Embedded components in 3D PCB designs provide significant advantages for modern electronics. They enable the creation of smaller devices, which is crucial for portable gadgets. For instance, embedding 50% of passive components within a GSM phone can reduce the PCB size by 25%. This compact design not only enhances device performance by conserving power and improving signal quality but also ensures shorter connections that eliminate unwanted effects, making high-speed circuits more reliable. Additionally, embedded components are better protected from damage, resulting in longer-lasting and more durable devices. With fewer solder points and simplified assembly processes, 3D PCBs with embedded components are both more dependable and cost-effective to produce.

Key Takeaways

Embedded parts make devices smaller and lighter for easy carrying.

Shorter links in these PCBs improve signals and cut down noise.

These PCBs last longer, keeping parts safe and devices working well.

Easier assembly lowers costs and reduces mistakes during production.

Fields like tech, cars, and medicine gain a lot from these PCBs.

What Are Embedded Components in 3D PCBs?

What Are Embedded Components?

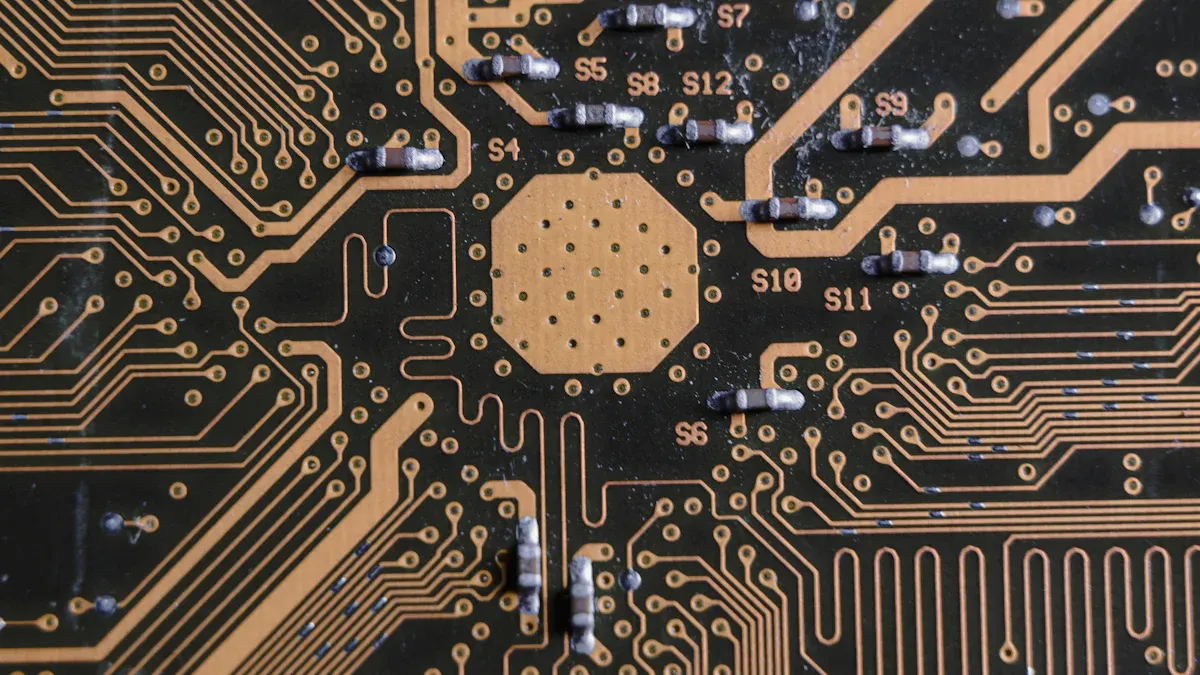

Embedded components are parts built inside a circuit board. Unlike regular parts placed on top, these are inside the board. They can be passive, like resistors, or active, like transistors. Passive parts help save space and stop unwanted effects. Special materials are used to make these parts, improving how they work. Methods like Integrated Module Board (IMB) and Embedded Wafer-Level Package (EWLP) are used to add them into the board.

Why Are Embedded Components Important in 3D PCBs?

