You will see there are eight main types of circuit boards. Each type is made for a special job. When you pick a circuit board, you should think about how hard your project is. You also need to think about what size works best. You should check how strong the board needs to be. You must know where the board will be used. Recent studies show that multilayer and high-density interconnection pcbs are very popular. They are used a lot in small, powerful devices. The table below shows how each pcb type does in the market:

PCB Product Type Segment | Description | Market Position |

|---|---|---|

Rigid Board | Includes single layer, double layer, and multilayer boards | Leading segment in the market |

HDI Board | High-density interconnection boards | Widely used for advanced applications |

Flexible Board | Flexible circuit boards | Used in specialized applications |

Others | Other types of pcbs | Smaller market share |

You can easily see which printed circuit boards you need. This is possible if you know the main types of pcbs and where to use them.

Key Takeaways

There are eight main types of circuit boards. Each type is made for a special use or project need. Single-sided boards are simple and cheap. They work well for basic devices with only a few parts. Double-sided boards have more room for parts and connections. They are good for projects that are not too simple or too hard. Multilayer boards hold many circuits in small spaces. These are best for advanced and powerful devices. Flexible and rigid-flex boards can bend to fit tight or moving spaces. They are great for wearables and medical tools.

Single-Sided Circuit Board

Overview

Single-sided pcbs are the most basic kind of circuit board. They have copper on only one side of the board. All the parts go on the other side. You can see copper lines on just one side. This design is simple and easy to use. Many people pick these pcbs for projects with few parts or easy connections.

Tip: If you want to make a simple device, single-sided pcbs are a good place to start.

Features

Single-sided pcbs are easy to spot because they are simple. Here are some things you will notice:

PCB Type | Defining Characteristics | Components Placement | Complexity Level | Cost | Typical Applications |

|---|---|---|---|---|---|

Single-sided PCB | Single conductive copper layer on one side of substrate; simple design; limited complexity | Components mounted on opposite side of copper layer | Simple, suitable for fewer components | Low | Simple electronics like calculators, LED displays, TVs, refrigerators, simple control panels |

Double-sided PCB | Copper layers on both sides connected by plated-through holes (vias); increased circuit density | Components can be mounted on both sides | Moderate complexity, more versatile | Moderate | Industrial controls, power supplies, devices needing more components and connections |

Multi-layer PCB | Three or more conductive layers with vias connecting layers; very high circuit density | Multiple layers with interconnections | High complexity, advanced functionality | High | High-performance electronics, mobile devices, telecommunications, medical devices |

Single-sided pcbs are not hard to build. You put all the parts on one side. This makes it quick and easy to put together. The simple design also keeps the price low.

Applications

Single-sided pcbs are used in things that do not need many parts. They are found in calculators, LED displays, and simple control panels. Toys and home appliances often use these pcbs. You can also find them in TVs and refrigerators.

Single-sided pcbs are simple and easy to make. This helps save time and money.

Drilling, soldering, and adding parts is faster since everything goes on one side.

The simple layout means there are fewer problems like short circuits.

Companies can make lots of single-sided pcbs at once, so they cost less.

These reasons make single-sided pcbs a smart pick for making lots of basic electronics.

If you want to save money and time on a simple device, think about using single-sided pcbs. They are a good choice and work well.

Double-Sided Circuit Board

Overview

Double-sided pcbs are better than single-sided boards. These pcbs have copper on the top and bottom. You can put parts and traces on both sides. This design lets you fit more things in less space. Double-sided pcbs help you make harder circuits without making the board big.

Tip: If you need more parts or connections, double-sided pcbs give you extra space.

Features

Double-sided pcbs are different because of how they are made. Here are some main ways they are not like single-sided pcbs:

Single-sided pcbs have copper on one side, so they are simple and cheap.

Double-sided pcbs have copper on both sides of the board.

You can put traces and parts on both sides, so you get more circuits.

The two layers let you make more advanced circuits.

