Choosing the best PCBA manufacturers is crucial for your project. It ensures you stay on budget and avoid potential issues. When selecting a manufacturer, consider factors like cost, quality, and services to save both time and money. For example:

Smaller PCBA manufacturers might offer lower prices but could compromise on quality and support, leading to higher costs over time.

Focusing on value and quality rather than just price helps prevent breakdowns and expensive repairs.

By partnering with reliable PCBA manufacturers, you can achieve excellent performance and long-term savings, keeping your projects running smoothly for years to come.

Key Takeaways

Pick manufacturers with clear prices to avoid hidden fees. Detailed quotes make comparing choices easier.

Focus on good materials and assembly for strong PCBs. This helps them work well and last longer.

Quick delivery is important for finishing projects on time. Choose manufacturers who are fast to keep your work moving.

Helpful customer service makes things better. Find manufacturers with teams that answer questions quickly.

Think about extra services like testing and green practices. These can make your project better and eco-friendly.

Key Factors When Comparing PCBA Manufacturers

Pricing and cost transparency

When picking PCBA manufacturers, knowing their prices is very important. Clear pricing helps you avoid surprise fees or extra costs. Choose manufacturers who give detailed quotes. These quotes should show costs for materials, assembly, and extra services. This makes it easier to compare prices between different companies.

Some companies may offer low prices but might lower quality or service. Others charge more but include helpful extras like design help or testing. Always check if the price matches the quality and services offered. For example, a company offering pre-production and functional testing may charge more but provide better reliability.

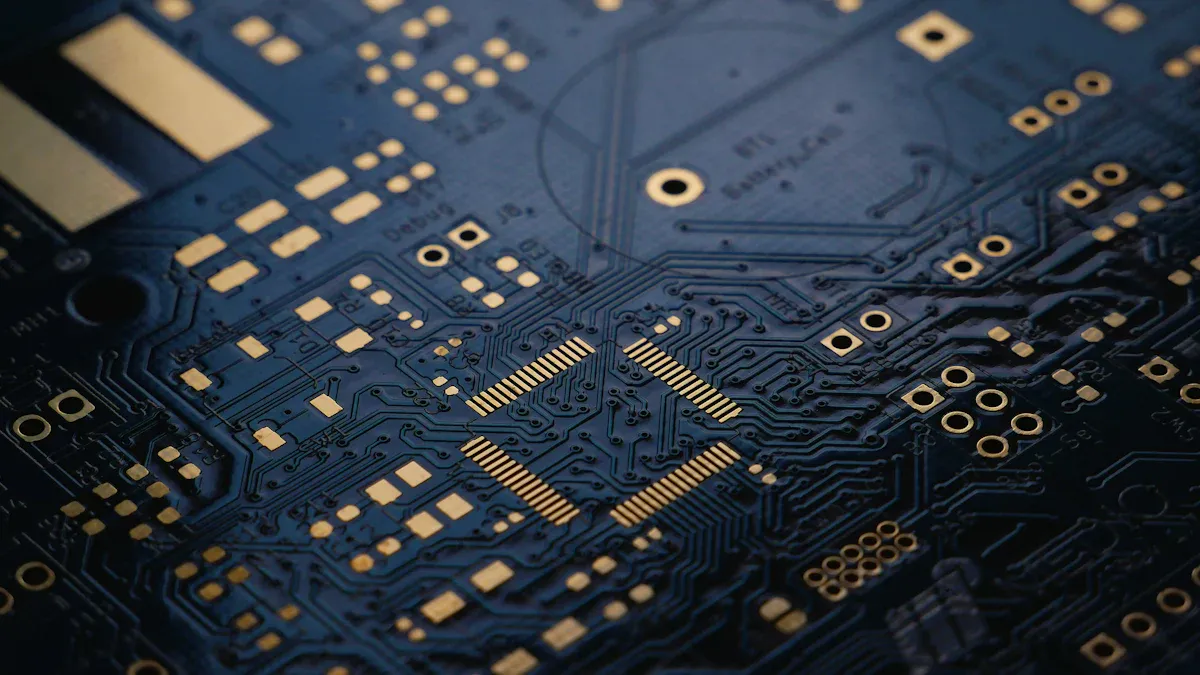

Quality of materials and assembly

Good materials and assembly affect how well your PCB works. High-quality materials, like polyimide and Rogers, are great for tough jobs like aerospace or communication systems. Metal core PCBs are best for LED lights and power electronics because they handle heat well.

