Advanced assembly services are very important in today’s electronics world. As you look into this area, you will see a big change towards smart devices and wearables. The need for these products pushes the use of new technologies. Think about the growth of 5G, IoT, and AI. These new ideas greatly affect the need for better manufacturing solutions. The electronics industry is complicated, with more than 7,100 companies around the world. This complexity shows how important advanced assembly is for meeting today’s market needs.

Key Takeaways

Advanced assembly services make production faster, more accurate, and flexible. This is important for making electronics today.

Methods like Surface Mount Technology (SMT) help with quicker assembly and lower costs. This makes them popular for large-scale production.

Automation and robots are very important in advanced assembly. They help make things more precise and reduce mistakes made by people.

Quality control gets much better with new technologies. This leads to fewer defects and more dependable products.

The global market for electronics manufacturing services is expected to grow. This shows how important it is to use advanced assembly methods for success in the future.

What is Advanced Assembly?

Advanced assembly means using new methods and processes in making electronic products. These services are very important for meeting the needs of today’s fast-changing technology. When you look into advanced assembly, you will see many ways to improve efficiency, accuracy, and flexibility in production.

Types of Assembly Techniques

In advanced assembly, some techniques are known for being effective and flexible. Here are some common methods:

Through-Hole Technology (THT)

Rigid-Flex PCB Assembly

Mixed Assembly

Ball Grid Array (BGA) Assembly

Each technique has its own benefits. This helps manufacturers pick what works best for them.

Key Characteristics

Advanced assembly services are different from older methods in several important ways. Here’s a closer look at what makes them special:

Characteristic | Advanced Assembly Services | Standard Assembly Practices |

|---|---|---|

Quality Control | Careful attention to detail with high standards | Basic quality checks |

Adherence to Standards | Strict following of industry standards | General following without specific rules |

Use of Advanced Technologies | Use of the latest technologies | Little or no use of advanced technologies |

These features make sure that advanced assembly meets and often beats industry standards.

The role of advanced assembly services in making electronics is very important. They provide accuracy and quality, ensuring tiny details are correct, which lowers mistakes in electronic parts. Also, these services save money by improving how things are made. This can cut labor and facility costs by up to 50%. This efficiency helps with both small and large production, meeting different market needs.

Additionally, advanced assembly supports new ideas by using technologies like IoT. This helps create smart devices. The faster processes also help launch products quickly, keeping businesses competitive in a fast-changing market.

Technologies in Advanced Assembly

Automation and robots are very important in advanced assembly services. Automation helps make production faster and more accurate. Robots help manufacturers improve their processes. This means they can put together parts and test finished products with fewer mistakes. Automation helps solve problems in manufacturing, like not having enough workers and increasing production needs.

Here’s a quick look at how robots help assembly:

Role of Robotics | Description |

|---|---|

Component Placement | Robots place parts accurately and handle changes well. |

Precision | High-quality cameras and sensors allow for real-time adjustments. |

Adaptability | Using flexible feeders increases how well operations can adapt. |

As you can see, robots not only make things more precise but also increase overall productivity. In fact, about 28% of advanced assembly lines in electronics manufacturing used robots or automation in 2022.

Now, let’s discuss Surface Mount Technology (SMT). SMT has changed how manufacturers put together electronic parts. This method lets them place parts directly on the surface of printed circuit boards (PCBs).

Here are some benefits of SMT:

SMT allows for automated placement and reflow soldering, improving speed and consistency.

It lowers labor differences, making assembly processes more reliable.

SMT makes it easier to design double-sided boards and reduces drilling needs.

Using SMT greatly improves manufacturing efficiency. It allows for more functions in smaller spaces. This has made SMT the top method for PCB assembly, while traditional through-hole technology is now mostly used for specific parts like connectors and high-power devices.

