Choosing the right circuit boards and printed circuit board services depends on what your project needs. You may need boards that are strong, bendy, or fit a special use. It is important to look at quality, how well they work, and what you get for the price. There are many pcb and printed circuit board products to pick from. The table below shows top types and where they stand in the market:

Product Type | Market Share | Key Companies |

|---|---|---|

Rigid PCBs | ||

Multilayer PCBs | Biggest overall | Samsung, Nippon Mektron |

Flexible PCBs | Rapid growth | Elephantech |

Makers all over the world sell single-sided, double-sided, multilayer, flexible, and rigid-flex pcb choices. These serve many kinds of businesses and help everyone find what they need.

Key Takeaways

Pick the best circuit board for your project’s needs. Think about strength, flexibility, size, and signal speed. Rigid boards are strong and resist heat. Flexible and rigid-flex boards fit in small or moving spaces. Surface finishes like ENIG help with soldering. They also protect boards from rust and make them last longer. Choose the right board class and maker to save money and get good quality. This helps you avoid problems later. Work with trusted makers from the start. Use design tools to make strong and reliable circuit boards.

Circuit Board Types

Rigid Boards

Rigid boards are used in most electronics. They are made from strong materials like fiberglass or epoxy resin. These boards let you put many parts close together. This helps make products smaller. Rigid boards are tough and handle heat well. They work well in computers, smartphones, and medical devices. Fixing them is easy. Making lots of them keeps the quality the same. Rigid boards have a good surface for soldering. This helps parts stick well.

Rigid boards are best when you need strength and heat resistance.

Flexible PCB

Flexible pcb can bend, twist, or fold. They use bendy materials. This makes them great for small things like cameras and wearables. Flexible pcb saves space and weight. They work fast and handle shaking or bumps. Many industries use flexible pcb because they fit in tight spots. They also last in tough places. Flexible pcb has a good surface for soldering. This helps parts stay on and lowers mistakes. Good flexible pcb works well even in hard conditions.

Flexible pcb lets you make 3D circuits for tiny devices.

Flexible pcb helps get rid of heat and blocks signals.

Flexible pcb cuts down on connectors, saving money and making things stronger.

Flexible pcb keeps soldering strong, even after bending.

Rigid-Flex Boards

Rigid-flex boards mix rigid and flexible pcb in one board. This lets you make small, light products that can bend. Rigid-flex boards are more reliable because they need fewer connectors. This means less chance of breaking. You find these boards in phones, laptops, and medical tools. They handle shock and stress well. Rigid-flex boards have a good soldering surface. This helps them last a long time.

HDI Boards

HDI boards are made for very small spaces. They use thin lines and tiny holes to fit more parts. HDI boards work better and send signals clearly. They are used in 5G, IoT, and AI devices. HDI boards have a smooth surface for soldering. This helps with putting on many pins.

HDI boards are good for fast, complex designs.

HDI boards give strong soldering for hard builds.

