How X-ray Inspection Boosts PCBA Quality Control

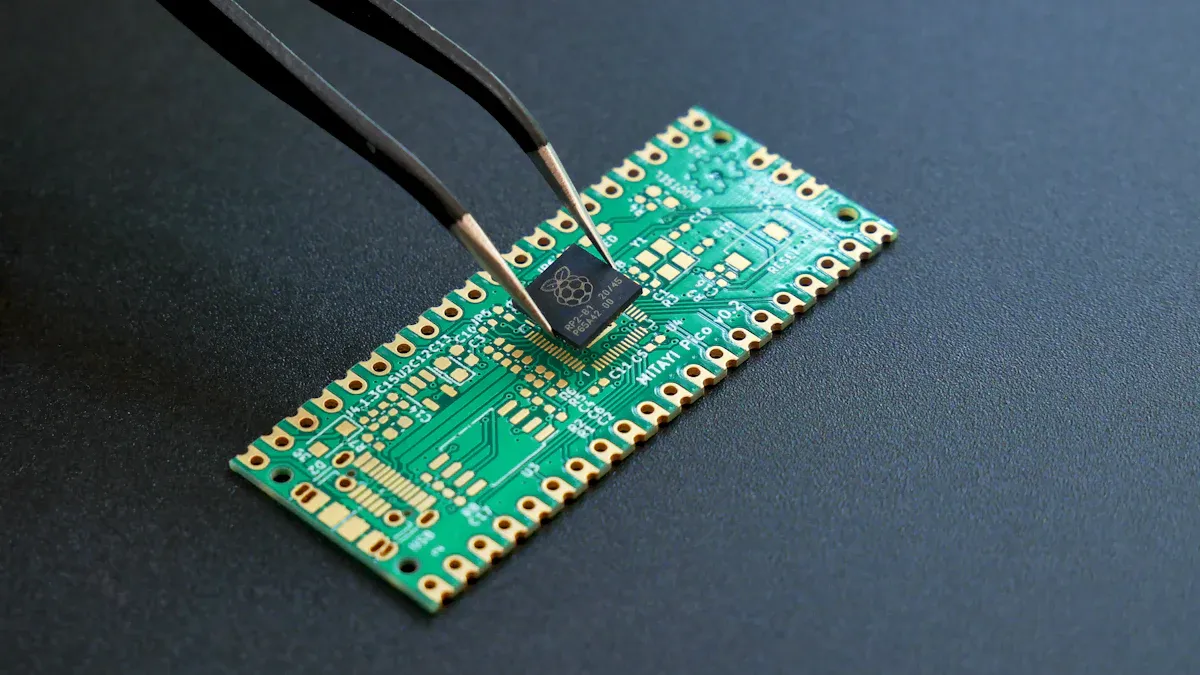

X-ray inspection for PCBA quality control detects hidden flaws like solder voids and misaligned parts, ensuring reliable electronics and reducing failures.

X-ray inspection for PCBA quality control detects hidden flaws like solder voids and misaligned parts, ensuring reliable electronics and reducing failures.