Embedded components make circuit boards smaller and better. They use the space inside the board, making layouts tighter. This shortens signal paths, improving signals and reducing noise. Fewer soldering steps are needed, making production easier. Below is a table showing their benefits:

Benefit/Innovation | Description |

|---|---|

Embedded parts make PCBs smaller, shrinking device sizes. | |

Easier Production | Fewer soldering steps are needed, speeding up production. |

Better Signal Quality | Shorter paths improve signals and reduce interference. |

How Are Embedded Components Different from Surface-Mounted Ones?

Embedded parts are inside the board, unlike surface-mounted ones on top. This difference affects heat control and reliability. For example, embedded PCBs stay cooler at 34 °C, while regular ones reach 52 °C. Cooler boards last longer. Embedded parts also avoid problems like shrinking or gaps in solder joints. This makes them more dependable over time.

Embedded components help circuit boards work better and last longer. They stay safe inside the board, improving durability and performance.

Key Benefits of Embedded PCBs

Miniaturization and Space Efficiency

Embedded components help make devices smaller and more compact. By placing parts inside the PCB layers, the board size gets much smaller. This removes the need for large surface parts, leaving more room for other features. For example, using embedded die packaging can shrink sizes by up to 70%. This is perfect for devices where space is tight.

The need for smaller electronics has pushed embedded PCB technology forward. By 2028, the Embedded Die Packaging Technology Market could grow to $214.1 million, with an 18.6% yearly growth rate. This shows how important space-saving designs are for industries like electronics, cars, and healthcare.

📌 Tip: Smaller designs also make devices lighter, which is great for portable and wearable gadgets.

Enhanced Signal Integrity and Electrical Performance

Embedded PCBs improve signals and reduce interference by shortening paths. When parts are inside the board, connections are more direct. This lowers noise and boosts performance. Tools like power analysis and EMI checks ensure steady power and fewer emissions.

These PCBs work well in tough conditions. Worst-case tests check designs for extreme situations. Signal simulations help create layouts for fast applications. These methods improve signals and cut interference, making embedded PCBs great for precise and reliable devices.

Embedded PCBs are perfect for fast data and low-noise needs, like in telecom and aerospace.

Improved Thermal Management

Embedded PCBs handle heat better, which helps high-performance devices. By putting parts inside the board, heat spreads out more evenly. This keeps devices cooler. Heat is managed using conduction, convection, and radiation.

New cooling methods, like microchannel systems, can handle over 500 W/cm² of heat. Compact models and advanced heat sinks improve cooling even more. Trends like immersion cooling add extra ways to manage heat in these PCBs.

Aspect | Description |

|---|---|

Heat Transfer Mechanisms | Conduction, convection, and radiation spread heat better. |

Cooling Methods | Air and liquid cooling improve heat control. |

Innovations | Heat pipes and thermoelectric cooling offer new solutions. |

Microchannel Cooling Systems | Handle high heat for powerful devices. |

📌 Note: Good heat control makes devices last longer and lowers repair costs.

Increased Reliability and Durability

PCBs with embedded components are very strong and reliable. They work well in tough places. Putting parts inside the PCB layers removes weak spots. For example, solder joints can crack from heat or stress. With embedded parts, this problem is gone. These PCBs handle extreme heat, shaking, and shocks easily.

Tests are done to check how durable these PCBs are. Engineers use special methods to mimic real-life conditions. This helps find and fix weak points. Below is a table showing common testing methods:

Testing Method | Purpose | Description |

|---|---|---|

Burn-In | Find early failures | Tests parts in tough conditions to spot weak areas like bond wires or packaging issues. |

Accelerated Life Testing (ALT) | Check reliability fast | Uses heat, RF, and DC stress to quickly find problems and gather data. |

High-Temperature Operating Life (HTOL) | Test long-term strength | Runs tests at high heat to see if parts last over time. |

These tests make sure embedded component PCBs are very reliable. Devices using them rarely break, even in hard jobs like industrial machines or powerful computers. This means fewer repairs, less downtime, and longer-lasting products.

📌 Tip: Always think about where the device will be used. Pick materials that can handle the stress.

Cost Savings in Manufacturing

Making PCBs with embedded components can save a lot of money. Parts are built into the board, so assembly is simpler. This cuts labor costs and lowers the chance of mistakes during production.

Studies show that while designing these PCBs can be tricky at first, they save money later. For example, embedding passive parts means fewer extra pieces are needed. This lowers material costs and speeds up production.