Making double-sided pcbs is harder than making single-sided boards.

You can use vias to connect the two sides. This lets you send signals in ways single-sided boards cannot. Double-sided pcbs give you more ways to design your project.

Applications

You will find double-sided pcbs in many electronics. These boards are good for projects that need more parts and connections. Some common uses are:

HVAC systems

Power conversion devices

LED lighting

Printers

Hard drives

Phone systems

Vending machines

Traffic systems

Car dashboards

Double-sided pcbs help you make strong and good devices. You can use them in home and work products. When you need a board for harder designs, double-sided pcbs are a good pick.

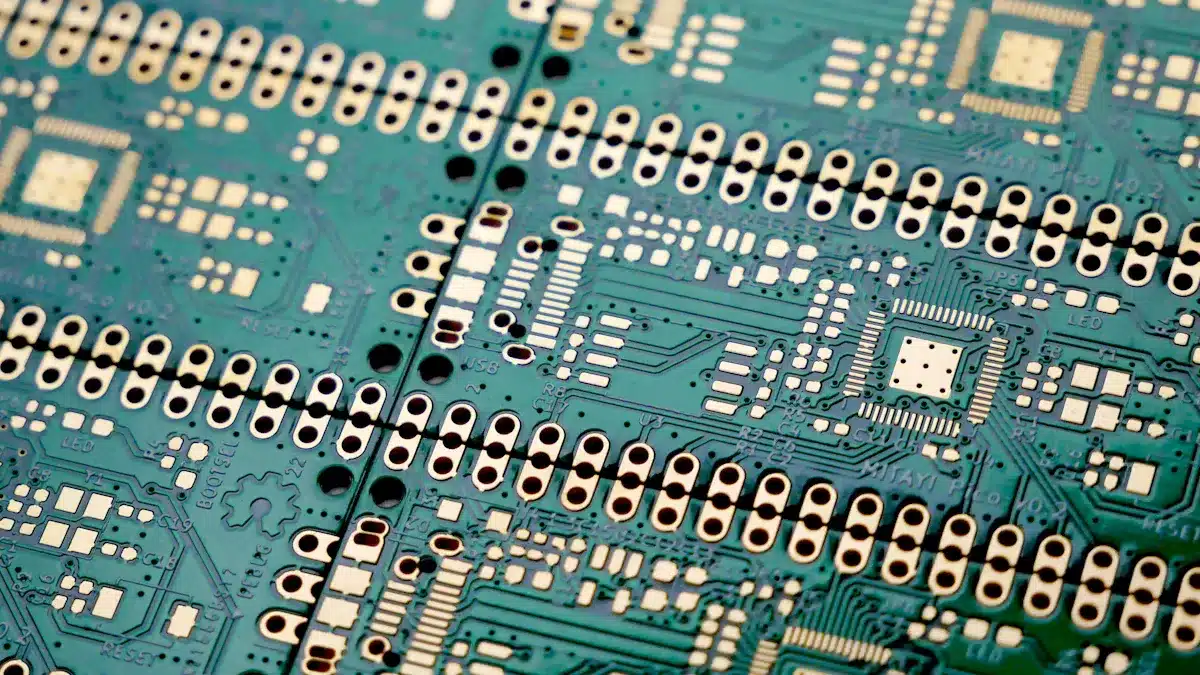

Multilayer Printed Circuit Boards

Overview

Multilayer printed circuit boards have at least three copper layers. These layers are stacked with insulation between each one. This design lets you fit many circuits in a small space. Multi-layer pcbs are used for complex devices that must be small. Each layer connects using small holes called vias. This setup helps you make advanced electronics with lots of connections.

Note: Multi-layer pcbs are best if you want to save space and add more features.

Features

Multi-layer pcbs have many benefits over single or double-sided boards. Here are some important things to know:

You can make very complex circuits in a small area. This helps make devices smaller and lighter.

