PCB market is expected to grow by 7-8% each year for the next five years. This growth will come from areas like aerospace and 5G telecommunications. Keeping up with these changes will help you understand the fast-changing world of electronics.

FAQ

What are PCB boards used for?

PCB boards are very important in electronic devices. You can find them in smartphones, computers, and appliances. They connect and support electronic parts, helping devices work correctly.

How do printed circuit boards work?

Printed circuit boards provide a base for electronic parts. They have conductive paths that connect these parts, allowing electrical signals to move between them.

What materials are used in PCB boards?

Common materials for PCB boards are FR4, CEM-1, and aluminum. These materials are strong, resist heat, and insulate electricity, ensuring they work well in different uses.

Can you repair PCB boards?

Yes, you can fix PCB boards. Methods like soldering and changing broken parts can make them work again. But, complicated repairs might need help from a professional.

How do I choose the right PCB type?

Choosing the right PCB type depends on what your project needs. Think about things like complexity, size, and heat management. For simple designs, single-sided PCBs are good. For more advanced uses, multilayered or rigid-flex PCBs might be better.

See Also

In-Depth Comparison of PCBWay and Other PCB Makers

Crucial Advice for Selecting Your Ideal PCBA Main Board

Uncovering Key Distinctions Between PCBA and PCB