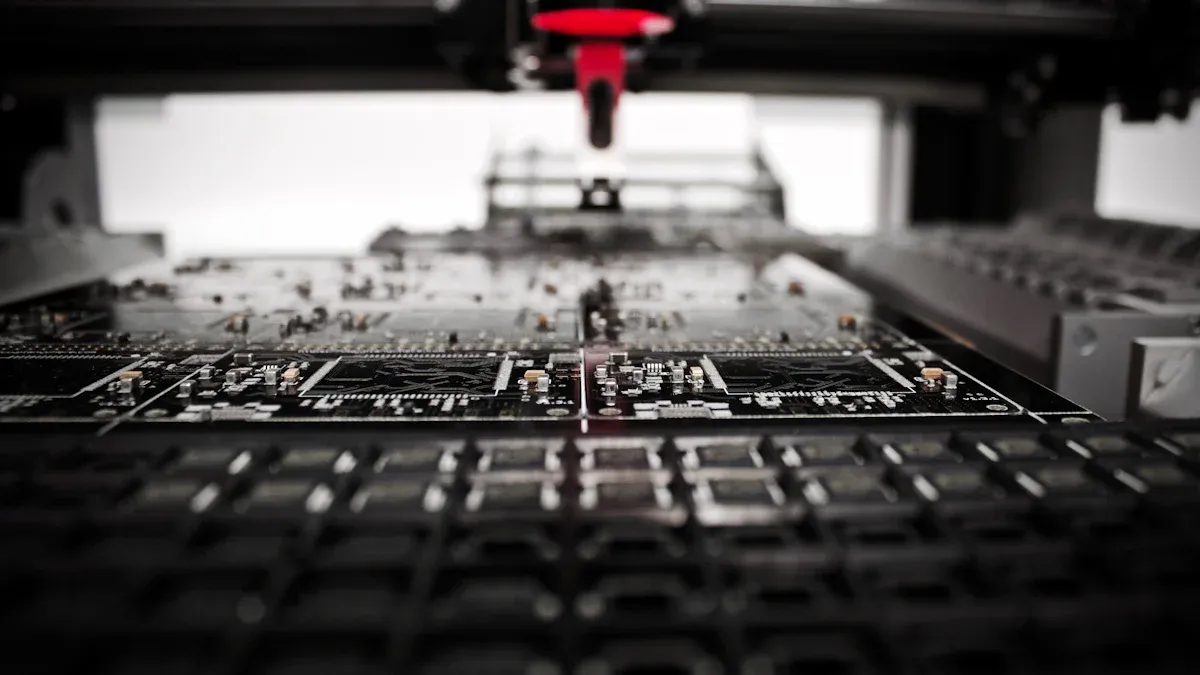

Keeping printed circuit board assemblies (PCBAs) safe needs a strong, precise, and affordable method. Overmolding helps by adding a smooth protective layer. This layer keeps your PCBA safe from things like water, dust, and shaking. Unlike older methods, overmolding makes the PCBA stronger but still flexible in design. It also uses fewer materials, which is better for the environment. Whether you work with cars, medical tools, or gadgets, overmolded PCBA solutions last longer and work better.

Key Takeaways

Overmolding protects PCBAs from water, dust, and chemicals. This helps electronics last longer.

It costs less because it uses fewer materials and steps. This saves both time and money.

Overmolding allows cool designs that look nice and still work well.

It is good for the environment by cutting waste and using recyclable materials. This helps keep things sustainable.

Industries like cars, healthcare, and gadgets use overmolding. They like it because it is strong and flexible for designs.

What is Overmolding?

Overmolding is a way to make PCBAs stronger and better. It covers the PCBA with a protective material using special molding tools. This process keeps the electronics safe and makes them tougher. It also gives them a nicer look.

Overview of the Overmolding Process

Overmolding uses injection molding to add a protective layer to PCBAs. There are two main methods: direct injection and cap encapsulation. In direct injection, the PCBA goes into a mold, and the material is added directly. This method allows for flexible designs. Cap encapsulation uses a cap to cover the PCBA before adding the material. Both methods protect PCBAs from damage caused by the environment.

