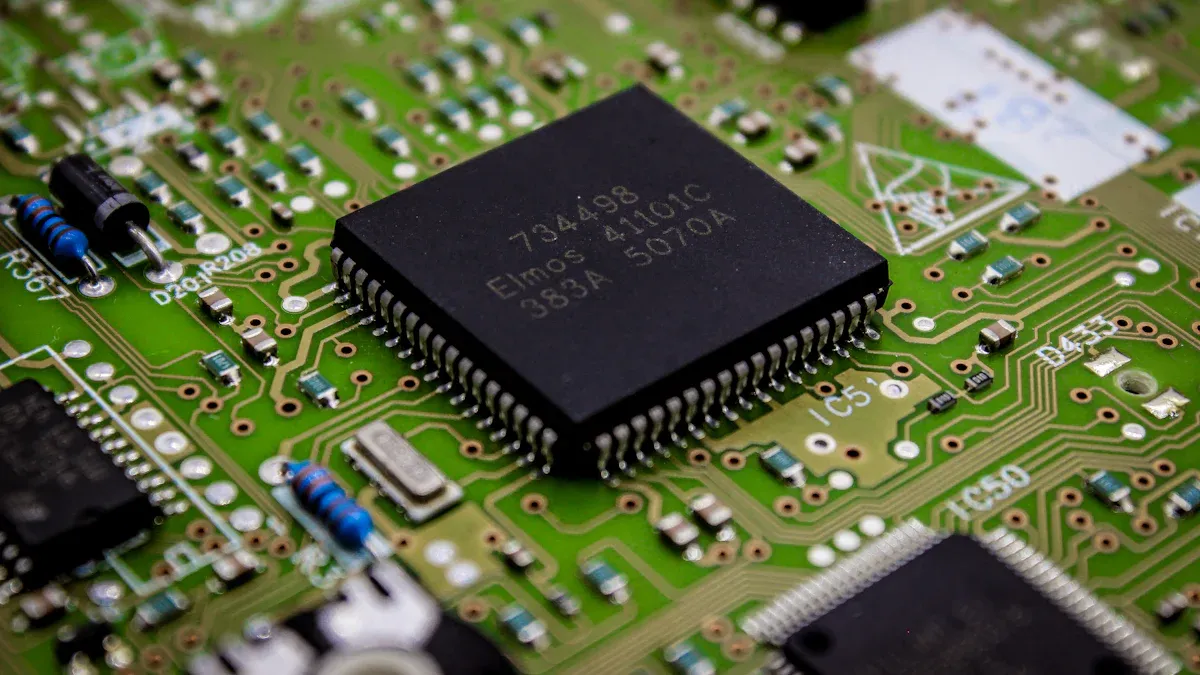

Understanding the Basics and Types of PCBA Coating

PCBA coating protects circuit boards from moisture, dust, and chemicals. Learn about acrylic, epoxy, silicone, polyurethane, and parylene coatings.

PCBA coating protects circuit boards from moisture, dust, and chemicals. Learn about acrylic, epoxy, silicone, polyurethane, and parylene coatings.