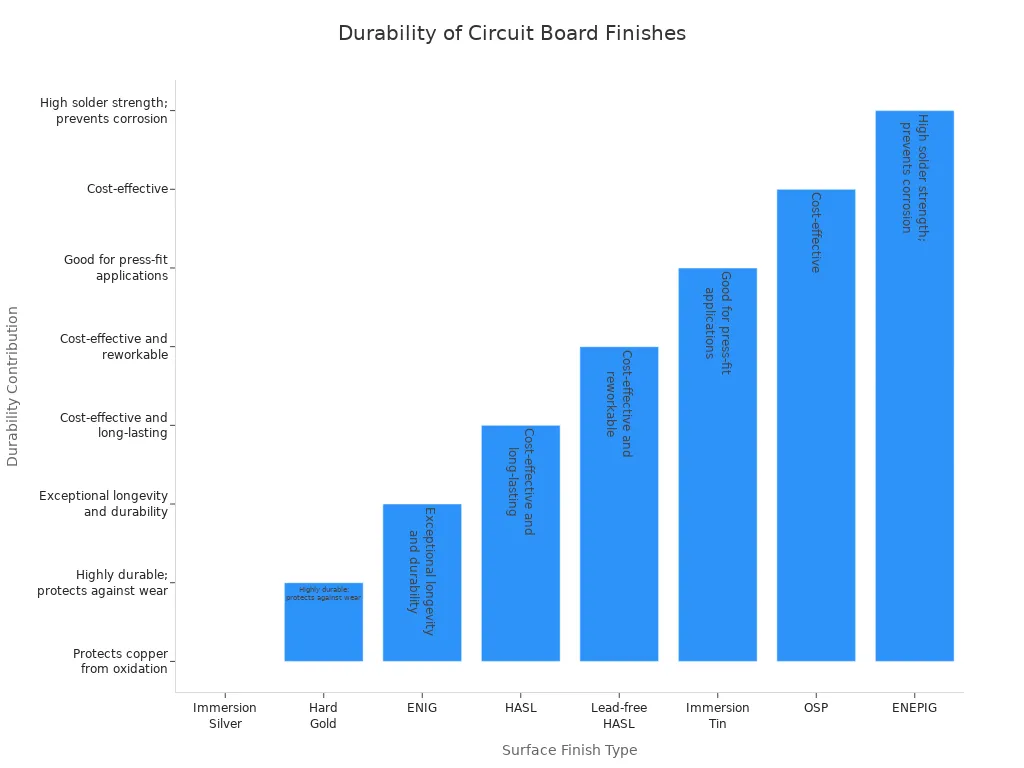

Surface Finishes

Surface finishes keep copper safe from rust and damage. They help the board work well and make soldering easier. ENIG and HASL are common finishes. ENIG stops rust, gives a flat surface, and is good for tiny parts. HASL is cheaper but not as flat or long-lasting as ENIG. Picking the right finish helps boards last longer and makes soldering better, even in tough places.

Surface Finish | Corrosion Resistance | Solderability | Surface Flatness | Signal Integrity | Cost |

|---|---|---|---|---|---|

ENIG | High | Excellent | Flat | High | Higher |

HASL | Moderate | Good | Uneven | Moderate | Lower |

The right finish gives a good surface for soldering and helps the board work well for a long time.

Features & Benefits

Durability

Durability is very important for any pcb. Good boards use strong materials and new ways to make them. This helps them last in tough places. These boards can handle shaking, heat, water, and dust. Surface finishes like ENIG and hard gold give more protection. They help the board last longer and make soldering easier. The right finish keeps copper safe from rust and harm. This focus on durability makes boards work well in medical, aerospace, and car uses.

Flexibility

Flexible pcb lets engineers make things that bend or twist. These boards use polyimide and rolled annealed copper. This gives them both strength and the ability to bend. Flexible pcb works well in wearables, foldable phones, and medical tools. They are thin and light, so they save space and weight. Flexible pcb also helps with soldering and keeps connections strong, even after bending many times. This flexibility helps devices work better in small or moving spaces.

Signal Integrity

Signal integrity is about how well a pcb sends data. Fast signals and high frequencies can cause problems. Bad layout can make crosstalk, reflection, and noise. Good design uses solid reference planes and the right trace width. Proper spacing helps keep signals clear. Flexible pcb and HDI boards need extra care for good signals. Good signal integrity means devices work right, even in hard systems.

Reflection and crosstalk can hurt signal quality.

Controlled impedance and solid ground planes help performance.

Careful layout and spacing cut down noise and mistakes.

Cost Factors

Cost depends on many things like board size and layers. The material and how hard it is to make also matter. Flexible pcb costs more because of special materials like polyimide. HDI and multilayer boards cost more because they need extra steps. Using machines and making lots at once can lower cost. Making boards overseas can be cheaper, but local makers give better service and faster delivery. Picking the right balance helps companies get good boards without spending too much.

Bigger boards and more layers cost more.

Material and surface finish change the price.

Bulk orders and machines make boards cheaper.

Application Fit

Each pcb type is good for different jobs. Single-sided boards are simple and cheap. They work for basic electronics and test projects. Double-sided and multilayer boards hold more parts and give better signals. Flexible pcb fits in small spaces and moving parts. Rigid-flex boards mix strength and bending for medical and aerospace uses. HDI boards are best for fast data and tiny designs. Picking the right board helps every project work well and last long.

