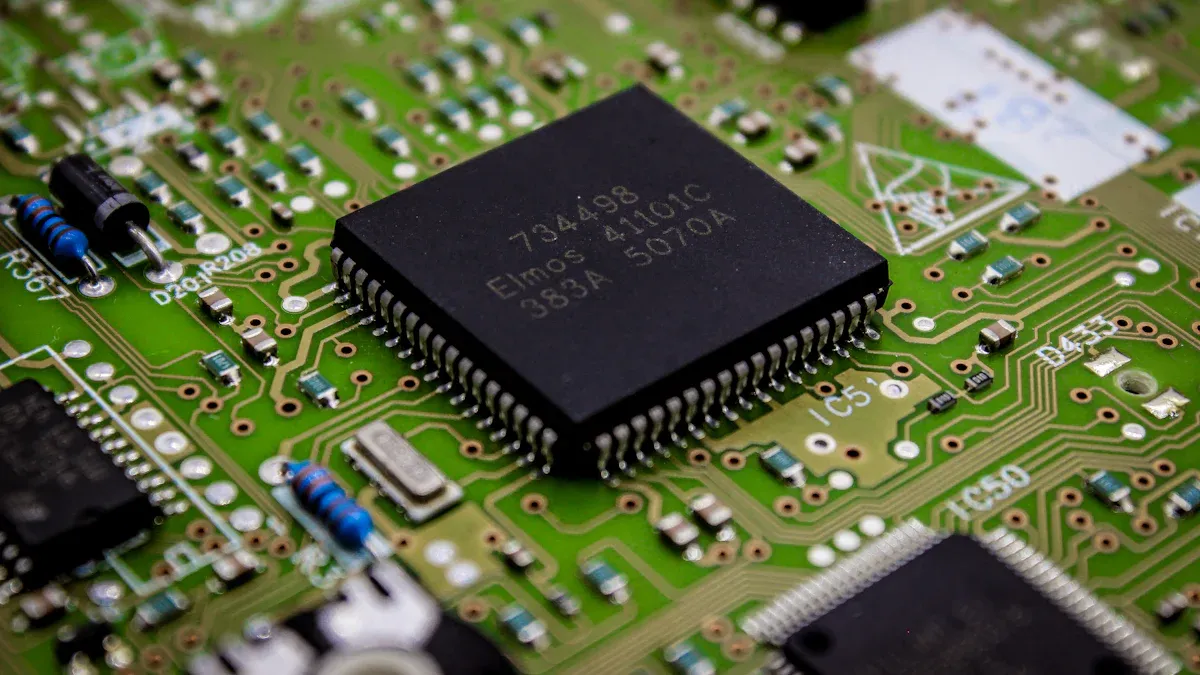

Printed circuit board assembly (PCBA), which refers to the meaning of PCBA, involves placing electronic components onto a printed circuit board (PCB) to ensure its functionality. This process is crucial in the production of modern electronics, providing devices with a robust and reliable foundation. Without PCBA, innovations such as smartphones, medical devices, and automotive systems would not be possible.

The global PCB market is projected to expand from $74 billion in 2022 to $95.4 billion by 2027, indicating a growing demand for advanced electronics. Rigorous testing, including in-circuit and environmental assessments, ensures that PCBA operates effectively. These evaluations help products comply with stringent quality standards. Ultimately, PCBA is essential for creating durable and efficient products.

Key Takeaways

PCBA is very important for modern gadgets like phones and medical tools to work well.

The need for PCBA is rising worldwide, with its market expected to hit $95.4 billion by 2027 due to new tech developments.

PCBA makes products more reliable by testing them to handle real-life use.

Custom PCBA designs help improve how devices work and meet special needs in fields like healthcare, cars, and space.

Using PCBA can cut production costs and save time, helping businesses stay ahead in a fast-moving market.

Applications of Printed Circuit Board Assembly

Consumer Electronics

PCBA is very important in making consumer electronics work. Devices like smartphones, laptops, and smartwatches need PCBA to function. New technologies like 5G and IoT have increased the need for better PCB assembly. From 2025 to 2029, the PCB market may grow by $26.8 billion because of these technologies.

