Printed Circuit Board Assembly (PCBA) is essential in the realm of consumer electronics PCBA manufacturing. It connects various parts and boards to ensure that devices operate effectively. Without PCBA, modern gadgets like phones, tablets, and smart home devices would struggle to function properly.

The process of consumer electronics PCBA manufacturing is crucial for maintaining quality and performance. Here are some key points:

The demand for smaller gadgets and faster data speeds makes PCBA indispensable.

Consumer electronics dominate the PCBA market as devices continuously require innovative solutions.

As consumers seek smaller and faster devices, multilayer PCBs have become increasingly significant.

PCBA enhances the performance of devices, making them better, faster, and more compact to satisfy today’s consumer demands.

Key Takeaways

PCBA is important for making today’s electronics work. It links parts and makes sure devices work well.

Knowing the difference between PCB and PCBA helps explain how gadgets are made. PCB is just a plain board, but PCBA has all the needed parts.

Checking quality during PCBA making stops expensive errors. Regular tests make products better and keep customers happy.

Using new tech like SMT and AOI makes production faster and lowers mistakes. These tools help make small and smart devices.

Picking a good PCBA maker is very important. Choose ones with modern machines and good testing to get top-quality products.

What Is PCBA and Its Role in Consumer Electronics?

Definition and purpose of PCBA

PCBA, or Printed Circuit Board Assembly, means adding parts to a circuit board. This process turns an empty PCB into a working unit. It helps devices do specific tasks. PCBA is the heart of modern gadgets, making them work well. Without it, things like phones, laptops, and gaming consoles wouldn’t work. It connects all parts so they work smoothly together. This ensures your devices perform as expected.

Difference between PCB and PCBA

Knowing the difference between PCB and PCBA is important. A PCB is a flat board with tracks and pads but no parts. It’s the base for connecting electronic components. PCBA, on the other hand, is a PCB with added parts like resistors and chips. A PCB is just the starting point. A PCBA is the finished product that performs tasks.

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Empty board with tracks for connections | Board with parts that make it work |

Function | Supports and connects parts | Does specific electronic tasks |

Components | None (just a plain board) | Includes resistors, chips, and other parts |

Applications | Used for testing and designing circuits | Found in finished products like phones and computers |

Importance of PCBA in consumer electronics manufacturing

PCBA is key to making reliable and working gadgets. Testing methods, like automated checks, find problems early. This improves device quality. For example, monitoring systems check performance to make products better. Advanced tests predict when parts might fail. These steps ensure PCBAs meet high standards for electronics.

The electronics market, worth $1.2 trillion by 2030, depends on PCBA. It helps make smaller, faster, and better devices. By linking and supporting parts, PCBA ensures gadgets like phones and tablets work well.

PCBA isn’t just putting parts together. It’s about making strong, high-quality gadgets for today’s needs.

Step-by-Step PCBA Manufacturing Process

Design and prototyping

The first step in making a PCBA is designing and testing. You create a plan for the circuit board. This plan shows where parts, tracks, and pads go. Special software like CAD helps you design the board. It lets you test how the circuit works before building it.

Next, you make a small test version of the board. This is called prototyping. Testing the prototype helps find mistakes in the design. It makes sure the board works well for consumer electronics. Fixing problems early improves how reliable and efficient the board is.

Tip: Test your prototype carefully. It saves time and money later.

PCB fabrication and preparation

After designing, you start making the physical board. This step is called PCB fabrication. You pick a strong base material like fiberglass or resin. The material must match what the board will be used for.

Making the board involves several steps. Etching removes extra copper to make tracks and pads. Drilling creates holes for parts and connectors. Layering combines sheets to make a multilayer board. These steps prepare the board for assembly.

Cleaning the board is also important. It removes dirt and dust. Clean boards help parts stick better during assembly. Good preparation ensures the board works well in consumer electronics.

