What Energy Monitoring Means in IIoT Manufacturing

Energy monitoring in IIoT device manufacturing tracks energy use, reduces waste, cuts costs, and supports sustainability with real-time data and analytics.

Energy monitoring in IIoT device manufacturing tracks energy use, reduces waste, cuts costs, and supports sustainability with real-time data and analytics.

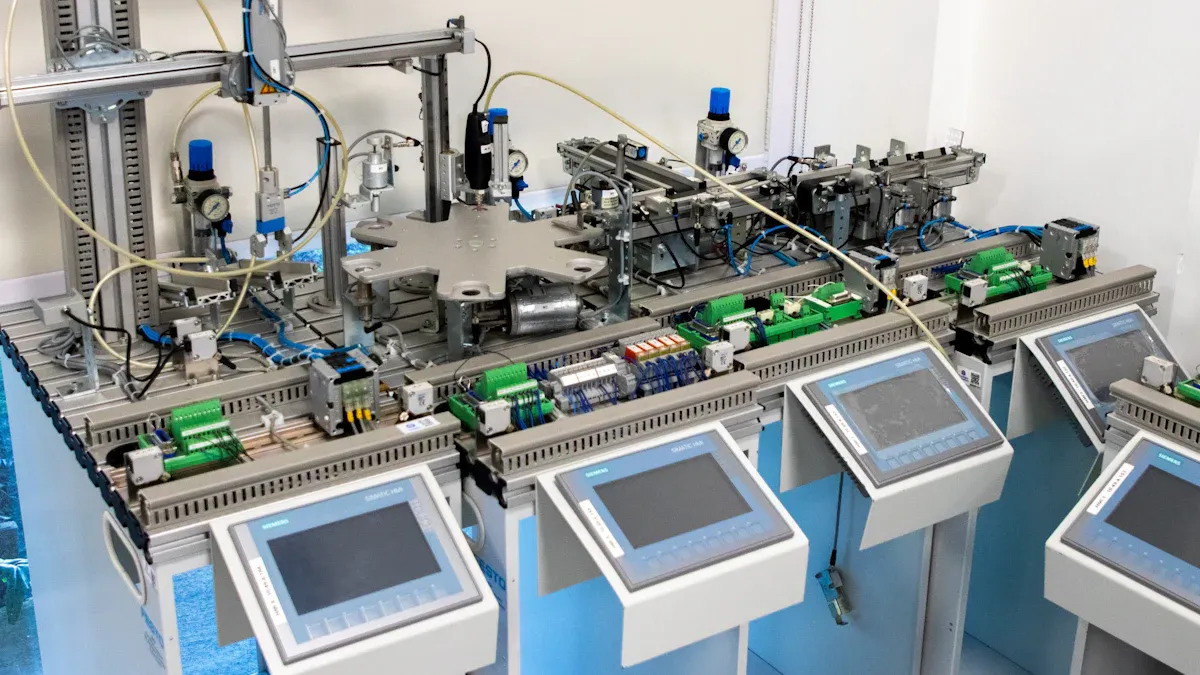

Energy monitoring IIoT device manufacturing boosts factory efficiency, reduces energy costs, and supports sustainability with real-time insights and automation.

