What makes components circuit board different in 2025? Engineers have many options when making a components circuit board. The right parts help the components circuit board work better. They also help save money and make it last longer. Each components circuit board has special features. Some are single-sided, and some have many layers. Printed circuit boards use passive, active, electromechanical, connectors, and sensors. The kind of printed circuit board affects which components circuit board parts designers pick. Today’s pcb technology keeps changing. Each components circuit board gets stronger and uses less energy. Every components circuit board needs the right parts for its job.

Key Takeaways

Circuit board components do many things. They control current and switch signals. They also move parts and connect sections. Some sense changes too. Picking the right parts and PCB type is important. It helps devices work better and last longer. It also saves space and money. Flexible PCBs can bend and fit in tight spots. Rigid PCBs hold heavy parts and stay in shape. In 2025, new trends are coming. Parts are getting smaller and smarter. Materials are becoming greener. Manufacturing methods are getting better. Good design is very important. Placing parts carefully helps a lot. Matching parts to the PCB’s job makes things work well. This also makes devices more reliable.

Types of Circuit Board Components

Passive Components

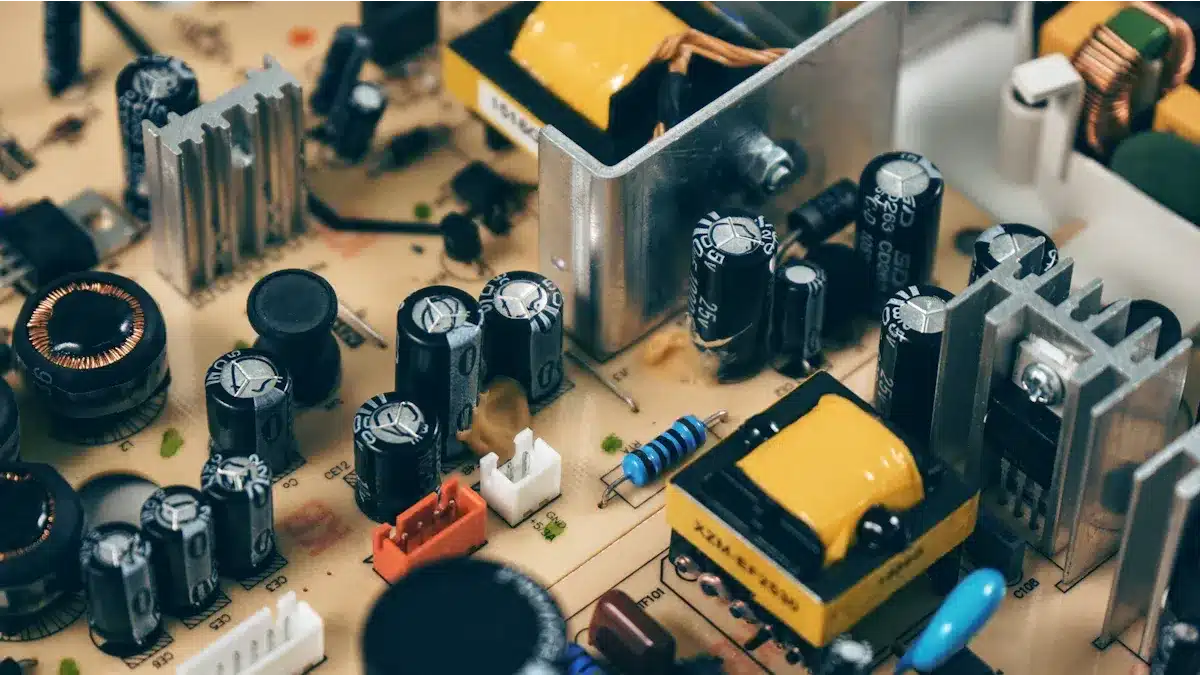

Passive components do not give energy to a circuit. They help control how electricity moves. Some common ones are resistors, capacitors, and inductors. Resistors slow down current and keep other parts safe. Capacitors hold energy and let it go when needed. Inductors help with changes in current. These passive components are important in almost every components circuit board.

Active Components

Active components use energy to control electricity. They can make signals stronger or turn them on and off. Transistors are very important active components. They work as switches or amplifiers in many things. Diodes are also active components. They let electricity go only one way. Some types of circuit board components in this group are integrated circuits. These have many active components in a small space. Active components help make electronics fast and strong.

