Exploring the Future of PCB Manufacturing: Latest Techniques and Materials

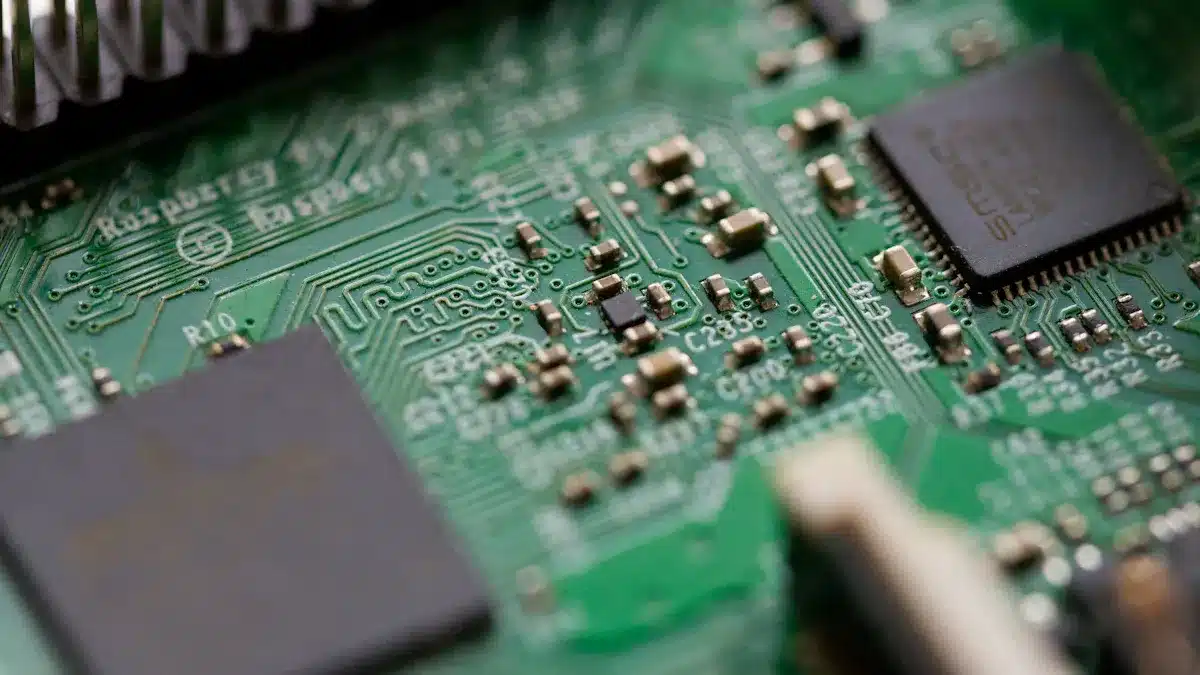

Manufacturing pcb in 2025 features HDI, flexible boards, AI, and eco materials for smarter, greener, and more reliable electronics.

Manufacturing pcb in 2025 features HDI, flexible boards, AI, and eco materials for smarter, greener, and more reliable electronics.

Compare top PCB manufacturing services for circuit board production, focusing on quality, speed, and user feedback to help you choose the best fit.

