Automotive grade PCBA for EVs is crucial for ensuring safety. These regulations establish strict guidelines for manufacturing automotive PCBs, which guarantees that every automotive grade PCBA functions effectively in electric vehicles. As EVs gain popularity, the demand for robust PCB standards becomes even more significant.

In 2023, global EV sales reached 10.5 million, marking a 35% increase from the previous year. Electric vehicles require up to five times more PCBs than traditional cars. For example, Tesla’s Model 3 contains over 150 PCBs. These statistics highlight the importance of safety and performance regulations in the automotive industry.

Key Takeaways

Special PCBA rules keep electric cars safe and working well.

AEC-Q rules test parts to handle hard conditions without breaking.

ISO 26262 checks for risks in EV parts to stop problems.

UL 94 and RoHS make sure parts don’t catch fire or harm nature.

Picking EVs with these rules means safer and better cars for buyers.

Key Automotive-Grade PCBA Standards for EVs

AEC-Q Standards and Their Role in Automotive Applications

PCBA for EVs must meet strict rules to stay safe. AEC-Q standards are important for this. These rules test car electronic parts to ensure they work well. For example, AEC-Q100 checks chips, and AEC-Q200 tests parts like resistors.

AEC-Q Standard | What It Covers | Parts Included |

|---|---|---|

AEC-Q100 | Tests for quality in chips | Integrated circuits (ICs) |

AEC-Q101 | Checks reliability of small semiconductors | Diodes, transistors, MOSFETs |

AEC-Q102 | Covers light-based devices | LEDs, photodiodes, infrared sensors |

AEC-Q103 | Tests sensors | Discrete sensors |

AEC-Q104 | Focuses on multi-chip parts | Multi-chip modules (MCMs) |

AEC-Q200 | Tests for basic electronic parts | Resistors, capacitors, inductors |

These rules make sure parts can handle heat, shaking, and tough conditions. For instance, AEC-Q200 ensures resistors and capacitors last long in EVs. As more people use EVs, following these rules is key for safe cars.

IPC-6012DA: High-Reliability PCB Standards for Electric Vehicles

The IPC-6012DA rule sets high standards for EV PCBs. It ensures circuit boards are strong and reliable for EV systems. This includes parts like battery controls and power systems.

Evidence Type | What It Shows |

|---|---|

Standard Identification | IPC-6012DA is the first rule for car circuit boards. |

Industry Application | It applies to making strong PCBs for electric vehicles. |

Coverage Expansion | Work is ongoing to include more types of rigid boards. |

By following IPC-6012DA, companies make PCBs that handle heat and stress. It also focuses on using the right materials for EV needs. This ensures your EV’s PCBs work well for a long time.

ISO 26262: Functional Safety Standards for Automotive Systems

ISO 26262 is a global rule for car safety. It helps find and fix risks in car electronics. For EV PCBA, this rule ensures safety checks to avoid failures in key systems.

This rule applies to all steps, from design to production. It requires safety tests and backup systems. For example, special devices can spot electrical leaks in EVs, keeping them safe.

In places like Asia Pacific, where EVs are growing fast, ISO 26262 is very important. Big companies are improving PCBs to meet these safety needs. By following this rule, companies gain trust and make EVs safer for everyone.

UL 94 and RoHS Compliance: Environmental and Safety Standards

Safety and caring for the environment are key for EVs. Two important rules, UL 94 and RoHS, help make sure printed circuit board assemblies (PCBAs) meet these needs.

What is UL 94?

UL 94 checks how easily plastic parts catch fire. It ensures materials in PCBAs resist flames and slow fires. This is vital for EVs because batteries and high-voltage systems can cause fires.

Here’s how UL 94 works:

Fire Ratings: Materials get ratings based on fire behavior:

V-0: Stops burning in 10 seconds, no flaming drips.

V-1: Stops burning in 30 seconds, with little dripping.

HB: Burns slowly in a flat position.

Testing Steps: Materials are tested by burning them vertically or horizontally.

Tip: A UL 94 V-0 rating means the PCBA has top fire safety.

Why RoHS Compliance Matters

RoHS stands for “Restriction of Hazardous Substances.” It limits harmful materials like lead and mercury in electronics. For EVs, this ensures PCBAs are safe for people and the planet.