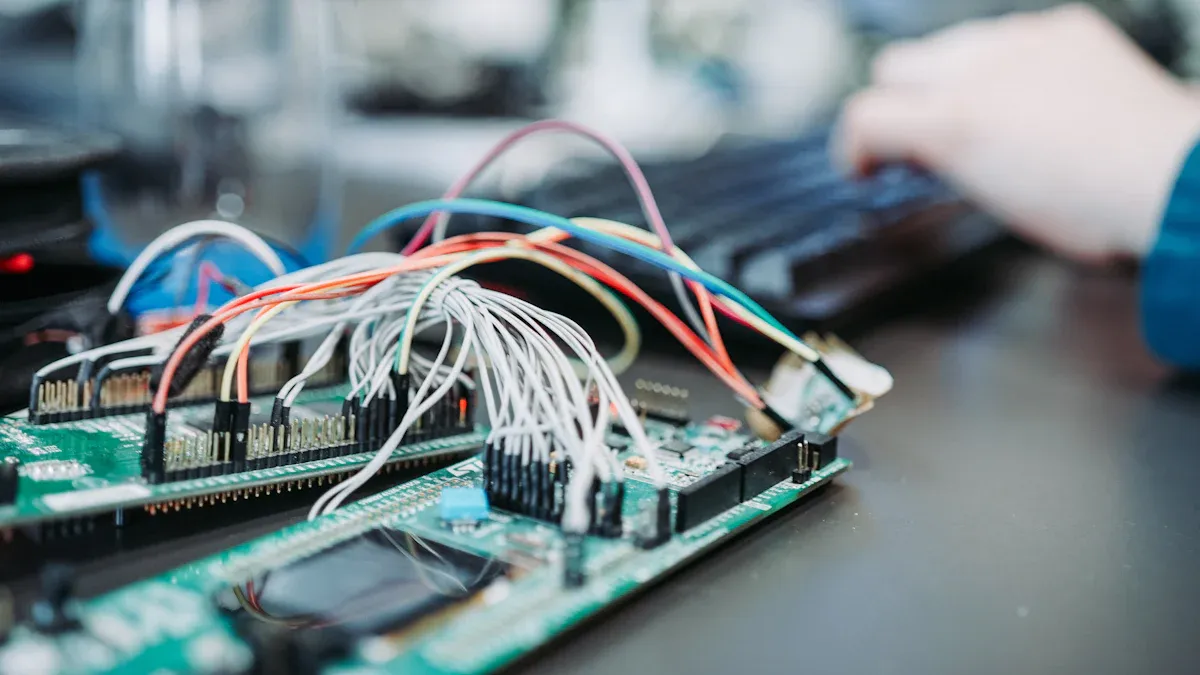

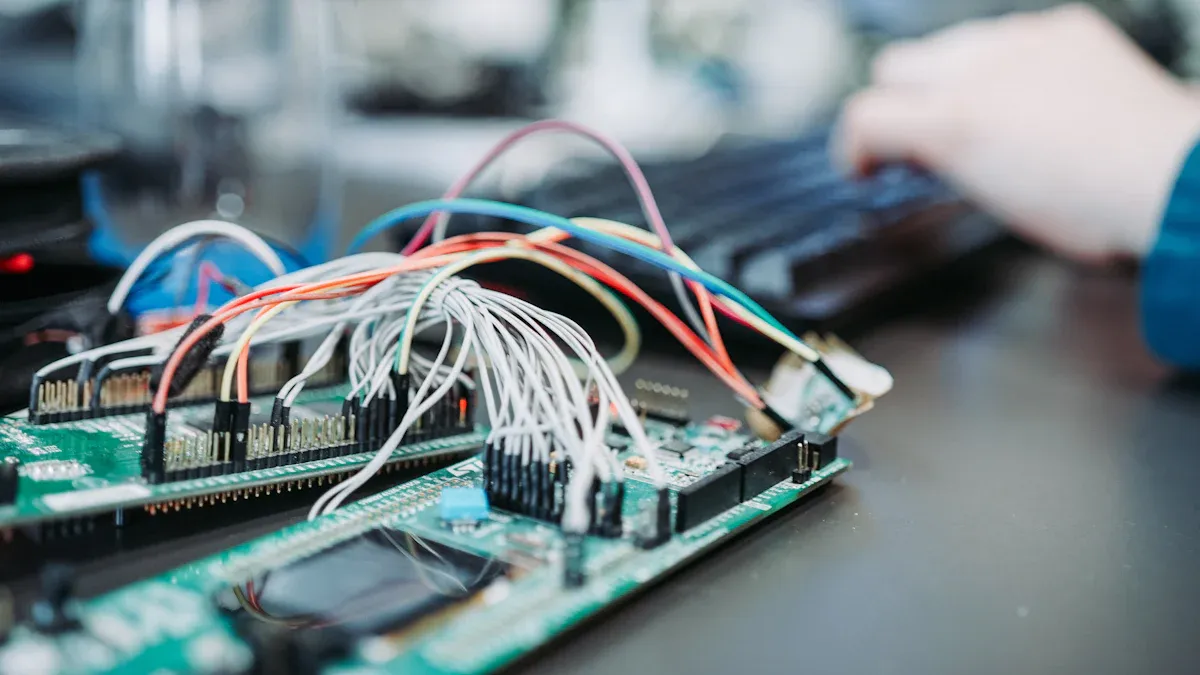

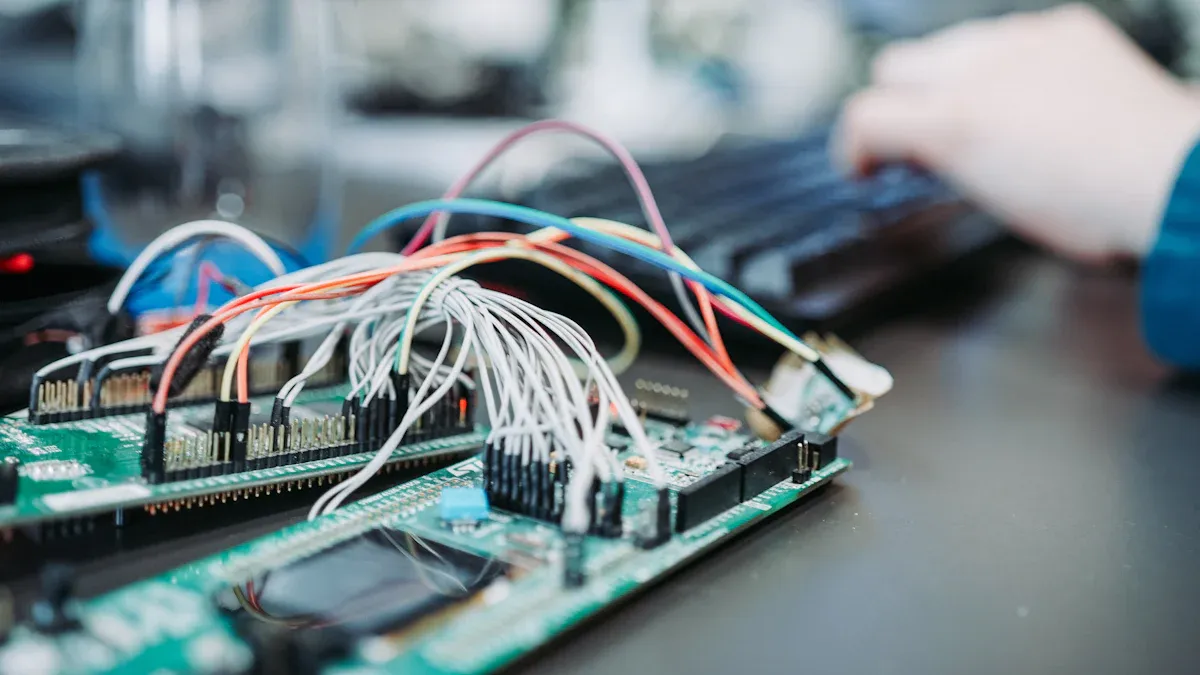

Industrial process control PCB assembly boosts efficiency by automating tasks, reducing errors, and ensuring precision in modern manufacturing.

Smart factory monitoring device PCBA ensures reliable data processing, energy efficiency, and durability, enabling seamless automation in industrial IoT systems.

