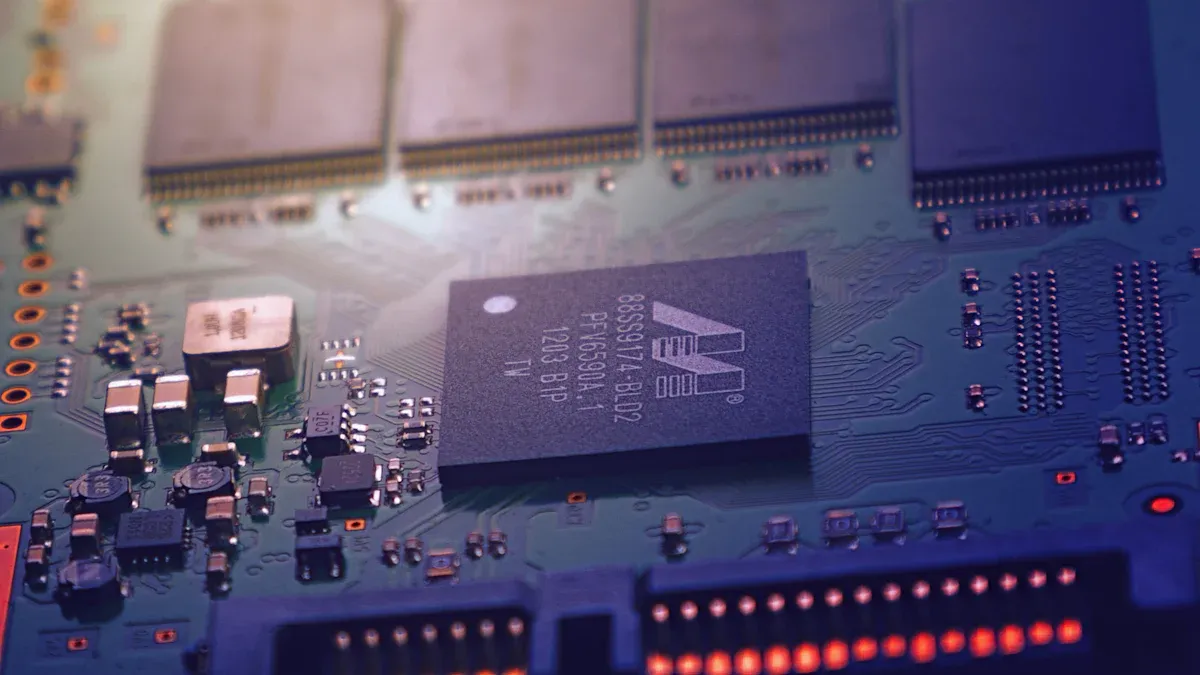

Automated test equipment (ATE) plays a crucial role in PCBA testing, ensuring that printed circuit board assemblies function correctly and adhere to required standards. ATE utilizes advanced machines to accurately identify issues, even when producing large quantities of PCBs rapidly.

The demand for ATE in PCBA testing is increasing significantly. The global ATE market is projected to rise from $7.8 billion in 2023 to $12.5 billion by 2033, reflecting an annual growth rate of 4.8%. This trend highlights how ATE enhances quality, efficiency, and reliability in PCB production, solidifying its importance in the modern electronics manufacturing landscape.

Key Takeaways

Automated Test Equipment (ATE) makes PCBA testing more accurate and reliable.

ATE works faster than people, helping products get made quicker.

Using ATE saves money over time by cutting labor costs.

ATE gives the same test results every time, ensuring good quality.

Keeping ATE in good shape and training workers is important.

What is ATE in PCBA Testing?

Definition of Automated Test Equipment

Automated Test Equipment (ATE) is a computer-run system. It tests printed circuit boards (PCBs) and electronic gadgets. ATE replaces manual testing by using programmed steps. It checks if devices work well and meet quality rules. ATE ensures circuit boards function as they should.