Component placement and assembly

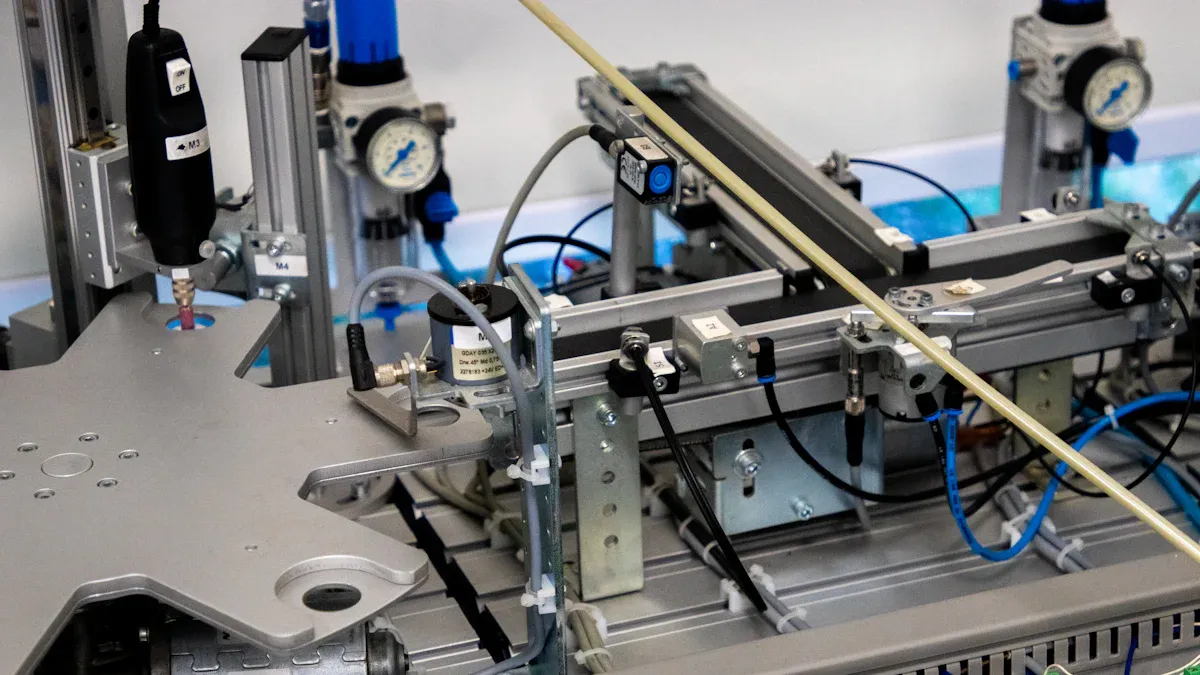

Once the board is ready, you add electronic parts. Machines place parts like resistors, chips, and capacitors on the board. These machines work fast and are very accurate.

Surface Mount Technology (SMT) attaches parts directly to the board’s surface. It’s great for small designs. For bigger parts, Through-Hole Technology (THT) is used. It puts parts into holes and solders them in place.

This step turns the board into a working PCBA. You check that all parts are in the right spots. This step is key to making sure the PCBA is high quality.

Note: Machines help avoid mistakes during assembly. They make production faster and more accurate.

Soldering techniques (e.g., SMT, THT, reflow soldering)