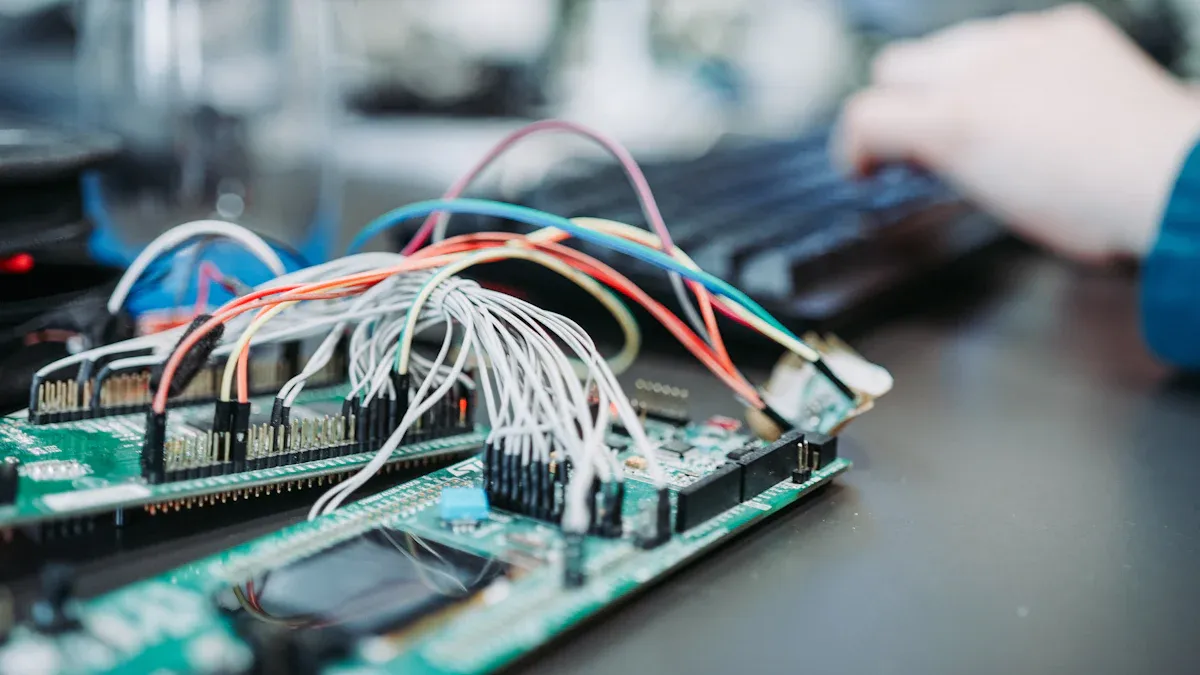

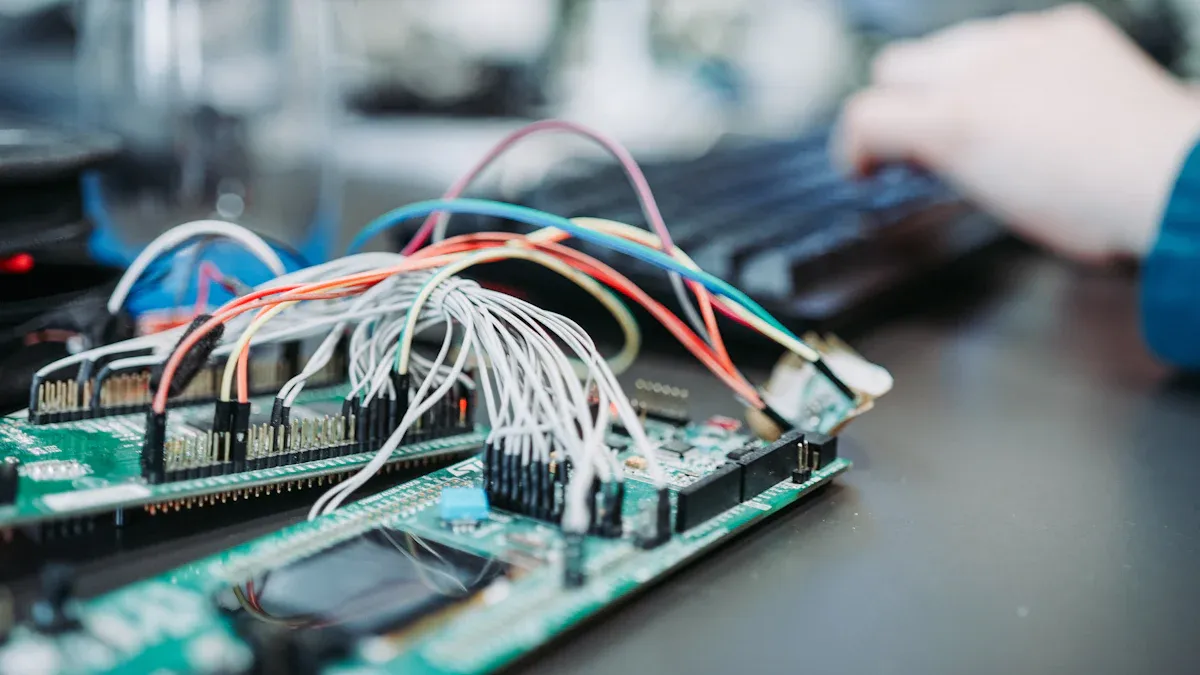

Industrial IoT retrofit kit manufacturing modernizes factories by connecting legacy systems to IIoT, boosting efficiency, reducing downtime, and cutting costs.