Smaller PCBs with embedded parts can do more in less space. This means fewer boards are needed for a project, saving even more money. Over time, these savings help industries like electronics, cars, and planes.

📌 Note: Think about both the upfront costs and long-term benefits, like better reliability and less maintenance.

Common Applications of Embedded PCBs

Embedded PCBs are changing industries with smaller and better designs. They are used in many areas, from everyday gadgets to space technology.

Consumer Electronics: Smartphones, Wearables, and IoT Devices

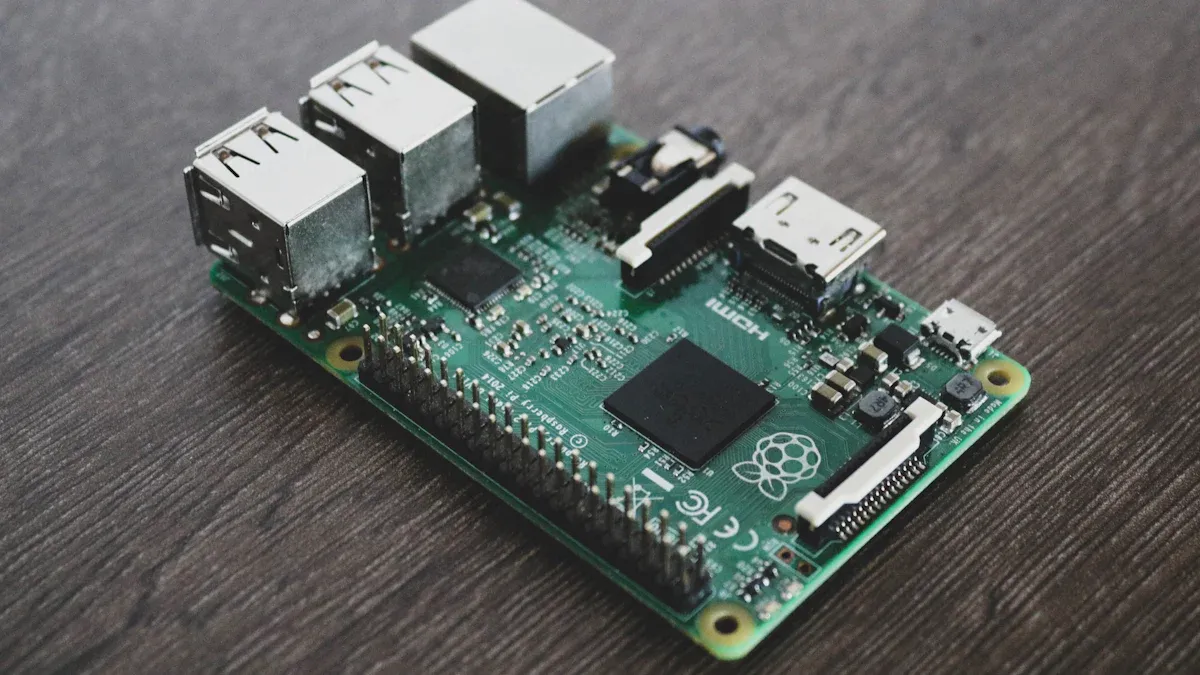

Embedded PCBs are important for devices like smartphones, wearables, and connected devices. Parts inside the PCB save space, making gadgets thinner and work better.

For example, most smartphones in 2024 used flexible PCBs (FPCs). These helped make phones smaller and improved signals. Also, about 69% of wearables, like smartwatches, used embedded circuits. This made them lighter and connect better. These designs are great for internet of things devices, which need to be small and efficient.

📊 Market Insight: Consumer electronics lead the FPC market with 52%. This shows how embedded PCBs are key for new designs like foldable screens and laptops.

Embedded PCBs also protect parts from damage. This is helpful for wearables that face tough conditions. They make gadgets last longer and work better.

Automotive: Electric Vehicles and ADAS

Cars use embedded PCBs for electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These systems need accurate and strong electronics for safety and performance.

In EVs, embedded PCBs control power and energy recovery. They also manage motors and transmissions for smooth driving. For ADAS, they process data for features like emergency braking and lane warnings.

🚗 Did You Know? The automotive embedded system market may grow to USD 15.05 billion by 2033. This is because cars need more advanced electronics.

Embedded PCBs fix problems with old sensors and actuators. For example, they help track car maintenance and theft. These improvements make cars safer and easier to use.