Wearable devices are growing fast and need small PCBA batches. By 2026, over 1 billion wearable devices may be shipped worldwide. This shows the need for smaller and lighter PCB designs. Southeast Asia is now a big area for PCB assembly. In 2023, Vietnam’s electronics production grew by 18% compared to the previous year.

Automotive Industry

Cars today use PCBA to meet modern technology needs. Systems like ADAS use advanced PCBs to improve safety and performance. Multi-layer PCBs are becoming more common as car electronics get more complex. Smaller and denser PCBs help fit more parts into less space, making cars smarter.

The car electronics market was worth $217.86 billion in 2020 and may double by 2028. This growth comes from IoT, digital screens, and better safety systems. Small PCBA batches help make custom circuit boards for specific car needs.

Medical Devices

In healthcare, PCBA makes sure devices are reliable and accurate. Machines like pacemakers, MRI scanners, and glucose monitors need custom PCBs to work well. Small PCBA batches help create special designs for unique medical uses.

Wearable health devices are also growing in popularity. These need small and strong PCBs to work properly. Thanks to PCBA, medical devices meet strict quality rules, keeping patients safe and cared for.

Aerospace and Defense

The aerospace and defense fields need very reliable electronics. PCBA helps create strong and high-performing devices for these industries. It is used in important systems like avionics, radar, and communication tools. These systems must work perfectly in tough conditions like high altitudes, strong vibrations, and temperature changes.

Strict rules like DO-254 and DO-178C ensure safety and quality. These rules require tracking every step of the development process. Tracking reduces risks, improves quality, and follows safety laws. It also helps teams work together better by keeping all parts aligned with goals.

PCBA use in aerospace and defense is growing fast. For example, the market may grow from USD 4.43 billion in 2024 to USD 7.01 billion by 2033. This growth is due to more demand for drones, satellites, and advanced airplane electronics.

Metric | Value |

|---|---|

Market Size (2024) | USD 4.43 Billion |

Projected Market Size (2033) | USD 7.01 Billion |

CAGR (2026-2033) | 5.4% |

Global Market Projection (2028) | USD 4.5 Billion |

CAGR (2021-2028) | 4.8% |

New technologies in PCB manufacturing are making production faster and cheaper. These changes help meet the growing needs of aerospace and defense while keeping quality high.