Definition/Description | Details |

|---|---|

ATE in PCB | A computer-run tool that tests devices and boards, replacing human work with programming. |

Functions of ATE | Checks chip functions, tests performance, finds faults, and ensures reliability. |

Works fast, easy to use, safe, flexible, and lowers labor costs. |

ATE reduces mistakes made by people. It speeds up production and is vital for modern PCBA testing.

How ATE works in PCBA testing

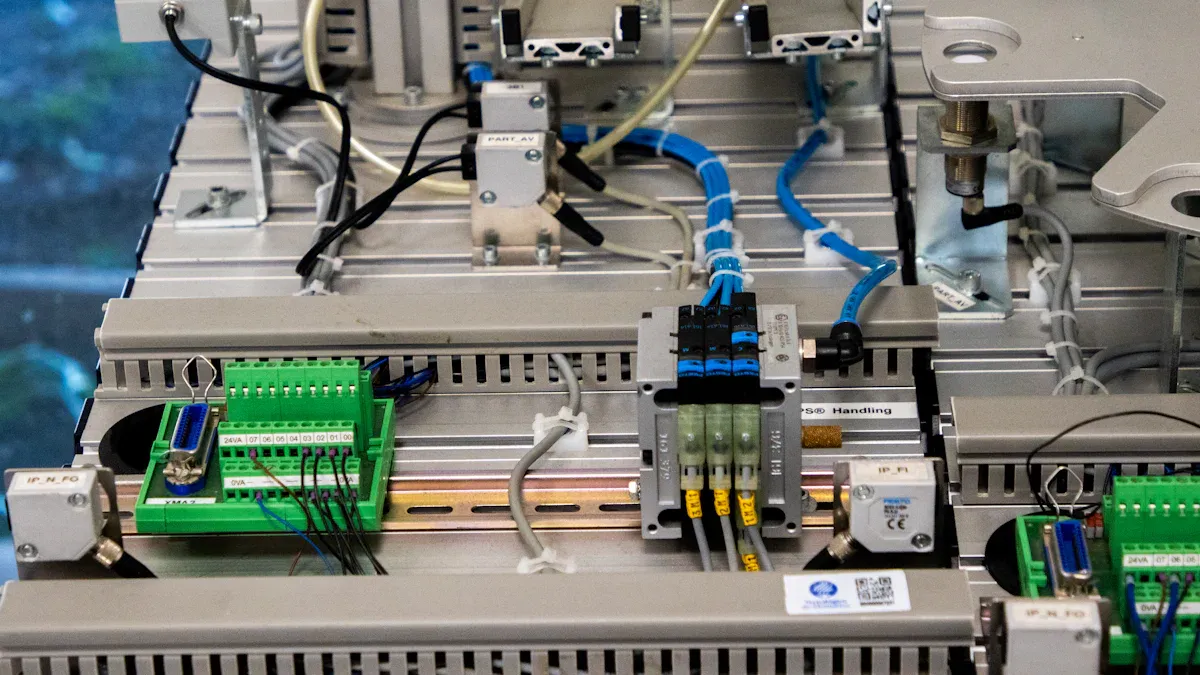

ATE connects the Device Under Test (DUT) to testing tools. It uses smart fixtures and probes to do this. Software controls the tests, checks data, and saves results. Matrix switches send signals to and from the DUT. Tools like oscilloscopes and multimeters measure electrical signals.

Component Type | Description |

|---|---|

Smart Fixtures | Hold the DUT firmly during testing. |

Chambers | Create controlled spaces for testing. |

Rackmount Servers | Handle testing and collect data. |

Workstations | Let operators control the tests. |

Matrix Switches | Send signals to and from the DUT. |

Controllers | Run the test tools. |

I/O Units | Link the DUT to the ATE. |

Test Instruments | Measure signals with tools like oscilloscopes. |

RF Signal Sources | Make signals to test RF parts. |

Test Probes | Connect to the DUT for testing. |

Test Framework | Software that runs and analyzes the tests. |

This method ensures thorough testing, reliable results, and consistent quality in PCBA testing.