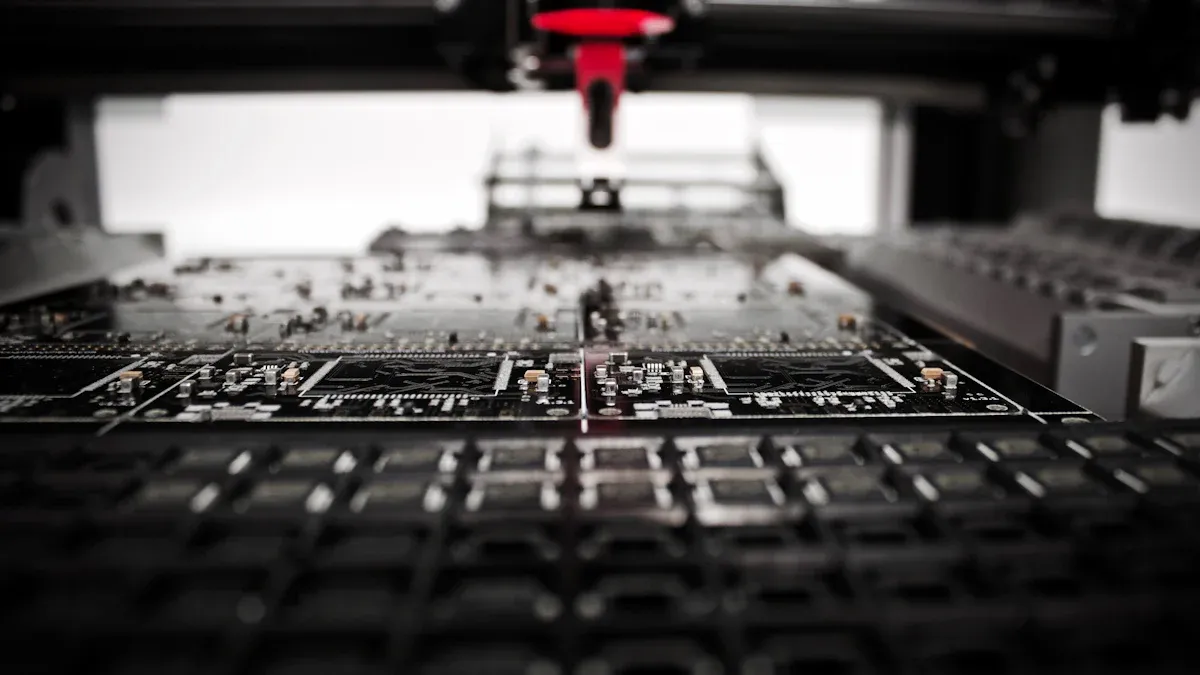

A Manufacturing Execution System in PCB assembly tracks production, ensures quality, and optimizes resources, enhancing efficiency and compliance.

Master Industrial IoT hardware lifecycle management with strategies for design, deployment, maintenance, and secure decommissioning to boost efficiency.

Optimize low volume high mix industrial PCB assembly with strategies for cost control, quality assurance, and handling design changes effectively.