Benefits of RoHS compliance include:

Less Pollution: Reduces toxic waste by removing harmful substances.

Better Recycling: Makes materials easier to reuse, helping the environment.

Worldwide Use: Many countries require RoHS, making it a global rule.

Substance | Maximum Limit | Common Uses |

|---|---|---|

Lead (Pb) | 0.1% | Soldering parts |

Mercury (Hg) | 0.1% | Light bulbs |

Cadmium (Cd) | 0.01% | Batteries, colors |

Hexavalent Chromium | 0.1% | Rust-proof coatings |

How These Standards Work Together in EVs

UL 94 and RoHS work together to make EVs safer and greener. UL 94 focuses on fire safety, while RoHS reduces harmful materials. Together, they ensure PCBAs are reliable and eco-friendly.

For example, a RoHS-compliant PCBA with a UL 94 V-0 rating is extra safe. It prevents fire risks and avoids toxic materials, making it ideal for EVs.

Note: Choosing an EV means supporting safer and greener technology. Thanks to UL 94 and RoHS, you’re helping protect people and the planet.

By learning about these rules, you’ll see the care behind making EVs safe and eco-friendly. These standards are more than rules—they’re a promise of quality and responsibility.

How Standards Improve Safety, Reliability, and Performance

Safety: Stopping Problems in Important EV Systems

Automotive-grade PCBA standards are key to keeping EVs safe. High-voltage parts like batteries and inverters need strong insulation. Rules like IEC 60664-1 require special materials, such as Rogers RO4835, to keep safe distances between electric parts. These materials stop short circuits, even in tough conditions.

To make things safer, manufacturers use coatings like silicone or polyurethane on high-voltage areas. These coatings keep insulation strong, even after 1,000 hours of testing at 85°C and 85% humidity. Devices called IMDs check for electric leaks and act fast to fix problems. Together, these tools protect passengers and the car from electrical failures.

Tip: Pick an EV that follows these safety rules. It lowers the chance of electric problems and keeps you safer.

Reliability: Making EVs Last in Tough Conditions

Reliability is very important for EVs, especially in hard environments. Automotive-grade PCBA standards, like AEC-Q200, test parts like resistors to handle heat, shaking, and moisture. These tests prove the parts can last a long time.

Tests show how parts work over time. Accelerated tests copy real-world stress, like extreme heat or vibrations. Field tests check how parts perform in real driving. Both help improve designs to meet strict car standards.

For example, materials like LCP don’t absorb water, so they stay strong. Special finishes, like ENIG+OSP, stop corrosion and keep parts working. These steps help EVs work well in all weather, from cold winters to hot summers.

Performance: Keeping EVs Working Smoothly

Good performance is needed for EVs to drive well. Automotive-grade PCBA standards make sure all parts work together properly. For example, copper-graphene materials help cool down chargers by lowering heat by 25°C. This stops overheating.

Advanced cooling systems, like liquid cooling with PCM, spread heat evenly. This keeps temperature changes small, even during fast charging. Tools like ANSYS Twin Builder help place parts better to manage heat and keep performance steady.

EMC standards also help by stopping electric noise. Shielding and filters protect sensitive parts from interference. By following these rules, EVs work well in all situations, from city trips to long drives.

Note: Reliable performance makes driving better and helps your EV last longer. It’s a smart and eco-friendly choice.

Challenges in EV Environments and How Standards Solve Them

High Heat and Cooling in Electric Cars

Electric cars create a lot of heat, especially in batteries and inverters. Too much heat can hurt parts and lower performance. Special rules for car PCBs require better cooling systems.

For example, makers use copper-graphene materials in chargers. These materials move heat away faster, lowering temperatures by 25°C. Liquid cooling with phase change materials (PCM) helps spread heat evenly. This keeps temperature changes small, even during fast charging. Tools like ANSYS Twin Builder help place parts to manage heat better. These ideas keep your car working well, even in hot conditions.

Shaking and Stress in Electric Cars

Electric cars deal with shaking and stress, especially on bumpy roads. These forces can break solder joints and harm PCBs. Car rules like AEC-Q200 make sure parts can handle these problems.