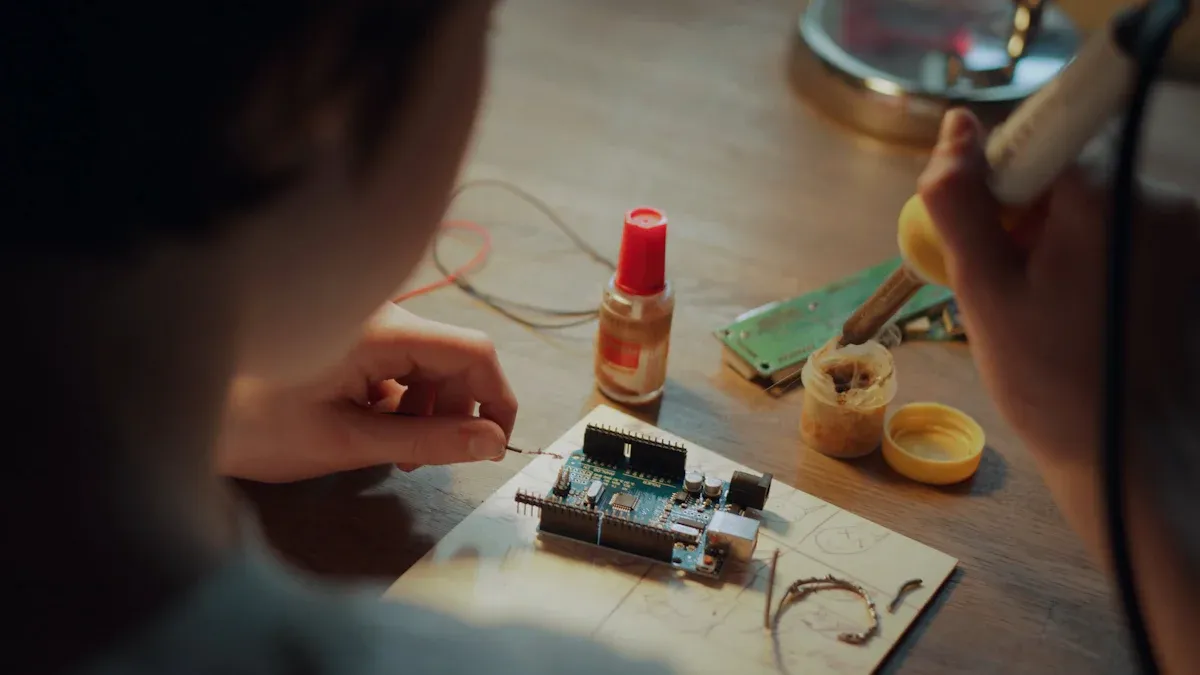

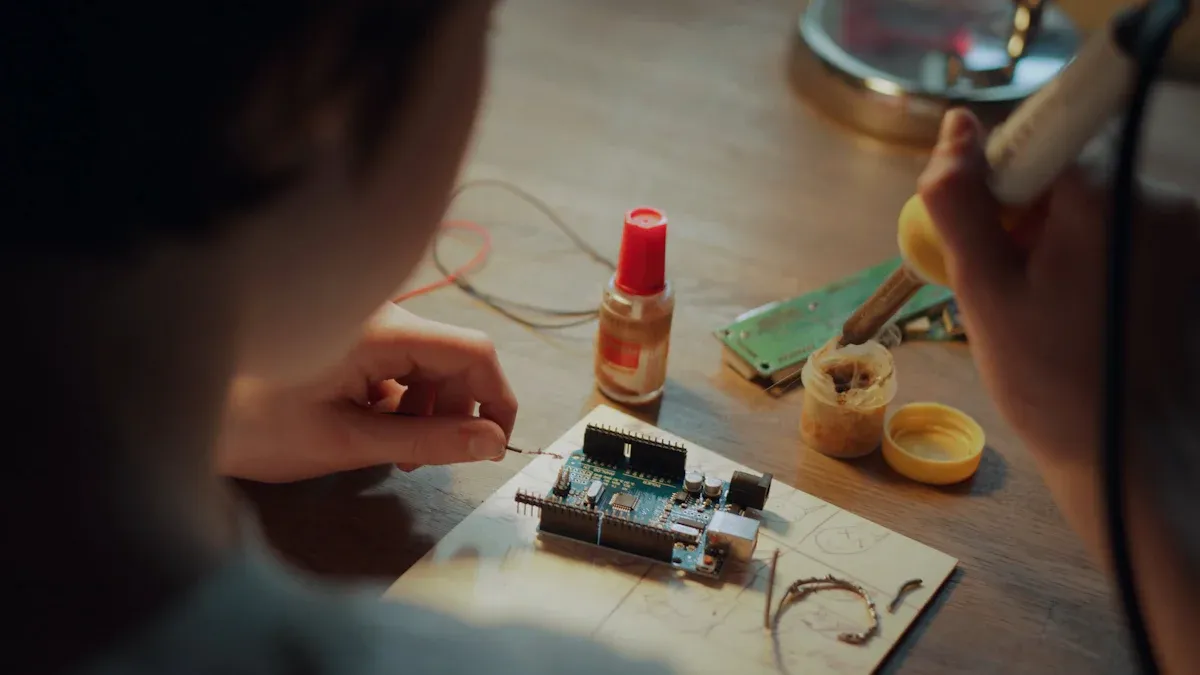

Discover 10 expert tips for efficient and cost-effective PCBA assembly. Learn how to optimize designs, reduce costs, and ensure quality in your projects.

Understand the key steps in PCBA manufacture, from design to testing, ensuring high-quality, reliable circuit boards for advanced electronic devices.

Choose the right PCBA contract manufacturer by evaluating location, IP protection, expertise, scalability, and cost to ensure quality and reliable production.

Find the best PCBA company for your business by evaluating quality, certifications, experience, and production capabilities to ensure reliable results.

Choose a reliable custom PCBA manufacturer by evaluating quality, certifications, delivery reliability, cost efficiency, and advanced technology for your needs.