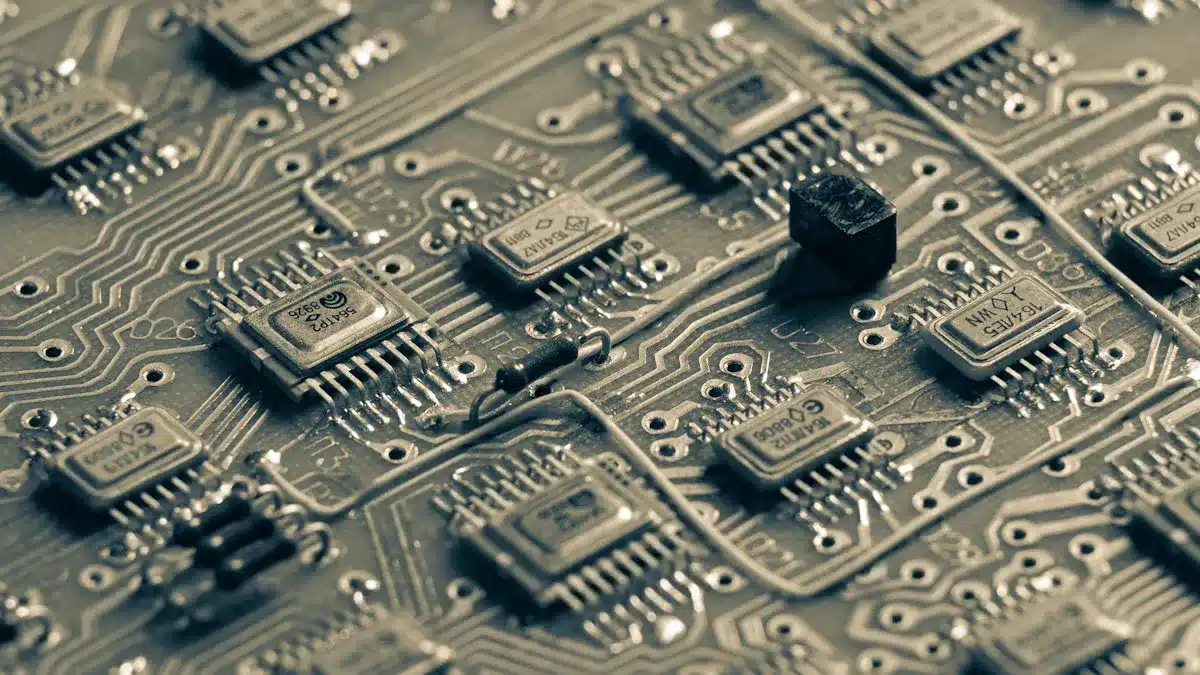

Compare PCB manufacturing methods and technologies to see how each impacts printed circuit board production cost, speed, complexity, waste, and quality.

Top industrial PCB manufacturing leaders in 2025 excel with advanced tech, strict quality, fast delivery, and custom solutions for demanding industries.