These pcbs improve signal quality. Special layers for power and ground help reduce noise.

You can add more parts without making the board bigger. This is good for high-density designs.

The strong lamination makes these pcbs tough and reliable. They handle heat and stress better than simple boards.

You get better power flow. Dedicated layers help stop power loss and keep your device working well.

Multi-layer pcbs allow faster data speeds. Shorter signal paths help your device work faster.

You can make many boards at once with high accuracy. This lowers mistakes and keeps quality high.

Over time, you save money. Even though the first cost is higher, you spend less on repairs and replacements.

Applications

Multilayer printed circuit boards are used in many advanced technologies. These pcbs work well where space, speed, and reliability are important. Here are some common uses:

Aerospace systems

Automotive electronics

Military and defense equipment

Medical devices like heart monitors and X-ray machines

Telecommunications and GPS technology

Computers, laptops, and cell phones

Wearable electronics and wireless gadgets

Industrial controls and semiconductors

Consumer products and autonomous machines

You should pick multi-layer pcbs if your project needs high performance in a small size. These printed circuit boards help you build modern devices that are powerful, reliable, and ready for the future.

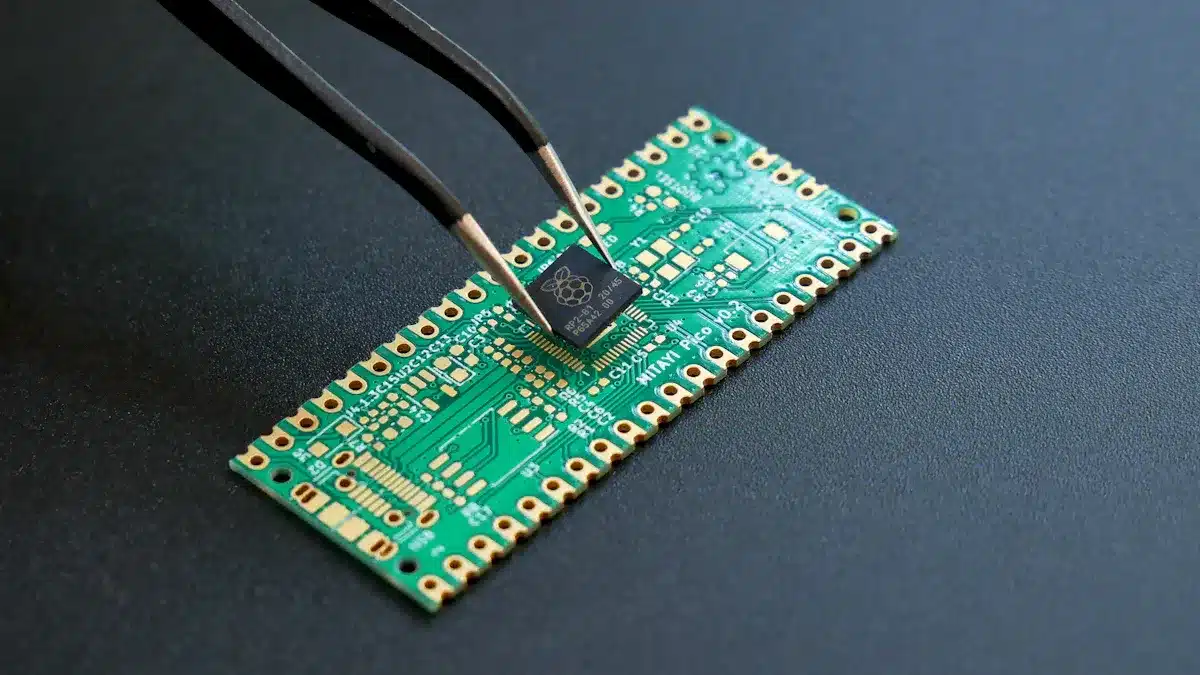

Rigid Circuit Board

Overview

Rigid circuit boards are the most common type of pcbs in electronics today. These pcbs have a hard base that does not bend or twist. The base keeps its shape all the time. Most rigid pcbs use copper laminates as the main material. Copper helps electricity move through the board. This makes your circuits work well. The most popular base material is called FR-4. FR-4 makes the board strong and hard to break. It also keeps electricity from leaking out. This keeps your circuits safe. But FR-4 does not let heat escape very well. When your pcbs get hot, most heat leaves through the air. As devices get smaller and use more parts, you need to think about how your pcbs handle heat.

