PCBA coating is a protective layer for circuit boards. It keeps them safe from harmful things outside. This coating helps PCBAs last longer and work better by blocking moisture, dust, and chemicals.

Moisture can harm circuit boards and cause them to fail. Coatings stop this by repelling water.

Dust and chemicals can damage boards and make them work poorly. Coatings protect them and help them last longer.

Coatings also shield boards physically, even in tough conditions.

By stopping these problems, PCBA coating helps boards work well under heat, vibration, and other stresses.

Key Takeaways

PCBA coating keeps circuit boards safe from water, dirt, and chemicals. This helps them last longer and work well.

There are different coatings like acrylic, epoxy, silicone, and polyurethane. Each type works best in certain places and for specific uses.

Picking the right coating depends on the environment, heat levels, and how it will be used. This helps it work better.

Think about both the starting cost and future upkeep when choosing a coating. This helps balance cost and strength.

Selective coating uses less material and protects only needed parts. This makes it more efficient.

What is PCBA Coating and Why is it Important?

Definition of PCBA Coating

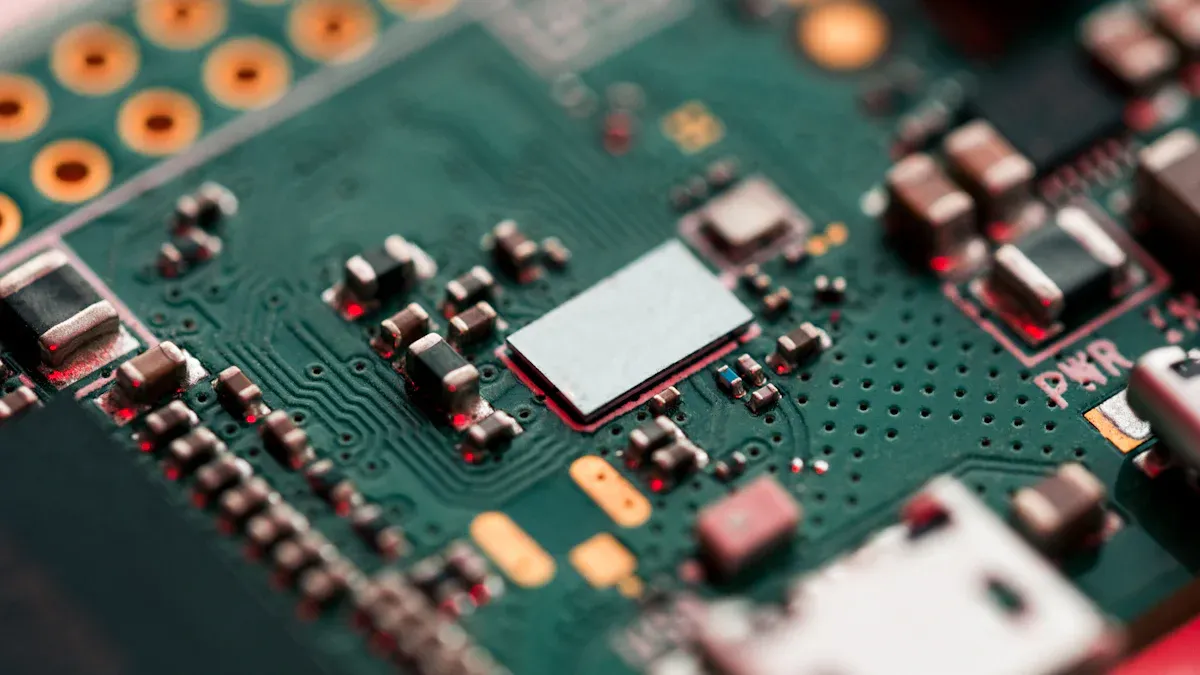

PCBA coating is a thin layer that protects circuit boards. It keeps boards safe from things that can harm them. This layer, called conformal coating, is very thin, about 25–250 micrometers. It fits the board’s shape without making it bigger or heavier.

Term | Definition |

|---|---|

Conformal coating | A thin, protective film added to circuit boards. |

Thickness | Usually 25–250 μm thick to guard against moisture. |

PCBA coatings are made from materials like acrylics, silicones, and epoxies. These coatings protect circuit boards from water, dust, chemicals, and heat.

