Choosing a good company for prototype to production PCBA services is very important. New tools like robots and AI have changed how electronics are made. These tools make things faster and cheaper. In March 2020, North American PCB shipments grew by 3.7% from the year before. Bookings also went up by 8.7% compared to the previous month. This shows why picking a provider with modern tools for prototype to production PCBA services matters. Check their skills, quality, prices, and ability to grow to succeed.

Key Takeaways

Pick a PCBA provider with up-to-date tools. New tools make work faster and better.

Find providers with good quality checks. Certifications like ISO and IPC mean safe and reliable PCBs.

Choose a manufacturer that makes prototypes quickly. Fast prototypes let you test and fix designs fast.

Think about long-term benefits, not just saving money now. Good designs can save money and improve quality later.

Make sure you can talk easily with your provider. Clear support prevents delays and keeps your project moving.

Evaluating Technical Capabilities in Prototype to Production PCBA Services

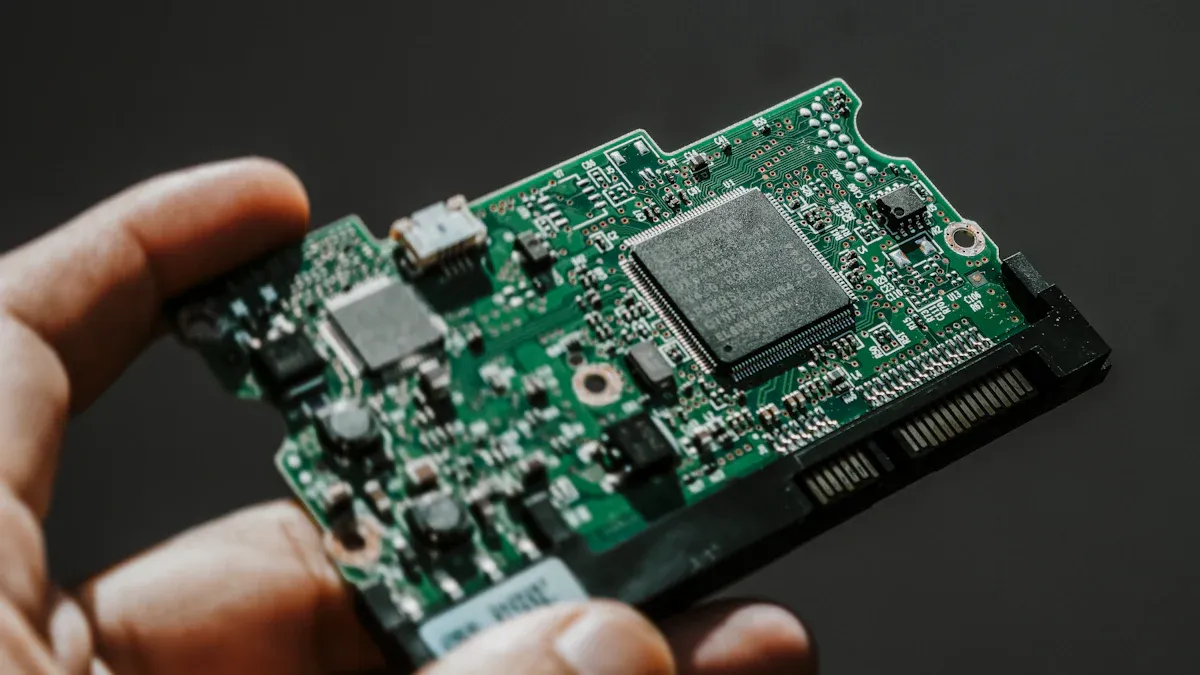

Importance of advanced technology and equipment

When picking a PCBA provider, choose one with modern tools. Automated machines, like pick-and-place, help place parts accurately. This improves speed and makes assembly more consistent. Reflow ovens with precise temperature control ensure good soldering quality. Tools like AOI systems and X-ray machines find errors in complex designs. These include tricky layouts like BGAs. Such technology reduces mistakes and makes PCBs more reliable.

To improve quality, providers use in-circuit and functional testing. These tests check if every PCB works before delivery. Picking a provider with these tools ensures fast prototypes without losing quality.

Expertise in pcb prototype assembly and complex designs

Good PCB prototype skills help fix design problems early. Prototyping lets you test your design before mass production. This is key for complex PCBs with tight layouts or many parts. Skilled providers run tests like IST and HAST to find hidden issues. They also do AOI and functional tests after production to meet your needs.

Prototyping checks each part step by step. This helps improve designs for large-scale production. A good provider will guide you, making the process smooth and efficient.