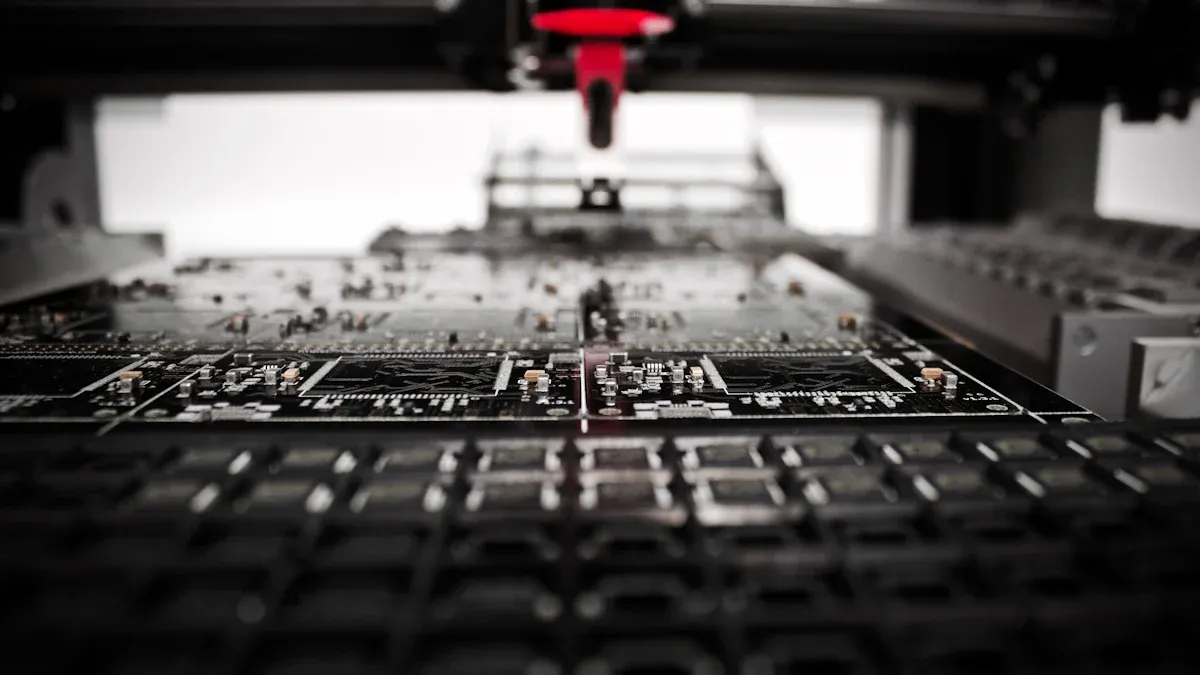

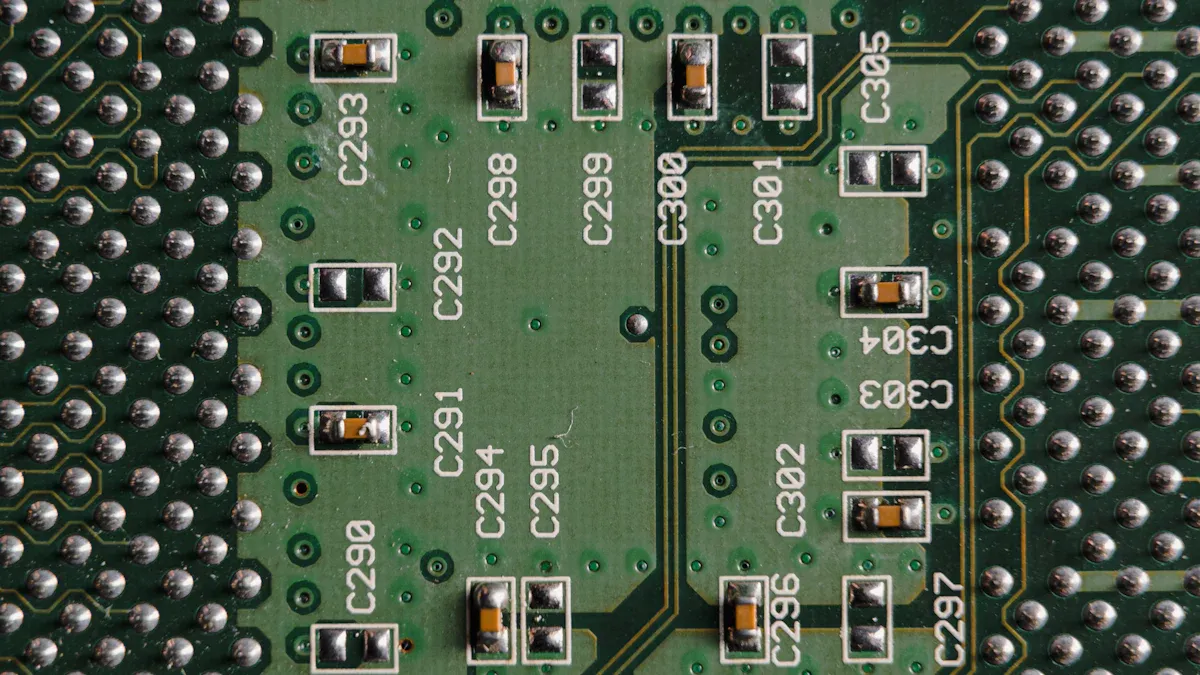

Automated optical inspection for PCBA ensures high-quality circuit boards by detecting defects early, improving efficiency, and reducing production costs.

Optimize your lead-free PCBA manufacturing process with tips on compliance, material selection, equipment upgrades, and quality control for better efficiency.

BGA and micro-BGA assembly services enable compact, efficient electronics for 5G, IoT, and automotive applications, ensuring reliability and performance.