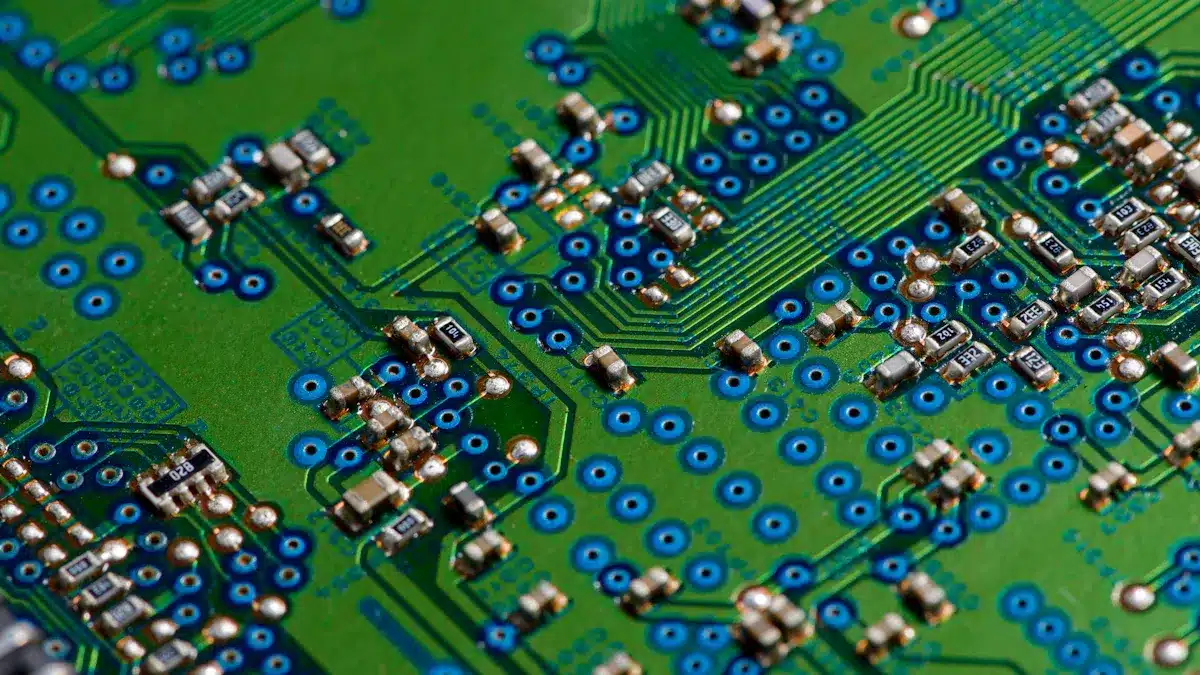

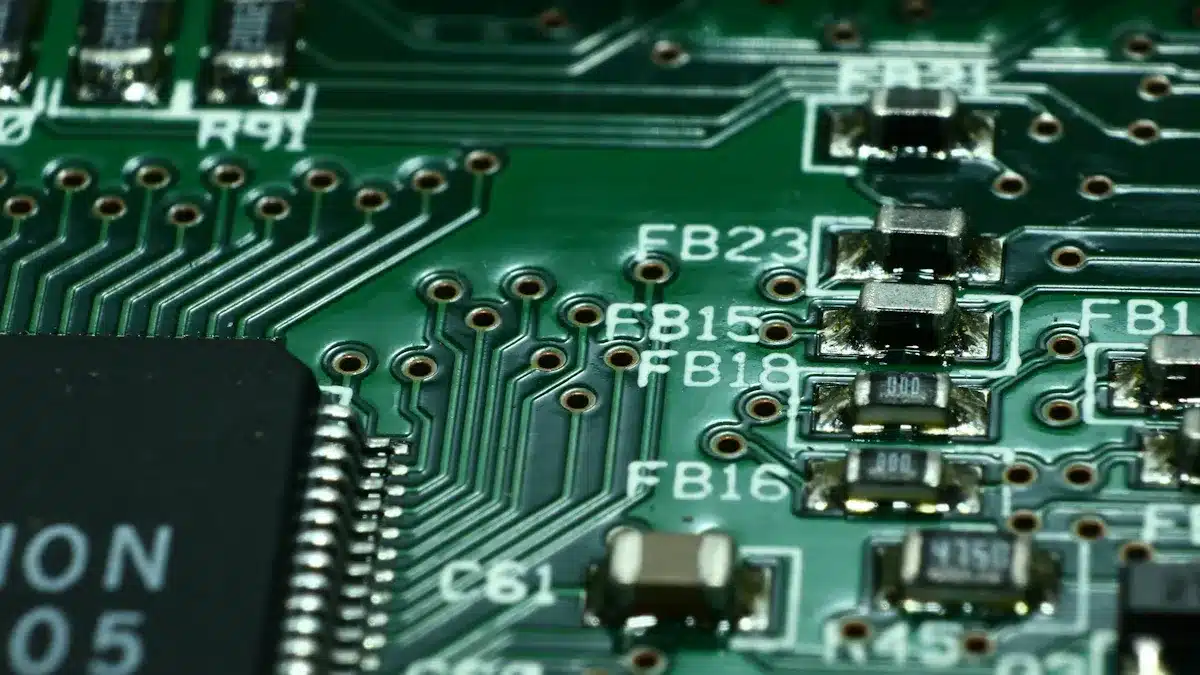

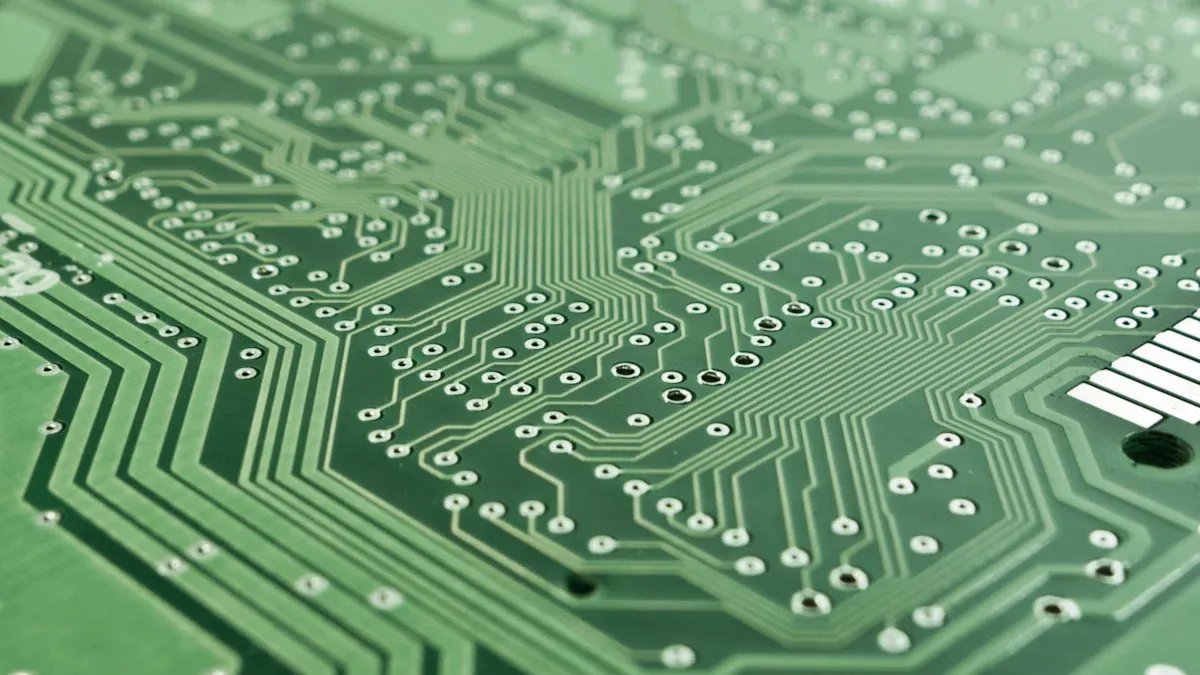