Tip: Rigid pcbs are a good pick if you want a strong board that keeps its shape.

Features

You can tell rigid pcbs by their hard, flat look. These pcbs do not bend, so they protect your circuits from damage. Rigid pcbs are easy to make in big numbers, so they cost less. You can use them for simple or hard designs. Most pcbs in computers, TVs, and cars are rigid. These boards last a long time if you use them right. If you need a board for a really tough job, you might want to try other types.

Here is a quick comparison between rigid and flexible circuit boards:

Aspect | Flexible Circuit Boards | Rigid Circuit Boards |

|---|---|---|

Durability | High durability in harsh environments | Good for normal use, less durable in extreme conditions |

Cost | More expensive to make and install | Less expensive, great for high-volume production |

Usage | Best for small, bendable devices | Best for standard electronics and cost savings |

Applications

You will see rigid pcbs in many different industries. These pcbs work well in products that need to last and stay strong. Here are some places where you will find rigid pcbs:

Aerospace and military equipment

Medical devices and hospital machines

Networking and telecom products

Computers and storage systems

Industrial controls and test tools

Cars and trucks

Cell phones and tablets

Home appliances like washing machines and microwaves

Rigid pcbs are important for products that need to handle heat, shaking, and long use. You can trust these pcbs in devices that must work every day. Many companies use rigid pcbs because they are reliable and save money. If you want a board that is easy to make and works well in most cases, rigid pcbs are a great choice.

Flexible Circuit Board

Overview

Flexible circuit boards, also called flex pcbs, change the way you design electronics. These pcbs use thin, bendable materials instead of hard boards. You can twist, fold, or shape them to fit inside small or oddly shaped devices. Flex pcbs help you build products that need to move or fit into tight spaces. You often see these pcbs in modern gadgets where space and movement matter.

Note: Flex pcbs let you create lighter and smaller devices without losing strength.

Features

You will notice several special features when you use flexible circuit boards. These pcbs bend and flex without breaking. This makes them perfect for devices that move or shake. Flex pcbs use fewer connectors and solder joints, so you get fewer weak spots. This helps your device last longer. They also handle heat better, which keeps your electronics safe from overheating. You can fit these pcbs into complex shapes, so you can design more creative products.

Here are some ways flex pcbs improve device reliability in tough environments:

They bend and flex, so they work well with vibration and movement.

They resist damage from shaking or bumps.

Fewer connectors and joints mean fewer chances for something to break.

They spread heat better, which helps prevent overheating.

You can fit them into small or odd spaces, like in cars, planes, or medical tools.

Applications

You will find flexible circuit boards in many industries. In consumer electronics, you see them in smartphones, cameras, and wearables. Medical devices use these pcbs because they fit into tiny spaces and handle movement. Cars and airplanes use flex pcbs for parts that must bend or move. You also find them in printers, scanners, and other office machines. When you need a pcb that can handle stress, heat, and tight spaces, flex pcbs give you the best solution.

Rigid-Flex Circuit Board

Overview

Rigid-flex circuit boards mix two types of boards. They have the strength of rigid boards. They also have the bendy parts of flex pcbs. These pcbs use layers with both stiff and bendy materials. You can fold or twist them to fit small spaces. They work well in devices with odd shapes. Rigid-flex pcbs help save space and make things lighter. You see these boards when regular boards do not work alone.

Tip: Rigid-flex pcbs help you build electronics for tight or strange spaces.