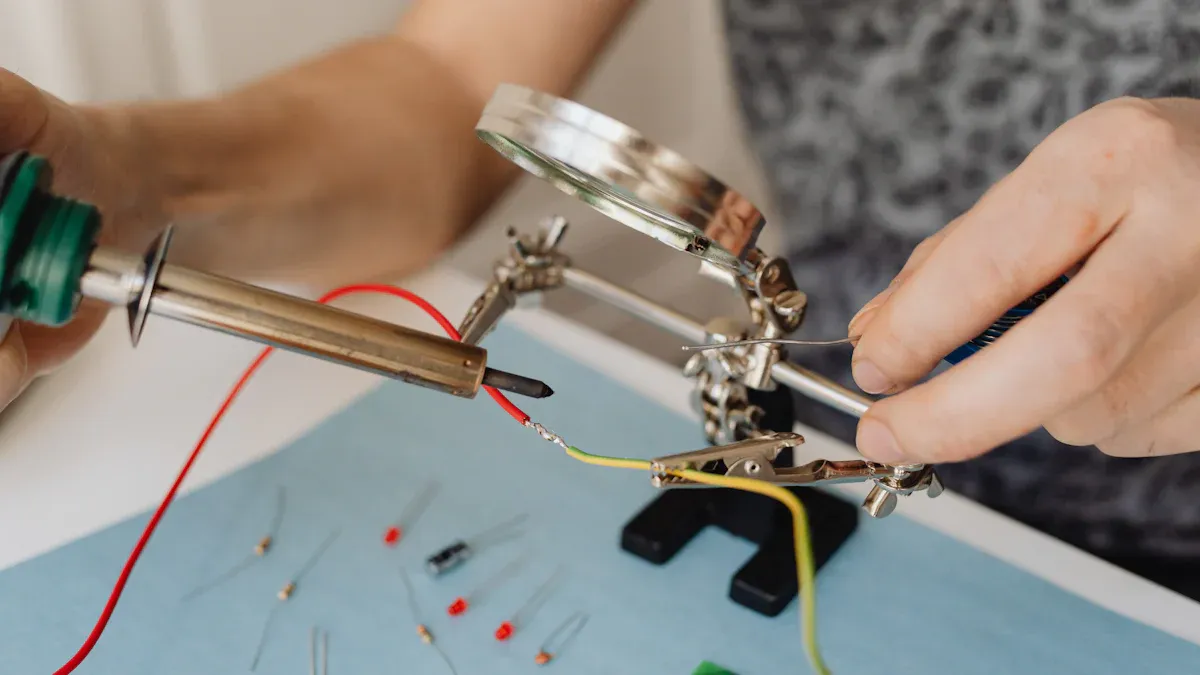

Soldering is an important part of making a PCBA. It connects parts to the board so the device works. Different methods are used based on the parts and board design.

Surface Mount Technology (SMT):

SMT is the most popular soldering method today. It places parts directly on the board’s surface. This method is great for small designs and fast production. Machines place parts accurately, and reflow soldering secures them. SMT helps make smaller and faster gadgets.Through-Hole Technology (THT):

THT puts part leads into holes on the board. These leads are soldered to pads on the other side. THT creates strong bonds, perfect for parts under stress like connectors. It’s slower than SMT but still needed for some uses.Reflow Soldering:

Reflow soldering melts solder paste to attach parts. After placing parts, the board goes through a heated oven. The heat melts the solder, creating strong connections. This method works well for SMT parts.

Each soldering method has a special purpose in making PCBAs. Picking the right one ensures the board is strong and works well.

Inspection and testing methods

Testing and checking are key to making good PCBAs. These steps find problems early so the product works as it should. Different methods check how well the board works.

Method Type | Description | How Well It Finds Problems |

|---|---|---|

Visual Inspection | Looks for clear issues by hand or machine. | Good for simple problems but misses small ones. |

Automated Optical Inspection | Uses cameras to check boards quickly and evenly. | Great for big batches and small issues. |

In-Circuit Testing | Checks electrical parts with special tools. | Finds problems in how parts are made. |

Functional Testing | Tests how the board works in real use. | Ensures the board works as planned. |

Boundary Scan Testing | Checks connections without touching the board. | Useful for crowded boards. |

X-Ray Inspection | Finds hidden issues in solder and connections. | Good for small and hidden parts. |

Solder Paste Inspection | Checks solder paste before adding parts. | Stops soldering mistakes early. |

Thermal Cycling Test | Tests how the board handles temperature changes. | Important for heat stability. |

Humidity Testing | Checks how moisture affects the board. | Finds problems like rust or damage. |

These methods help fix issues before they cause bigger problems. Automated Optical Inspection (AOI) and X-ray are great for large batches. Functional testing checks if the board works in real life.

