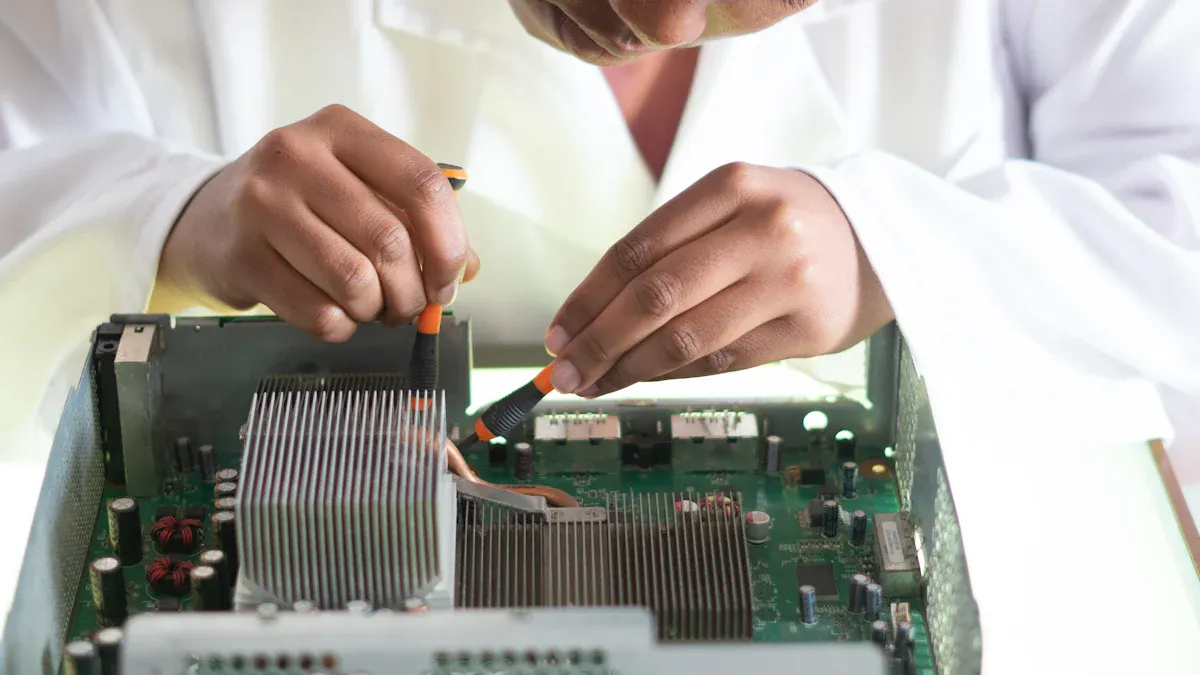

Industrial areas can be tough on IIoT devices, especially in the context of conformal coated IIoT device manufacturing. Water, chemicals, and temperature changes can harm electronics over time. Conformal coatings work like a shield to stop damage and keep devices working well. These coatings create a thin, even layer on parts to protect them from rust and electrical problems. Adding conformal coating to your IIoT device design makes it stronger and more reliable in tough conditions. This protection helps devices run without stopping and last longer, making it crucial for conformal coated IIoT device manufacturing.

Key Takeaways

Conformal coatings shield IIoT devices from water, chemicals, and heat.

Picking the right coating, like acrylic or silicone, is important.

These coatings lower repair costs and help devices last longer.

Coatings also meet industry rules, keeping devices safe and reliable.

Adding coatings stops expensive fixes and boosts device performance.

Understanding Conformal Coatings for IIoT Devices

What are conformal coatings?

Conformal coatings are thin layers that protect electronic parts. They shield delicate components from things like water, dust, and chemicals. These coatings fit the shape of the device perfectly, creating a smooth barrier. Think of them as a protective cover that makes IIoT devices stronger and more dependable.

These coatings are crucial for electronics in tough environments. They stop rust, lower the chance of electrical problems, and keep devices working well. Rules like IPC-CC-830B make sure these coatings meet high standards for quality and performance, making them great for industrial use.