Key Benefits of PCBA Coating

PCBA coatings have many benefits that help devices last longer:

They stop rust, short circuits, and other damage.

They protect boards from water, dust, and harmful chemicals.

They make boards stronger against heat and shaking.

These coatings keep boards working well in tough conditions without adding size or weight.

Common Applications of PCBA Coating

PCBA coatings are used in many industries to protect electronics. For example, in the military, coatings follow rules like MIL-I-46058C to ensure boards work in harsh places.

Term | Definition |

|---|---|

MIL-I-46058C | A rule for coating materials to protect military circuit boards. |

In everyday electronics, coatings keep devices safe from water and dust, helping them last longer. Factories use coatings to protect machines from chemicals and heat.

A study on FBGA packages shows why coatings matter. Under a 1500G load with a 0.5ms shock, solder joints with encapsulant underfill had 35 MPa stress. With epoxy underfill, stress was 17 MPa. This shows coatings make boards stronger under stress.

From planes to cars, PCBA coatings help electronics work well in tough situations.

Types of PCBA Coatings

Acrylic Coatings

Acrylic coatings are very common and easy to use. They are simple to apply and remove, which is helpful for repairs. These coatings protect circuit boards from water and dust. This keeps the boards working in tough places. Acrylic coatings also dry fast, saving time during production.

But they have some downsides. They don’t work well in high heat or with strong chemicals. Even so, they are cheap and easy to use, making them a good choice for general needs.

Epoxy Coatings

Epoxy coatings are strong and resist chemicals very well. They create a tough layer that protects boards from scratches and damage. These coatings are great for factories where chemicals and stress are common.

However, epoxy coatings are stiff and can crack under too much stress. They are also hard to remove if repairs are needed. Despite these issues, they are perfect for rough environments because of their strength.

Silicone Coatings

Silicone coatings are flexible and handle extreme temperatures well. They work great in wet places or where it rains a lot. These coatings keep water out, protecting the circuit board. They also block UV light, making them good for outdoor use.

Research shows silicone coatings last longer than other types. They stay strong even after long exposure to sunlight. This makes them a dependable choice for harsh conditions.

Tip: Think about temperature, flexibility, and environment when picking a coating. This helps your PCB work its best.

Polyurethane Coatings

Polyurethane coatings are both strong and flexible. They protect circuit boards from water, chemicals, and scratches. These coatings are great for places with heavy use or tough conditions.

A key feature of polyurethane is its ability to stretch and return to shape. This makes it perfect for boards that bend or move often. Its strength also ensures long-lasting protection in hard environments.

Property | Description |

|---|---|

Flexibility | |

Toughness | Its strength comes from being both hard and resilient. |

Removing polyurethane coatings can be tricky if repairs are needed. Think about this before choosing it for your board. Even with this downside, its durability makes it a favorite in many industries.

Tip: Use polyurethane coatings for flexible and tough needs. They are great for cars, planes, and factories.

Parylene Coatings

Parylene coatings are one of the best protective layers for circuit boards. They are applied as a thin, even layer using a special vapor process. This coating sticks perfectly to the board’s surface.

Parylene offers excellent protection against electricity, chemicals, and water. It also prevents rust in salty air, making it ideal for marine or medical uses.

Test Type | Result |

|---|---|

Dielectric Withstanding Voltage | |

Insulation Resistance | Over 10 GΩ |

Salt Spray Test | No rust on chip parts |

Moisture Protection | Excellent |

Chemical Resistance | Excellent |

Great at stopping electrical problems.

Strong against harmful chemicals.

Blocks water and moisture completely.

Works well in tough environments.

Parylene coatings cost more and need special tools to apply. But if you need top-level protection, they are worth it.

Note: Choose parylene coatings for projects needing high precision and safety, like medical tools or space electronics.

