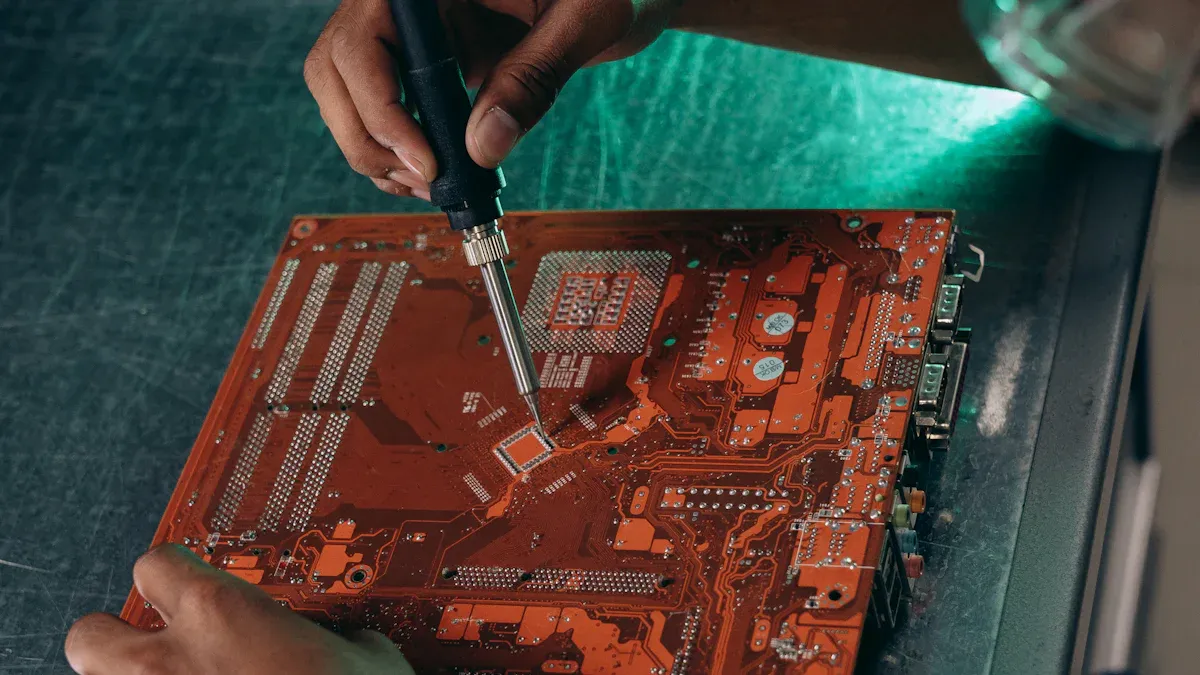

How to Implement a Lead-Free PCBA Manufacturing Process in 2025

Implement a lead-free PCBA manufacturing process effectively in 2025 by ensuring RoHS compliance, upgrading tools, and optimizing soldering techniques.