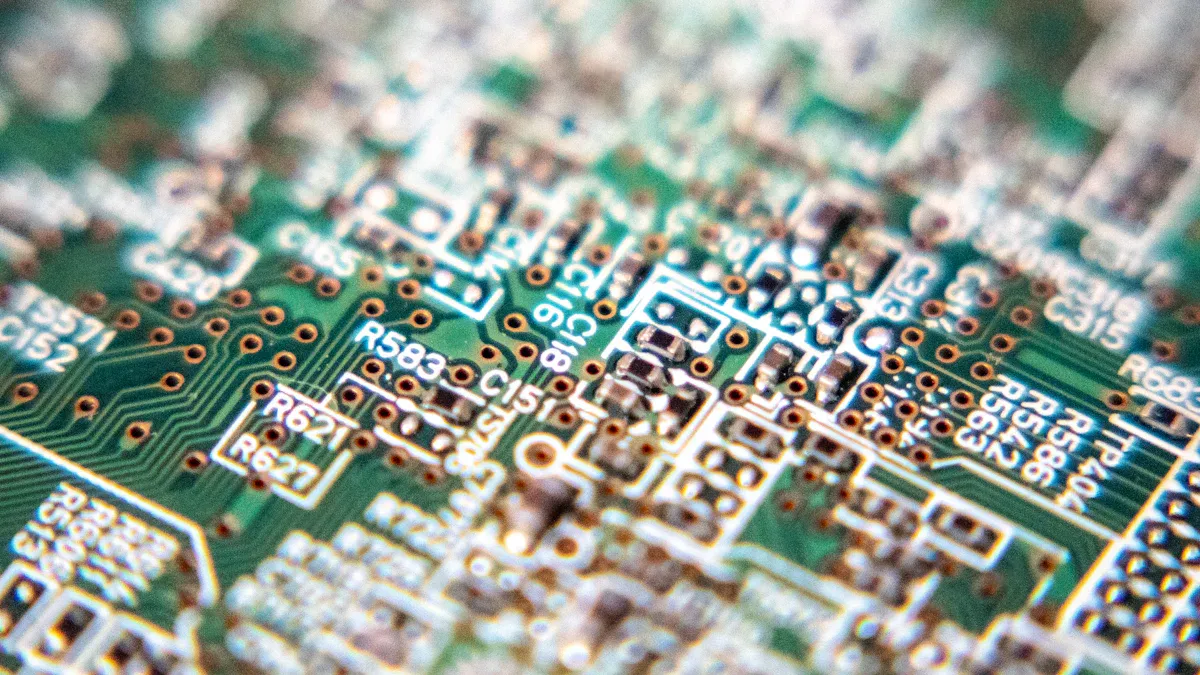

How Overmolding Protects PCBA

Overmolding shields PCBAs from water, dust, and chemicals. These things can harm electronic parts. Strong molds and polymers keep the electronics safe from outside damage. Overmolding also makes PCBAs tougher against hits and shaking. Materials like duroplastics work well in tough conditions because they resist water and stay stable.

Materials Used in Plastic Over-Molding

The material used for overmolding depends on where it will be used. Engineers pick materials based on strength, heat resistance, and chemical safety. Below is a table showing common materials and their uses:

Material | Properties | Applications |

|---|---|---|

High-Density Polyethylene (HDPE) | UV resistance, impact resistance, low cost, versatile | Bottles, pipes, packaging containers |

Polycarbonate (PC) | Strong, impact-resistant, UV resistant | Safety glasses, car headlights, bulletproof windows |

Polyetherimide (PEI) | Strong, heat and chemical resistant | Planes, cars, medical tools |

Polypropylene (PP) | Flexible, chemical resistant, conducts electricity | Packaging, fabrics, car parts |

Liquid Silicone Rubber (LSR) | Safe for people, heat resistant, chemical resistant | Medical tools, cars, electronics |

Optical Silicone Rubber (OSLR) | Clear, lets light through, weather resistant | Lenses, LED lights, medical imaging devices |

Picking the right material is important for overmolding to work well. Simple tips can help non-engineers choose the best material for their needs.

Comparison with Other Encapsulation Methods

Overmolding vs. Potting

Potting fills a mold with liquid that hardens to protect PCBAs. It works well but has limits. Overmolding uses injection molding to add a strong, smooth layer. This layer blocks water and chemicals better than potting. Potting materials can crack under pressure. Overmolding makes PCBAs tougher and lasts longer. Overmolding also fits complex shapes and small devices. Potting often adds extra size to the assembly.

