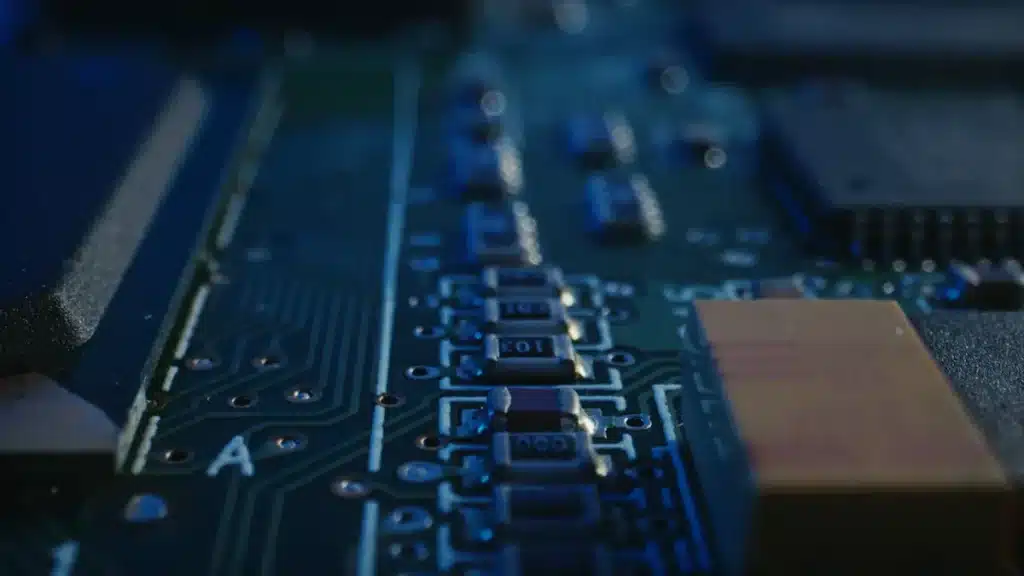

Acoustic emission monitoring PCBA has transformed how we inspect circuit boards. It detects tiny cracks and solder issues early, enhancing the reliability of the boards. Recent advancements indicate that it improves the performance of circuit boards:

Acoustic emission monitoring PCBA can now easily identify solder problems. It assesses their strength before failure occurs.

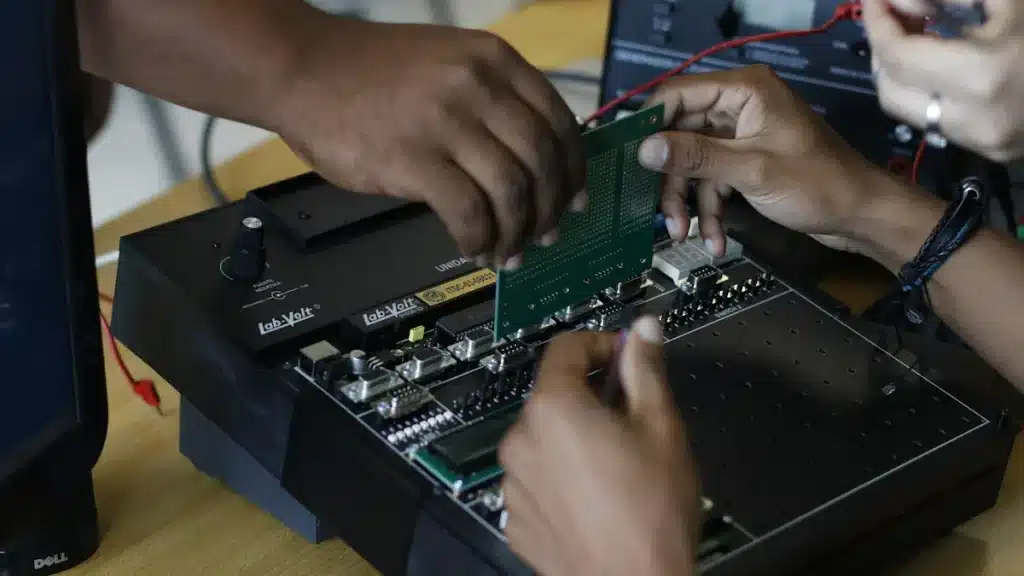

A new method combines acoustic emission monitoring PCBA with bending tests, making the evaluation of solder joints more dependable.