Key features of ATE systems

ATE systems have advanced features for modern PCB testing. They adapt to new technology and handle complex designs. They also work well with IoT devices. Data tools and machine learning improve test insights. Eco-friendly designs follow environmental rules.

Rapid Technological Advancements: ATE keeps up with new tech.

Greater Complexity: It tests more for complex products.

Interconnected Devices: ATE ensures IoT devices work together.

Data Analytics: Machine learning gives better test insights.

Environmental Considerations: Designs follow eco-friendly rules.

These features make ATE systems key for reliable and efficient PCBA testing.

Applications of Automated Test Equipment in PCBA Testing

In-circuit testing (ICT)

In-circuit testing (ICT) is a popular use of ATE systems. It checks each part on a PCB to ensure proper placement and function. ICT works like a close inspection, testing resistors, capacitors, and other parts without turning on the whole board. This method helps find problems like bad soldering or wrong component values.

Did you know? ICT is in high demand in industries like cars, electronics, and healthcare. New ICT technology is making testing better and more important for modern PCBA testing.

Evidence Type | Description |

|---|---|

Rising Demand | More need for ICT in cars, electronics, and medical devices. |

Technological Advancements | New ICT tools improve testing abilities. |

Importance of ICT Testing | ICT helps reduce defects and improve product quality. |

Challenges | High costs and lack of skilled workers make ICT harder to use. |

Functional testing of PCBs

Functional testing checks if a PCB works as it should in real life. ATE systems help by copying the conditions the PCB will face. This testing ensures the board meets design needs and works well.

The steps include:

Build a fixture to connect to the board.

Run tests using ATE systems.

Study the results and create reports.

Fix problems if any are found.

Testing Method | Description |

|---|---|

Tests if parts like lights and screens work when powered. | |

Automated Testing | Sends signals to the PCB and checks the outputs. |

Burn-In Testing | Runs boards in tough conditions to catch early failures. |

Margin Testing | Tests boards in extreme conditions for safety-critical uses. |

Functional testing makes sure PCBs are ready to use, lowering the chance of failures later.

Fault diagnosis and troubleshooting

ATE systems are great at finding and fixing PCB problems. If a board fails, the system shows where and what the issue is. This saves time compared to doing it by hand.

For example, ATE systems can spot short circuits, open wires, or broken parts. They use smart tools and software to find the root cause. This process speeds up repairs and improves testing quality.

Adding fault diagnosis to your testing process ensures bad boards are fixed before reaching customers. This step keeps customers happy and lowers warranty claims.

End-of-line testing for product validation

End-of-line (EOL) testing is the last step in making products. It checks if the product works well and meets quality rules before going to customers. Automated Test Equipment (ATE) is very important here. It ensures every product is good enough to sell. This step keeps customers happy and stops bad products from being sold.

ATE systems make EOL testing faster and easier. Automated tests are quicker than manual ones, often taking less than a minute. This speed helps test more products in less time, meeting high production needs. The results are always accurate because ATE uses the same testing methods every time. It also saves test results for each product, making it easy to track and keep data safe.

Pro Tip: Using ATE for EOL testing improves product quality and helps find ways to make production better.

Benefit | Description |

|---|---|

Faster Testing | Automated EOL testing is quicker, saving time during production. |

Better Quality | It finds problems early, ensuring products meet quality rules. |

Data Tracking | Systems collect and study test data, spotting issues fast. |

Process Improvement | Watching trends helps improve production and keep quality high. |

With ATE, EOL testing gives real-time data to find problems fast. This data helps improve how products are made. By watching trends, you can adjust and keep quality high. EOL testing with ATE ensures products are safe, reliable, and ready for customers.