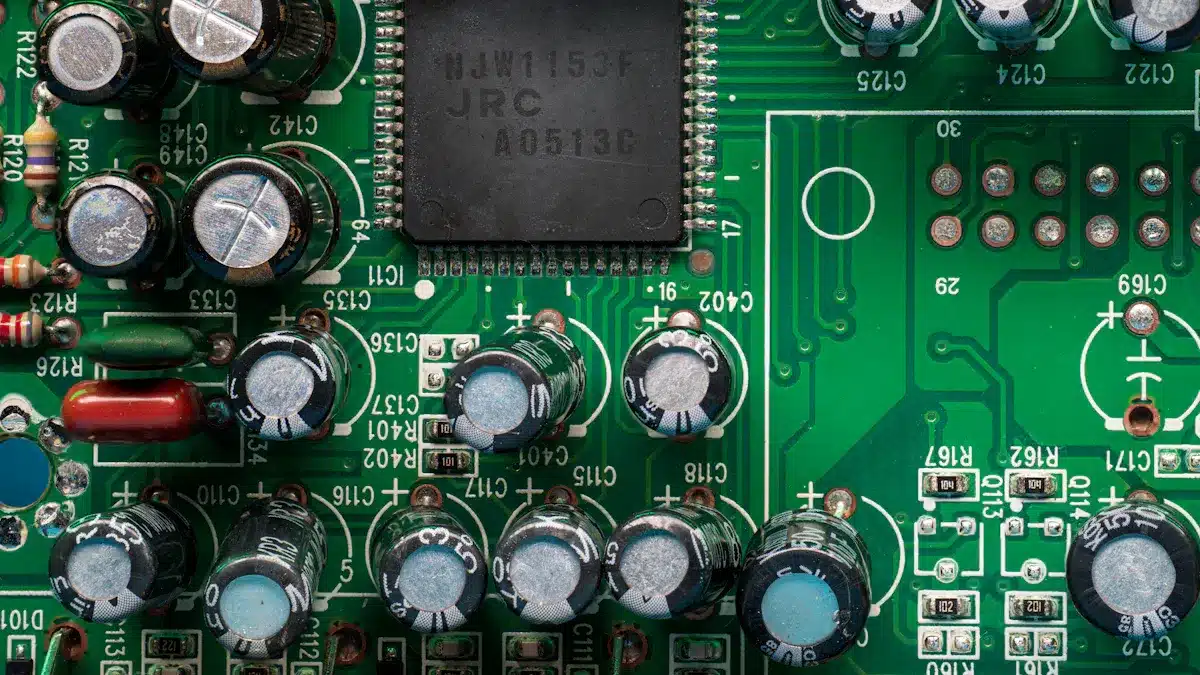

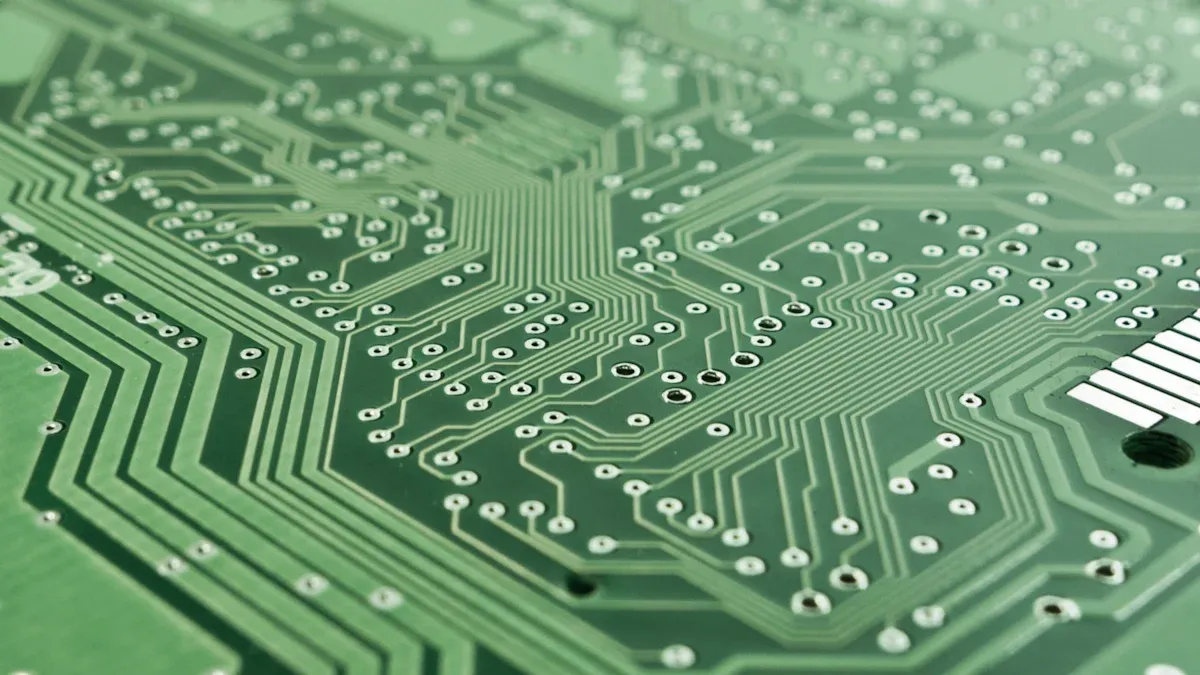

Definition PCB: In electronics, a PCB is a printed circuit board that connects and supports components in electronic devices.