Sensors have improved their signal clarity, increasing from 17 dB to 37 dB. This enhancement allows for better visibility during testing.

When selecting an acoustic emission monitoring PCBA solution, it’s essential to compare options. This ensures alignment with your testing requirements and quality objectives.

Key Takeaways

Acoustic emission monitoring finds small cracks and solder problems in PCBA. This helps make devices work better and last longer.

Pick the right monitoring type—passive, active, or hybrid—based on what you need and your testing setup.

Collecting accurate and detailed data is important to spot tiny issues and get dependable results.

Adding acoustic monitoring to current systems makes testing faster and gives instant updates.

Think about cost, how it fits with your system, and if it can grow when choosing a monitoring solution for PCBA testing.

Acoustic Emission Monitoring and Its Role in PCBA Testing

What Is Acoustic Emission Monitoring?

Acoustic emission monitoring finds and studies sound waves in materials. These waves happen when cracks grow or materials shift. The waves move through the material as elastic signals. Special sensors, like piezoelectric ones, pick up these signals. They turn the waves into voltage-time graphs for analysis. This lets you “hear” what’s happening inside without breaking anything. But understanding the signals can be tricky. Material type and wave movement can change the data.

Relevance of Acoustic Emission Monitoring in PCBA Testing

In PCBA testing, acoustic emission monitoring ensures boards are reliable. It spots tiny cracks, solder issues, and other defects. These problems can weaken the board’s performance. Unlike older methods, this testing gives real-time updates. It helps find problems early, saving time and money. Adding this method to your tests improves accuracy and trust in results.

Benefits of Acoustic Emission Testing for PCBA

Acoustic emission testing has many benefits for PCBA testing. First, it doesn’t harm the board during checks. Second, it shows problems as they happen in real-time. Third, it finds even the smallest flaws with high sensitivity. Also, it works well with current testing tools. Using this method improves the quality and dependability of your products.

Overview of Acoustic Emission Monitoring Solutions

Acoustic emission monitoring has three types: passive, active, and hybrid. Each type has special features and benefits. Choosing the right one depends on your testing needs.

Passive Acoustic Emission Monitoring

Passive monitoring listens for natural sounds from stressed materials. It finds tiny cracks and changes without adding outside forces. For example, a study showed it works well for spotting small stress changes in soil. But, it can have trouble with weak signals in some materials.

In PCBA testing, passive monitoring finds stress-related defects. It gives real-time updates without affecting the board’s function. This makes it a safe and dependable testing method.

Active Acoustic Emission Monitoring

Active monitoring sends signals into materials and studies the response. This method focuses on specific areas for detailed results. It’s helpful when passive methods miss weak signals or need extra testing.

For instance, sensors like Nano30 work well for active monitoring. They cover a wide frequency range and find small defects. Active monitoring lets you control the process and adjust it to your needs.

Hybrid Acoustic Emission Monitoring

Hybrid monitoring mixes passive and active methods for better results. It uses passive techniques to find issues and active ones to confirm them. This makes it great for complex PCBA testing.

For example, hybrid systems spot cracks with passive monitoring. Then, they use active testing to double-check the findings. This method combines data for more accurate results. Hybrid monitoring is flexible and ready for future testing needs.

Comparing Acoustic Emission Monitoring Solutions for PCBA

Principles and Functionality of Each Solution

Each type of acoustic emission monitoring works in its own way. Passive monitoring listens for natural sounds caused by stress or defects. It doesn’t add any outside signals, making it great for real-time checks. Active monitoring sends signals into the material and studies the response. This method focuses on specific spots to find detailed problems. Hybrid monitoring mixes both methods. It uses passive listening to find issues and active testing to confirm them. This gives a complete and thorough analysis.