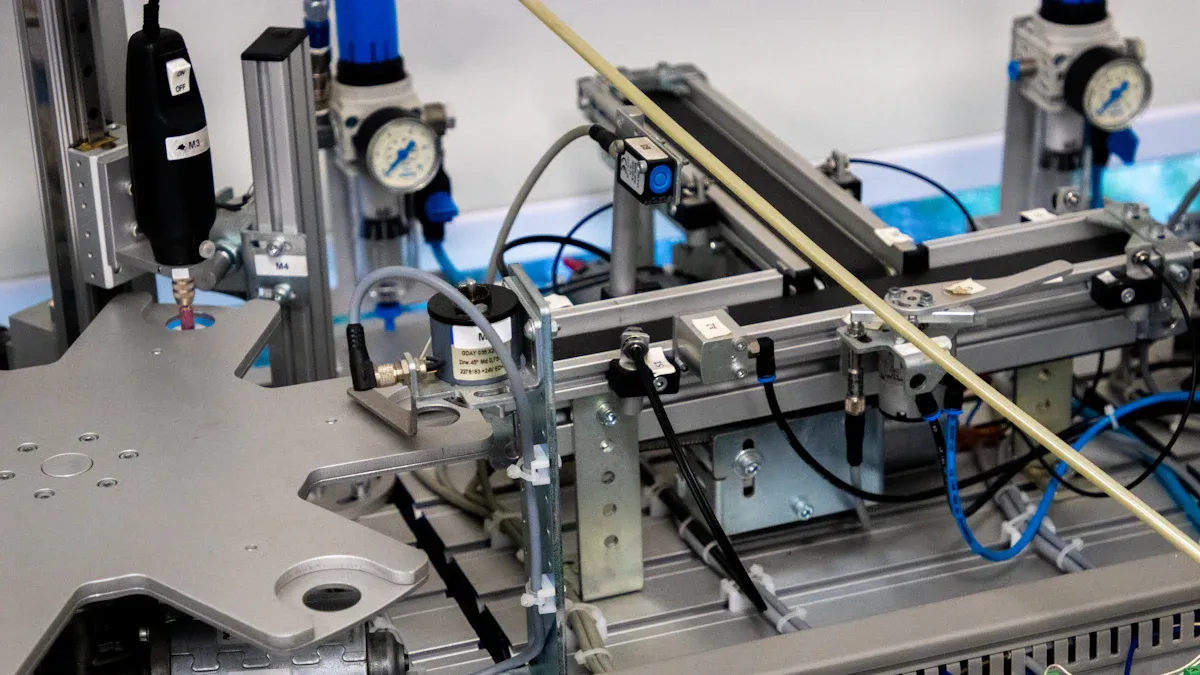

Industrial Equipment and Automation

PCBA is changing how industrial machines and automation work. It is used in robots, assembly lines, and control systems. These systems need to be precise and reliable. With PCBA, manufacturers can make machines that work better and stop less often.

Unplanned machine stops can cost companies a lot of money. They can lose up to USD 250,000 per hour, adding up to USD 50 billion yearly. Automation with PCBA has cut errors by over 65%. This makes machines work better and reduces costly stops.

The industrial automation market is growing quickly. In China, it may reach 3,225 billion yuan by 2025. Companies use PCBA to make flexible systems that adjust to customer needs. These systems improve efficiency and allow for more customization.

Metric | Description |

|---|---|

Improved Efficiency | Faster processes, less waste, and better workflows for quicker results and higher output. |

Cost Reduction | Using fewer resources and cutting waste to save money. |

Enhanced Quality | Better standards and improvements for fewer defects and higher-quality products. |

Flexibility and Responsiveness | Systems that change easily for customer needs and allow more custom options. |

Employee Engagement | Workers feel involved and help improve operations. |

With PCBA, industries can save money, improve quality, and work more efficiently. This makes PCBA very important for modern industrial machines.

Benefits of PCBA in Electronics Manufacturing

Miniaturization and Compact Design

PCBA helps make devices smaller and more efficient. Examples include smartphones, wearables, and IoT gadgets. Advanced PCBA methods keep devices durable while shrinking their size. It also manages heat and keeps signals strong in high-frequency circuits.

Smaller designs improve performance and save space on PCBs. They also allow for creative and flexible designs. For instance, the Apple iPhone X uses advanced PCBA to work better and save energy. This shows how PCBA supports modern technology.