Types of conformal coatings used in electronics

Different coatings have different benefits. Here’s a simple comparison of the main types:

Coating Type | Key Features | Things to Consider |

|---|---|---|

Acrylic Resin (AR) | Affordable, good protection, strong insulation, decent moisture resistance | Easy to use and fix, but weak against some solvents like jet fuel fumes |

Silicone Resin (SR) | Works well in extreme temperatures, resists chemicals and moisture | Flexible but scratches easily, hard to remove |

Urethane Resin (UR) | Great at resisting moisture and chemicals, tough against wear | Hard to take off, often used in planes due to fuel vapor exposure |

Each type has pros and cons. For instance, acrylic coatings are cheap and simple to apply, while silicone coatings handle heat better. Picking the right one depends on what your IIoT devices need.

Why conformal coatings are vital for IIoT devices

IIoT devices often face harsh conditions. Without protection, water, chemicals, and temperature changes can harm them. Conformal coatings act like a shield, keeping devices safe and reliable.

They also stop electrical shorts by covering sensitive circuits. For example, in wet places, they block water from causing rust or failures. Using these coatings helps devices last longer and cuts down on repairs. This makes them a key part of designing and using IIoT devices.

Challenges for Conformal Coated IIoT Device Manufacturing

Environmental stressors in manufacturing environments

Manufacturing areas can be tough on IIoT devices. High humidity, chemical fumes, and temperature changes are common issues. These conditions can harm electronic parts, making them less reliable over time.

The need for reliable electronics is growing fast. For example:

The Environmental Stress Screening (ESS) Services Market may grow 8.5% yearly from 2026 to 2033.

Its value, USD 1.25 Billion in 2024, could reach USD 2.50 Billion by 2033.

Jobs for quality assurance experts might increase by 14% in the next 10 years.

These trends show why protecting devices from harsh conditions is so important.

Impact of moisture, chemicals, and temperature fluctuations

Moisture, chemicals, and temperature changes can damage IIoT devices. Moisture causes rust, while chemicals can weaken coatings or break materials. Extreme heat or cold can crack parts or make them fail.

Without protection, these problems can ruin devices. Conformal coatings block moisture and chemicals from reaching delicate parts. They also help devices handle temperature changes, keeping them working in tough conditions.

Risks of physical damage and electrical failures

Physical damage and electrical problems are big risks during production and use. Bad handling, transport, or coating mistakes can cause defects. Here’s a table of common risks:

Risk Factor | Description |

|---|---|

Poor surface preparation | The surface isn’t cleaned or ready for the coating. |

Wrong coating choice | The coating doesn’t match the environment it’s used in. |

Bad application | The coating isn’t applied correctly or as required. |

Issues with drying or curing | The coating doesn’t meet the needed standards or specs. |

No water protection | Water with harmful chemicals, like chlorides, causes corrosion. |

Physical damage | Happens when items are handled or moved carelessly. |

Fixing these problems helps IIoT devices stay strong and work well in tough places.

Protective Properties of Conformal Coatings

Moisture resistance and corrosion prevention

Water is a big problem for electronics. It can cause rust, which harms parts and makes devices stop working. Conformal coatings act like a shield, keeping water and dirt away from the inside of IIoT devices. This helps devices stay reliable, even in wet places.

Stopping rust is very important in factories where water mixes with bad chemicals. These coatings protect metal parts from rusting and breaking down. For example, in salty or damp areas, the coatings stop water from damaging the metal, helping devices last longer.

Using conformal coatings protects IIoT devices from water damage. This keeps them working well in tough conditions.

Chemical protection and thermal stability

Factories expose IIoT devices to strong chemicals and extreme heat or cold. Without protection, these can weaken materials and break devices. Conformal coatings create a strong barrier against harmful chemicals like acids or solvents, keeping devices safe.

These coatings also handle temperature changes well. They stop cracking and keep protecting devices even in extreme heat or cold. Standards like IPC-CC-830B and UL746E test coatings for things like heat resistance and safety. Here’s a quick look at these tests:

Standard | What They Test |

|---|---|

IPC-CC-830B | Tests for moisture, heat, fire, and fungus resistance. |

UL746E | Checks electrical safety, fire resistance, and heat handling. |

These tests make sure coatings are strong and safe for factories. Picking the right coating protects devices from chemicals and heat, making them last longer.