Features

Rigid-flex circuit boards have many good points:

You can bend and twist them, and they will not break.

They are thinner and lighter than most rigid boards.

You do not need as many cables or connectors, so your device is simpler.

These pcbs fit where rigid boards cannot go.

The flexible parts keep bending for the whole life of the device.

Their light weight is great for medical tools, wearables, and aerospace gear.

Rigid-flex pcbs have both flexible and stiff areas. This means you need fewer connectors and wires. There are fewer places where things can break. These boards are more reliable. They can handle shock, shaking, and heat very well. You can use them in tough places.

Applications

Many industries use rigid-flex circuit boards to fix hard design problems. Here is a table that shows where you find these pcbs and why they matter:

Industry | Why Use Rigid-Flex PCBs? |

|---|---|

Consumer Devices | Makes gadgets smaller and lighter; fits tricky shapes like cameras and smartwatches. |

Medical Devices | Gives long-lasting use for implants and portable tools; needs little care. |

Automotive | Handles heat and shaking; used in dashboards and control units. |

Wearable Technology | Helps make small, light designs with cool features. |

Industrial Machinery | Cuts downtime by removing loose wires; lasts longer in hard jobs. |

Military & Aerospace | Works in high heat, shaking, and stress; keeps devices safe and working. |

Satellite | Needed for perfect, always-on work in space; lasts for years without fixing. |

Telecommunications | Makes signals better in antennas and base stations; helps with connections. |

You will find rigid-flex pcbs in products that must be small, light, and strong. These boards help you make devices that last longer and work well, even in tough places.

Perfboard

Overview

Perfboards give you a simple way to build circuits by hand. You see them often in electronics labs and classrooms. Many hobbyists and students use perfboards to test ideas before making final pcbs. Each perfboard has a grid of holes. You can place electronic parts like resistors and microcontrollers into these holes. You connect the parts with wires or by soldering. Perfboards do not have printed tracks like other pcbs. You decide how to make the connections. This makes perfboards a favorite for learning and quick experiments.

Tip: If you want to try out a new circuit, start with a perfboard. You can change your design as you go.

Features

Perfboards stand out because they let you build and change circuits fast. You do not need to design or order custom pcbs for every idea. Here are some ways perfboards help you:

You can quickly connect parts like capacitors and transistors without making permanent changes.

You use jumper wires to set up and change your circuit. This saves time and lets you reuse parts.

You can test, fix, or redesign your circuit before moving to a final pcb.

Perfboards support flexible setups. You can try many layouts and see what works best.

Perfboards also have some limits. You must wire everything by hand. This takes more time for big or complex circuits. Mistakes can happen if you mix up wires. Finished pcbs look neater and work better for large projects. Professional pcbs have features like soldermask and perfect hole alignment. Perfboards work best for small, simple, or urgent projects.

Applications

You use perfboards most when you want to build a prototype. They help you test ideas before you spend money on custom pcbs. Many students use perfboards in science fairs and school labs. Engineers use them to check if a new design works. Makers and hobbyists use perfboards to build small gadgets at home. You can also use perfboards to teach others about electronics. When you finish testing, you can move your design to a real pcb for better quality and reliability.

Use Case | Why Choose Perfboard? |

|---|---|

Prototyping | Fast setup, easy changes, low cost |

Education | Great for learning and teaching electronics |

Hobby Projects | Simple builds, reusable parts, quick results |

Testing Circuits | Easy to fix mistakes and try new ideas |

Perfboards help you learn, test, and create. They give you the freedom to explore electronics before you make final pcbs.

Semi-Flexible Circuit Board

Overview

Semi-flexible circuit boards mix the good parts of rigid and flexible pcbs. These boards start with a hard FR-4 base. Some spots are made thin by deep milling. This lets you bend those areas when you need to. You do not have to use flexible materials everywhere. This design helps you make devices that bend in some places but stay strong in others. The board can bend at angles like 45°, 90°, or even 180° without breaking.