Performance measurements are important for comparing these solutions. For example, how well clusters match known data shows effectiveness. Studies say at least 75 signals per angle are needed for steady results. Picking the right features, like partial power, improves accuracy. Using weak features can hurt performance. These measurements show why precision and good feature choices matter in acoustic emission monitoring.

Advantages of Passive, Active, and Hybrid Solutions

Each solution has its own strengths for different needs. Passive monitoring is gentle and doesn’t harm the board. It finds problems without changing the board’s condition, making it safe for live checks. Active monitoring gives more control. It targets specific areas and finds even small defects. Hybrid monitoring combines the best of both. It’s flexible and works well for complicated PCBA tests. This method ensures accurate and complete results.

Another benefit is how these solutions fit with current systems. Passive monitoring works easily with existing setups. Active monitoring can be adjusted for special needs. Hybrid systems are future-ready and adapt to new testing challenges. These features make acoustic emission monitoring a great tool for improving PCBA quality and reliability.

Limitations and Challenges of Each Solution

Even with their benefits, these solutions have some challenges. Passive monitoring struggles with weak signals in certain materials. This makes it harder to find small defects. Active monitoring needs careful setup and may not match real-world conditions. Hybrid monitoring is powerful but can be costly and harder to use.

Research shows more challenges too. For instance, past stress on materials affects acoustic signals, limiting lab results for real use. It’s also hard to link acoustic signals directly to how strong a material still is. This makes spotting surface damage tricky. Additionally, uneven materials change wave speeds, making it harder to locate signal sources. These challenges highlight the need to carefully pick the right solution for your PCBA tests.

Challenge/Limitations | Description |

|---|---|

Dependence on Prior Loading History | Past stress changes AE signals, limiting real-world use. |

Correlation Between AE Activity and Strength | Hard to connect AE signals to material strength. |

Accuracy of Source Localization | Uneven materials slow waves, reducing location accuracy. |

By knowing these challenges, you can choose the best solution for your testing needs.

Key Data Considerations for Acoustic Emission Monitoring PCBA

Sensitivity and Accuracy in Data Collection

Sensitivity and accuracy are very important in acoustic testing. High sensitivity helps find tiny problems like microcracks or weak solder joints. These issues might be missed without sensitive tools. Accuracy ensures the data shows the board’s real condition. For example, modern sensors with 37 dB clarity improve testing precision. By focusing on these factors, you can trust the results. This helps you make better decisions during testing.

Data Analysis and Interpretation in Acoustic Emission Testing

Data analysis is key to acoustic emission testing. Sensors collect data, which is then studied for patterns or problems. Advanced tools, like machine learning, make analyzing big data faster. For example, researchers used acoustic signals during metal work to find defects. This method improves how well problems are spotted. It also makes testing more reliable. Using strong analysis methods helps find hidden issues. This ensures your PCBA is dependable.

Integration of Data with Existing Testing Systems

Adding acoustic data to current systems makes testing easier. Real-time monitoring tracks manufacturing as it happens. For instance, General Electric uses non-contact acoustic systems for better production. These systems cut waste and boost efficiency. The table below shows key integration points:

Integration Metric | Description |

|---|---|

Tracks manufacturing in real-time using acoustic signals. | |

Correlation with Defects | Links acoustic events to defects in parts. |

Machine Learning Integration | Uses machine learning to find problems in acoustic data. |

By using these methods, you can easily add acoustic testing to your process. This ensures a thorough check of your PCBA.

Applications of Acoustic Emission Monitoring in PCBA Testing

Detecting Microcracks and Structural Defects

Acoustic emission monitoring finds tiny cracks and defects in PCBA. These cracks happen from stress, heat changes, or worn-out materials. It catches sound waves made by cracks before they cause big problems. This method checks the board’s condition without harming its parts.

Research shows acoustic signals are good at spotting damage. For example:

They track damage in materials like wood and rock to check strength.

Engineers use them to test bridges and tunnels for safety.

They help find wear in materials with complex designs using advanced tools.

These examples show how useful acoustic monitoring is in many fields. In PCBA testing, it spots small defects early. This makes products more reliable and safer.