PCB Type | Key Features | Best Fit Applications |

|---|---|---|

Single-sided | Simple, low cost | Basic electronics, prototypes |

Double-sided | More parts, better signal quality | Consumer, industrial control |

Multilayer | Complex, high-quality, durable | Aerospace, medical, high-speed tech |

Flexible pcb | Thin, bendable, reliable | Wearables, automotive, medical |

Rigid-flex | Strong, flexible, high reliability | Aerospace, medical, wearables |

HDI | High density, top performance | 5G, computing, advanced electronics |

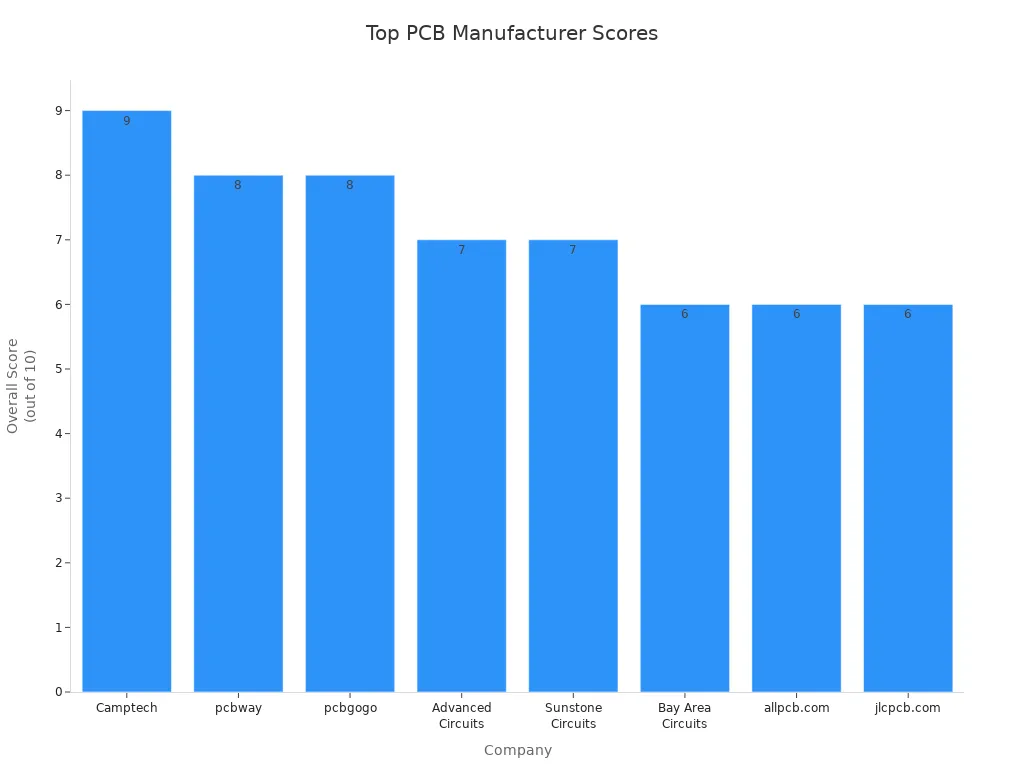

Printed Circuit Board Service Providers

Top Manufacturers

Many companies are leaders in pcb manufacturing around the world. Most of the market is in Asia Pacific, and China is a big center. The table below shows top pcb companies and where they are from:

Leading PCB Service Providers | Country/Region |

|---|---|

Zhen Ding | China |

Unimicron | China |

DSBJ | China |

Nippon Mektron | Japan |

Compeq | China |

Tripod | Taiwan |

TTM Technologies | U.S. |

SCC | China |

Ibiden | Japan |

Hannstar Board | China |

AT&S | Austria |

Rhyming Technology | China |

Sanmina Corporation | U.S. |

Asia Pacific had over half the market in 2023. These companies make many kinds of pcb and do pcb assembly for electronics.