Trusted companies use advanced tools to check for mistakes. Automated Optical Inspection (AOI) finds issues like solder problems. X-ray checks for hidden errors in multilayer PCBs. Good manufacturers test at many stages, like before production, during assembly, and after production. These steps ensure your PCB is top quality.

Material | Properties | Applications |

|---|---|---|

Polyimide Substrates | Handles high heat | Military and Aerospace uses |

Rogers Materials | Low signal loss, great dielectric | RF and microwave systems |

Metal Core PCBs | Great at handling heat | LED lights and power electronics |

Delivery speed and lead times

Fast delivery is key to finishing projects on time. Some PCB companies deliver much faster than others. For example, ALLPCB can send 1-2 layer boards in one day. Other companies may take 3-5 days. For 6-layer boards, ALLPCB delivers in two days, which is three times faster than most.

PCB Type | Traditional Manufacturer Lead Time | ALLPCB Lead Time | Speed Comparison |

|---|---|---|---|

Standard 1-2 layer board | 3-5 days | 1 day | three times faster |

Standard 4-layer board | 5-7 days | 2 days | twice faster |

Standard 6-layer board | 7-10 days | 2 days | three times faster |

Standard 1-2 layer low volume | 7-15 days | 1-3 days | five times faster |

Quick replies and fast file checks also help with faster delivery. Picking a reliable PCB company with proven speed keeps your projects on schedule.

Customer service and communication

Good customer service and clear communication are very important. A company that communicates well helps your project go smoothly. Look for manufacturers with helpful support teams and fast replies. They should also give regular updates about your order.

Great customer service makes a big difference. Companies with happy customers often get more repeat business. For example, manufacturers with a Net Promoter Score (NPS) over 50 see more returning customers. Fast replies also make customers happier by solving problems quickly.

Metric | How It Helps Customers |

|---|---|

Customer Satisfaction Scores | Show service quality and customer happiness |

Net Promoter Score (NPS) | |

Response Times | Faster replies lead to happier customers |

Picking a manufacturer with great service saves time and reduces stress. They fix problems fast, keeping your project on time and on budget.

Extra services from PCBA manufacturers

Some PCBA manufacturers offer extra services to help your project. These services handle complex designs and cut down on waste. For example, rapid prototyping lets you make custom PCBs faster. This saves time and allows for unique designs.

Other manufacturers focus on being eco-friendly. They use green materials, save water, and recycle. These actions lower harmful waste and support the environment.

Many manufacturers also test their products to ensure they work well. High-quality PCBs prevent problems and save money by avoiding repairs.

Choosing a manufacturer with these extra services improves your process. It boosts product quality and supports a greener future.

PCB Manufacturers Comparisons: Strengths and Weaknesses

Affordable PCB manufacturers: Pros and cons

Affordable PCB makers are great for saving money. They offer low prices, perfect for small projects or hobbies. For example, JLCPCB is fast and cheap, while OSHPark makes high-quality boards but costs more. These companies help you save money while keeping basic features.

But, low cost can mean some downsides. Some companies might not have advanced tools or consistent quality. For instance, DigiKey Red has great solder masks but poor silkscreen details. They may also struggle with complex designs. It’s important to balance price and quality when picking affordable PCB makers.

Pros | Cons |

|---|---|

Quality may vary | |

Quick production times | Fewer advanced features |

Good for small or hobby projects | May not handle complex designs |

High-quality PCB manufacturers: What to expect

High-quality PCB makers focus on precision and dependability. They use advanced machines and skilled workers to meet high standards. For example, ISU Petasys and Daeduck Electronics make top-notch multi-layer and HDI PCBs for tough jobs.

These companies follow strict quality checks, like automated tests and inspections. They invest in the best tools to ensure reliable results. While they charge more, their durable and high-performing boards are worth it in the long run.

Advanced tools and modern factories.

Careful testing to meet exact needs.

