How PCBA Enhances Industrial Automation Processes in 2025

Industrial automation PCBA services boost efficiency, reliability, and precision in 2025, integrating IoT, AI, and robotics for smarter factory systems.

Industrial automation PCBA services boost efficiency, reliability, and precision in 2025, integrating IoT, AI, and robotics for smarter factory systems.

ITAR compliant PCBA manufacturing ensures adherence to strict regulations, safeguarding sensitive defense data and securing government contracts.

AS9100 certified PCB assembly ensures aerospace-grade quality, safety, and reliability, meeting strict industry standards and boosting customer trust.

Explore 2025’s key innovations in aerospace PCBA manufacturing services, including HDI, 3D printing, AI, IoT, and eco-friendly practices for advanced systems.

Discover the top ISO 13485 certified PCBA assembly manufacturers for medical devices in 2025, ensuring safety, quality, and compliance with global standards.

FDA-compliant PCBA services ensure medical devices are safe, reliable, and meet strict regulations, protecting patients and building trust in 2025.

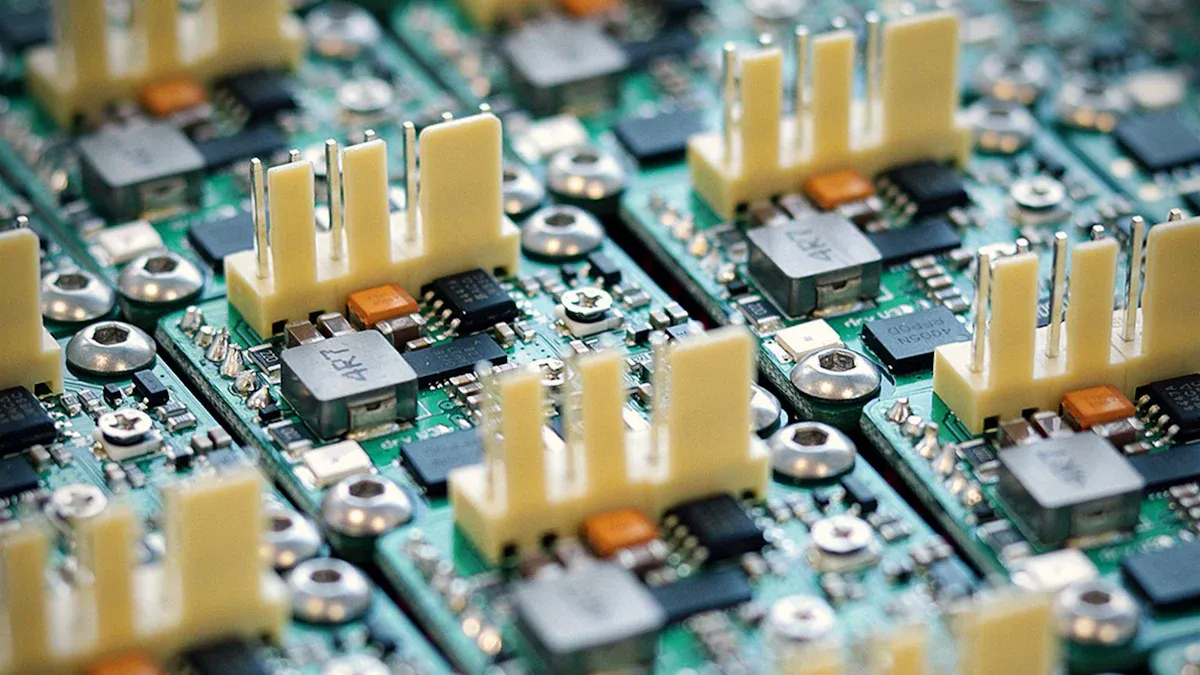

Medical device PCBA manufacturing involves precise design, material selection, SMT assembly, and rigorous testing to meet healthcare safety standards.