Mechanical strength and electrical insulation

Conformal coatings don’t just protect from the environment. They also make devices stronger. The coatings are flexible, so they absorb stress and stop physical damage. This flexibility helps them adjust when circuit boards expand or shrink due to heat.

But coatings need to be both flexible and tough. For example:

Coatings face high stress, which can crack them if they’re too stiff.

Acrylic coatings expand more with heat than Parylene coatings, showing how they handle stress differently.

Another big benefit is electrical insulation. Conformal coatings stop dust and water from causing short circuits. This keeps IIoT devices working safely, even in hard conditions. Using these coatings lowers the chance of electrical problems and boosts device performance.

Real-World Uses of Conformal Coatings

Keeping sensors safe in wet places

Sensors in wet areas often face water damage. This can cause rust and make them stop working. Conformal coatings act like a shield, stopping water from touching important parts. Silicone coatings work great because they resist water and stay flexible. Epoxy coatings are also strong, protecting against scratches and blocking water well. Urethane coatings help too but need careful use to avoid tiny holes.

Water Resistance | Extra Features | |

|---|---|---|

Silicone | Excellent | Resists chemicals, flexible, handles vibrations well |

Epoxy | Very good | Strong against scratches and chemicals, blocks water completely |

Urethane | Good | Protects well if applied without holes |

Picking the right coating keeps sensors working, even in tough, wet places.

Helping controllers in chemical factories

Controllers like PLCs work in places with chemical fumes, dust, and oil. These things can harm electronic parts over time. Conformal coatings, especially epoxy ones, protect controllers from chemical damage and dust. They also help controllers handle temperature changes, which are common in factories.

Using these coatings makes devices work better and last longer. It also supports eco-friendly goals by protecting devices while following environmental rules.