Final assembly and packaging

The last step in making a PCBA is assembly and packaging. This step puts the board into the device and gets it ready to ship. Good assembly and packaging keep the product safe and working.

Assembly: The board is placed inside the device’s case. Extra parts like batteries or plugs are added. Tests are done to make sure the device works. This step ensures the product meets its design goals.

Packaging: Packaging protects the product during shipping and storage. It includes labels, manuals, and certifications. Good packaging makes the product look better and keeps it safe for customers.

Finding problems early during assembly saves time and money. It also ensures the product meets rules and customer needs.

By focusing on assembly and packaging, you can make reliable electronics. This step is key to keeping customers happy and building trust in your brand.

Key Technologies in Consumer Electronics PCBA Manufacturing

Surface Mount Technology (SMT)

Surface Mount Technology (SMT) changed how PCBs are assembled. It places parts directly on the board’s surface. This method skips drilling holes, making assembly faster. SMT is popular for making small and fast devices.

Machines place parts like microchips and resistors very precisely. This reduces mistakes and saves time. SMT helps create compact gadgets, which are highly wanted today.

Tip: Use SMT for quick and accurate production of many boards.

Reflow soldering and wave soldering

Soldering connects parts to the board, making it work. Two common methods are reflow soldering and wave soldering. Each has its own uses.

Reflow Soldering:

Reflow soldering works well with SMT designs. Solder paste is added to secure parts. The board goes through a heated oven to melt the paste. This creates strong connections. It’s great for small and detailed designs.Wave Soldering:

Wave soldering is used for Through-Hole Technology (THT). The board passes over molten solder, which attaches to metal areas. This method is best for bigger parts and mixed designs with SMT and THT.

Choosing the right soldering method depends on your board’s design. Both methods help make reliable PCBAs.