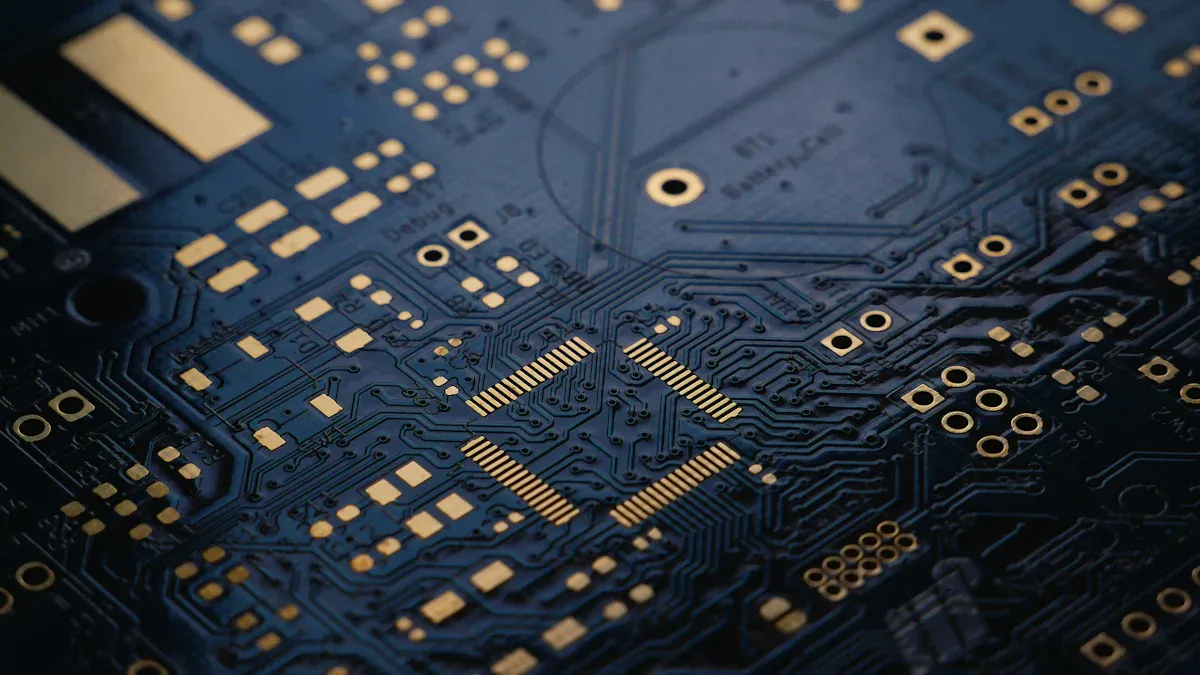

Optimize flex and rigid-flex PCBA manufacturing with smart design, material selection, and advanced techniques for cost-effective, durable, and reliable PCBs.

