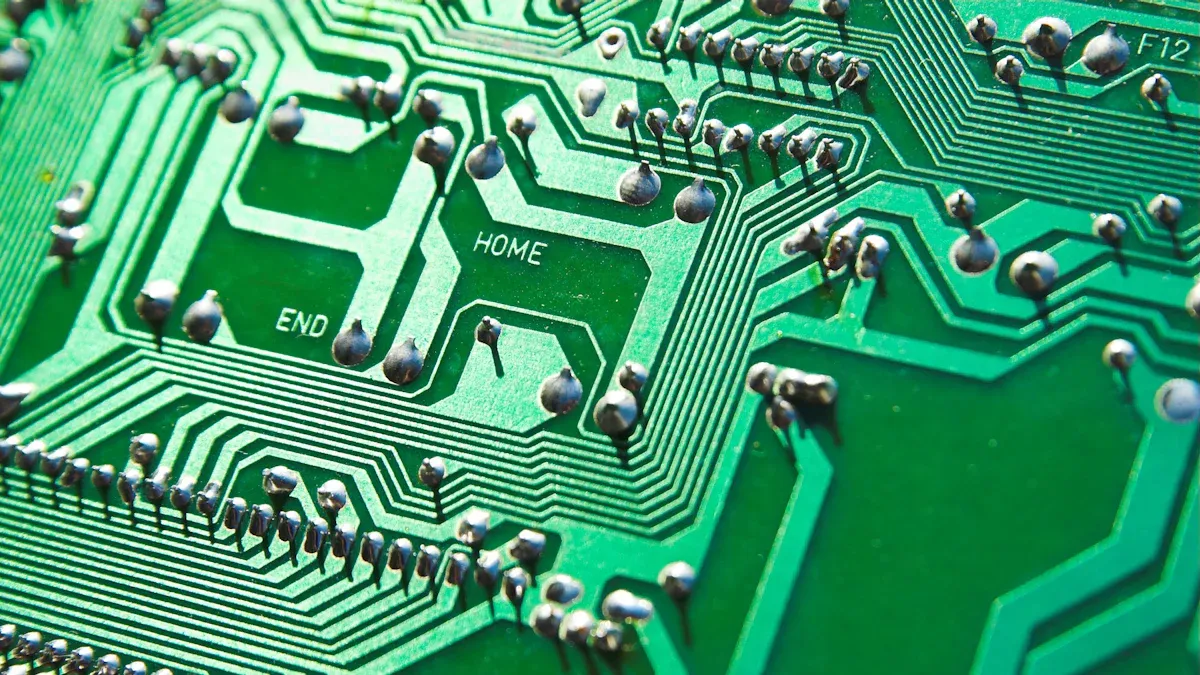

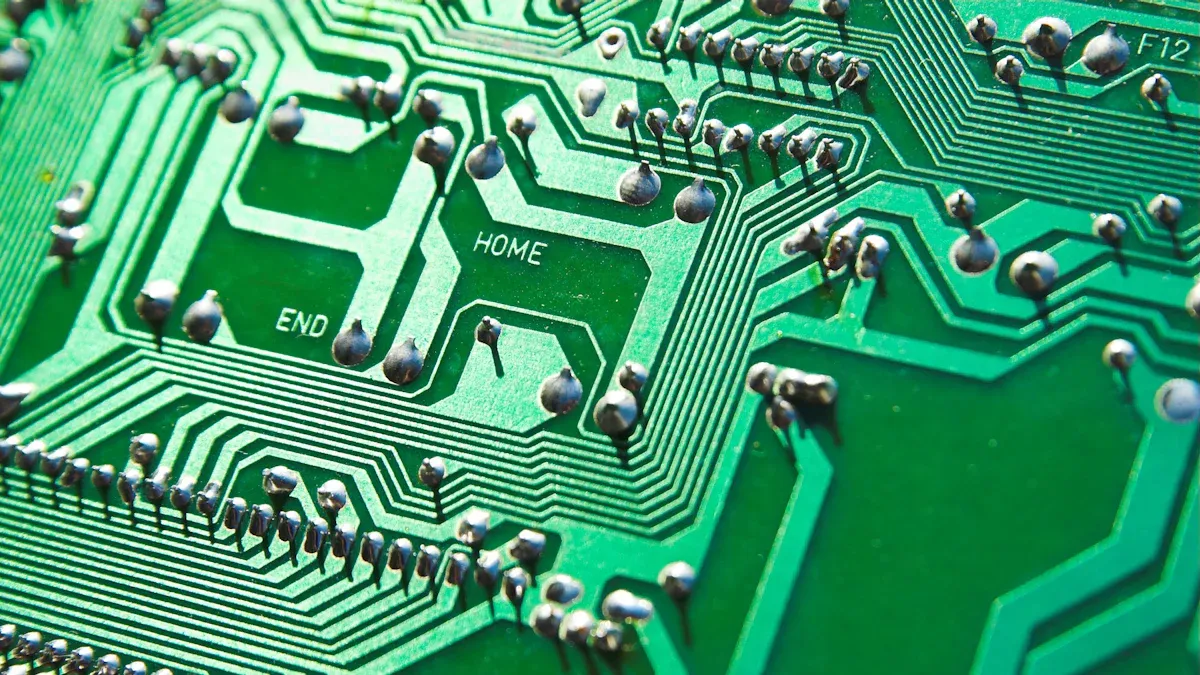

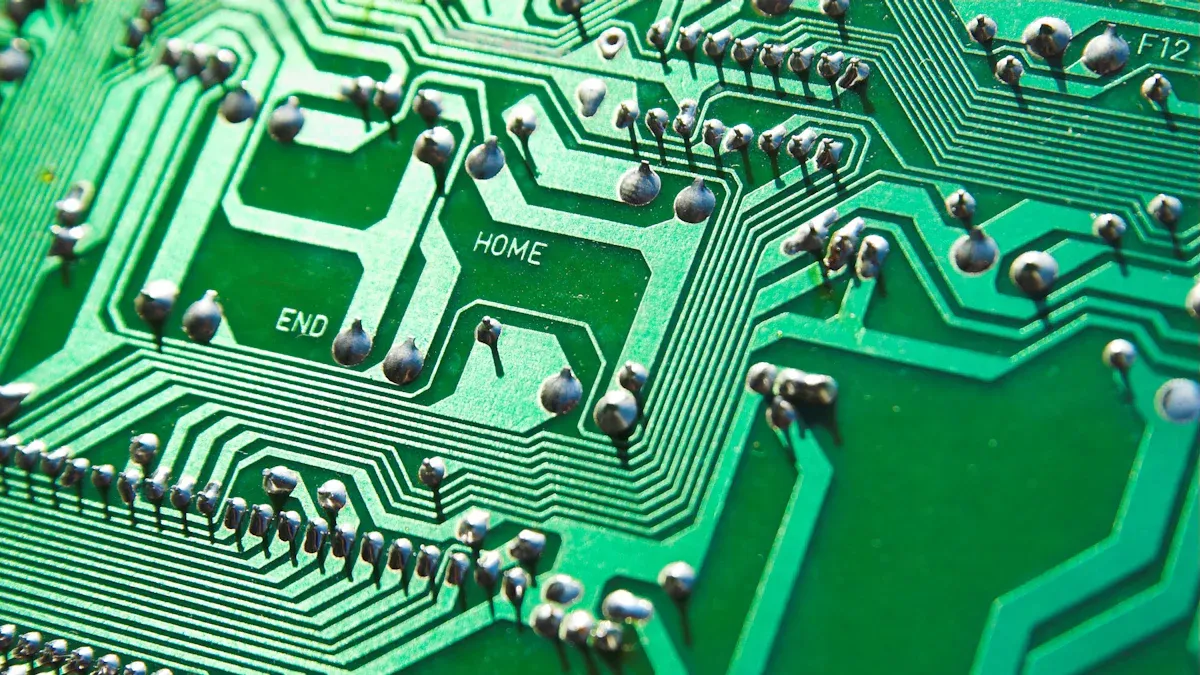

How PCBA Functional Testing Ensures Quality and Reliability

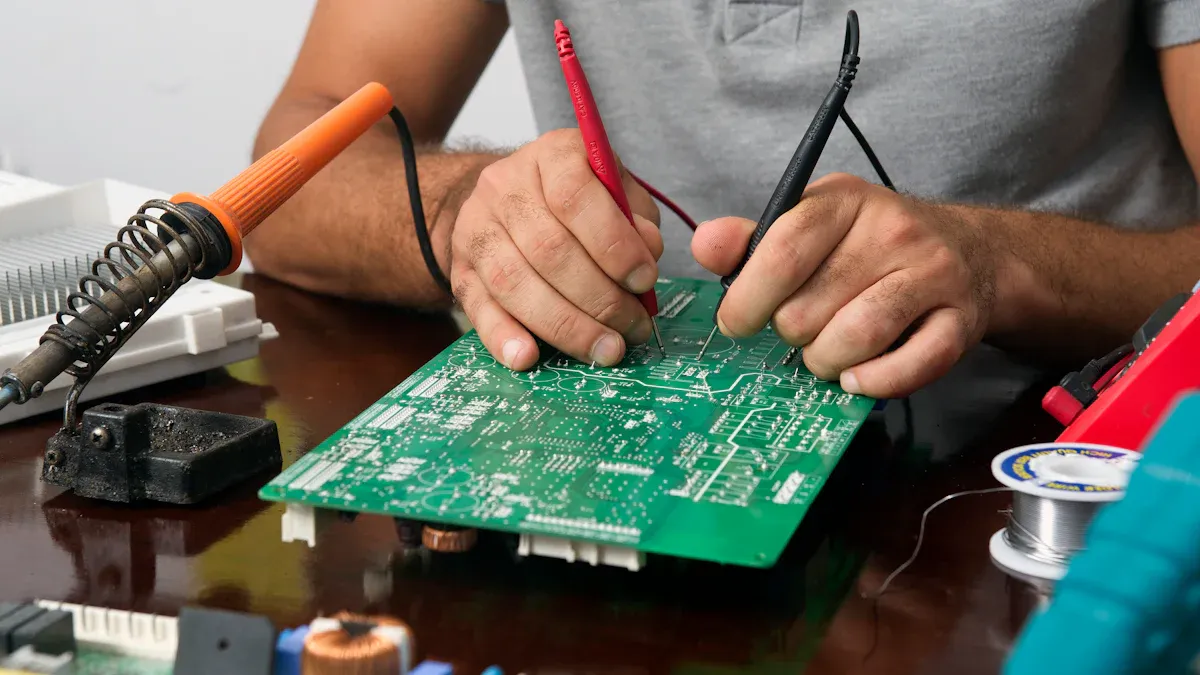

PCBA functional testing ensures circuit boards meet quality standards by simulating real-world conditions. A PCBA functional tester identifies defects early.

PCBA functional testing ensures circuit boards meet quality standards by simulating real-world conditions. A PCBA functional tester identifies defects early.

Compare PCBA manufacturers by pricing, quality, and services to find the best fit for your budget and project needs. Ensure reliability and long-term savings.

Learn how to choose the best PCBA factory by evaluating quality, certifications, technology, and communication to meet your custom requirements effectively.