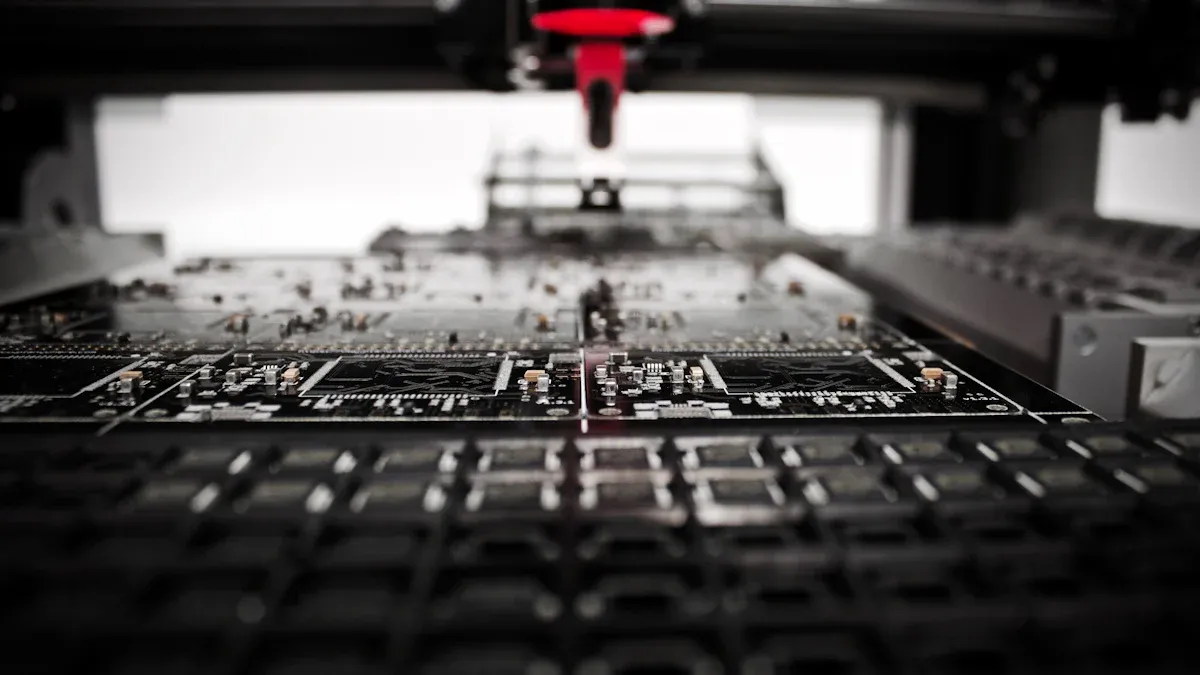

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) uses cameras to check PCBs for problems. It finds misplaced parts, solder mistakes, and missing components. AOI works faster and better than manual checks.

Finding issues early saves time and money. It prevents costly fixes or throwing away bad boards. AOI ensures your PCBA meets high standards before moving forward.

Advantages of AOI | Description |

|---|---|

Faster Production | Speeds up inspections for quicker manufacturing. |

Reduced Errors | Finds mistakes better than human checks. |

Cost Savings | Stops expensive fixes by catching problems early. |

AOI helps avoid late-stage problems, saving money and boosting profits.

In consumer electronics PCBA manufacturing, AOI is key for quality and efficiency. It ensures your boards work well in finished products.

In-Circuit Testing (ICT) and functional testing

In-Circuit Testing (ICT) and functional testing are important for PCBA reliability. ICT checks each part and connection on the PCB. It makes sure every component works correctly. Probes test circuits without harming the board. ICT finds problems like broken connections or bad parts early in production.

Functional testing checks how the whole PCBA works in real-life conditions. It ensures the board meets design goals and functions properly. This test happens before the PCBA is added to the device. It confirms the product works as expected, giving confidence in its performance.

Tip: ICT catches errors early. Functional testing ensures the product satisfies customer needs.

Evidence Type | Description |

|---|---|

Finds defects early, reducing waste and extra work. | |

Reliability Verification | Confirms products meet rules and customer needs. |

Customer Satisfaction | Builds trust by ensuring products work well. |

Functional testing also checks how the PCBA handles real-world use. It tests performance under working conditions. Combining ICT and functional testing improves product quality and lowers warranty claims.

Pick-and-place automation

Pick-and-place automation changed how PCBAs are made. Robotic arms place parts on the PCB with great accuracy. This technology removes human mistakes and speeds up production. Robots handle tiny parts that are hard to place by hand.

Pick-and-place machines work with Surface Mount Technology (SMT). They carefully position parts like resistors and chips on the board. These machines follow the design plan to ensure correct placement.

Note: Automation reduces mistakes and boosts speed, making it vital for modern PCBA production.

Pick-and-place automation makes production faster and keeps quality consistent. Large batches of PCBAs can be made without losing accuracy. This technology is perfect for consumer electronics, where small designs need precise assembly.

Quality Control in PCBA Manufacturing

Why quality assurance matters in PCBA

Quality assurance is key to making reliable PCBAs. It helps find and fix problems early. This saves time, money, and avoids product failures. Quality checks make sure every PCB meets high standards before use. This improves product reliability and keeps customers happy.

Fewer problems: Fixing issues early stops recalls and failures.

Better performance: Regular checks ensure the PCBA works properly.

Saves money: Quality assurance reduces waste and boosts efficiency.

Focusing on quality builds customer trust and keeps you ahead in the market.

Common ways to check quality (e.g., visual checks, X-ray tests)

Quality checks help find and fix problems during PCBA production. Each method has its own strengths and weaknesses. Picking the right one is important.

Method | Benefits | Drawbacks |

|---|---|---|

– Finds hidden problems early, saving money. | – Expensive to buy and maintain equipment. | |

– Gives clear images for detailed checks. | – Needs special tools and training. | |

– Best for complex boards like BGAs. | ||

Visual Checks | – Easy and good for spotting surface issues. | – Only works for visible problems. |

Automated Optical Inspection (AOI) | – Quick and accurate for surface checks. | – Can’t find hidden flaws inside the board. |

X-ray is great for complex boards, while visual checks suit simple ones. AOI is fast and works well for large batches. Using these methods ensures your PCBA meets quality needs.