Electromechanical

Electromechanical components use both electric and moving parts. Switches, relays, and small motors are in this group. These circuit board components can turn things on or off or move parts inside a device. Electromechanical components are often found in control panels and robots.

Connectors

Connectors join different parts of a components circuit board. They let signals and power move between sections. The table below shows common connector types and what they do:

Connector Type | Primary Application / Characteristics |

|---|---|

Board-to-Board Connectors | Join two PCBs for easy design and small size. |

Wire-to-Board Connectors | Attach wires to a PCB for power or signals from outside. |

Input/Output Connectors | Connect devices to other systems, like USB, HDMI, and RJ45. |

Power Connectors | Give electrical power safely and reliably. |

FFC/FPC Connectors | Join flat cables or PCBs in small devices like phones. |

High-Frequency Connectors | Used in telecom and satellites for fast signals. |

Rugged/Waterproof Connectors | Handle tough places in outdoor, marine, and factory uses. |

Sensors

Sensors notice changes in the world. They measure things like heat, light, or movement. These circuit board components send data to other parts. Sensors help devices react to what is around them.

Emerging Types

New circuit board components come out every year. In 2025, smart components and tiny sensors are popular. These can handle data or connect to the internet. Some even use artificial intelligence to make choices. New types of circuit board components help make devices smarter and better.

Components Circuit Board Comparison

Function

Every circuit board component has its own job in a pcb. Passive components help control how current moves and store energy. Active components use power to change or make signals stronger. Electromechanical parts connect or move things inside the board. Connectors join different pcb sections so signals and power can move. Sensors notice changes around them and send data to other parts. These jobs decide how a pcb works and what it can do.

Tip: Picking the right job for each part helps the pcb work well and last longer.

Performance

Performance shows how well each part does its job. Passive components keep circuits safe and steady. Active components make signals stronger and faster. Electromechanical parts give steady switching and movement. Connectors make sure pcb sections stay connected. Sensors give correct readings for things like heat or movement. Good performance in every area makes a pcb work better and last longer.

Cost

Cost matters at every step of pcb design and making. Passive components usually cost less than active ones. Sensors and electromechanical parts can cost more if they are complex. Connector prices change based on size and type. The cost of parts is often the biggest part of pcb cost. Material and process costs add up, especially for boards with many layers or special finishes. Good design and smart buying can help keep costs low.

Size

The size of parts changes how a pcb is built and used. Big parts take up more space and make it harder to fit other parts. Small parts let you fit more on the board and make designs more complex. Pad sizes, track widths, and via sizes depend on the part size. Good planning and placement help use space well. Small features can make building harder and may lower yields, especially in flexible pcbs.

Big parts need more space and make routing harder.

Small parts let you fit more but are harder to place.

Pad and track sizes must match the part and how it is put on.

Good placement keeps the pcb easy to build and strong.

Reliability

Reliability means how long and how well the board works. Passive components last a long time and break less often. Active components can wear out faster, especially with lots of power or heat. Electromechanical parts can wear down because they move. Connectors can get loose or rusty over time. Sensors may stop being correct. Good design, good materials, and careful building all help make boards last longer.

Use Cases

Different parts fit different uses. Passive components are in almost every pcb, from toys to computers. Active components power things like phones, computers, and cars. Electromechanical parts work in control panels, robots, and home machines. Connectors link boards in servers, phones, and factory machines. Sensors are in smart devices, wearables, and safety systems. Each part helps the pcb do its job.

Side-by-Side Comparison Table

Component Type | Function | Performance | Cost | Size | Reliability | Typical Use Cases |

|---|---|---|---|---|---|---|

Passive Components | Control current, store energy | Stable, supports operation | Low | Small to medium | High | Power supplies, filters, signal control |

Active Components | Amplify, switch, process signals | High speed, signal boost | Medium-High | Small | Medium | Computers, phones, amplifiers |

Electromechanical | Switch, connect, move parts | Reliable switching/movement | Medium | Medium-Large | Medium | Relays, switches, robotics |

Connectors | Join circuit sections, transfer signals/power | Steady connections | Low-High | Small-Large | Medium-High | Board links, I/O ports, power delivery |

Sensors | Detect and report physical changes | Accurate measurement | Medium-High | Small | Medium | Smart devices, safety, automation |

Note: The best mix of parts depends on the pcb’s type, size, and job.