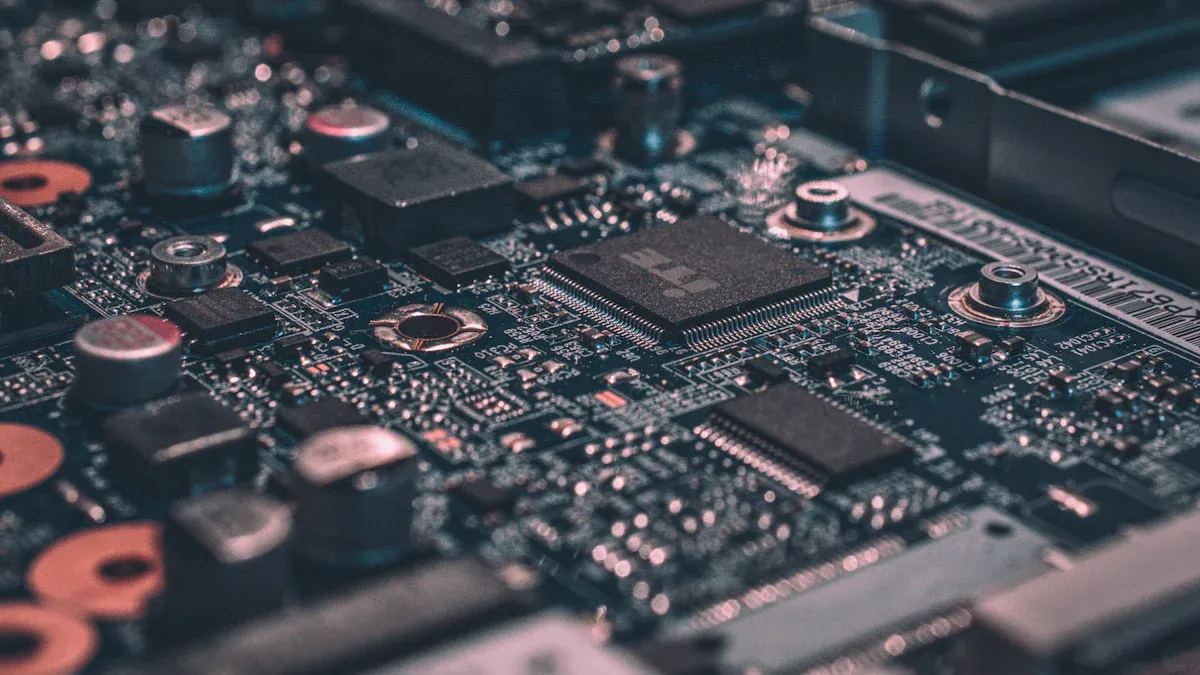

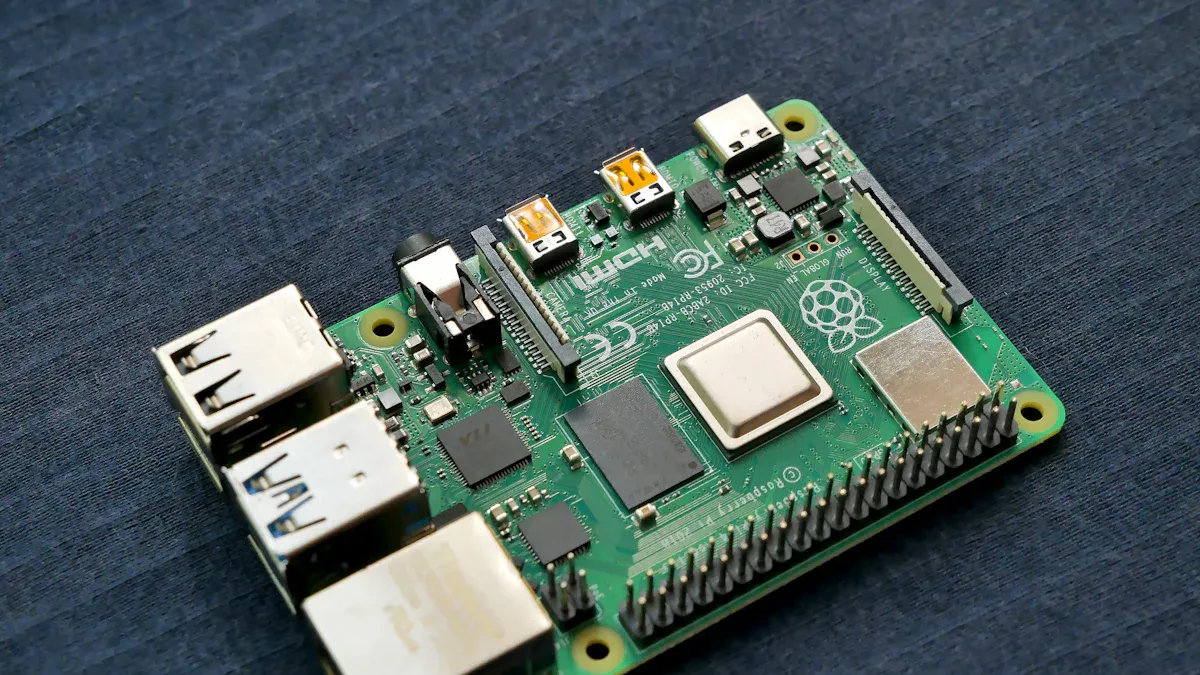

Understand what is PCBA and its components, including key steps like solder paste application, component placement, reflow soldering, and testing.

PCBA definition: the process of assembling components onto a PCB to create functional electronics. Explore its applications in consumer, medical, and automotive fields.

PCBA design is the process of creating circuit boards that connect and power components, ensuring reliable, efficient, and compact electronic devices.

Understand the meaning of PCBA and its role in electronics manufacturing. Explore its applications in consumer devices, automotive, medical, and aerospace.