Benefits of Using ATE in PCBA Testing

Enhanced accuracy and reliability

ATE systems offer great accuracy and dependability in PCBA testing. They mimic real-world conditions to check printed circuit boards. This ensures every part works as it should. Automated testing frameworks help confirm PCB functionality step by step. This removes human mistakes and makes products more reliable.

ATE systems also track performance constantly, spotting issues right away. For example, they quickly find problems like short circuits or misplaced parts. This accuracy saves time on finding and fixing faults, improving quality checks. Industries like aerospace trust ATE systems for strict reliability tests. They provide proof that products meet tough industry rules.

Tip: Adding ATE systems to your testing process makes PCBs more reliable for users.

Improved efficiency and reduced testing time

ATE systems make production faster by automating the testing process. Manual testing takes a lot of time, but ATE systems are much quicker. For example, if manual testing needs 40 hours, ATE systems can do it in just 4 hours. That’s a 90% time saving.

This speed helps you finish production faster. Faster testing means products reach the market sooner. ATE systems also keep test times consistent, ensuring all PCBs are tested equally. By automating repeated tasks, you can focus on other important production steps, boosting efficiency further.

Metric | Description |

|---|---|

Time-to-Market Impact | Speeds up product launches by cutting release times. |

Execution Time Reduction | Shows time saved by comparing automated and manual testing. |

Cost-effectiveness and scalability

Buying ATE systems may seem expensive at first, but they save money over time. These systems cut manufacturing time and costs by simplifying testing. Automated testing shortens test times, letting you produce more without losing quality.

The global ATE market shows its growing value. It was worth $7.1 billion in 2022 and could reach $13.6 billion by 2035. This growth is due to new tech like 5G and IoT. It proves ATE systems can handle the needs of modern electronics production.

Pro Tip: Using ATE systems boosts efficiency and reliability, making them a smart investment for your business.

Consistency in testing results

Using ATE systems ensures testing results stay the same every time. Manual testing can lead to mistakes from tired workers or human error. Automated systems avoid these problems by following fixed steps for each test. This guarantees all printed circuit board assemblies (PCBA) meet the same quality rules.

ATE systems run tests using programmed instructions. These instructions check things like electrical signals, part placement, and how well signals flow. Automation keeps testing results steady, no matter how many boards you test. Whether testing a few boards or thousands, the results stay reliable.

Note: Reliable testing improves product quality and builds customer trust. Fewer returns mean happier customers and better satisfaction.

Another advantage is tracking test data over time. ATE systems save detailed results for every board tested. This data shows patterns, like repeated problems or areas needing improvement. Fixing these issues helps make production faster and reduces mistakes.

Industries like aerospace and healthcare need dependable testing. These fields have strict rules for safety and performance. ATE systems offer the accuracy and repeatability needed to meet these tough standards.

Using ATE systems helps you create a consistent testing process. This improves product reliability and keeps high-quality standards for all your PCBs.

Challenges and Considerations in Using ATE

High costs and ROI

Buying automated test equipment (ATE) can seem expensive at first. Costs include hardware, software, training, and upkeep. But looking at return on investment (ROI) shows its long-term value. ROI explains how ATE saves time and finds defects better. This helps improve profits over time.

Some people worry about spending so much money upfront. Sharing clear cost and benefit details can ease these worries. For example, ATE cuts down on manual work and speeds up testing. This leads to faster production and quicker product releases. In fast-paced industries, ATE is key for quality checks. Showing how ATE helps financially can win support and ensure future success.

Setup and programming challenges

Setting up ATE systems can be tricky, especially for beginners. These systems need careful settings for complex tests. For example, you might use special software to create test programs. A test sequencer runs many programs at once. Debugging tools help fix problems in the test code.

What It Does | |

|---|---|

Programming Software | Helps make test programs using common coding languages. |

Test Sequencer | Runs several test programs at the same time. |

Debugging Tools | Fixes errors by letting you check and change code. |

Data Handling | Manages large data amounts, up to 1 GB per hour. |

These tools make ATE powerful but need skill to use well. You may also need to adjust test plans and handle big data, adding to the difficulty. Good planning and technical skills are needed to solve these problems.