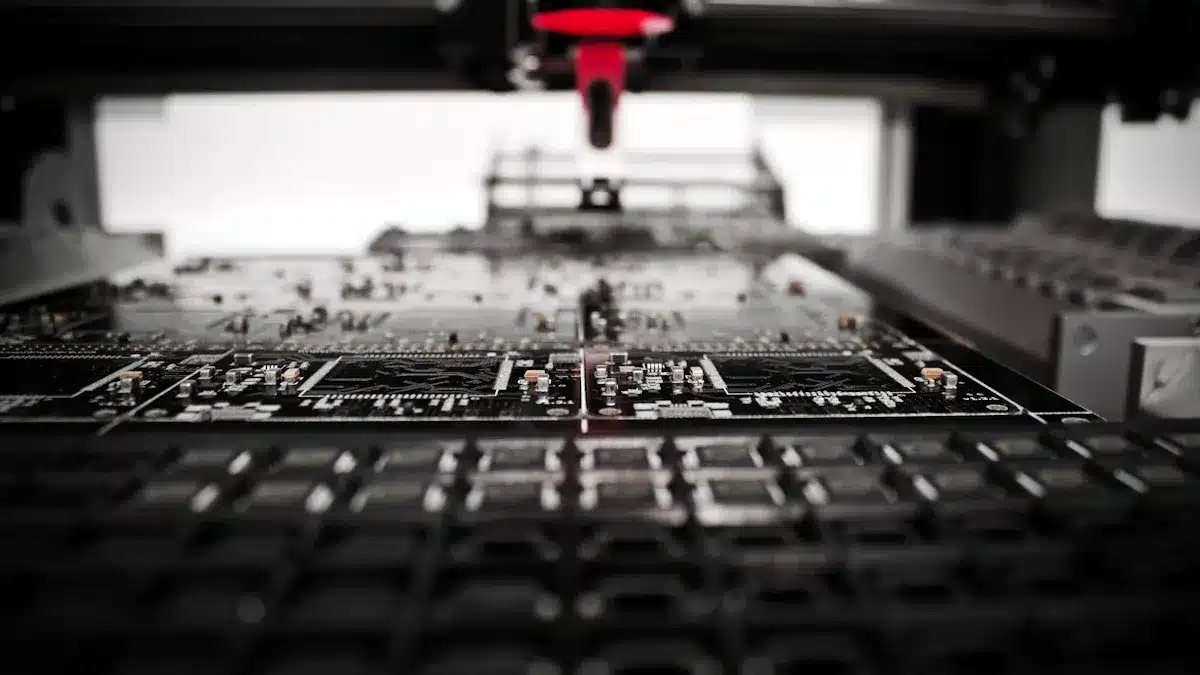

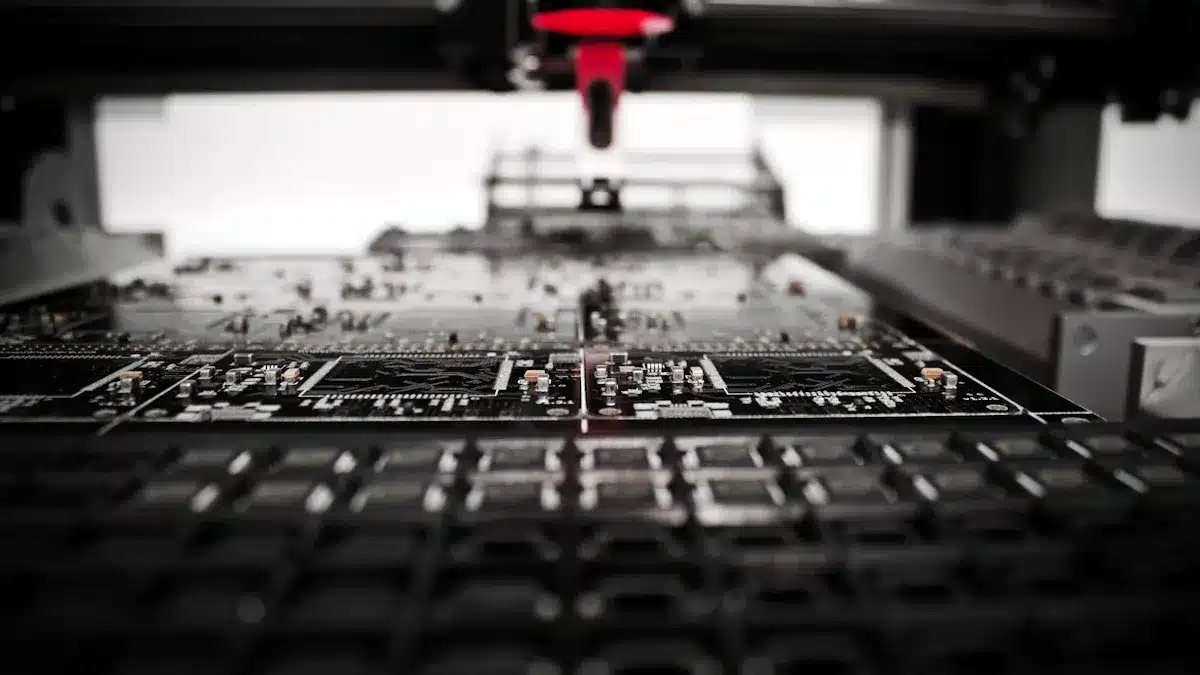

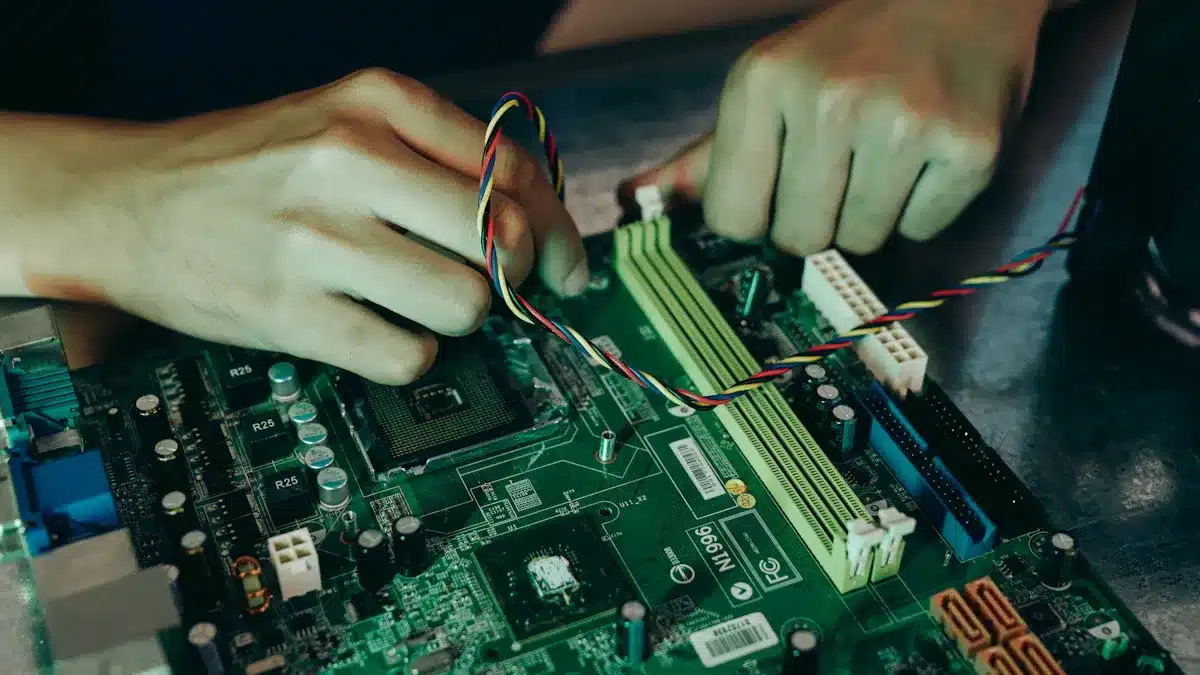

Circuit board assembly connects electronic components to a PCB, ensuring device reliability, safety, and performance in modern electronics.

Understand the key stages of assembling circuit boards, from design and soldering to inspection and testing, for reliable and high-quality PCB assembly.

Whats pcb? A PCB connects, powers, and supports electronic parts, enabling devices to work efficiently and reliably in modern electronics.

In electronics, PCB stands for Printed Circuit Board, a key component that connects and supports electronic parts. What does pcb stand for explained.

PCB meaning centers on enabling compact, reliable electronics for medical, automotive, and consumer devices, making PCBs vital in modern technology.