Great for complex and high-tech uses.

Different PCB manufacturers and their unique offerings

Different PCB makers offer special features for various needs. For example, Samsung Electro-Mechanics makes high-density PCBs for advanced uses. Nippon Mektron creates flexible PCBs for tiny gadgets. Unimicron Technology focuses on multi-layer and high-frequency PCBs for top performance.

Manufacturer | Unique Offering | Focus Area |

|---|---|---|

Samsung Electro-Mechanics | High-density PCBs | Advanced technology |

Nippon Mektron | Flexible PCBs | Small and flexible devices |

Unimicron Technology | Multi-layer and high-frequency PCBs | High quality and performance |

Zhen Ding Technology | Wide product range and eco-friendly practices | Various industries |

Knowing these specialties helps you pick the right company. Whether you need flexible, high-speed, or eco-friendly boards, there’s a maker for your project.

Balancing cost and quality in PCB manufacturer selection

Choosing a PCB manufacturer means finding the right mix of cost and quality. Picking the cheapest option might seem smart, but it can cause issues later. Cheaper manufacturers might use bad materials or offer fewer services. This could lead to poor performance, delays, or expensive fixes.

On the flip side, pricier manufacturers often provide better quality and extras. They use strong materials, advanced tools, and do more testing. These steps make sure your PCB works well and lasts longer. For example, some companies include design checks or testing in their services. These extras help avoid mistakes and add value to your project.

Why balancing matters:

Cheap options may mean lower quality and fewer services.

Higher prices often bring faster delivery and stronger materials.

Extra services, like design checks, improve your project’s success.

When comparing manufacturers, think about what they offer besides price. Pick one that fits your project’s needs. If your design is complex, choose a company with advanced tools. If speed is important, go for one with quick delivery times.

Spending a bit more now can save money later. Reliable manufacturers help you avoid delays and costly mistakes. By checking prices, quality, and services, you can pick the best option for your project.

Customer Reviews and Trustworthiness of PCBA Manufacturers

How to understand customer feedback

Customer reviews help you learn if a PCB manufacturer is reliable. They show what past clients think about the company’s work. Look for reviews that talk about product quality, delivery speed, and customer service. Companies with many good reviews often have a strong reputation.

Clear communication is also important in reviews. Companies that reply quickly and explain things well are easier to work with. Even skilled manufacturers can cause problems if they don’t communicate clearly. Pick companies with helpful teams and simple processes for better teamwork.

Tip: Read reviews on trusted websites or forums for honest opinions about different PCB manufacturers.

Spotting warning signs in reviews

Some reviews may show problems with PCB manufacturers. Watch for repeated complaints about late deliveries, bad quality, or poor support. These issues can hurt your project.

Good Signs | Bad Signs | |

|---|---|---|

Experience | Certifications, long history | No credentials or bad reviews |

Delivery Speed | On-time delivery stats | Many delays |

Communication | Quick replies | Slow or unclear responses |

Customer Support | Helpful support teams | Poor service |

Very low prices can be a problem too. Cheap manufacturers might use bad materials or skip important steps. If they won’t share references or factory tours, it’s a bad sign. Always check their certifications and ask for detailed info to avoid mistakes.

What makes a PCB manufacturer trustworthy?

Trustworthy PCB manufacturers focus on quality and reliability. They use advanced tests like AOI and flying probe checks to find errors. These tests make sure the PCB works well and lasts longer.

Testing Type | Why It’s Important |

|---|---|

DFM (Design for manufacturability) | Makes sure the design is easy to produce and cost-effective. |

Automated optical inspection (AOI) | Finds defects by comparing images of the PCB automatically. |

Flying probe test | Tests different parts of the PCB using software-guided probes. |

Good manufacturers also have certifications that prove their quality and eco-friendly practices. These certifications build trust and show they care about high standards. Companies with strong records of reliability and honesty deliver better products.

Note: Picking a manufacturer with certifications and advanced testing tools ensures better PCB quality and fewer problems later.

Decision-Making Tips for Choosing a PCB Manufacturer

Matching your budget to your project needs

Matching your budget to your project helps use money wisely. Start by asking PCB companies for detailed price quotes. These quotes should list costs for materials, assembly, and extra services. Knowing the cost breakdown helps you plan better and avoid surprises.