Benefits of Advanced Assembly

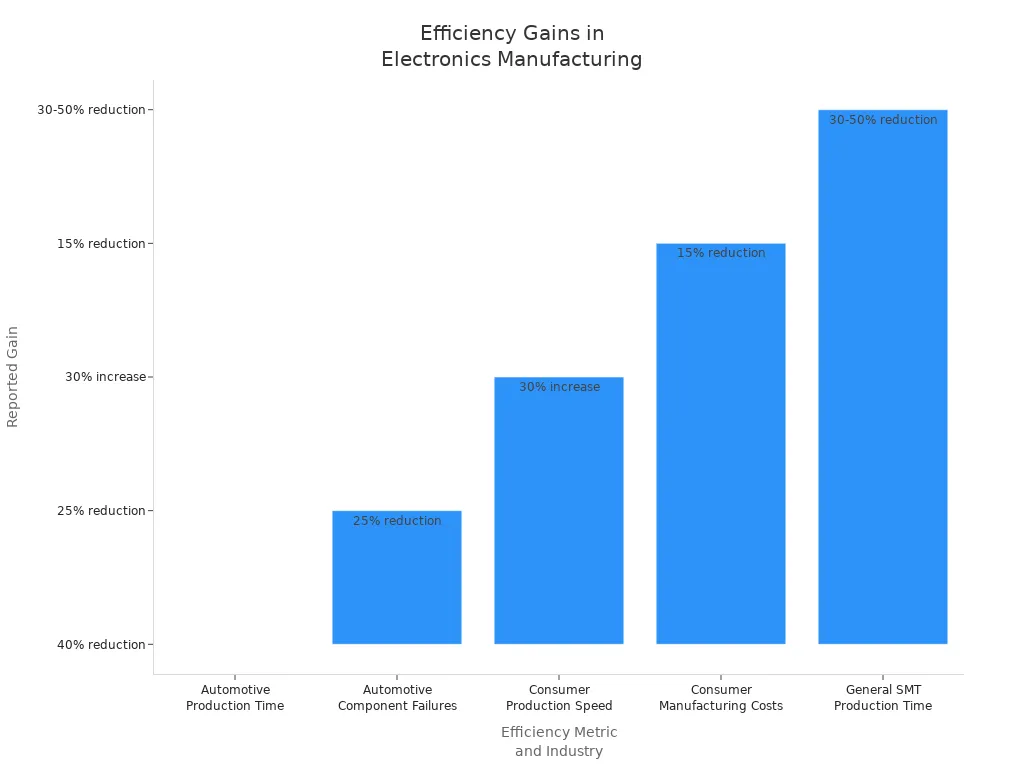

Advanced assembly services help electronics makers work better and faster. By using these new methods, you can make production easier and save money. Here are some efficiency improvements seen in different industries:

Industry | Efficiency Gain |

|---|---|

Automotive | |

25% fewer problems with parts | |

Consumer Electronics | 30% faster production |

15% lower manufacturing costs | |

General SMT Benefits | 30-50% less overall production time |

Fewer than 100 defects per million parts | |

Return on investment usually in 1-2 years |

You can see that advanced assembly services greatly improve speed and save money. These benefits come from using automation and data analysis. Data analysis helps find problems and slow spots in your production. By looking at production data, you can spot issues like machines not working and uneven material use. This information helps you make changes, improving output and cutting waste.

Robotic systems have changed how PCB assembly works. They provide accuracy and speed that humans cannot match. These machines can handle tiny parts that are 0.4mm x 0.2mm, which is much smaller than a human hand can manage. Benefits of robots in PCB assembly include better placement accuracy, faster production, fewer mistakes, and consistent quality.

Quality control also gets better with advanced assembly methods. You can expect improved defect detection and better processes with new technologies. Here are some key improvements in quality control:

Evidence Description | Source |

|---|---|

Computer vision technology speeds up quality checks and cuts down human mistakes in PCB assembly. | |

AI and machine learning help find defects and improve processes by looking at large amounts of data. | |

New imaging methods like 3D imaging and CT scans help find defects in complex boards. | |

IoT sensors check conditions during assembly to keep the best manufacturing environment and reduce defects. | |

Data analysis helps find patterns and problems, leading to better quality control practices. |

These improvements help ensure your products are high quality. By using advanced assembly services, you can lower defect rates and make your products more reliable.

Advanced Assembly vs. Traditional Methods

When you look at advanced assembly services and traditional methods, you see big differences in cost, speed, and how well they can grow. Knowing these differences can help you choose the best option for your electronics manufacturing.

Cost Implications

The costs for different assembly methods can be very different. Here’s a simple breakdown of costs for various methods:

Assembly Method | Cost Characteristics | Automation Level |

|---|---|---|

SMT | Low cost per unit, good for high volume | High |

THT | High unit costs, needs more manual work | Low |

Hybrid | Cost between SMT and THT, depends on design | Medium |

Advanced assembly methods like SMT have lower costs per unit, especially when making a lot of items. On the other hand, traditional methods like THT have higher costs because they need more manual work and less automation.

Speed and Scalability

Speed is also very important. Advanced assembly methods, especially SMT, are much faster than traditional ones. Here are some key points to think about:

Advanced assembly methods like SMT are much quicker than traditional methods like THT.

SMT uses machines for high-volume production, making it better for small, complex devices.

Traditional THT relies on manual work, which takes more time.

Scalability is another key factor. Advanced assembly services can adjust better to changing needs. Traditional methods have a hard time keeping everything in sync and maintaining quality as production grows. You might face issues like:

Unstable supply chains and special customer requests.

Slow workflows and fixed quality checks in traditional methods.

In contrast, advanced assembly focuses on being efficient and flexible, which is important for growing production. This flexibility helps you meet market needs without losing quality.

In short, advanced assembly services are very important in making electronics today. These services help make production faster, improve quality checks, and lower costs. Recent studies show that using AI and deep learning can greatly improve how well defects are found, reaching over 99.5% accuracy in spotting problems during assembly.

In the future, you can look forward to trends like IoT use, smart factories, and AI-based quality checks that will change how things are made. Using these new technologies will help you stay ahead in a fast-changing market.

Keep in mind, the global electronics manufacturing service market is expected to go over $700 billion by 2030. Adjusting to these changes will be very important for success in this field.

FAQ

What is the main advantage of advanced assembly services?

Advanced assembly services make production faster. They help cut costs and improve quality checks. These services help makers keep up with the rising need for complex electronic devices.

How does automation impact advanced assembly?

Automation makes the assembly process quicker. It boosts accuracy and lowers mistakes made by people. This technology helps manufacturers create more items in less time.

Why is Surface Mount Technology (SMT) preferred?

SMT is liked because it allows for smaller designs. It lets machines place parts automatically, which speeds things up and keeps them consistent. SMT also cuts down on drilling, making assembly simpler.

Can advanced assembly services handle small production runs?

Yes, advanced assembly services can easily manage small production runs. They provide flexibility and can change to meet different production needs without losing quality.

What role does quality control play in advanced assembly?

Quality control is very important in advanced assembly. It makes sure that products meet high standards. New technologies like AI and computer vision help find defects and make products more reliable.

See Also

Innovative Testing Methods for PCBA in Electronics Production

A Comprehensive Guide to EMS and PCBA Solutions Today

An Overview of PCBA Production and Assembly Techniques

Choosing Advanced PCBA Manufacturing Services: A Helpful Guide