Comprehensive range of pcb assembly services

Providers with many PCB assembly options can handle different projects. Top companies offer SMT, PTH, and mixed technology assembly. They also use soldering methods like wave and reflow soldering. Whether you need small or large production, flexible providers can adjust.

Special services like lead-free assembly and turnkey solutions are also offered. These services manage everything from buying parts to final assembly. Choosing a provider with full services keeps your project on track and meets standards.

Ensuring Quality Assurance with the Best PCB Manufacturer

Role of certifications like ISO and IPC standards

Certifications help ensure PCB assembly is reliable and high-quality. Look for manufacturers with certifications showing they meet strict rules. ISO 9001:2017 checks their quality system, while ISO 14001:2017 focuses on eco-friendly practices. ISO 13485:2016 is for medical devices, and IATF 16949:2016 is for cars. These certifications prove they can handle specific industry needs.

The IPC sets global rules for PCB quality. It divides PCBs into three classes, with Class 3 being the most reliable. Manufacturers following IPC rules make strong and durable PCBs. This is crucial for industries like aerospace and automotive, where mistakes can’t happen.

Certification | What It Ensures |

|---|---|

ISO 9001:2017 | Strong Quality Management |

ISO 14001:2017 | Eco-Friendly Practices |

ISO 13485:2016 | Medical Device Quality |

ISO 45001:2018 | Workplace Safety |

ISO 27001:2013 | Information Security |

IATF 16949:2016 | Automotive Quality |

Testing processes to minimize failure rates

Testing helps reduce mistakes in PCB assembly. Manufacturers use different tests to check quality. AOI finds soldering errors and misplaced parts. X-ray testing spots hidden problems in tricky designs like BGAs. Functional testing checks if the board works under real conditions.

Other tests, like ICT, find electrical issues like shorts or open circuits. Solderability testing ensures joints are strong, while contamination testing stops corrosion. These tests help manufacturers deliver reliable PCBs with fewer problems.

Testing Method | What It Does |

|---|---|

Visual Inspection | Finds soldering and assembly mistakes. |

Electrical Testing | Spots shorts and open circuits. |

X-ray Testing | Finds hidden solder joint issues. |

Micro-Sectioning | Examines material problems. |

Solderability Testing | Checks if solder sticks well. |

Contamination Testing | Stops corrosion from dirty surfaces. |

Use of high-quality materials and components

Good materials make PCBs last longer and work better. High-quality metals and polymers resist moisture and heat. These materials keep PCBs working for a long time. Manufacturers also check materials carefully to meet industry rules.

Eco-friendly materials are important too. They last longer and help protect the planet. Recyclable products reduce waste and support sustainability. Picking a manufacturer that uses strong and green materials ensures your PCBs are reliable and eco-friendly.

Turnaround Time and Delivery Efficiency in PCB Assembly Services

Quick-turn capabilities for prototypes

Quick-turn services help speed up making prototypes. They let you test and improve designs quickly. This saves time in fast-moving fields like healthcare and electronics. With quick-turn PCBs, you can get working models in just 24 hours. This helps you test ideas and make changes faster. Most quick-turn services deliver in 1 to 5 days. This is great for checking designs and fixing problems early.

Tip: Pick a provider with smart tools and smooth processes. This ensures fast delivery without losing quality. It’s very important for industries like cars and medicine, where speed matters.

Turnaround Time | What It Means |

|---|---|

24 hours | Get prototypes fast for quick testing. |

5 days | Rapid services help improve designs quickly. |

2 to 8 weeks | Regular timelines show why quick-turn is better. |

On-time delivery for production orders

Delivering on time is key to keeping schedules and happy customers. Providers with good systems and smart tools can handle urgent orders well. This avoids delays and keeps promises. For example, companies aiming for 95% on-time delivery often fix delays and improve shipping plans.

Metric | Current Rate | Goal Rate | Steps Taken |

|---|---|---|---|

On-Time Delivery (OTD) | 85% | 95% | Improved shipping and fixed production delays. |

Delivery Accuracy | 93% | N/A | Added checks to match orders with needs. |

Order Cycle Time | 10 days | ≤ 7 days | Made supplier times faster and approval steps easier. |

Meeting project deadlines without compromising quality

Staying on schedule while keeping quality high is important. Providers with 90% to 100% on-time rates deliver steady results. Missing deadlines can cause problems and upset customers. Picking a provider with strong quality checks helps avoid delays. This ensures your PCB assembly meets all rules and stays on time.

Note: High on-time rates lower risks like making too much or too little. This helps your projects succeed without issues.

Balancing Cost-Effectiveness and Quality in a PCB Assembly Company

Looking at long-term value instead of short-term savings

Picking a PCB assembly company just for low prices can cause problems. Hidden costs and poor quality might show up later. Instead, focus on ways to save money over time. Design for Manufacturability (DFM) makes production easier and keeps quality high. Choosing common parts avoids delays from shortages. Making the right number of products helps balance costs and future needs.