Ways to Apply PCBA Coatings

Brushing

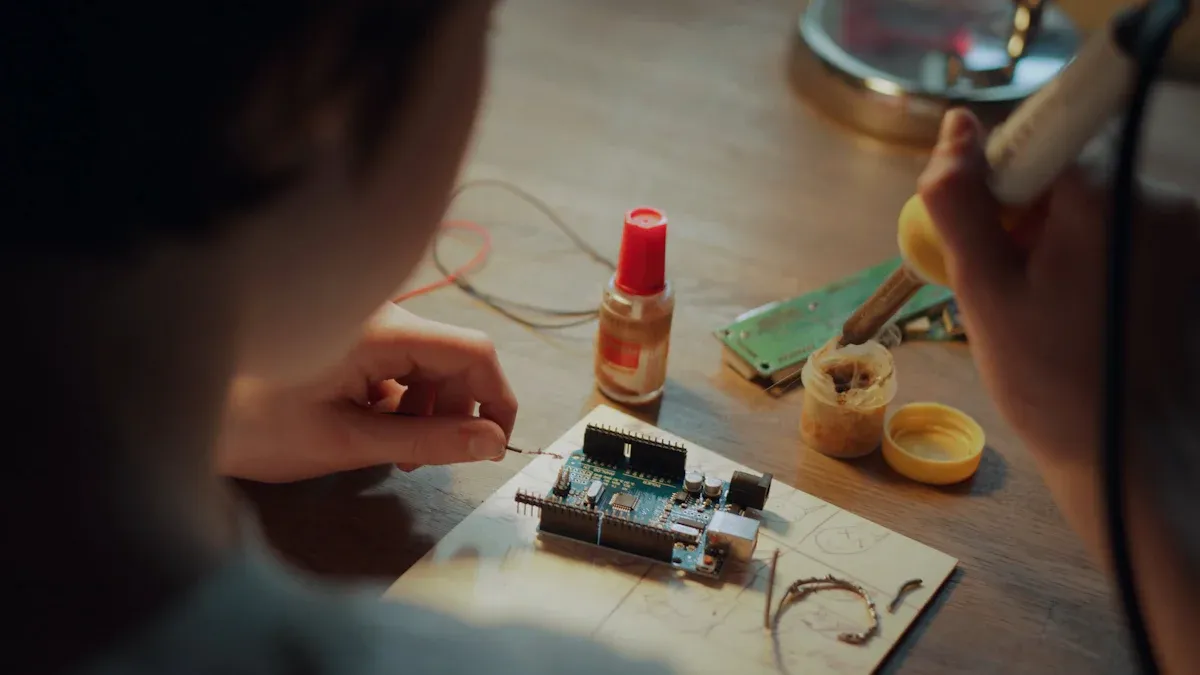

Brushing is a simple way to add coating to circuit boards. You use a brush to spread the coating by hand. This method is good for small jobs or fixing specific spots. It lets you control where the coating goes, making it great for repairs.

But brushing has some downsides. The coating quality depends on how skilled you are. Mistakes like uneven layers or missed areas can happen. Brushing also takes time, so it’s not ideal for big projects.

Tip: Brushing works well for small tasks or tricky spots. It’s cheap but needs care and patience.

Spraying

Spraying is a quick way to coat circuit boards evenly. You use a spray gun or can to apply the coating. This method covers large areas fast and wastes less material. It’s great for factories that make many boards.

Spraying avoids problems like bubbles or streaks. But you need the right tools and setup. Controlling the spray thickness is important to prevent overcoating. Always work in a ventilated space for safety.

Fun Fact: Experts can spray up to 15,000 square feet daily with even layers, showing how fast this method is.

Dipping

Dipping means putting the whole board into a tank of coating. This method covers every part, even hard-to-reach areas. It’s useful for boards with lots of parts.

However, dipping can cause uneven layers or sagging near tall components. To fix this, pull the board out slowly and let extra coating drip off. Dipping is best for medium or large projects needing full coverage.

Note: Slower dipping gives smoother layers and fewer mistakes, making the coating better.

Selective Coating

Selective coating is a way to protect only certain parts of a PCB. Instead of covering the whole board, it focuses on specific areas. Machines with nozzles or dispensers apply the coating exactly where needed.

Why is selective coating useful? It saves material by not coating unneeded parts. It also avoids covering connectors or sockets that don’t need protection. This method works well for complex boards with delicate parts.

There are many advantages to this process. It applies the coating evenly, making the board more reliable. It reduces waste, which is better for the environment. It also speeds up production for big projects. But, it needs special tools and skilled workers. This can cost more at first, but it saves money over time.

When using selective coating, think about the types of coatings that fit this method. Acrylic and silicone coatings are good choices because they are easy to use. Also, check your PCB design. If it has tightly packed parts, selective coating gives the precision you need.

Tip: Use selective coating for important electronics like medical tools or space devices. It protects without affecting how they work.