Aerospace: Lightweight and High-Performance Systems

In aerospace, embedded PCBs help make strong and light systems. Planes and spacecraft need electronics that handle heat, shaking, and radiation. Embedded PCBs meet these needs by putting parts inside the board.

These PCBs also improve signals for communication and navigation. Shorter paths mean less interference and better performance.

🌍 Global Perspective: North America leads in using embedded PCBs, with 51% of the market. Europe follows with 24%, focusing on lightweight designs.

Embedded PCBs help make advanced systems like satellites and drones. Their small and efficient designs allow engineers to create safe and innovative technology.

Embedded PCBs keep improving aerospace systems, making them ready for future challenges.

Medical Devices: Small and Reliable Tools

Embedded PCB parts are very important for modern medical tools. These tools need to be small and work well in healthcare settings. By putting parts inside the PCB, makers can shrink devices without losing features. This is crucial for portable tools like insulin pumps, pacemakers, and hearing aids, where space is tight.

Putting parts inside the PCB also makes medical tools more reliable. The parts are protected from things like water, dust, and damage. This helps devices like imaging machines and patient monitors work correctly for a long time. Fewer solder joints also mean fewer chances of breaking, which is vital for life-saving tools.

Another benefit is better heat control. Medical tools often run all the time and get hot. Embedded parts spread heat evenly, stopping hot spots and keeping performance steady. For example, special cooling systems like microchannels can be added to handle heat better.

📌 Tip: Use materials and methods that meet healthcare rules, like ISO 13485, to make safe and effective devices.

Industrial Automation: Tough and Compact PCBs

Factories depend on embedded PCBs to make strong and compact systems. These systems must handle tough conditions like heat, pressure, and shaking. Embedded PCBs are great for these jobs because they are durable and save space.

In factory sensors and machines, embedded PCBs face stress and material problems. Shaking and shocks can break parts or solder joints. Embedded designs fix this by keeping parts safe inside the board. Coatings can also protect against water and chemicals, making them work well in rough places.

High-density embedded PCBs pack many features into one board. This removes the need for extra boards, saving space and making systems simpler. For example, robots use embedded PCBs to control motors, process data, and communicate in a small space. This makes them work better and need less fixing.

📊 Fact: Embedded PCBs in factories cut downtime by reducing failures, boosting productivity.

To improve even more, makers use advanced methods like adding copper layers or antennas into 3D-printed parts. These ideas balance performance and design, making embedded PCBs perfect for factory systems.

📌 Note: For factory use, pick materials that handle heat and use tools to predict and fix risks.

Challenges in Designing and Manufacturing Embedded Components 3D PCB

Design Complexity and Simulation Needs

Creating embedded components for 3D PCBs is a detailed process. Designers must think about signal quality, heat control, and power flow. Advanced simulation tools are needed to predict how the design will work. These tools can also find problems like IR drop, where resistance in power paths lowers performance. The formula ( R = rho cdot frac{L}{A} ) shows how material and size affect circuits.

Some simulation tools offer features like batch testing and power reports. However, many do not support embedded components, making the job harder. Below is a table showing what current tools can and cannot do:

Feature/Limitations | Description |

|---|---|

User Interface | Compact design for better productivity |

Batch Analysis | Allows multiple simulations at once |

Network Complexity | Handles more complex circuit networks |

Simulation Results | Provides detailed power usage reports |

Limitations | Lacks support for embedded components |

Resistance in power paths affects performance |

To solve these issues, use simulation tools made for embedded PCB designs.

Changes in Manufacturing Processes

Making 3D PCBs with embedded components needs special methods. Regular techniques often don’t work well for these designs. Processes like injection molding and laser activation are key for precise circuits. For example, lasers activate metal particles in plastic to create conductive paths. This ensures accuracy and reliability.

Here’s a table of the main steps in the manufacturing process:

Step | Description |

|---|---|

Injection Molding | Uses thermoplastic material with added components. |

Laser Activation and Structuring | Lasers activate metal particles in plastic to form circuits. |

Metallization | Adds nickel and gold layers for conductivity. |

Assembly | Uses standard SMT processes for placing and soldering parts. |

By using these methods, you can simplify the production of embedded PCBs.