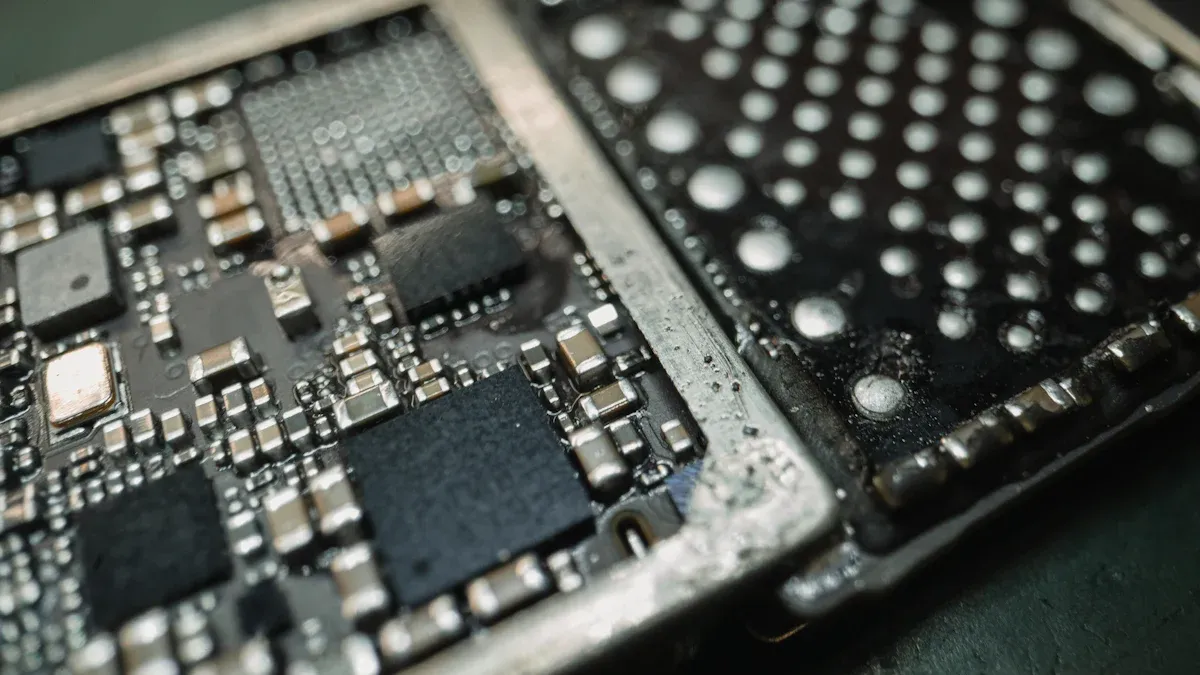

IIoT device quality assurance services ensure reliability, safety, and compliance for industrial IoT systems, vital for seamless operations in 2025.

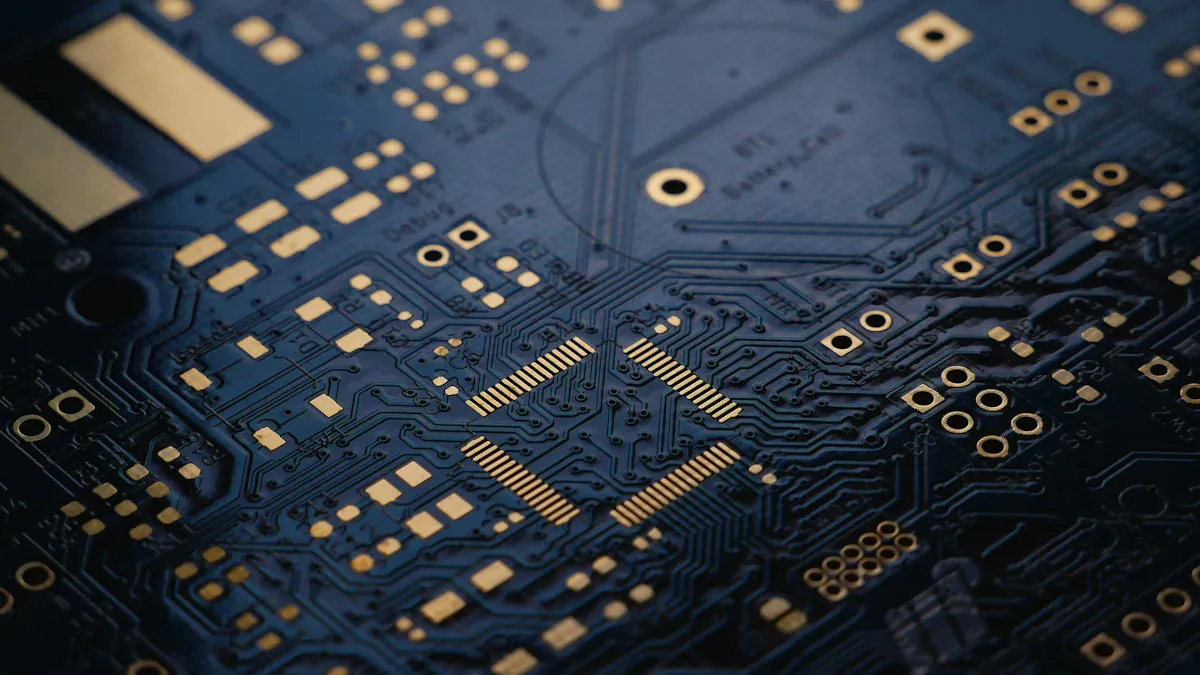

Ensure reliable Industrial IoT PCB testing and validation with methods like AOI, ICT, and stress tests to meet industry standards and tough factory conditions.