Method | Test Results | Cost Info |

|---|---|---|

PDMS | N/A | |

Epoxy-only | Failures at 10 min, 1 hour, 1 day | N/A |

Epoxy with hermetic feedthrough | No full failures, partial failure at 4 hours | N/A |

Overmolding vs. Conformal Coating

Conformal coating adds a thin layer to protect PCBAs. It is light and cheap but not very strong. Overmolding wraps PCBAs in tough materials that block water, scratches, and chemicals. This keeps PCBAs safe for a long time, even in bad conditions. Conformal coating can peel or wear out, leaving PCBAs exposed. Overmolding uses injection molding to make a strong, even layer. This makes it better for important uses.

Overmolding protects PCBAs by using materials that resist water, chemicals, and damage.

Overmolding vs. Traditional Housings

Traditional housings cover PCBAs with hard cases. They protect but leave gaps that can let dirt in. Overmolding uses injection molding to make a snug layer without gaps. This reduces contamination risks. Traditional housings need extra steps to build, which takes more time and money. Overmolding simplifies production, saves materials, and works faster. It also lets you design products that look sleek and professional.

Advantages of Overmolded PCBA

Protection Against Environmental Factors

Overmolded PCBA keeps electronics safe from harsh conditions. The process adds a smooth layer that blocks water, dust, and chemicals. Unlike regular housings, overmolding has no gaps, stopping dirt from getting in. Low-pressure overmolding protects fragile parts without causing damage. High-pressure overmolding makes PCBAs tough against heat and stress. Tests show polycarbonate (PC) overmolding lowers surface temperature by 17.7 °C. This proves it can protect electronics in tough situations.

Enhanced Mechanical Strength

Overmolding makes PCBAs stronger and harder to break. It adds a protective layer that stops impacts, shaking, and wear. The process tightly bonds the layer to the PCBA, preventing cracks or peeling. Insert molding makes products last longer than other methods. High-pressure overmolding adds extra strength for heavy-duty use. Engineers can adjust material thickness to improve durability. For example, thicker PC film raises temperature differences, making assemblies tougher.

Design Flexibility and Aesthetics

Overmolding allows creative designs and makes products look better. It works with complex shapes and detailed designs for sleek results. Co-molding locks inserts tightly, enabling unique designs that still work well. Visual checks during molding catch shape errors and cosmetic flaws. Testing helps improve usability and design quality. Overmolding builds fast-curing layers, saving time and money. It’s great for industries needing custom designs and large-scale production.

Cost and Material Efficiency

Overmolding saves money and materials compared to older methods. Using plastic injection molding, companies make lighter and cheaper parts. New overmolding technology creates parts 20-30% lighter and nearly half the cost of metal ones. Lighter parts lower material costs and shipping fees. This makes overmolding a smart choice for protecting PCBAs in many industries.

The co-molding process applies materials carefully, reducing waste. Unlike older methods needing extra steps, overmolding combines tasks into one process. This saves time and improves quality. Low-pressure overmolding gently protects delicate parts without harm. High-pressure overmolding makes strong parts for heavy-duty use.

Overmolding materials are flexible and cost-effective. Engineers can pick materials for heat, chemical, or impact resistance. Plastic injection molding ensures great performance without extra costs.

Environmental Benefits of Overmolding

Overmolding helps the environment by using fewer materials and cutting waste. The process uses only what’s needed, saving resources and lowering costs. This also reduces the environmental impact of making products.

Co-molding combines parts into one unit, cutting the need for extra pieces. This saves energy and reduces waste during production.

Many overmolding materials can be recycled, supporting eco-friendly practices. Low-pressure overmolding uses less energy, making it greener. High-pressure overmolding lasts longer, reducing the need for replacements.

Choosing overmolding protects PCBAs and helps create a cleaner planet.

Applications of Overmolded PCBA

Overmolding has changed how industries protect electronics. It combines strength, accuracy, and flexible designs. This makes it a top choice in many fields. Below are some areas where overmolded PCBA works best.