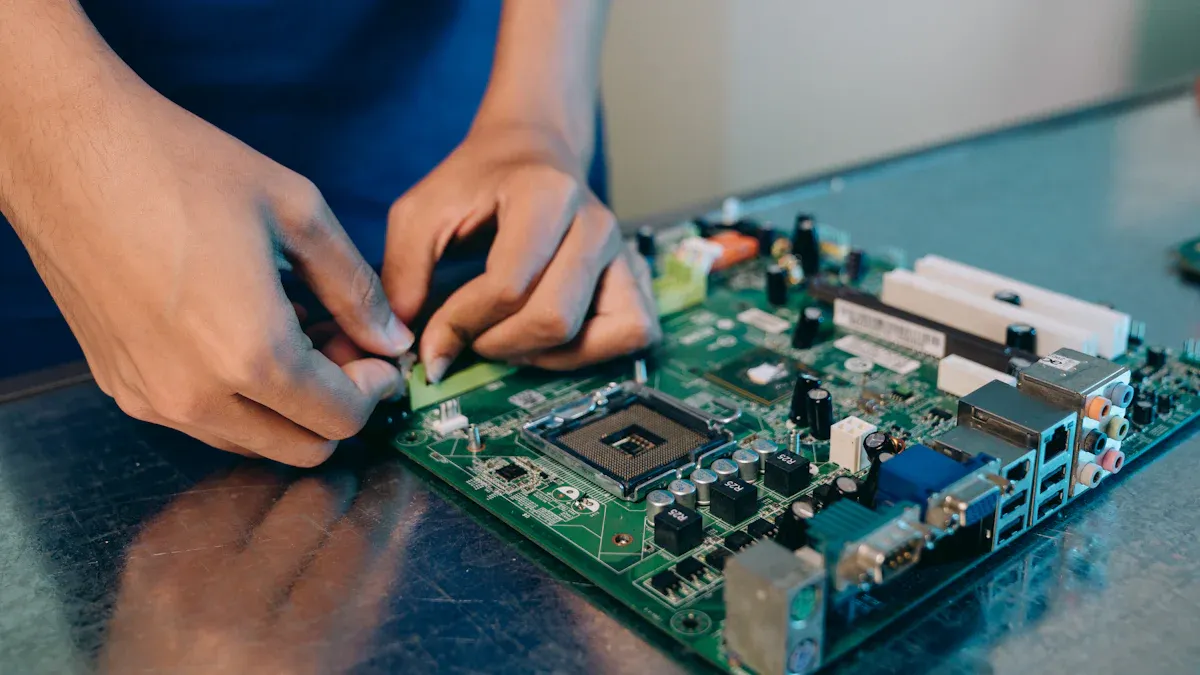

Understand the key differences in pcb vs pcba to choose the right option for your project. Save time, reduce costs, and ensure optimal performance.