Selective coating is precise and efficient, making it great for PCB protection.

How to Pick the Best PCBA Coating

Environmental Factors

Think about where your PCB will be used. Different coatings work better in certain places. For example, silicone coatings are great for wet and hot areas. Urethane coatings protect well against chemicals and water. Epoxy coatings are strong and handle temperature changes and chemicals.

Check what challenges your PCB might face. If it will be near salty air, like by the ocean, pick a coating that stops rust and handles moisture well. The chart below shows how different coatings perform:

Tip: Look at all environmental factors to choose the best coating.

Heat and Stress Needs

Heat and physical stress can affect your PCB. Some coatings help manage heat by either blocking or spreading it. Silicone coatings are good for high heat. Epoxy coatings are strong but can cause stress at joints.

Tests like thermal cycling and power cycling check how coatings handle stress. Thermal cycling switches between hot and cold to mimic real conditions. This shows if the coating can handle sudden changes without breaking.

Test Type | Description | Key Metrics |

|---|---|---|

Thermal Cycling | Switching between very hot and cold temperatures. | Acceleration Factor |

Power Cycling | Turning the PCB on and off under stress. | Time to Failure |

Note: Pick coatings that won’t crack or damage solder joints under stress.

Special Application Needs

Choose a coating based on what your PCB will do. For wet places, use moisture-resistant coatings like silicone or acrylic. In factories with chemicals, epoxy or parylene coatings work best because they resist chemicals.

If your PCB will face high heat, pick a coating that won’t break down. Silicone coatings are a good choice for hot conditions.

Tip: Match the coating to your PCB’s job for better performance and durability.

Cost and Maintenance Factors

Picking a conformal coating for your PCB needs careful thought. Think about both the price now and the future costs.

Cost Considerations

The price of a coating depends on its type, how it’s applied, and the tools needed. For example:

Material Costs: Acrylic coatings are cheap and simple to use, making them a good choice for saving money. Parylene coatings cost more because they need special tools to apply.

Application Costs: Brushing or spraying is less expensive but takes more work. Selective coating is accurate but costs more upfront due to special machines.

Also, think about how big your project is. Big projects can save money with machines that lower labor costs over time.

Maintenance Factors

Maintenance includes fixing, how long the coating lasts, and how easy it is to remove. Acrylic coatings are simple to take off, making repairs easier. Epoxy coatings are very strong but hard to remove, which makes fixing harder.

How long a coating lasts also matters. Silicone coatings stay strong in tough places, so you won’t need repairs often. But they cost more, which might not fit every budget.

Tip: Choose a coating that balances cost and how often it needs fixing. A strong coating might cost more now but save money later by needing fewer repairs.

By thinking about these points, you can pick a coating that fits your budget, is easy to maintain, and works well for your PCB.

PCBA coating is important for keeping circuit boards safe. It protects them from water, dust, and harmful chemicals. It also helps the board handle shocks and vibrations. This makes sure the PCB works well in tough places.

When picking a coating, think about the material and how it’s applied. Also, consider the environment where the board will be used. These things affect how strong and useful the coating will be.

Look at what your board needs carefully. Choosing the right coating can make your circuit board last longer and work better.

FAQ

What does PCBA coating do?

PCBA coating keeps circuit boards safe from water, dust, and chemicals. It also protects them from damage caused by stress. This helps electronics last longer and work well in tough places.

Can I put PCBA coating on myself?

Yes, you can use a brush or spray for small jobs. But for bigger or more detailed work, experts with special tools do it better.

How do I pick the best coating for my PCB?

Think about where your PCB will be used. Silicone is good for wet areas, and epoxy works well with chemicals. Choose a coating that fits your PCB’s needs.

Can PCBA coatings be removed?

Some coatings, like acrylic, are easy to take off for repairs. Others, like epoxy, are harder to remove. Pick a coating based on how often you might need to fix it.

Is PCBA coating costly?

The price depends on the type and how it’s applied. Acrylic is cheap, but parylene costs more because it needs special tools. Spend wisely to protect your PCB and avoid future repairs.

Tip: Spending on the right coating now can save money later by making your PCB last longer.

See Also

Exploring PCBA: Definition and Significance in Electronics

Decoding PCBA: Its Definition and Essential Uses in Electronics

PCBA Explained: Its Importance and Function in Electronics