Strategy | What It Does |

|---|---|

Design for Manufacturability (DFM) | Makes designs simpler to build, saving money and keeping quality. |

Smart Component Selection | Picks easy-to-find parts to avoid delays and keep costs low. |

Optimizing Production Volume | Produces the right amount to save money and plan for growth. |

Balancing Automation and Manual | Combines machines and people to work faster and cheaper. |

Streamline Testing and Quality | Uses smart testing to save money without lowering quality. |

Using these ideas helps save money while keeping products reliable and working well.

Tip: Work with your PCB maker to find ways to save money during the product’s life.

Clear pricing and avoiding surprise costs

Clear pricing is important when choosing a PCB assembly company. Hidden costs, like extra inventory or slow processes, can raise your budget. Companies like XYZ Manufacturing show why tracking costs matters. They studied their production and fixed unprofitable items.

Watching production closely can improve efficiency by 15-20%.

Managing inventory well stops leftover stock and hidden costs.

Picking a trusted company ensures clear communication and honest pricing.

Tracking important numbers and working with your provider helps avoid surprise costs and keeps your budget safe.

Why DFM and DFA checks matter

DFM and DFA checks help lower costs and improve quality. These methods make production and assembly easier. Fewer parts mean less complexity and lower costs. Using standard parts makes tools simpler and reduces mistakes.

Principle | Before | After |

|---|---|---|

Many parts make things costly and complicated. | Combining parts into one saves money and time. | |

Standardization | Different tools are needed for different parts. | Using the same parts makes tools simpler and faster. |

Orientation and Handling | Odd-shaped parts can be placed wrong. | Symmetric parts are easier and quicker to assemble. |

Adding DFM and DFA checks improves product quality, speeds up production, and meets industry rules. These steps also cut waste and use materials better, helping the environment.

Note: A smart design saves money and makes moving from prototype to production easier.

Customer Service and Communication in PCB Prototype Assembly

Importance of responsive and knowledgeable support

Good support helps make the PCB assembly process smooth. Quick replies and helpful answers solve problems fast. This saves time and avoids costly delays. Top companies reply in 1-2 hours to show they care. Fast responses build trust and keep customers loyal. Companies that listen to feedback improve their services. They value your ideas and follow industry trends to get better.

Clear communication on BOM and assembly instructions

Clear BOM and instructions are key for making PCBs. A detailed BOM shows costs clearly and avoids surprises. Limit who can edit the BOM to keep it organized. Let others view it but assign one person to manage changes. Clear part instructions save time and prevent confusion. A complete BOM helps avoid mistakes and ensures your ideas work well.

Availability of technical consultation and guidance

Expert advice improves your PCB assembly project. Good providers help with design, materials, and quality checks. Their tips stop common mistakes and meet industry rules. Skilled consultants solve tricky design problems easily. Picking a provider with strong technical support helps your project succeed.

Tip: Check how fast a provider replies and handles feedback. This shows if they meet your needs.

Certifications and Compliance in Prototype to Production PCBA Services

Following rules like RoHS and UL

Pick a PCB maker that follows important industry rules. RoHS limits harmful substances in electronics. UL checks the safety of electrical devices. These certifications keep products safe and ready for global markets.

Good PCB makers provide proof they follow these rules. Material lists show all substances used. Certificates confirm each batch meets RoHS standards. Lab tests check materials for safety. Product labels show compliance, and tracking systems ensure rules are followed during production.

What It Ensures | |

|---|---|

ISO 9001 | Strong quality management |

IPC Standards | Reliable electronics manufacturing |

UL Certification | Safe electrical devices |

RoHS | No harmful substances in electronics |

REACH | Safe use of chemicals |

Proof Type | What It Shows |

|---|---|

Material Lists | Lists chemicals used, including RoHS ones. |

Certificates | Confirms batches meet RoHS rules. |

Lab Tests | Validates materials are safe. |

Product Labels | Shows RoHS compliance on items. |

Tracking Systems | Ensures rules are followed in production. |

Eco-friendly practices and following environmental rules

Modern PCB makers care about the planet. They use less energy and materials to save resources. Recycling systems help reduce waste. Pollution controls manage emissions and water use to avoid harm.

Certified makers follow eco-friendly rules like ISO 14001. Choosing these providers helps protect the environment and meet global standards.

Saving Resources: Uses less energy and materials.

Recycling Waste: Reduces trash with recycling systems.

Stopping Pollution: Controls emissions and water use.

Following Rules: Meets ISO 14001 and local laws.