Note: Semi-flexible pcbs cost less than fully flexible or rigid-flex pcbs. They also avoid problems like expansion mismatch, which can make boards less reliable.

Here is a table to show how semi-flexible pcbs compare to other types:

PCB Type | Construction Materials and Process | Flexibility Characteristics | Cost and Reliability Considerations |

|---|---|---|---|

Semi-Flexible | Rigid FR-4 with deep milling for local flexibility | Local bending (45°, 90°, 180°) | Cost-effective, reliable, avoids expansion mismatch |

Fully Flexible | Thin polyimide, rolled copper, flexible adhesive | High bendability, complex 3D shapes | More expensive, better dielectric properties |

Rigid | Interwoven glass fiber, less uniform thickness | No flexibility | Low cost, stable, no bending capability |

Rigid-Flex | Rigid and flexible materials laminated together | Rigid and flexible sections, multilayer flex | High cost, expansion mismatch can reduce reliability |

Features

Semi-flexible pcbs bend only in certain spots. This gives you both strength and flexibility. The boards still work well after bending. You save money because you do not need flexible materials everywhere. These pcbs can handle heat and shaking, so they last longer. You can make smaller and lighter devices since you do not need extra cables.

Semi-flexible pcbs help you design new products. You can fold or shape them to fit small spaces. This makes them great for modern electronics that must be small and strong.

Applications

Semi-flexible pcbs are used in many important products. Here are some common uses:

Car electronics such as dashboard controls and driver help systems

Aerospace and defense gear, including avionics and radar

Consumer electronics like smartphones, tablets, and portable gadgets

These pcbs give you many good features. In cars, they handle heat up to 150°C and resist shaking. In wearables, they bend with your body and feel comfortable. In phones and laptops, they let you make screens that fold without breaking. Medical devices use them for portable blood pressure meters and temperature controls.

You get smaller, lighter devices that control heat better and last longer. Semi-flexible pcbs help you make products that work well in tough places and tight spaces.

You now know about eight types of pcbs. Each type works best for a certain job. Look at this table to compare them fast:

PCB Type | Cost | Complexity | Common Uses |

|---|---|---|---|

Low | Simple | Toys, calculators | |

Double-sided | Moderate | Medium | Power supplies, lighting |

Multilayer | High | Complex | Phones, computers |

Rigid | Low | Simple | Appliances, cars |

Flexible | High | Complex | Wearables, cameras |

High | Complex | Medical, aerospace | |

Perfboard | Low | Simple | Prototyping, education |

Semi-Flexible | Moderate | Medium | Automotive, medical |

Pick the right pcb for your project’s needs. Think about how much you want to spend. Check what size and strength you need. If you are not sure, ask an expert or use a trusted guide to help you choose.

FAQ

What is the main difference between single-sided and double-sided circuit boards?

Single-sided boards have copper and parts on one side. Double-sided boards have copper on both sides. You can place more parts and make more connections with double-sided boards.

Can you cut or shape a circuit board to fit your project?

You can cut some boards, like perfboards or flexible pcbs, with simple tools. Rigid boards need special tools for cutting. Always wear safety gear when you cut any board.

Why do some devices need multilayer circuit boards?

You need multilayer boards for complex devices. These boards let you fit many circuits in a small space. Phones, computers, and medical tools use multilayer boards for better performance.

Are flexible circuit boards as strong as rigid ones?

Flexible boards bend and twist without breaking. They handle movement well. Rigid boards stay strong in one shape. Each type works best in different situations.

How do you choose the right circuit board for your project?

Think about your project’s size, cost, and how many parts you need. Check if your device needs to bend or stay strong. Ask an expert if you feel unsure.

See Also

Essential PCBA Parts And Their Primary Roles Explained

Exploring How PCBA Is Utilized In Consumer Devices

Key Advantages And Uses Of PCBA In Today’s Electronics