Testing and Quality Checks

Testing 3D PCBs with embedded components is very important. Tests must mimic real-world conditions like heat, shaking, and moisture. Burn-in tests push parts to their limits to find weak spots early. Accelerated life testing (ALT) predicts how long parts will last under stress, like heat or heavy use.

Modern tools also help improve quality. For example, AI-powered platforms can spot risks like mismatched thermal expansion. These tools help refine designs and make them stronger. Using thorough testing ensures your embedded PCBs meet standards and work well in tough environments.

📌 Tip: Use different testing methods to catch problems early and make products last longer.

Cost Implications for Low-Volume Production

Making embedded 3D PCBs in small amounts costs a lot. Buying equipment and materials can be more expensive than the benefits. For example, a Dragonfly 3D PCB printer costs $200,000 to $400,000. This price includes basic software but not extra features. Advanced software and yearly licenses add $5,000 to $20,000 each year.

Special materials like conductive and dielectric inks also cost a lot. These inks can cost $5,000 to $15,000 per year, depending on how much is used. Maintenance and support services, like training, add $10,000 to $30,000 yearly. Below is a table showing these costs:

Cost Type | Details | Estimated Cost Range |

|---|---|---|

Printer Cost | Price of the Dragonfly system with basic software | $200,000 – $400,000+ |

Software & Licenses | Advanced software and yearly license fees | $5,000 – $20,000+ per year |

Consumable Materials | Cost of special inks for printing | $5,000 – $15,000+ per year |

Maintenance & Support | Training, repairs, and technical help costs | $10,000 – $30,000+ per year |

These high costs make small-scale production hard for startups or small companies. But for industries needing custom designs or prototypes, the benefits may be worth the expense.

Material and Supply Chain Challenges

Making embedded parts for 3D PCBs has supply chain problems. A global shortage of semiconductors has slowed production and raised costs. This shortage, made worse by COVID-19, affects industries that use embedded components.

Other issues, like world events, also disrupt supply chains. These events can limit raw materials and factory services. Below are some key problems:

Semiconductor shortages raise costs and slow production.

High demand for electronics strains supply chains.

Trade restrictions and global events limit material availability.

These problems show why planning and flexibility are important in 3D PCB production. Using different suppliers and materials can help reduce risks and keep production running smoothly.

Embedded components in 3D PCBs bring big changes to electronics. They help make devices smaller and fit more parts inside. Shorter connections improve signals and make devices work better. Fewer solder joints mean stronger devices that last longer. Easier assembly also cuts costs, making these PCBs great for cars, planes, and healthcare tools.

More industries are using embedded PCBs because of their benefits. From phones to 3D-printed gadgets, these parts boost innovation. New trends include 3D printing and eco-friendly materials like plant-based fibers. The market is growing fast due to IoT, AI, and 5G needs.

In the future, 3D PCBs will keep improving. Advanced methods will allow custom designs for special uses. Flexible and heat-resistant PCBs will handle next-gen devices. As green production grows, embedded parts will shape smarter and cleaner electronics.

📌 Note: Using embedded components in 3D PCBs isn’t just about better tech. It’s a move toward smarter, stronger, and greener electronics.

FAQ

What are the main advantages of embedded components in 3D PCBs?

Embedded components help make devices smaller and stronger. They improve signals and lower production costs by simplifying assembly. These features are useful for industries like electronics, cars, and planes.

How do embedded components improve thermal management?

Embedded components spread heat evenly across the PCB. This stops overheating and keeps devices working well. Special cooling systems, like microchannels, help manage heat for powerful devices.

Are embedded PCBs more expensive to produce?

Making embedded PCBs costs more at first because of special tools. But over time, they save money by needing less assembly and lasting longer. For big projects, the savings are worth the higher starting cost.

Can embedded PCBs handle harsh environments?

Yes, embedded PCBs are very tough. Parts inside the board stay safe from damage, shaking, and extreme heat. This makes them great for jobs in planes, cars, and factories.

What industries benefit the most from embedded PCBs?

Industries like electronics, cars, planes, healthcare, and factories use embedded PCBs. They make devices smaller, work better, and last longer, which is important for modern technology.

💡 Tip: Think about where the device will be used. Match the design to the environment for the best results.

See Also

Exploring The Role And Advantages Of PCBA Today

Unveiling The Surprising Advantages Of PCBA SMT

Understanding The Pros And Cons Of Flex PCBA