Automotive Applications

Cars need parts that handle tough conditions. Overmolding makes strong parts with many features in one piece. High-pressure overmolding keeps parts durable in engines. It cuts vibration problems by 50% compared to old methods.

Evidence Type | Details |

|---|---|

Weight Reduction | |

Integration of Multifunctional Components | Places electrical contacts and heat control features in one part. |

Durability in Harsh Environments | Handles 50% more vibration in engine parts than other methods. |

Cost Efficiency | Lowers assembly steps by 40-60%, saving money. |

Top car brands like BMW, Tesla, and Volkswagen use overmolding. BMW’s i3 EV uses lightweight thermoplastic brackets for strength. Tesla’s Cybertruck uses molded charge ports with heat sensors. Volkswagen’s ID.4 uses molded connectors for cooling lines in hot, tough conditions.

Medical Devices

In healthcare, overmolding keeps devices safe and reliable. Overmolded cables are flexible and block water or chemicals. They protect delicate electronics from damage. Overmolding is common in surgical tools and diagnostic machines. It creates smooth, easy-to-clean surfaces, which are perfect for medical use.

Consumer Electronics

Overmolding helps make better gadgets. It allows sleek designs while protecting parts inside. Overmolded devices last longer and resist damage from daily use. Phones, headphones, and wearables often use overmolded PCBAs. This process supports compact, multi-use gadgets, making it key in modern electronics.

Industrial Equipment

Industrial machines often work in tough places. They need strong protection for their electronics. Overmolded PCBA adds a smooth layer that blocks dust, water, and stress. This keeps machines working well, even in hard conditions.

Overmolding makes tools stronger by combining many features into one part. For example, sensors and connectors can be built right into the tool. This cuts down on extra parts and lowers the chance of problems. Using advanced molding, companies make lighter, smaller parts. These are easier to use and set up.

The molding process is very precise. It allows custom designs for special industrial needs. Whether for big machines, robots, or unique tools, overmolding fits your needs. It also handles heat and chemicals, making it great for factories, building sites, and energy work.

New Uses

Overmolded PCBA is now used in new tech areas. One cool idea is adding electronics into 3D shapes. This combines many features into one part, saving space and weight. It also makes supply chains simpler by cutting out extra parts.

Overmolding is better than older methods. It uses fewer parts, lowers costs, and speeds up production. Smaller designs also open doors for new things like smart gadgets, wearable tech, and green energy tools.

The overmolding market is growing fast. Below is a table showing key trends and benefits:

Trend/Benefit | Details |

|---|---|

Electronics in 3D shapes | Growing trend to combine features into single parts. |

Better than old methods | Saves space, reduces parts, simplifies supply chains, and lowers weight. |

Market growth prediction | 10-year forecast by sector, showing revenue and panel area growth. |

As these ideas grow, overmolding will shape future technology. Its flexibility and efficiency solve modern design and production challenges.

Overmolding gives excellent protection to PCBAs, better than older methods. It handles tough conditions, adds strength, and cuts material waste. This makes it reliable for a long time.

Key Takeaway: Overmolding is strong, precise, and eco-friendly. It works well in industries like cars, medical tools, and electronics.

Think about using overmolding to protect your PCBAs. It boosts product quality and helps the environment with smarter manufacturing.

FAQ

What industries use overmolded PCBA the most?

Overmolded PCBA works well in cars, medical tools, electronics, and machines. It is strong, protects from damage, and allows creative designs. This makes it great for tough jobs and new ideas.

How does overmolding make products stronger?

Overmolding adds a tough layer to protect PCBAs. This layer blocks hits, shaking, water, and dust. It helps products last longer and work well in hard conditions.

Can overmolding save money during production?

Yes, overmolding combines many steps into one easy process. It uses less material, saves time, and lowers shipping costs by making lighter parts.

What materials are used in overmolding?

Engineers use materials like polycarbonate, polypropylene, and liquid silicone rubber. These materials are chosen for their heat resistance, flexibility, or chemical safety, depending on the job.

Tip: Ask a materials expert to find the best choice for your product.

Is overmolding good for the environment?

Yes, overmolding reduces waste and saves energy. Many materials can be recycled, and fewer extra parts are needed. This helps make products in a greener way.

See Also

Uncovering Key Distinctions Between PCBA And PCB

The Role of PCBA in Advancing Today’s Electronics