Benefit | Description |

|---|---|

Enhanced electrical performance | Better signal quality with fewer losses. |

Reduced PCB size | Makes devices smaller and more compact. |

Increased design flexibility | Allows for creative and smaller designs. |

Enhanced Reliability and Durability

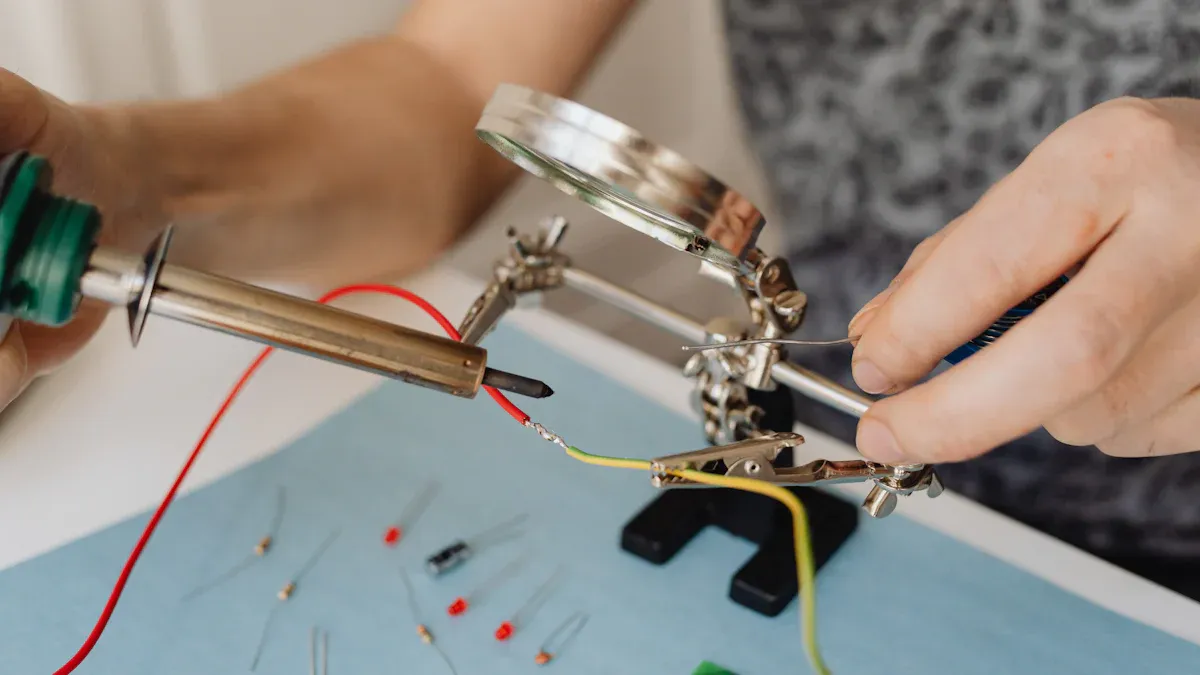

PCBA ensures products are strong and meet high standards. Tests like stress and vibration testing find weak spots. These tests mimic real-life conditions like temperature changes and moisture.

For example, temperature tests check how parts handle heat changes. Humidity tests see if parts resist rust and moisture. These tests make devices more reliable for tough uses like aerospace and medical tools.

Testing Type | Purpose | What it Reveals |

|---|---|---|

Mimics real-life conditions for PCBs/PCBAs | Checks durability and solder strength | |

Temperature Cycling | Tests how parts handle heat changes | Finds thermal stress issues |

Humidity Testing | Checks resistance to moisture and rust | Reveals moisture-related problems |

Cost-Effectiveness in Production

PCBA helps save money in electronics production. Good PCBA services prevent costly mistakes in design and assembly. Cheap options may seem good but often cause hidden problems. Checking parts carefully avoids fake components that raise costs.

By reviewing BOM (Bill of Materials), manufacturers can cut extra costs. Smart sourcing based on BOM helps balance cost and quality. This method improves budgeting and keeps production affordable.

Key Advantages of PCBA in Cost Management:

Saves money over time with better efficiency and less labor.

Adapts easily to design changes using modern robotic tools.

Properties | Applications | |

|---|---|---|

Polyimide Substrates | Handles heat well and is flexible | Used in military and aerospace. |

Rogers Materials | Great for low-signal loss and RF uses | Ideal for microwave systems. |

Metal Core PCBs | Transfers heat efficiently | Perfect for LED lights and power devices. |

PCBA combines quality, flexibility, and cost savings, making production reliable and affordable.

Scalability for Diverse Applications

PCBA is very flexible and works for many industries. It fits needs from consumer gadgets to aerospace tools. Manufacturers can use it for small or big production runs easily.

Using outside PCBA services can cut costs by 15%. This lets companies focus on creating new ideas. In the U.S., reshoring electronics has added over 700,000 jobs. In 2022, the Computer and Electronic Products industry was the second-biggest to reshore. This shows how PCBA supports local production.

Tip: Scalable PCBA solutions help lower costs and keep quality high.

PCBA also helps with quick prototyping and large-scale production. It moves fast from design to assembly, meeting market needs. This makes PCBA a key part of modern electronics.