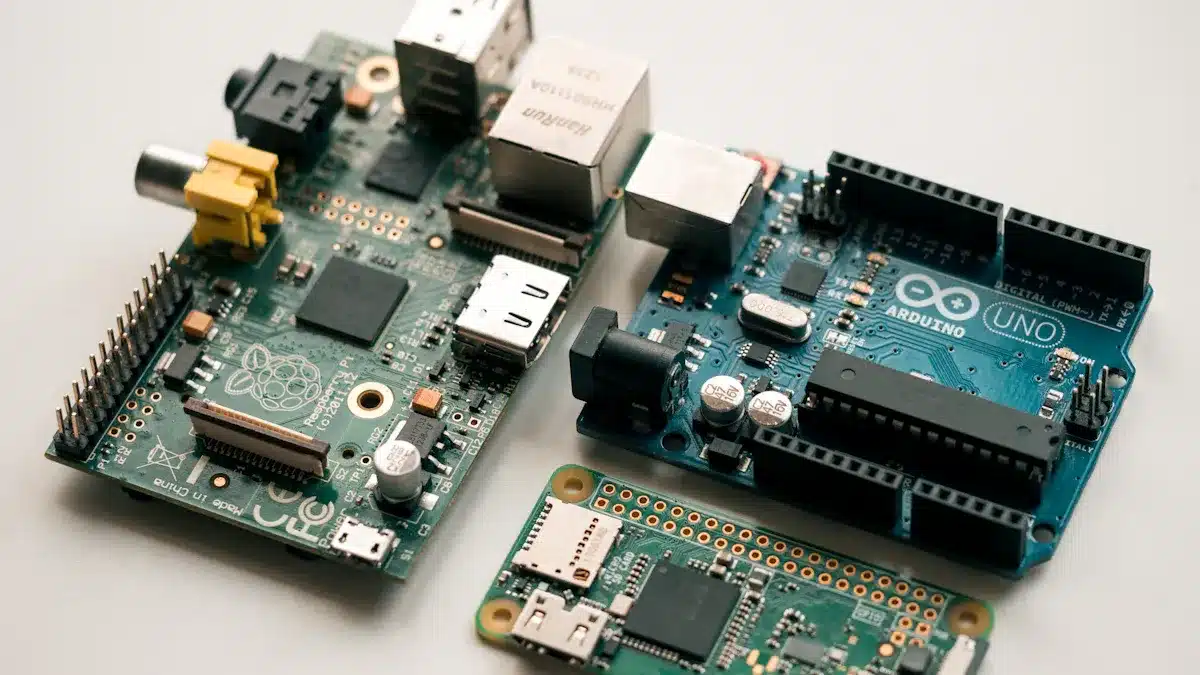

Flexible PCB Manufacturer Comparison

Picking a flexible pcb maker means looking at many things. Companies are different in quality, price, and how they help customers. Certifications like ISO 9001 and UL mean good quality checks. Some, like JHYPCB, focus on making flexible pcb with strict rules and fast work. PCBONLINE uses new machines and gives discounts for big orders. PCBWay ships fast and helps all day but does simple designs. JLCPCB is cheap but only does single-layer flexible pcb. PCBCart sells flexible pcb but does not own factories, so delivery can be slow. People should check experience, machines, and help when picking a flexible pcb maker for good products and happy customers.

Domestic vs Overseas

Both U.S. and overseas companies make pcb and do assembly. U.S. companies like Advanced Circuits and Sunstone Circuits give high quality, fast work, and easy talk. Overseas makers like JLCPCB and PCBWay cost less and let you order small amounts. But shipping takes longer, and customs or quality can be a problem. U.S. companies protect ideas better and are more reliable, but cost more. Overseas is good for hobby pcb makers and cheap samples, but extra costs can show up later.

Domestic PCB Providers (USA) | Overseas PCB Providers (China) | |

|---|---|---|

Quality | High, strict standards | Varies, needs vetting |

Cost | Higher | Lower |

Shipping | Fast, no customs | Longer, customs delays |

Communication | Easy, same time zone | Time zone, language barriers |

Order Flexibility | Standard sizes | Flexible, small batches |

U.S. companies give top pcb making and fast delivery, while overseas makers save money for hobby pcb makers and small jobs.