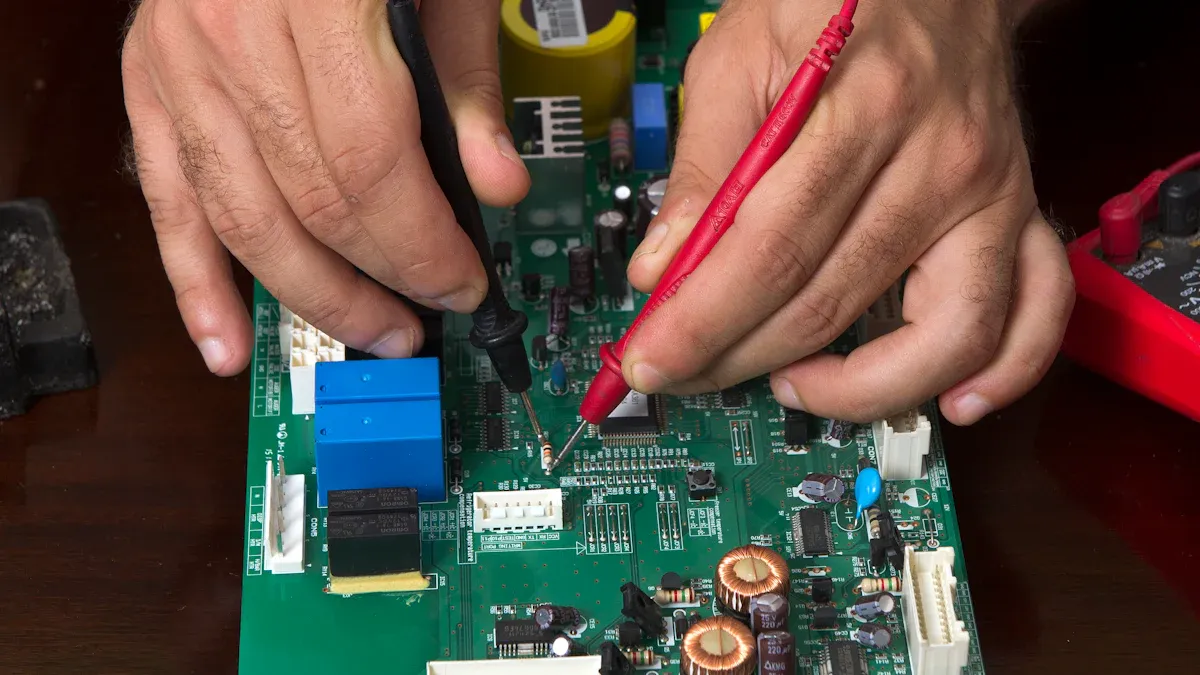

Implement a lead-free PCBA manufacturing process effectively in 2025 by ensuring RoHS compliance, upgrading tools, and optimizing soldering techniques.

Optimize through-hole PCB assembly techniques with advanced soldering, thermal management, and automation strategies for reliable and efficient designs in 2025.

Learn how to choose a reliable PCBA manufacturing company in 2025 by evaluating experience, certifications, quality control, and customer support.

Implement PCBA design for manufacturability (DFM) to reduce errors, optimize layouts, meet standards, and enhance PCB production efficiency and reliability.

Learn how to choose reliable quick turn PCBA services in USA. Discover key factors like experience, quality, speed, and cost transparency for your projects.

Circular economy PCBA practices reduce waste, boost sustainability, and cut costs by reusing materials, designing for recycling, and improving efficiency.

Discover top companies offering biodegradable PCB solutions, reducing e-waste and promoting eco-friendly electronics with innovative green technology.

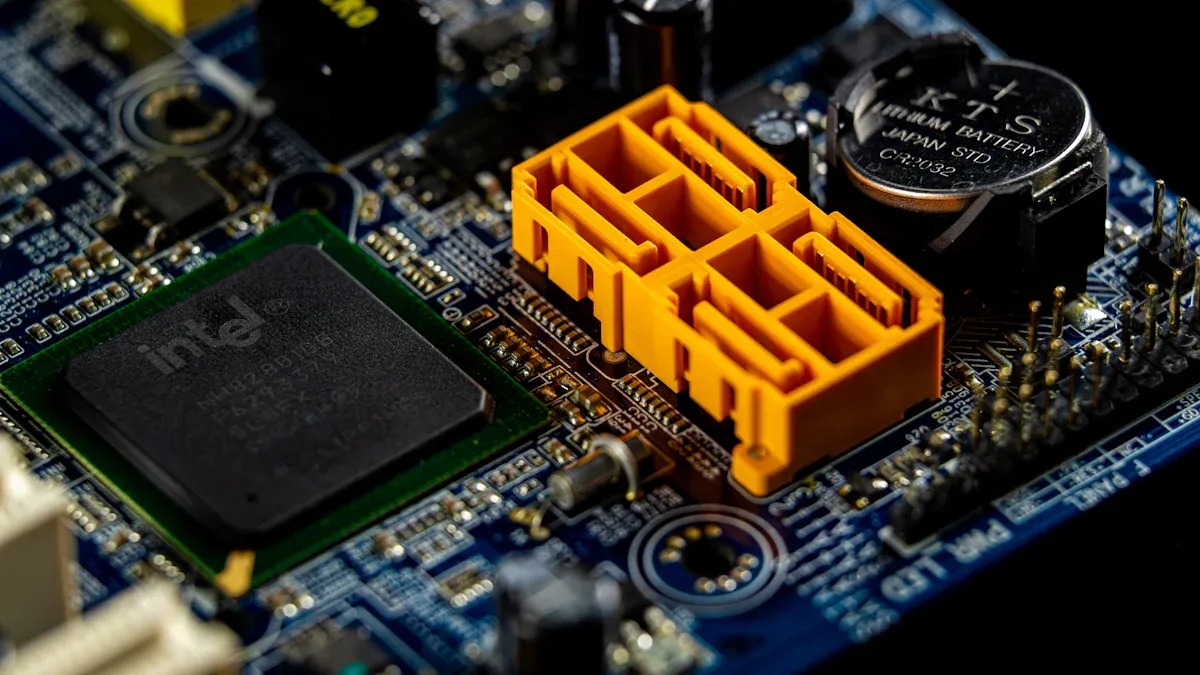

Lead-free and halogen-free PCBA uses eco-friendly materials, removing harmful substances like lead and halogens, ensuring safer electronics and compliance with RoHS.

Sustainable PCB materials like lead-free solder, halogen-free laminates, and recycled metals reduce e-waste, save resources, and ensure eco-friendly manufacturing.

Choose eco-friendly PCBA manufacturing USA for reduced waste, energy savings, and green certifications. Support sustainability while boosting your brand.