Custom PCBA for Specific Needs

Custom PCBA lets you create designs for special purposes. You can pick materials or features to match your needs.

Flexible designs allow changes for different laminate types. Prototyping improves designs and ensures they meet standards. Changing materials and testing designs can save money.

Key Benefits of Custom PCBA:

Better reliability with custom designs.

Saves money by using the right materials.

Boosts performance with accurate adjustments.

Custom PCBA is great for healthcare, cars, and aerospace. These fields need precise and reliable products. Custom solutions help meet strict rules and specific needs.

Note: Custom PCBA helps you stay ahead by making better products.

The Role of PCBA in Advancing Modern Electronics

Speeding Up Prototyping and Production

PCBA helps make prototyping and production faster in electronics. Its smooth processes cut waiting times and improve work speed. Companies like MacroFab use many factories to scale production quickly. This helps finish both small and large orders fast.

Using live data makes the process even better. Engineers can fix problems quickly and avoid supply chain issues. Making products closer to home also reduces risks from overseas delays. These methods improve teamwork and help meet tight schedules.

In today’s world, long delays are not okay. PCBA helps get products to customers faster, making them happy. Using advanced tools, you can launch products quickly and stay competitive.

Making Products Better and More Reliable

PCBA improves product quality with careful testing and checks. Tools like Automated Optical Inspection (AOI) and X-rays find problems early. AOI can catch over 95% of defects, ensuring high-quality products.

Quality programs like Six Sigma aim to reduce mistakes to very low levels. This improves success rates and lowers customer complaints. Checking quality during production keeps products consistent and meets industry rules.

Statistical Process Control (SPC) tracks changes and improves assembly steps. Root Cause Analysis (RCA) finds and fixes problems effectively. These steps make sure products work well, even in tough situations.

Launching New Products Faster

PCBA helps bring new products to market quickly. Automated tools and smart testing speed up production. For example, AOI finds problems fast, so fixes happen without delays.

Live data and tracking improve how production is managed. This helps companies meet market needs quickly. High defect detection reduces faulty products, saving time and resources.

New trends like bendable PCBs and AI make development faster. These ideas let you create advanced designs while keeping quality high. With PCBA, you can launch products quickly, satisfy customers, and beat competitors.

PCBA is key to improving modern electronics. It is used in healthcare, cars, planes, and gadgets. It helps with testing, custom products, and repairs. PCBA makes devices smaller and more reliable, boosting innovation and efficiency.

Benefits | |

|---|---|

Prototyping and R&D | Helps test new ideas and advanced technologies. |

Specialized and Niche Markets | Affordable for custom and small-batch electronics. |

Short-Run Production | Supports limited editions and seasonal items. |

Repair and Maintenance | Offers parts for old and current electronic systems. |

Tip: Using PCBA keeps you ahead in fast-changing technology.

FAQ

What does PCBA mean, and why is it important?

PCBA means Printed Circuit Board Assembly. It adds parts to a PCB to make working electronics. This process makes devices reliable and efficient, which is key for modern technology.

What are the benefits of flex PCBA?

Flex PCBA is light and bendable, fitting into small spaces. It lasts longer and lowers the chance of damage. This makes it great for wearables, medical devices, and car systems.

Why is small batch PCBA processing useful?

Small batch PCBA helps test ideas before making many products. It cuts waste, saves money, and checks quality. This is great for prototypes or special electronics.

How is bulk PCB manufacturing different from small batch assembly?

Bulk PCB manufacturing makes many boards cheaply. Small batch assembly focuses on custom designs and flexibility. Bulk is for mass production, while small batches are for unique needs.

How does PCBA help in making electronics?

PCBA makes assembly easier by adding parts quickly. Automated tools and tests ensure good quality. This lowers mistakes, speeds up work, and makes devices more reliable.

See Also

PCBA’s Impact on Advancing Today’s Electronic Technologies

Understanding PCBA: Its Definition and Importance in Electronics

Defining PCBA: Its Essential Function in Electronic Devices

Exploring PCBA Services and Their Importance in Electronics Production