Online Quoting

Now, online pcb services use tools to help people compare makers fast. These tools let you upload designs, pick materials, and see prices right away. Sites like PCBShopper let you check price, speed, and service from many flexible pcb makers. Real-time quotes help balance cost, quality, and delivery time. Error checks and customer help in these tools lower mistakes and help projects go well. Online quoting makes it simple for teams to pick the best pcb making and assembly for their needs.

Circuit Boards Comparison Table

Features

Circuit boards have different features for many projects. Rigid boards are strong and stable. Flexible PCBs can bend and fold for small devices. Rigid-flex boards mix both for special uses. HDI boards fit lots of parts for fast electronics. ENIG and HASL finishes keep copper safe and help soldering. Many makers let you pick shapes, layers, and special materials.

PCB Type | Strength | Flexibility | Density | Customization | Surface Finish Options |

|---|---|---|---|---|---|

Rigid | High | Low | Medium | Yes | ENIG, HASL, OSP |

Flexible | Medium | High | Medium | Yes | ENIG, OSP |

Rigid-Flex | High | High | High | Yes | ENIG, HASL |

HDI | Medium | Low | Very High | Yes | ENIG, HASL |

Quality

Makers use new tech and strict checks for good boards. Many top companies follow ISO 9001 rules and test at each step. They use good materials for better boards that last longer. IPC rules sort boards by how reliable they are: Class 1 is for simple things, Class 2 is for service, and Class 3 is for very important jobs. TTM Technologies makes boards for planes, while others focus on saving money.

Good makers use machines to check boards and flying probe tests.

Quality checks include DFM review and first article checks.

Customer reviews and warranties show if a company is reliable.

Boards with IPC and ISO rules work well and are always the same.

Pricing

Circuit board prices change by type, size, and how many you buy. Prototypes cost $30 to $250 each, but making many lowers the price to $0.3–$8 each. FR-4 boards are cheap and work well. Aluminum and flex PCBs cost more because they use special stuff and are harder to make. Some, like ALLPCB, sell five 6-layer boards for about $1, but most cost more. Price tools help you guess cost by layers, finish, and how fast you need them.

Material | Prototype Price | Mass Production Price | Notes |

|---|---|---|---|

FR-4 | $30–$100 | $0.3–$2 | General use, low-medium cost |

Aluminum | $50–$200 | $2–$8 | Better heat dissipation |

Flex | $80–$250 | $5–$15 | High flexibility, high cost |

Rogers | $150–$300 | $10–$30 | High-frequency, very high cost |

Services

Top PCB companies do more than just make boards. They help with design checks, fast samples, and putting boards together. Schweizer Electronic and Sanmina do everything, like layout, testing, and building boxes. JLCPCB and PCBWay help find parts and put them on. Many companies let you get quotes online, check designs, and order any amount. Fast samples and quality checks help stop delays and make boards better.

Design help and engineering checks

Fast samples and small orders

Assembly, testing, and full service

Online tracking and customer help

These services help people go from idea to finished board fast and easy.

Choosing the Right Circuit Board

Project Needs

Every project has its own needs. The right circuit board depends on what the device does and where it goes. Some boards must last a long time. Some need to fit in small spaces or handle fast signals. Others must bend or work in tough places.

Factor | Explanation |

|---|---|

Fast or high-frequency signals need special materials and careful design. | |

Mechanical Constraints | Flexible or rigid-flex PCBs are good for tight or 3D spaces. |

Cost and Volume | You must balance cost for one board and for many boards. |

Reliability and Longevity | Cars, planes, and medical tools need strong boards and good checks. |

Thermal Management | Boards must not get too hot or parts can break. |

Manufacturability | Working with makers early helps avoid problems and saves money. |

Common Pitfalls | Do not forget heat, skip maker advice, pick only by price, or miss hard steps. |

Project needs help you pick single-sided, multilayer, or flexible boards. A smartwatch maker may use flexible PCBs for curved shapes. A lighting company may pick rigid aluminum boards to handle heat. Making a sample board helps test ideas before making many.