Tests copy real-world shaking. For example, vibration tests use forces from 1 G at 7 Hz to 8 G at 200 Hz. These tests check if resistors and capacitors stay strong. Makers also use materials like LCP that don’t soak up water. This stops damage from moisture. These steps help your car stay reliable, even in tough places.

Frequency Range | Force Applied |

|---|---|

7 Hz – 18 Hz | 1 G |

18 Hz – 50 Hz | Slowly increased to 8 G |

50 Hz – 200 Hz | Kept at 8 G |

Electromagnetic Noise and Compatibility in Electric Cars

Electric cars can cause electromagnetic noise that affects nearby devices. Big systems like battery controls and wireless chargers can send out this noise. Car rules use shields and filters to stop this problem.

Studies show why following rules like ICNIRP is important. These rules keep electromagnetic levels safe. Reports also suggest checking new tech often to fix noise issues. Makers use multi-layer shields and special frequency tools to lower noise by 20 dBμV/m. These methods make sure your car works safely without bothering other electronics.

Protecting EV Systems from Moisture, Dust, and Corrosion

Electric cars often face moisture, dust, and harmful substances. These can harm PCBAs and cause system problems. Special car PCBA standards help keep your EV working in tough conditions.

How Moisture Causes Problems

Water can get into parts and cause short circuits or rust. To stop this, makers add coatings like silicone or acrylic. These coatings form a shield over the PCBA, keeping water out. Rules like IPC-CC-830 make sure these coatings are high quality.

Tip: Choose EVs with PCBAs tested for humidity, like 85°C/85% RH for 1,000 hours. This shows they last longer.

Dust and Its Effects

Dust can pile up on PCBAs, causing overheating or failures. To fix this, makers use cases with IP ratings. For example, an IP67 case blocks dust and water. This keeps your EV’s parts safe and working well.

IP Rating | What It Protects Against |

|---|---|

IP65 | Dust and water sprays |

IP67 | Dust and short water dips |

Fighting Corrosion in EVs

Salt and chemicals can damage PCBAs, especially near oceans. To prevent this, makers use finishes like ENIG or HASL. These finishes protect against rust and chemical harm.

Note: Tests like MIL-STD-810 check if PCBAs resist corrosion from salt and other chemicals.

By following these rules, EV makers protect your car’s electronics. This ensures your EV stays reliable, no matter where you drive.