Following industry rules (e.g., IPC standards)

Following rules like IPC standards ensures your PCBA is high quality. These rules guide design, making, and assembly to reduce errors and improve reliability. For example:

IPC-2221 and IPC-A-600 focus on PCB design and materials.

IPC-6012 and IPC-A-610 explain how PCBs should perform and be assembled.

IPC-7711/7721 gives tips for fixing and repairing boards.

These rules help everyone in the industry work together. They also make sure your PCBA can handle tough conditions and last longer.

Using IPC standards sets a quality baseline, ensuring your products work well and last a long time.

Final Considerations for High-Quality PCBA Manufacturing

Picking trustworthy PCBA manufacturers

Choosing a good PCBA manufacturer is very important. They should know advanced methods like via-in-pad and impedance control. Their tools must be modern and accurate for precise work. They also need to handle special materials for your project.

Check their testing skills too. Reliable manufacturers do burn-in tests to mimic long use. In-circuit testing (ICT) checks connections, and functional testing ensures the board works. Automated optical inspection (AOI) and X-ray tests find problems early. Certifications like ISO 9001, UL, and RoHS show they care about quality and safety.

Tip: A manufacturer focused on quality and testing can save you money later.

Managing cost, quality, and efficiency

Balancing these three is tricky in PCBA production. Picking the right materials helps. For instance, CEM substrates can cut costs by 20-30% while still working well. Using automation like SMT lowers labor costs by 40% and speeds up production.

Quality checks are just as important. A four-step quality system can reduce rework from 8% to 1.2%, saving money. Skipping quality steps can cause big losses. One company lost $47,000 because they chose the wrong material. Smart choices prevent such mistakes.

Note: Balancing cost, quality, and speed keeps your product reliable and competitive.

New trends in PCBA manufacturing for electronics

PCBA manufacturing is changing with new trends. Flexible PCBs are becoming popular because they are small and strong. These are great for wearables and car electronics. By 2032, multilayer flexible PCBs will lead the market, fitting complex designs into tiny spaces.

Consumer electronics are also driving growth. Gadgets like phones and smartwatches need thinner, lighter PCBs. This matches the rise of flexible PCBs. The Asia Pacific region, especially China and South Korea, is growing fast in PCBA production due to more demand and industrial growth.

Keeping up with these trends helps you adjust your process to meet market needs.

Knowing how consumer electronics PCBA is made shows how devices are built to last and work well. Each step, from planning to assembly, ensures high-quality products. Tools like SMT, reflow soldering, and AOI make production faster and more precise. Checking quality is important to find problems early so devices work properly. Understanding these steps helps you make smart choices and create products that meet what people want.

FAQ

What is the difference between SMT and THT in PCBA manufacturing?

SMT places parts on the board’s surface. It’s great for small designs. THT puts part leads into holes, making stronger connections. SMT is best for tiny gadgets, while THT handles stress better.

Why is Automated Optical Inspection (AOI) important in PCBA?

AOI uses cameras to find mistakes like misplaced parts or bad soldering. It catches problems early, saving time and materials. This helps make production faster and more reliable for many devices.

How does reflow soldering work in PCBA?

Reflow soldering melts solder paste to stick parts to the board. The board goes through a hot oven, and the solder hardens. This method works well for SMT designs and is very efficient.

What are the benefits of using flexible PCBs?

Flexible PCBs can bend and twist easily. They fit in small gadgets like smartwatches. They save space, weigh less, and last longer. These features make them popular in modern electronics.

How can you ensure high-quality PCBA manufacturing?

Pick a trusted manufacturer with good tools and tests like AOI. Follow rules like IPC standards. Test prototypes to find and fix problems early. These steps help make strong and reliable PCBAs.

See Also

Key Phases In The PCBA Production Workflow

An In-Depth Overview Of PCBA Production Steps

Detailed Instructions For The PCBA Manufacturing Procedure