Think about future costs too. A cheaper PCB company might save money now but cost more later if quality is bad. Balancing price and quality is key to success. For example:

Ask for detailed quotes to see all costs.

Choose durable and reliable options to save money long-term.

Balance low prices with good quality for the best results.

By matching your budget to your needs, you can get affordable and reliable PCBs.

Choosing quality over cost for better results

Picking quality over cost gives big benefits in the long run. Good PCBs lower the chance of problems and last longer. This also improves your brand’s image and work efficiency.

Benefit Type | Description |

|---|---|

Better Savings | Avoiding bad quality saves money and boosts profits. |

Stronger Brand Image | High-quality products make customers trust your brand more. |

Competitive Edge | Quality helps attract customers and charge higher prices. |

Higher Efficiency | Better processes reduce waste and improve productivity. |

Following Rules | Meeting standards avoids risks and keeps your business safe. |

Encouraging Improvement | Focusing on quality inspires new ideas and better products. |

Investing in quality makes sure your PCBs work well and last. It also helps your business stand out as trustworthy and reliable.

Checking how reliable PCB manufacturers are

Checking how reliable PCB companies are helps avoid problems. Look at things like First Pass Yield (FPY), defect rates, and return rates. These numbers show how well a company makes quality products. For example, high FPY means fewer mistakes, and low defect rates mean better quality.

First Pass Yield (FPY): Shows how many products pass tests the first time.

Defect Rate: Measures how many products have problems, with lower being better.

Return Rate: Tracks how many products are sent back due to issues.

Failure Rate: Shows how often products break during use.

Good PCB companies use tools like Statistical Process Control (SPC) to keep quality steady. Certifications and a good history also show they care about doing great work. By checking these things, you can pick a PCB company that fits your project perfectly.

Questions to ask before finalizing a PCBA manufacturer

Before picking a PCBA manufacturer, asking smart questions is important. These questions help you check their skills, quality, and trustworthiness. Focus on these key points:

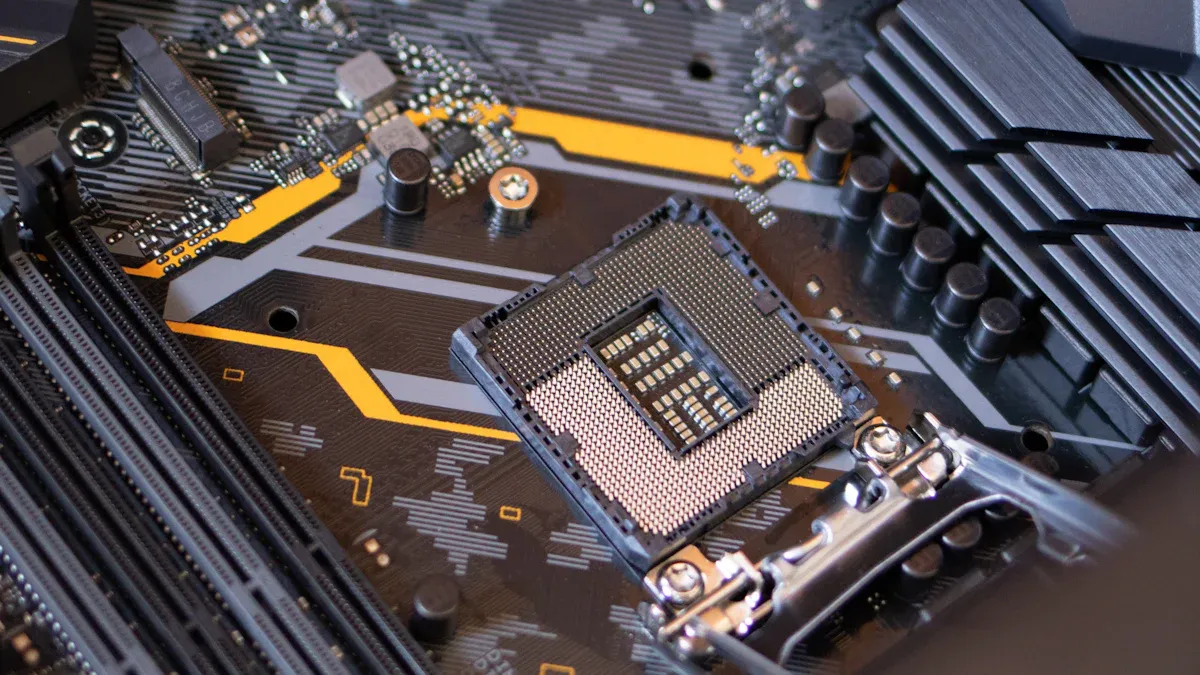

Design Complexity and Capabilities

Find out if they can handle your design needs. For example:Can they make multi-layer boards or use advanced tech like impedance control?

Do they meet your needs for trace width, hole size, or surface finishes?

Knowing their skills ensures they can deliver what you need.

Material Selection and Suitability

Ask about the materials they use. Questions like:What types of substrate materials and copper weights do they provide?

How do they manage heat for your PCB?

Good materials improve how well your product works.

Pricing and Cost Transparency

Understand their pricing to avoid surprises. Key questions:What are the direct and hidden costs?

Do they lower costs without hurting quality?

Clear pricing helps you plan your budget better.

Quality Assurance and Compliance

Check if they follow strict quality rules. Ask:Do they meet IPC class standards and have certifications?

How do they test and inspect during production?

Good manufacturers focus on quality to avoid mistakes.

Turnaround Times and Flexibility

Delivery speed and flexibility matter. Ask:How long do they take for different order sizes?

Can they handle rush orders or change schedules?

Flexible companies help you meet deadlines without losing quality.

Risk Mitigation Strategies

Learn how they handle risks. Important questions:Do they offer prototypes or small-batch testing?

How do they track performance and fix problems?

These steps ensure your project stays reliable.

Details | |

|---|---|

Design Complexity Factors | Layers, Trace width, Hole size, Impedance control, Surface finish needs |

Material Selection | Substrate type, Copper weight, Heat management, Dielectric properties |

Pricing and Cost Structure | Direct costs, Hidden costs, Cost-saving strategies |

Quality Assurance and Compliance | IPC standards, Certifications, Safety rules, Testing methods |

Negotiation and Contract Finalization | Clear specs, Communication plans, Performance goals, Backup plans |

Risk Mitigation Strategies | Prototypes, Small-batch testing, Quality checks, Performance tracking |

By asking these questions, you can see if the manufacturer fits your project. Careful checks ensure you get great PCBs and dependable service.

Picking the right PCBA manufacturer needs careful thought. Look at pricing, quality, and services. Check if they have certifications like ISO 9001. This shows they care about quality and meeting standards. Pricing is also key. Making a PCBA costs more than just the bare board. For example, a bare PCB might cost $5, but adding assembly can raise it to $30. Services like delivery times are important too. PCBA production takes longer because it has more steps than making bare PCBs.

By focusing on these points, you can choose wisely. Use this guide to balance cost and quality. This way, you’ll find a reliable manufacturer that fits your needs.

FAQ

What is the difference between PCB and PCBA?

A PCB is just a plain board with no parts. PCBA means the PCB has all parts added and is ready to use. PCBA includes steps like soldering and testing to make it work in devices.

How do you choose the best PCB manufacturing company?

Pick companies with clear prices, good materials, and fast delivery. Read reviews and check for certifications. Make sure they offer services like prototyping or testing that fit your project.

Why is quality important in PCB manufacturing?

Good quality makes sure your PCB works well and lasts longer. Bad boards can break, cause delays, or cost more to fix. High-quality boards lower risks and help your project succeed.

Can affordable PCB manufacturing companies deliver good quality?

Yes, some low-cost companies make good boards for simple projects. But for complex designs, you might need to spend more on companies with better tools and testing.

What certifications should PCB manufacturing companies have?

Look for ISO 9001 for quality and IPC standards for PCB making. These show the company follows strict rules and makes reliable products.

See Also

Selecting The Ideal PCBA Manufacturer For Your Needs

Finding The Perfect PCBA Supplier For Business Growth

Essential Tips For Selecting A Reliable PCBA Partner