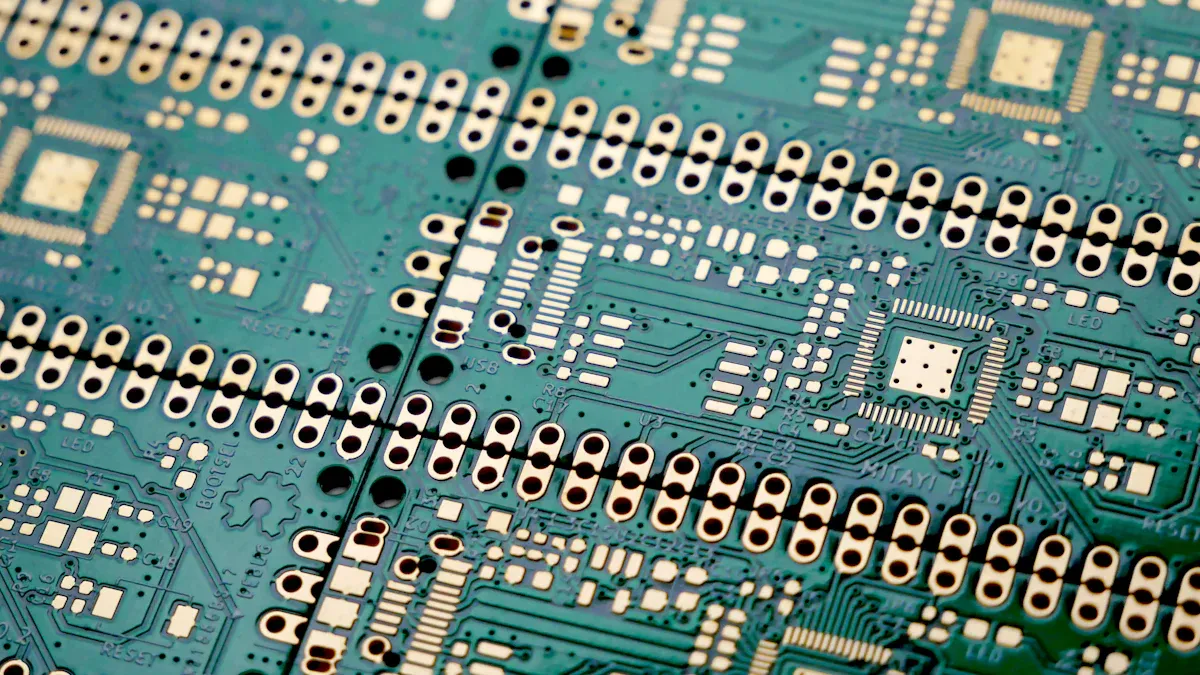

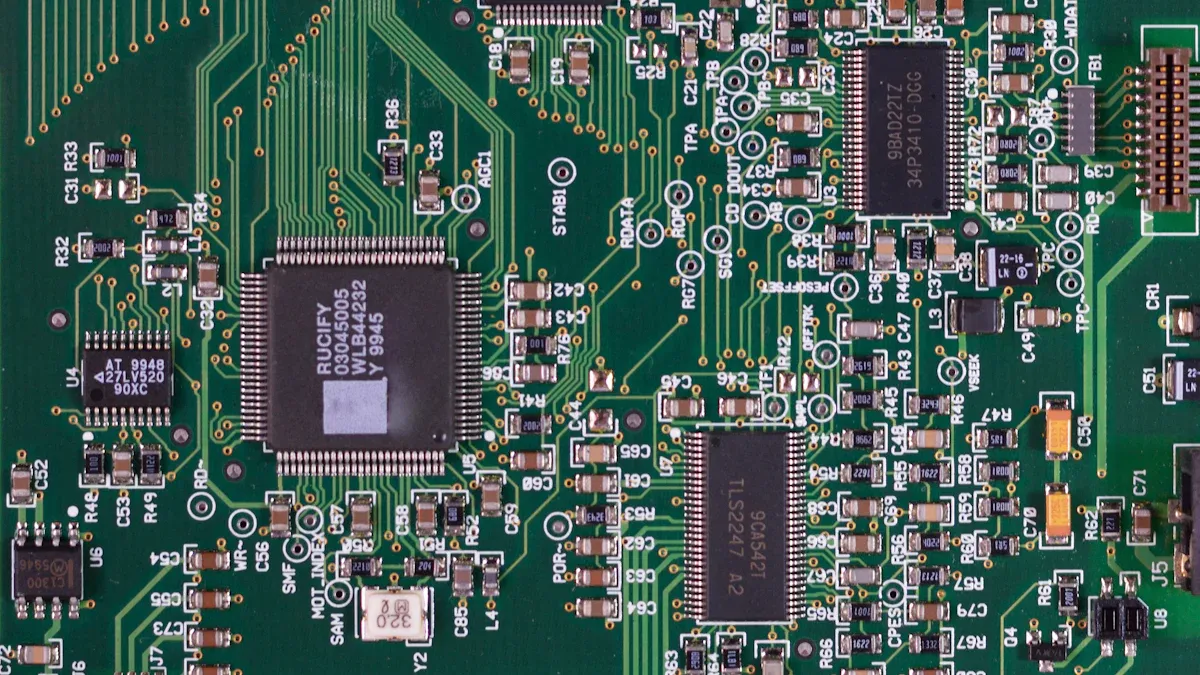

High-density interconnect (HDI) PCBA technology enables compact, high-performance designs with microvias, blind vias, and multi-layered structures.

Learn how to choose the best PCBA conformal coating services in 2025 by evaluating skills, certifications, quality checks, and project experience.