PCB and Printed Circuit Boards Overview

Single-Sided PCB

A single-sided pcb has copper on just one side. This kind of printed circuit board is simple. All the parts go on one surface. Single-sided pcb is good for easy electronics. There is not much room for many parts. Making these boards does not cost much. These printed circuit boards are used in toys, calculators, and power supplies.

Double-Sided PCB

Double-sided pcb has copper on both sides. This lets circuits be more complex. Parts can go on both surfaces. Double-sided pcb fits more parts and better paths. The traces cross each other using vias. These printed circuit boards work in harder devices. Double-sided pcb helps signals and heat move better.

Double-sided pcb lets you design in more ways.

More traces fit in less space.

These printed circuit boards give better performance.

Multi-Layer PCB

A multi-layer pcb has many layers of traces. These printed circuit boards have insulation between copper sheets. Multi-layer pcb is used for fast signals and hard circuits. People use them in computers, phones, and medical tools. Extra layers mean more traces and more parts. Making these boards is harder. Multi-layer pcb makes signals better and cuts down on noise.

Rigid PCB

Rigid printed circuit boards do not bend at all. These printed circuit boards use hard stuff like fiberglass. Rigid pcb holds heavy parts and keeps its shape. Making rigid boards puts traces in the right place. People use rigid pcb in computers, TVs, and big machines. The strong board helps it last longer.

Flexible PCB

Flexible pcbs can bend and twist without breaking. These printed circuit boards use things like polyimide. Flexible pcb fits in small or weird spaces. The traces can curve and fold. Flexible pcbs are in cameras, wearables, and medical tools. Making flexible boards needs special steps. Flexible pcb lets you make cool shapes and saves space.

Rigid-Flex PCB

Rigid-flex pcbs mix stiff and bendy parts. These printed circuit boards use both hard and soft stuff. Rigid-flex pcbs link moving parts inside things. The traces go over both stiff and bendy areas. Making rigid-flex pcbs takes careful planning. Rigid-flex pcbs are in phones, army gear, and planes.

The kind of pcb material and how hard it is changes which parts work best. Materials with low dielectric constant and low dissipation factor help fast or high-frequency parts. Good thermal conductivity and high glass transition temperature help hot parts. Polyimide in flexible pcbs lets them bend and stay dry. Hard multi-layer pcb designs fit more traces and help sensitive parts. The right material and shape keep printed circuit boards working well and lasting long.

Circuit Board Components Selection

Footprint and Size

Engineers have to think about the size and shape of each part. Every component takes up a certain space on the pcb. Small parts let you put more things and lines on the board. Big parts can block other pieces or make it hard to add lines. Flexible boards often use very small parts to fit in tight spots. Rigid boards can use bigger parts, but you need to leave enough space. Planning well helps make building easier and keeps the pcb strong.

Mounting Style

How you attach parts to the pcb changes how long they last. The main ways to mount parts are spacers, standoffs, screws, nuts, washers, mounting brackets, card guides, pullers, ejectors, and extractors. These help keep the board steady, move heat away, and stop damage from bumps. Flexible pcbs might use special ways to mount parts so they can bend. Rigid boards often use metal pieces to stay strong. Designers should put holes in the right places so the board does not bend. Using plastic or metal helps the board work well in different places. Following rules for making boards makes them safe and easy to put together.

Application Needs

Different jobs need different parts and ways to design the pcb. For example, high-voltage boards need more space between lines and special covers. Flexible circuits need stuff that bends without breaking. Rigid boards are good for heavy or still things. The table below shows how rules help pick the right things for each pcb type:

IPC Standard | Application Focus | Key Design Considerations |

|---|---|---|

General, high-voltage | Spacing, insulation, thermal management | |

IPC-2222 | Rigid boards | Hole specs, routing, materials |

IPC-2223 | Flexible circuits | Bend radius, pad placement |

IPC-2224 | PC Cards | Securing components, multilayer types |

IPC-2225 | Multichip modules | Adhesives, microvias |

IPC-2226 | HDI boards | Layer separation, via formation |

Designers need to match the pcb type, job, and how it is made to the right parts for the best results.