Testing Protocols and Material Selection for Compliance

Common Testing Methods for Automotive-Grade PCBA for EV

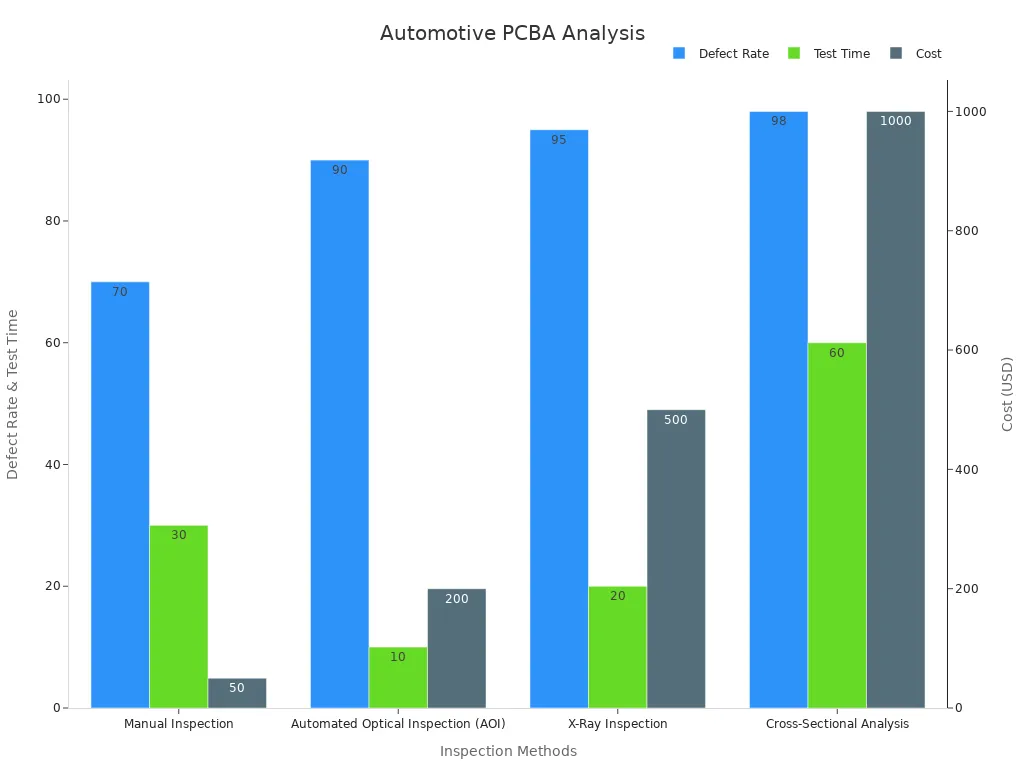

Testing makes sure car PCBs are safe and reliable. Different methods check for problems, each with its own benefits. Manual checks are cheap but less accurate. Automated Optical Inspection (AOI) and X-ray tests find more defects. Cross-sectional analysis costs the most but gives detailed results.

Defect Detection Rate (%) | Testing Time (minutes) | Cost (USD) | |

|---|---|---|---|

Manual Inspection | 70 | 30 | 50 |

Automated Optical Inspection (AOI) | 90 | 10 | 200 |

X-Ray Inspection | 95 | 20 | 500 |

Cross-Sectional Analysis | 98 | 60 | 1000 |

These tests check if PCBs can handle EV demands. Thermal tests see how well PCBs cool down. Mechanical tests copy shaking and bumps. Electrical tests make sure circuits work in all conditions.

Importance of Material Selection in Meeting Automotive Applications Standards

Picking the right materials is key for meeting car PCB rules. High-CTI materials, like Rogers RO4835, improve insulation and meet IEC 60664-1 rules. These materials stop electrical leaks and keep high-voltage areas safe.

Coatings, like silicone or polyurethane, protect PCBs from water and dirt. They keep PCBs working even after tough tests at 85°C and 85% humidity for 1,000 hours.

Using good materials helps meet rules like ISO 26262. It also makes EV electronics last longer. Advanced materials help car makers meet strict standards for safety and performance.

Ensuring Durability Through Rigorous Validation Processes

Durability tests make sure car PCBs survive tough conditions. HALT tests use fast temperature changes and strong vibrations to find weak spots. This helps improve designs and make PCBs stronger.

For lasting performance, low-water-absorption materials like LCP are used. These materials block water and stay strong over time. Finishes like ENIG+OSP stop rust and keep parts working well.

By using strong materials and tough tests, makers earn certifications for reliable PCBs. This ensures your EV works well, even in extreme weather or rough roads.

Automotive-grade PCBA standards are key to making EVs safer. They help solve problems like heat, shaking, and electric noise. These rules make sure EV parts last longer and work well.

When companies follow these rules, they improve EV technology. This builds trust with buyers and keeps EVs reliable. These efforts make electric cars a smart and lasting choice for the future.

FAQ

What are automotive-grade PCBA standards?

These rules make sure circuit boards in EVs are safe and reliable. They cover testing, picking materials, and handling tough environments.

Why is following these standards important for EVs?

Following these rules keeps EV systems safe and working well. It also helps companies follow laws, build trust, and improve EV technology.

How do these standards handle environmental challenges?

They use materials and designs that fight heat, water, dust, and rust. For example, special coatings and sealed cases protect circuit boards from damage.

What tests check if PCBAs are durable?

Tests like HALT and heat cycling copy extreme conditions to find weak spots. These tests make sure circuit boards meet rules and last a long time.

How do these standards boost EV performance?

They improve cooling, stop electric noise, and use strong materials. This helps EV systems work better and stay reliable, making the car perform well.

See Also

Ensuring Quality And Reliability Through PCBA Functional Testing

The Importance Of PCBA Cleanliness For Reliable Performance

Best Practices For Achieving Quality And Efficiency In PCBA Production

Exploring EMS And PCBA Services In Today’s Electronics Landscape

Advantages And Challenges Of Flex PCBA In Modern Electronics