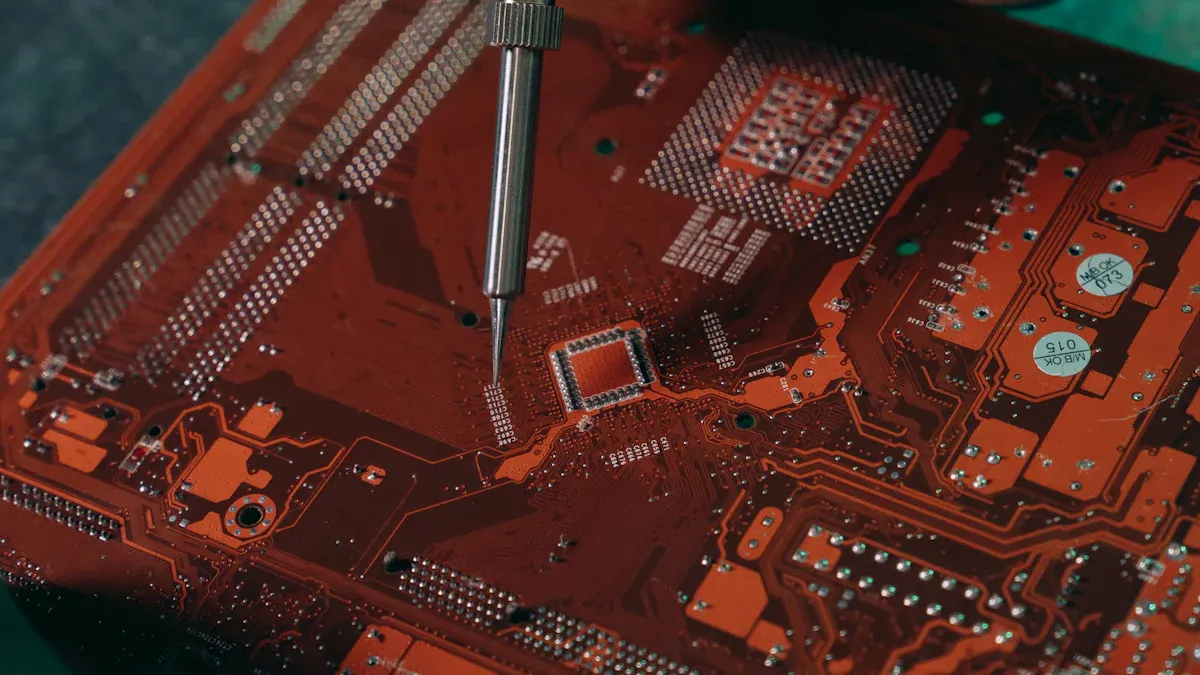

Understand the PCBA manufacturing process, from solder paste stenciling to quality control, ensuring reliable and high-quality electronic devices.

PCBA, or Printed Circuit Board Assembly, is the process of adding components to a PCB, transforming it into a functional part of electronic devices.

Collaborate with PCBA manufacturers to enhance quality and efficiency. Learn tips on DFM, sourcing, testing, and communication for better PCB assembly.

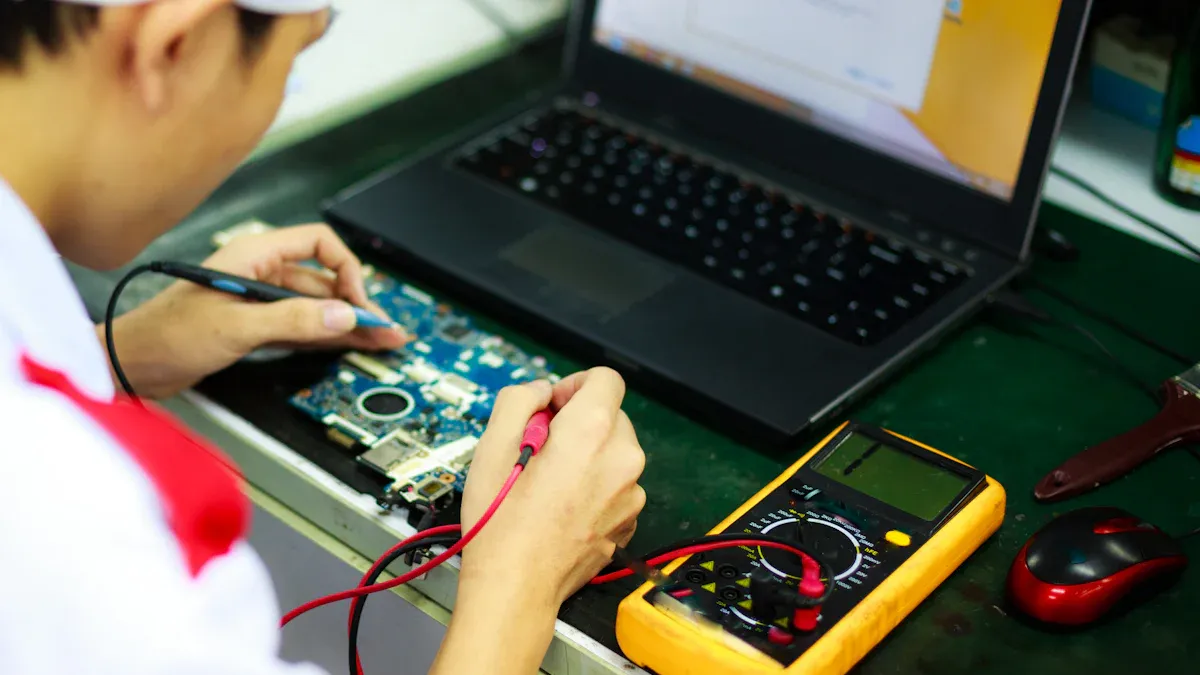

In-circuit testing ensures PCBA quality by detecting defects early. A pcba in circuit tester improves reliability, reduces costs, and boosts production efficiency.

A PCBA tester ensures circuit boards function correctly by simulating real-world conditions, identifying flaws, and verifying performance for reliability.

PCBA test fixtures ensure PCB quality by detecting defects, verifying functionality, and streamlining production, making them vital for electronics manufacturing.