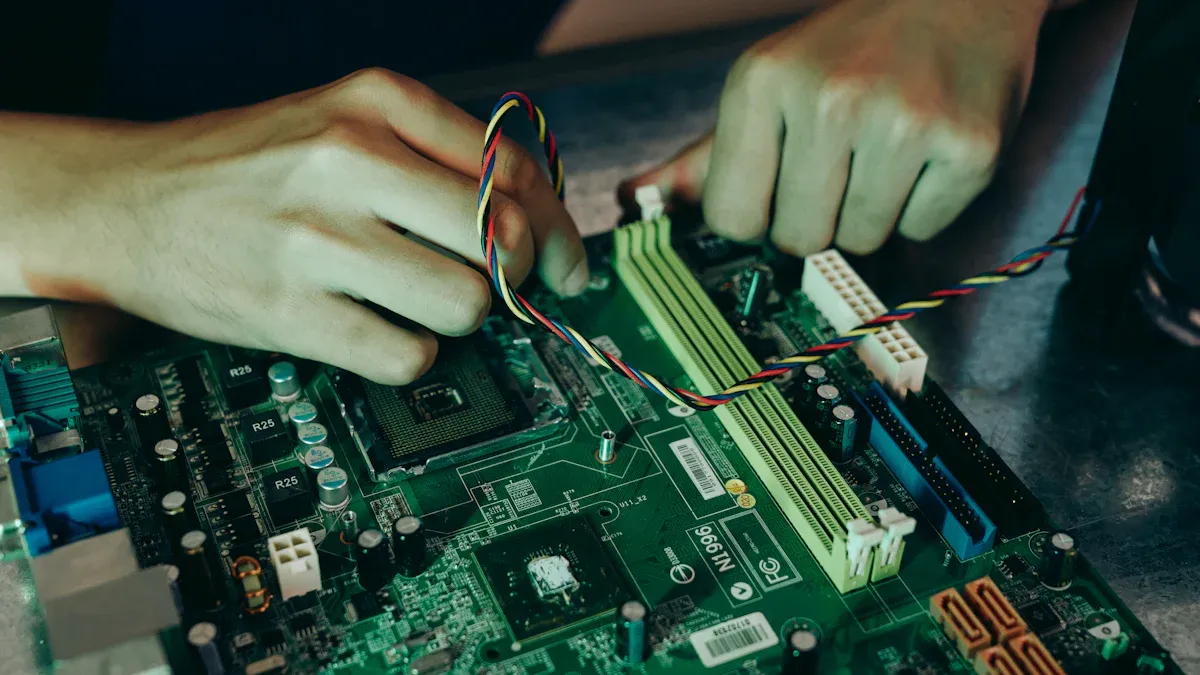

Mixed technology PCBA manufacturing combines SMT and THT methods to create reliable, flexible, and cost-effective circuit boards for modern electronics.