Electrical Characteristics

How electricity moves is important when picking parts for a pcb. Power-supply bypassing uses a few capacitors close to power pins to keep noise down. Extra inductance and capacitance from lines, holes, and pads can make signals worse. Controlled-impedance lines help fast signals stay clear. A solid ground layer under lines cuts noise and keeps signals steady. Picking the right package for each part can lower problems and make building easier. Flexible boards need careful line layout so they do not break. Rigid boards can use thicker lines for more power. Good planning for electricity keeps the pcb safe and working well.

Trends in Circuit Board Components 2025

Miniaturization

Miniaturization is changing how pcbs are made. High-Density Interconnect technology lets engineers put more lines in small areas. Fine-line patterning helps fit lots of parts on one pcb. Devices like smartwatches and hearing aids need very small parts. Flexible pcbs use tiny parts so they can bend and twist. Rigid boards are also getting smaller as lines move closer together. Smaller lines mean circuits can be more complex in less space. Miniaturization brings new problems for making pcbs. Engineers have to control heat and signal loss in tight spots. Both flexible and rigid boards need careful planning to stop issues.

Smart Components

Smart components are changing how pcbs work. These parts can sense things, process data, and react. System-in-Package technology puts many jobs in one small spot. Embedded passive and active parts save space and help the board work better. Flexible pcbs use smart sensors in wearables and medical tools. Rigid boards use smart chips in computers and cars. Smart parts need special lines for fast signals. They also need strong links to other parts. Smart parts make building pcbs harder. Designers must test every line to keep the board working well.

Sustainability

Sustainability is important when making pcbs. Companies use materials and ways that are better for the planet. Flexible pcbs often use less material, which is good for the earth. Rigid boards now use safer chemicals and recycled layers. New rules make factories cut waste and save energy. Making pcbs in a green way lowers pollution and keeps workers safe. Engineers pick materials that last longer and break down safely. Both flexible and rigid boards do better with green choices. Sustainability brings new problems, but it also gives new chances.

Manufacturing Advances

New ways to make pcbs are changing how engineers work. Additive manufacturing, like 3D printing, makes custom shapes and lines. AI and machine learning help find mistakes and speed up design. New substrate materials help control heat and signals. Flexible pcbs use new films to bend better. Rigid boards use strong layers for heavy parts. These new ways help fix old problems in making pcbs. Engineers can now make boards for 5G, electric cars, and smart homes. Better ways to make pcbs mean faster, safer, and stronger products.

PCB trends in 2025 make boards smaller, smarter, greener, and more advanced. Flexible and rigid boards both change as new tech comes out. Engineers must balance size, how well it works, and being green in every pcb.

Every device is strong because of its circuit board parts and PCB type. Flexible boards can bend and fit into small spaces. They let people make cool and new shapes. Rigid boards are hard and hold heavy parts well. Sensors, connectors, and passive parts all have their own job. Engineers need to pick the right part for what the pcb will do. They also have to think about how to make the board. Flexible pcb designs help make new things like wearable tech. The way we make boards keeps changing, so circuit boards will keep getting better.

The future for pcb design is exciting. Flexible tech and smart ways to build will make new circuit board ideas.

FAQ

What is the main purpose of a pcb in electronics?

A pcb holds and connects electronic components. It gives each part a set place and path for electricity. This helps devices work safely and reliably.

How do engineers choose the right pcb for a project?

Engineers look at the size, shape, and job of the device. They pick a pcb that fits the space and supports the needed parts. They also check how much heat and power the pcb must handle.

Why do some devices use flexible pcb instead of rigid ones?

Flexible pcb can bend and twist. This lets them fit into small or odd-shaped spaces. Devices like wearables and cameras often need flexible pcb for their special shapes.

What makes a pcb reliable over time?

Good materials and careful design help a pcb last longer. Engineers use strong parts and plan for heat and movement. They test the pcb to make sure it works well in real life.

How have pcb trends changed in 2025?

In 2025, pcb trends focus on smaller size, smart features, and green materials. Engineers use new ways to make pcb faster and safer. Devices now need pcb that can handle more jobs in less space.

See Also

Benefits And Obstacles Of Flexible PCBA In Electronics

Emerging Innovations In PCB And PCBA Design Processes

Streamlined Fast PCBA Solutions For Electronic Projects

The Role Of PCBA In Advancing Modern Electronics

Essential PCBA Parts And Their Important Functions Explained