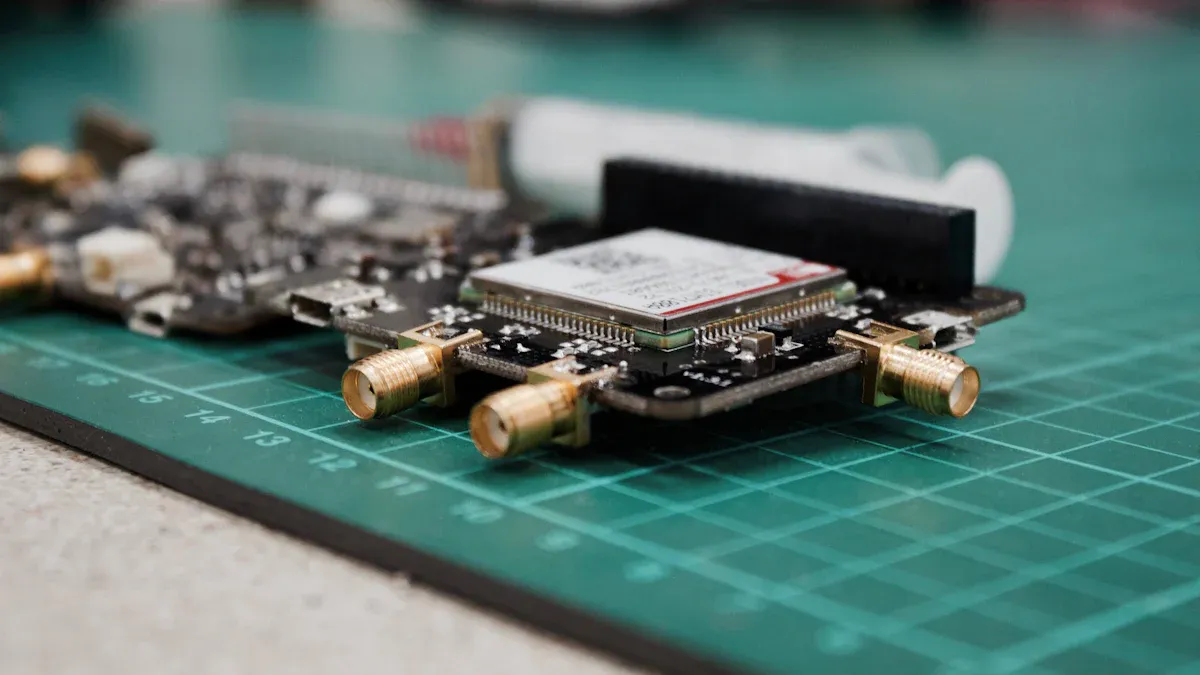

Protecting wireless modules in harsh conditions

Wireless modules often face tough conditions like water, shaking, and sudden temperature changes. Conformal coatings give strong protection, helping these modules work well. Devices with IP66/67 ratings, for example, are safe from dust and water. Some, like ProSoft’s XT series, work in temperatures from -25°C to 70°C, showing how coatings help in extreme conditions.

These coatings also make device designs simpler by reducing the need for extra seals. This improves how devices work and makes them more reliable. Picking the right coating is key to keeping wireless modules working in hard environments.

Benefits of Conformal Coatings for IIoT Devices

Longer device life and less maintenance

Conformal coatings help devices last longer in tough places. They protect parts from water, dust, and harmful chemicals. This stops damage and keeps devices working for a long time.

Fixing broken devices can cost a lot of money. Repairs need special tools and skills, causing delays in work. Coatings make parts stronger, so they break less often. For example, coated circuit boards don’t rust or short-circuit easily, even in bad conditions. This means fewer repairs and lower costs over time.

As factories need smaller and better circuit boards, coatings are more important. They protect and improve how circuits work in hard environments. Using these coatings saves money and makes devices work better for longer.

Better performance in tough factory conditions

IIoT devices must work well in rough factory settings. Conformal coatings help by protecting parts from water, chemicals, and heat changes. They fit tightly on devices, creating a strong shield. This keeps devices running smoothly, even in harsh places.

In wet or chemical-filled areas, unprotected devices can rust or wear out. Coatings stop this by blocking water and chemicals. This is especially helpful for sensors and controllers used in factories.

As technology grows, reliable IIoT devices are more important. Coatings make devices tougher and better. Adding them to your devices ensures they meet the hard demands of factories.

Following rules and improving safety

Conformal coatings help devices meet strict industry rules. These rules ensure devices are safe and work well. For example, coatings help pass tests by groups like the FDA. This builds trust and proves devices are safe for important jobs.

Some rules guide how coatings are used in factories and the military. MIL-I-46058C is one such rule, though IPC-CC-830 has replaced it. Following these rules shows devices can handle tough conditions and still work well.

Safety is another big benefit of coatings. They stop short circuits and electrical problems, lowering accident risks. This is vital for devices in dangerous places. By meeting rules and passing tests, coatings keep devices safe and reliable for users.

Conformal coatings are important for keeping your IIoT devices safe in tough factory settings. They protect electronics from water, harmful chemicals, and extreme temperatures. This helps devices work well for a long time.

Tip: Adding conformal coatings to your design can prevent expensive fixes and delays.

These coatings make devices stronger, so they run smoothly without stopping. Use conformal coatings to protect your IIoT investments and ensure they perform reliably in harsh environments.

FAQ

What is parylene, and why is it used in coatings?

Parylene is a special material that starts as a vapor. It forms a thin, even layer on electronics. This layer blocks water, chemicals, and electricity problems. It’s great for keeping IIoT devices safe.

How is parylene different from other coatings?

Parylene is applied as a vapor, not a liquid. This makes it spread evenly without gaps. It covers tricky shapes perfectly and protects against water, chemicals, and heat changes better than liquid coatings.

Can parylene handle very hot or cold temperatures?

Yes, parylene works well in extreme heat or cold. It keeps protecting devices in tough conditions, making it perfect for IIoT devices in factories.

Is parylene safe for the environment?

Parylene is eco-friendly because it doesn’t use harmful liquids. It also helps devices last longer, which means less electronic waste.

How do I pick the right parylene coating?

Think about where your device will be used. Parylene is best for places with water, chemicals, or big temperature changes. Talk to an expert to find the best option for your device.

See Also

Improving Quality Control Measures Within PCBA Production

Benefits and Challenges of Flex PCBA in Electronics

Ensuring ITAR Compliance in PCBA Production Processes