Operator training needs

Your team needs training to use ATE systems properly. Workers must learn how to set up, operate, and fix the equipment. Without training, even advanced systems can cause mistakes or delays.

Training should teach programming, reading results, and keeping the equipment working. Hands-on practice is important for learning. Regular training may also be needed for updates and new features. Teaching your team ensures they can use ATE fully. This leads to better testing and fewer problems.

Maintenance and calibration needs

Taking care of Automated Test Equipment (ATE) is very important. It keeps the system working well and giving accurate results. Without proper care, the equipment might fail or give wrong results. This can cause delays and cost more money. A good maintenance and calibration plan can prevent these problems.

Having a clear schedule for maintenance helps the equipment work better. Regular calibration makes sure the machine gives correct measurements. This is important for keeping product quality high. Preventive maintenance finds small issues before they become big problems. This reduces downtime and improves work efficiency.

Tip: Regular maintenance saves money by avoiding expensive repairs later.

Feature | What It Does |

|---|---|

Streamlining | Makes tracking and maintenance easier |

Scheduling | Helps plan when to do maintenance |

Performance Monitoring | Checks how well the equipment is working |

Compliance | Ensures the system follows industry rules |

Reporting | Keeps records of maintenance and calibration |

To keep your ATE in good shape, follow these steps:

Calibrate the equipment regularly to keep it accurate.

Do preventive maintenance based on how often it is used.

Clean and check important parts to avoid problems.

Note: Skipping maintenance can cause breakdowns, slow production, and increase costs.

By maintaining your ATE, you ensure it works its best. This helps you meet your testing goals and makes the equipment last longer. Regular care is a smart way to improve reliability and productivity.

Automated Test Equipment (ATE) is very important in PCBA testing. It helps make sure every PCB is high-quality and reliable. ATE uses machines to handle hard tests, saving time and cutting mistakes. This makes it a key tool for today’s PCBA production. Over time, using ATE saves money by lowering labor and running costs. It also keeps workers safe and organizes data better. This helps find errors quickly and speeds up production. Even though it can be tricky at first, ATE is worth it. It keeps quality steady and improves how much you can produce.

Tip: Using ATE helps your PCBs meet industry needs and stay ahead in a busy market.

FAQ

1. What does ATE do in PCBA testing?

ATE checks if your PCBs meet quality rules. It finds problems, tests how they work, and makes sure they are reliable. This helps avoid mistakes and speeds up making PCBs.

Tip: ATE helps test faster and gives steady results for every PCB.

2. Can ATE be used for small PCB batches?

Yes, ATE works for both small and big PCB batches. It adjusts to your needs and saves money. Even for small amounts, it ensures good testing.

Note: Buying ATE early can save time and money as you grow.

3. How does ATE make testing more accurate?

ATE uses programmed steps and smart tools to test PCBs. It removes human mistakes by automating the tests. This gives exact and repeatable results every time.

Pro Tip: Calibrate your ATE often to keep its accuracy high.

4. Which industries use ATE the most?

Industries like cars, planes, healthcare, and electronics depend on ATE. These fields need safe and reliable PCBs for important uses.

Did you know? ATE is needed to meet strict rules in these industries.

5. How can you take care of your ATE system?

Make a plan to clean, check, and calibrate your ATE often. Look at parts regularly to stop problems before they happen. This keeps your system working well.

Reminder: Skipping care can cause expensive fixes and slow production.

See Also

Innovative PCBA Testing Methods in Modern Electronics Production

Ensuring Quality and Reliability Through PCBA Functional Testing

Understanding In-Circuit Testing for PCBA and Its Importance

Defining PCBA Testers and Their Operational Mechanisms

The Importance of PCBA Test Fixtures in Electronics Manufacturing