Why certified providers matter

Certified PCB makers meet industry and environmental rules. ISO 9001 and IPC standards ensure high-quality processes. RoHS and UL certifications mean products are safe and follow rules. These certifications also make products easier to sell in strict markets.

Certified makers are more reliable. They test products carefully and track materials. This lowers risks and keeps quality steady. Working with certified providers ensures your project succeeds without problems.

Tip: Check a provider’s certifications before starting. This avoids issues and ensures compliance.

Flexibility and Scalability with the Best PCB Manufacturer

Ability to handle varying production volumes

Managing production sizes well is very important. A good PCB manufacturer can handle both small and large orders easily. They use strong supply systems to get materials on time. By studying past data, they predict needs and avoid running out of stock. Tracking inventory in real-time keeps everything on schedule and efficient.

Aspect | Description |

|---|---|

Supply Chain Management | Reliable suppliers deliver materials quickly, avoiding delays. |

Demand Forecasting | Past data helps predict needs and prevent shortages. |

Production Planning | Plans match demand, ensuring materials are ready. |

Cost Control | Buying in bulk lowers costs for big orders. |

Inventory Management | Real-time tracking stops overstock or running out. |

Flexible Contingency Management | Backup suppliers reduce risks during production. |

Picking the right PCB manufacturer keeps your project smooth and cost-friendly, no matter the order size.

Support for custom requirements and design changes

Modern devices need special PCBs for unique designs. Flexible PCBs, made from bendable materials, fit into tight spaces. These are great for wearables and cars with small designs. Manufacturers with advanced tools and research can meet these needs. They also give design advice to improve your ideas and match production needs.

Tip: Choose a manufacturer focused on new ideas and flexibility. This ensures your custom PCBs work well and last long.

Adapting to future growth and scaling needs

The PCB world is changing fast with new trends. Smaller, stronger devices need advanced designs like HDI PCBs. Some manufacturers use new methods to make complex designs with less waste. AI tools help by spotting problems early and improving workflows.

Eco-friendly methods are also becoming popular. Using recyclable materials and saving energy helps the planet. These changes not only meet today’s needs but also prepare for future growth.

Note: Work with a forward-thinking manufacturer to stay competitive and ready for market changes.

Picking the right PCBA provider is key to your project’s success. Look for strong skills, good quality checks, fair prices, and helpful support. Providers with certifications like ISO 9001 and IPC Standards show they care about making reliable PCBs.

When choosing between local and overseas providers, think about cost, delivery time, and communication. Local providers often deliver faster and are easier to talk to. Overseas providers may cost less for big orders but take longer to ship.

Factor | Local Providers | Overseas Providers |

|---|---|---|

Cost | Higher costs due to labor and other expenses. | Lower costs for large orders. |

Lead Time | Faster delivery with shorter wait times. | Slower delivery due to shipping delays. |

Communication | Easier to talk with fewer barriers. | Harder to talk due to time zone differences. |

To make a smart choice, ask for quotes, check certifications, and get advice from experts.

FAQ

1. What is the difference between prototype and production PCBA?

Prototypes check if your design works and find mistakes. They are made in small amounts. Production PCBA is for making many units after the design is ready. It ensures all products are the same and meet market needs.

Tip: Test your prototype carefully before starting production.

2. How do certifications like ISO and IPC impact PCBA quality?

Certifications show the manufacturer follows strict rules for quality and safety. For example, ISO 9001 ensures good quality management, and IPC standards make sure PCBs are reliable. These certifications lower risks and make products better.

Note: Always check a provider’s certifications before starting your project.

3. Why is quick-turn PCB assembly important?

Quick-turn services make prototypes faster. This helps you test and improve designs quickly. It saves time in fast-moving fields like healthcare and electronics. You can meet tight deadlines without losing quality.

4. How can I ensure my PCBA project stays within budget?

Pick a provider with clear pricing. Avoid extra costs by checking the bill of materials (BOM) and assembly steps. Use Design for Manufacturability (DFM) to make production easier and save money.

Tip: Talk to your provider early about ways to save money.

5. What should I look for in a PCBA service provider?

Choose one with modern tools, strong quality checks, and helpful support. Make sure they can grow with your needs and follow rules like RoHS and UL. A good provider will guide you through every step.

Emoji Reminder: ✅ Certifications, 🕒 On-time delivery, 💬 Clear communication.

See Also

Guidelines for Choosing the Right PCB Prototype Manufacturer

Finding the Ideal PCBA Manufacturer for Your Business

Selecting the Perfect PCBA Factory for Custom Needs

Essential Advice for Picking a PCBA Contract Manufacturer

Important Considerations When Selecting a Custom PCBA Manufacturer