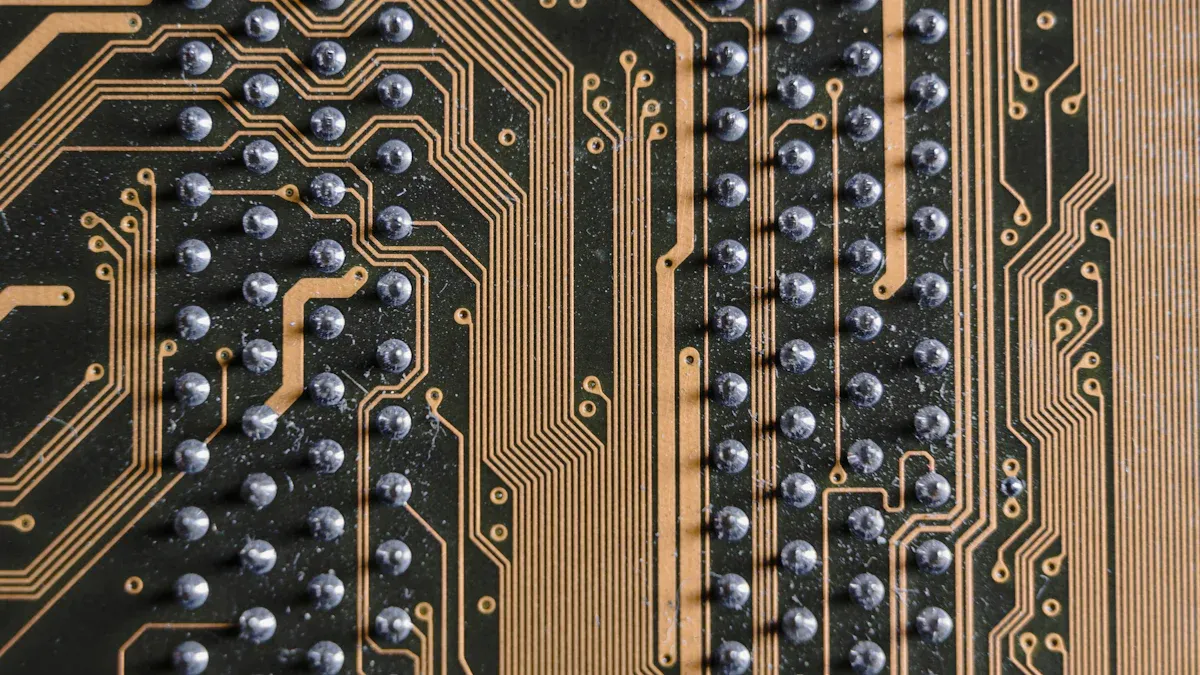

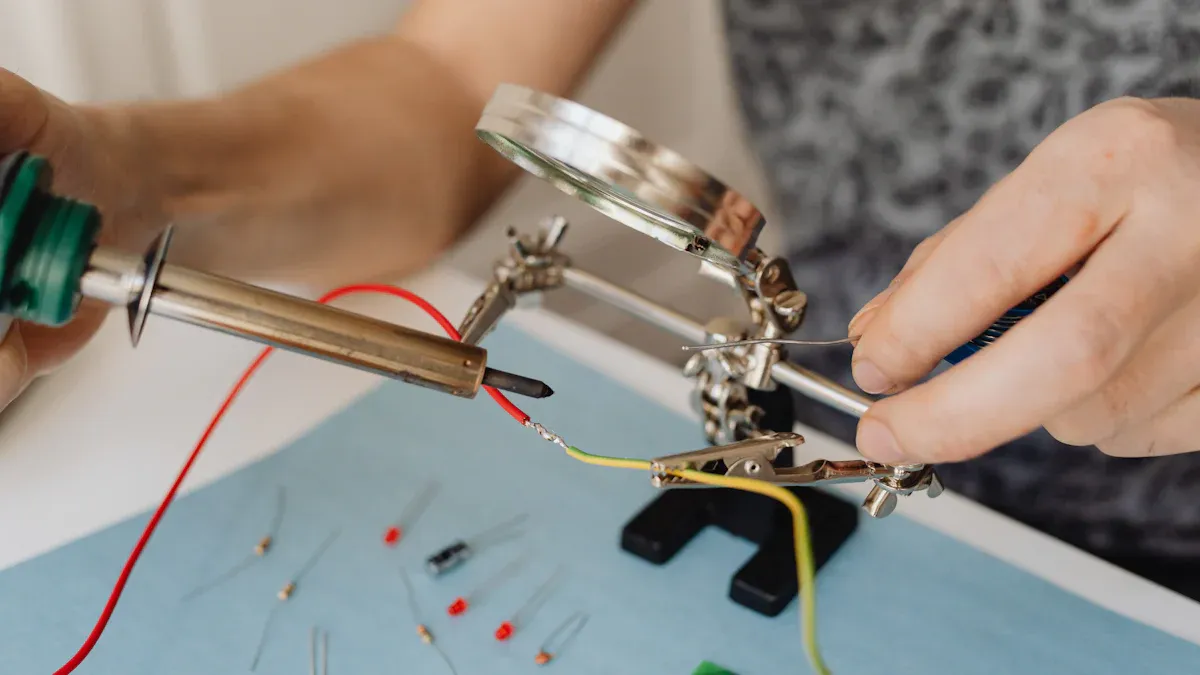

Optimize through-hole PCB assembly techniques with tips on planning, DFA, batch processing, and automation to enhance efficiency and reduce errors.

Explore 2025’s trends in Surface Mount Technology (SMT) assembly services, including automation, AI, miniaturization, and eco-friendly practices driving innovation.

One-stop PCBA manufacturing services streamline processes, reduce costs, and improve quality, making them essential for competitive electronics production in 2025.

Learn how to choose a reliable PCBA manufacturing company in 2025. Focus on quality, certifications, experience, and on-time delivery for dependable results.

Find out how to choose the best small batch PCB assembly services. Learn key factors like quality, flexibility, certifications, and cost-effectiveness.