Provider Evaluation

Picking a good maker is about more than price. Quality, speed, and help are important too. Top makers have special certificates and follow strict rules. They help with design and fix problems early.

Certificates like ISO 9001 or IPC show a maker cares about quality.

Good makers give design tips and help fix issues before making boards.

Reliable makers keep parts ready and avoid delays.

Where the maker is can change how fast you get boards and how easy it is to talk.

Good customer service and tech help solve problems fast and keep work moving.

A good maker delivers on time, answers questions, and keeps high standards. For example, PCBWay checks designs before making boards. Some focus on fast shipping or low prices.

Cost vs Quality

You must balance cost and quality for each project. Cheap boards save money at first but may cause trouble later. Projects that must always work, like in medicine or planes, need the best boards. The table shows how IPC classes change quality and price:

IPC Class | Quality Level | Cost Implication | Typical Use Case / Reliability Requirement |

|---|---|---|---|

Class 1 | Lowest standards | Cheapest | Simple electronics, short life |

Class 2 | Medium quality | Medium price | Service electronics needing to last |

Class 3 | Best quality | Highest price | Very important electronics (medical, military) |

Makers offer different classes for different needs. Class 1 is fine for simple things. Class 3 is best for things that must never fail. Picking the right class helps save money and keep things safe.

Tips

Engineers and designers can use these tips to match boards to their projects:

Put connectors first, then power, then sensitive and important parts.

Keep power and control grounds apart to stop noise.

Use trace width tools to pick the right size for wires and stop heat.

Place decoupling capacitors close to IC power and ground pins.

Change wire directions between layers to make routing easier.

Leave space between parts for wires and soldering.

Face parts the same way to avoid mistakes.

Make high-frequency loops small to cut down noise.

Use pro pcb design and making services for hard projects.

Make sure test points are easy to reach for fixing problems.

Keep hot and heat-sensitive parts apart, and use thermal vias or solid ground planes.

Tip: Work with makers early and plan well during samples to avoid mistakes and make better boards. 🛠️

Picking the best circuit board means you must match design, strength, and price to what your project needs. Engineers should make sure the board is strong and has the right number of layers. They need to check how exact the making process is, how long it takes, and how hard it is to build. The design should fit what the product must do and keep signals working well. Working with skilled makers helps you get good advice.

The table and tips above make choosing easier. Designers can also use special tools for more help, like calculators for wire size, checks for design files, and tools to pick the right parts:

Tool/Resource | Purpose |

|---|---|

Trace Width Calculator | Makes sure wires are the right size |

Finds design problems before making | |

Component Selector | Helps pick parts that fit the design |

Planning carefully and using the right tools helps you get strong, high-quality circuit boards.

FAQ

What is the difference between rigid and flexible PCBs?

Rigid PCBs are made from hard stuff like fiberglass. They cannot bend at all. Flexible PCBs use soft, bendy materials. These can twist or fold easily. Each kind works best for different products.

How do surface finishes affect PCB performance?

Surface finishes keep copper from rusting. They also help make soldering easier. ENIG gives a smooth, strong surface that lasts longer. HASL is cheaper but does not last as long as ENIG. Picking the right finish helps the board work better and last longer.

Why do some projects need HDI boards?

HDI boards hold lots of parts in tiny spaces. They use thin lines and very small holes. These boards are great for fast and tricky devices like smartphones and 5G gear.

What should engineers look for in a PCB manufacturer?

Engineers should look for companies with quality certificates. Fast delivery and helpful customer service are important too. Good companies help with design and test boards before sending them out.

Can online quoting tools help save time?

Online quoting tools let people check prices and delivery times fast. These tools help teams pick the best choice without waiting or sending lots of emails.

See Also

In-Depth Comparison Between PCBWay And Other PCB Makers

How To Discover The Ideal PCBA Manufacturer Within Budget

Choosing The Right PCBA Manufacturer To Meet Business Goals

Tips For Picking The Best RF PCBA Provider For You

Selecting The Perfect PCBA Factory For Custom Specifications