Identifying Solder Joint Failures

Solder joints often fail due to heat, shaking, or stress. Acoustic emission monitoring is great for finding these problems. It listens to sound waves from stressed solder joints to locate weak spots.

This method works instantly. It shows when cracks start forming in solder joints. Fixing these issues early prevents bigger problems later. Adding acoustic data to current systems links sound signals to specific defects. This makes testing faster and more accurate.

Monitoring Thermal and Mechanical Stress

Heat and physical stress can shorten a PCBA’s life. Acoustic monitoring tracks these stresses as they happen. For example, heat changes make materials expand and shrink, creating sound signals. These signals show where stress is highest, helping fix issues.

Physical stress, like bending or shaking, also creates sound signals. Monitoring these sounds finds weak areas in the board. This ensures the design can handle real-world use. Fixing problems early makes the board last longer and avoids costly failures.

Tip: Use machine learning with acoustic monitoring to better understand stress signals. This helps predict problems sooner and keeps your products dependable.

Factors to Think About When Picking an Acoustic Emission Monitoring Solution

Cost and Budget Limits

Cost is a big factor when choosing a solution. Look at the upfront costs, like buying hardware, software, and setting it up. Some systems, like hybrid ones, have more features but cost more. Make sure these features match what you need for testing.

Running costs are important too. For example, energy-saving parts or self-powered systems can save money over time. Wireless options, like LoRaWAN or BLE 5.2, make setup easier and cut maintenance costs. Balancing your budget with the system’s features helps you get good value without overspending.

Working with Current Systems

The solution should work well with what you already use. This avoids problems and saves money on upgrades. For example, non-invasive sensors, like clamp-on current sensors, let you check equipment without changing it. These are great for updating older setups.

It’s also important that the system works with condition monitoring tools. A platform that uses different sensors, like vibration and acoustic ones, improves testing. Edge computing can process data locally, so you don’t rely on the cloud as much. This makes things run faster and smoother.

Growing and Staying Updated

A scalable system can grow as your needs change. Modular designs let you add features, like acoustic sensing, without replacing everything. This keeps costs down and makes the system last longer.

Future-proofing means picking tech that keeps up with changes. The condition monitoring market is growing fast. Features like predictive maintenance, IoT, AI, and real-time monitoring are key to staying ahead. These tools make your system flexible and useful for years.

Tip: Pick a system that works with cloud data analytics. This helps you use AI to predict problems and make smart choices.

Picking the best acoustic emission monitoring solution means knowing each type. Passive monitoring is great for safe, real-time checks. But it may miss weak signals. Active monitoring gives detailed control and focuses on specific areas. Hybrid systems mix both methods for thorough testing.

Match the solution to your PCBA testing needs for better results. Think about defect types, testing conditions, and how it fits with current tools.

Recommendation: Use passive monitoring for simple tests first. Switch to active or hybrid systems for harder checks or future growth. Choose solutions that balance cost, accuracy, and flexibility for dependable results.

FAQ

What is the easiest acoustic emission monitoring method for beginners?

Passive monitoring is great for beginners. It gives live updates without changing the board. Start with this to find simple problems. Later, try active or hybrid systems for harder tests.

How does acoustic monitoring make PCBA more reliable?

Acoustic monitoring finds tiny cracks, solder issues, and stress problems early. Fixing these quickly keeps your PCBA working well and lasting longer. This method improves product quality and avoids expensive repairs.

Are hybrid systems worth spending more money?

Hybrid systems use both passive and active methods for better testing. They are accurate and flexible, especially for tough PCBA checks. If you need advanced testing or future upgrades, hybrid systems are a smart choice.

Can acoustic monitoring work with tools I already have?

Yes, most systems work easily with current setups. Non-invasive sensors and edge computing tools fit well with older systems. This saves money and makes testing easier.

How do I pick the best solution for my budget?

Look at costs, ongoing expenses, and features you need. Passive systems are cheaper for simple tests. Active and hybrid systems cost more but offer better options. Match your budget to your testing needs for the best choice.